Automatic hasp fastening equipment

An equipment and automatic technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of improvement, complicated operation steps, limit the automation degree of box production and processing, etc., and achieve the effect of improving the degree of automation and high coincidence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

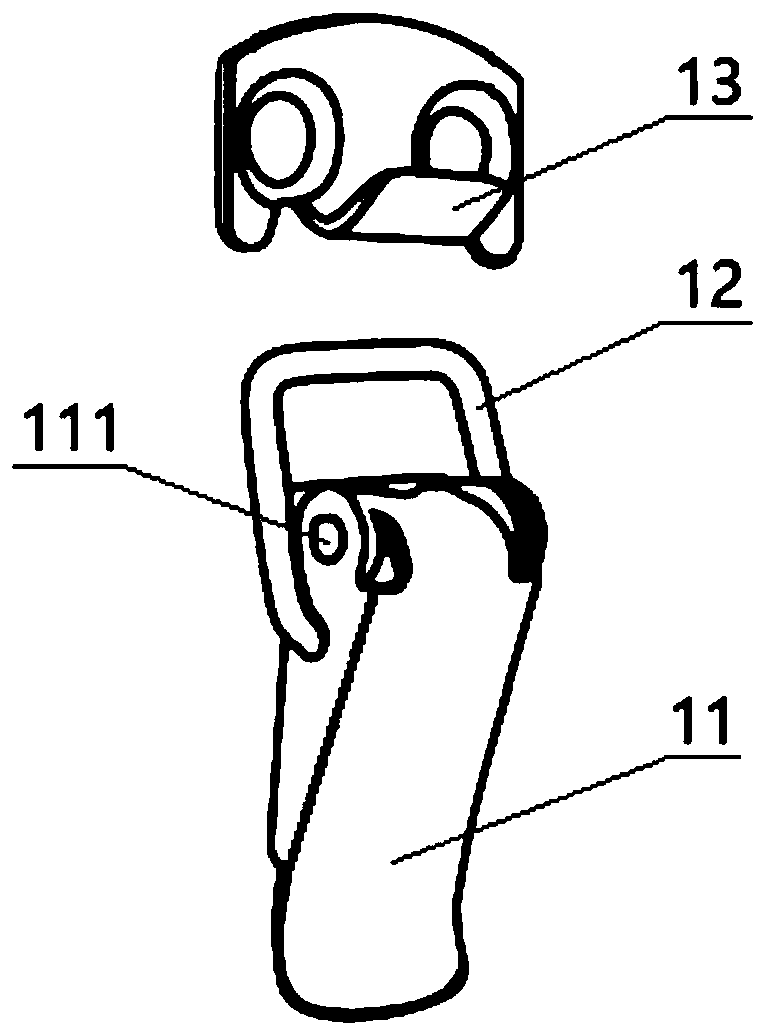

[0031] like figