Electromechanical integrated pipe cutting device

A technology for cutting devices and pipe fittings, applied in positioning devices, metal processing machinery parts, clamping, etc., can solve the problems of inability to meet the needs of pipe cutting and use, poor fixing effect of pipe fittings, and vibration of pipe fittings, so as to achieve enhanced firmness and smooth movement Slip stability, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

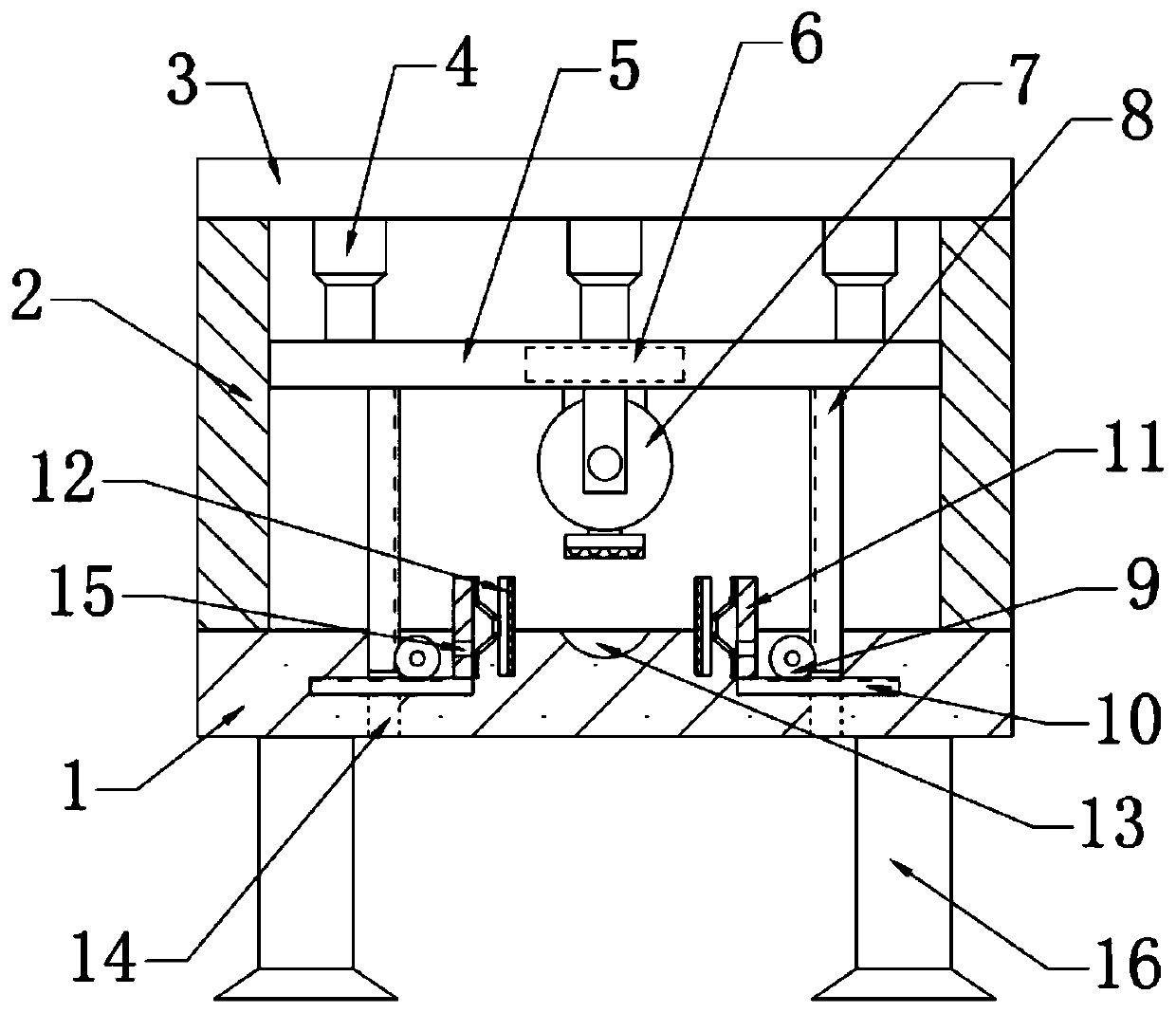

[0027] see Figure 1-4 , in an embodiment of the present invention, a mechatronic pipe cutting device includes a workbench 1, the top of the left and right ends of the workbench 1 is fixedly connected with a support plate 2, and the top of the support plate 2 on both sides is fixedly connected with a support plate 2 Top plate 3, the lower side of the top plate 3 is provided with a movable plate 5 slidingly connected to the support plate 2, and a telescopic rod 4 is fixedly connected between the movable plate 5 and the top plate 3, and the front and rear sides of the movable plate 5 are all provided There is a longitudinal fixing mechanism, the bottom of the movable plate 5 is provided with a cutting mechanism, the top of the workbench 1 is provided with a card slot 13, and the left and right sides of the card slot 13 are provided with a horizontal fixing mechanism, and the bottom of the workbench 1 is fixed The connection is provided with several support feet 16 .

Embodiment 2

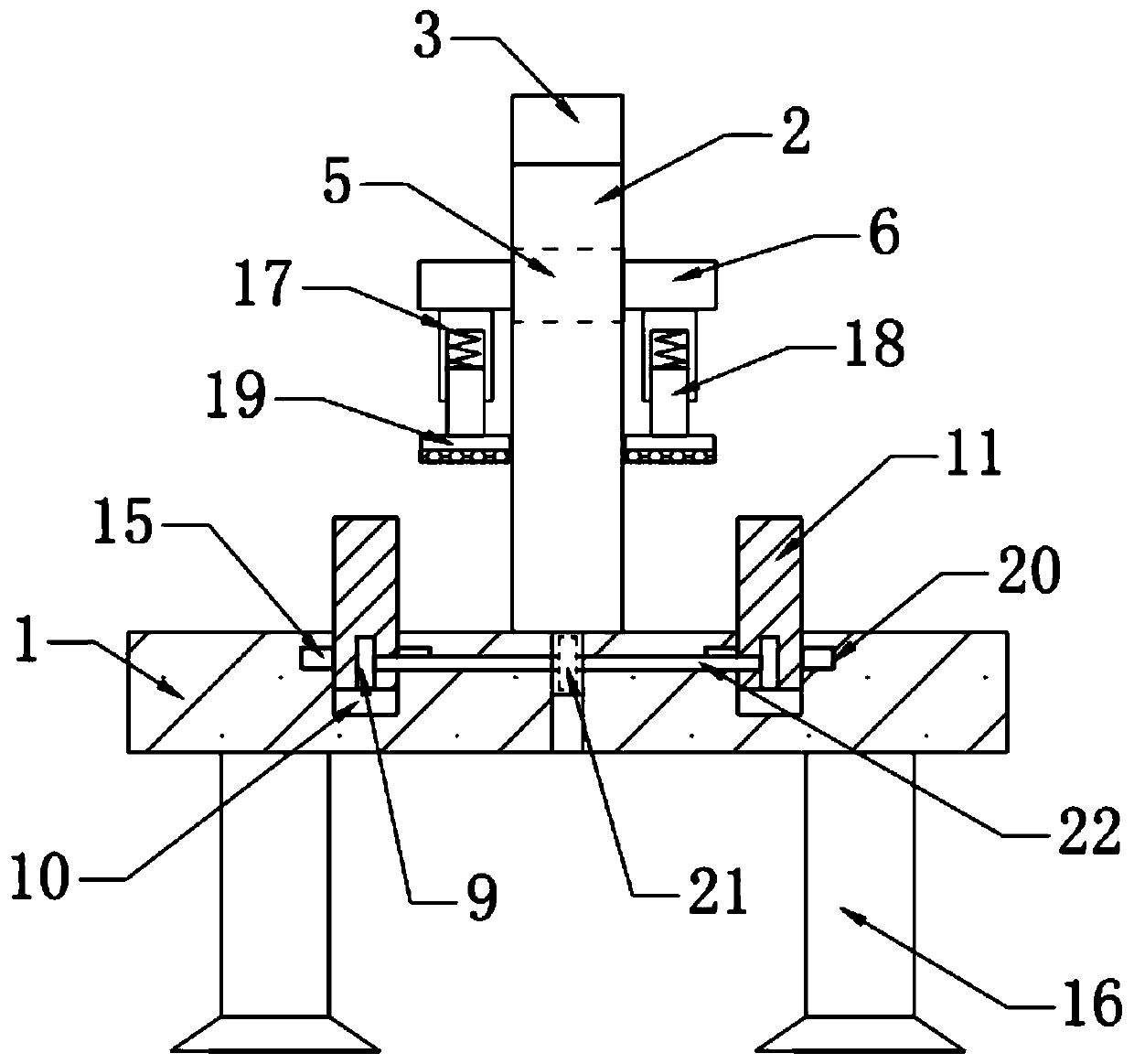

[0029] In this embodiment, the longitudinal fixing mechanism includes a fixed plate 6 and a second pressure plate 19, the fixed plate 6 is fixedly connected to the front and rear sides of the movable plate 5, and the bottom of the fixed plate 6 is fixedly connected to a first fixed block 17. The inner side of the first fixed block 17 is slidably connected with a slider 18, the fixed connection between the slider 18 and the first fixed block 17 is provided with a spring, and the other end of the slider 18 is fixed to the second pressure plate 19 Connection, by setting the vertical fixing mechanism, the pipe fittings can be fixed longitudinally during the cutting process of the cutting blade 7, so as to avoid the vertical vibration of the pipe fittings during cutting, and further strengthen the fixing degree of the pipe fittings.

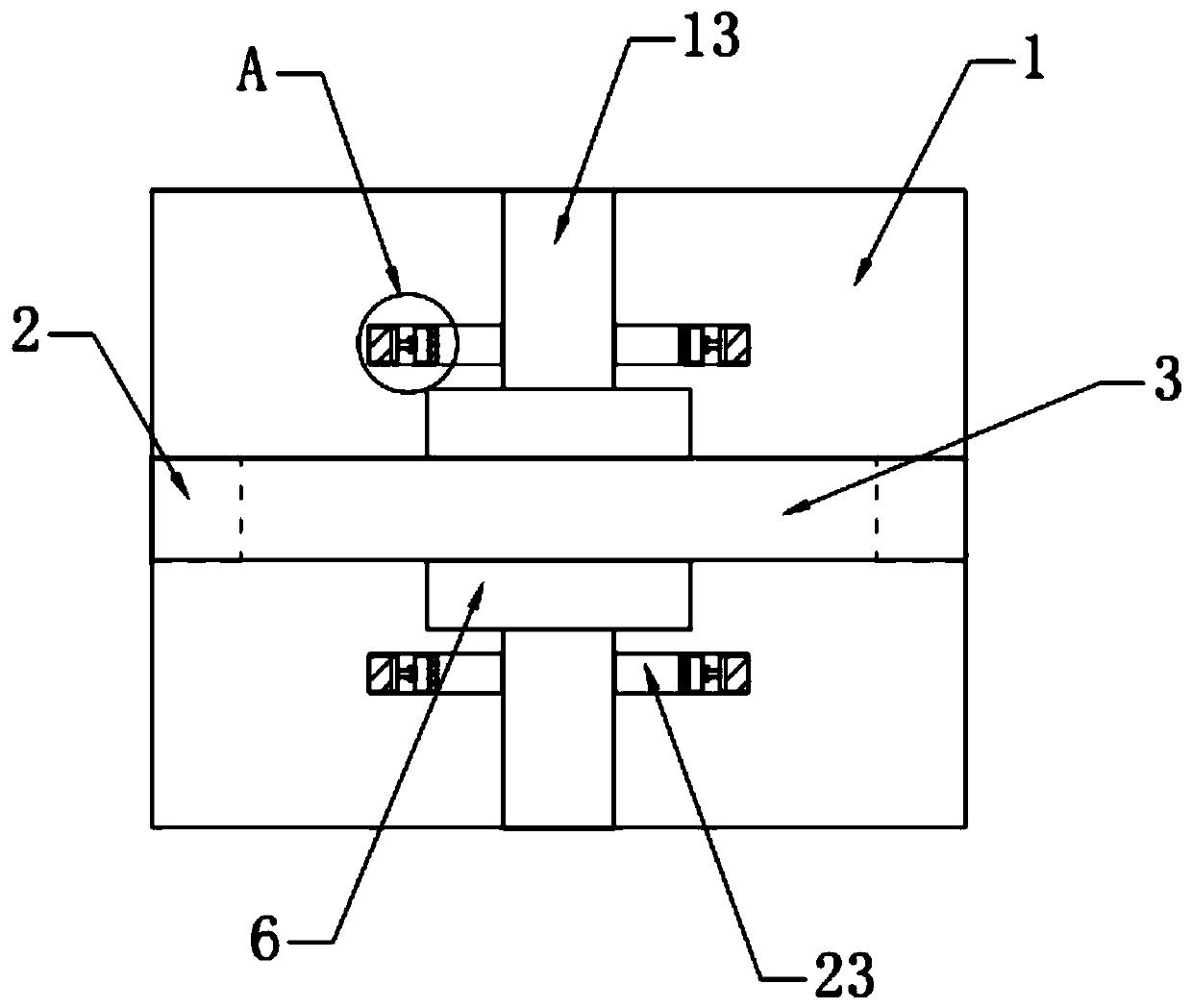

[0030] In this embodiment, the horizontal fixing mechanism includes a connecting plate 11, a first pressure plate 12 and a chute 23, the chute 23 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com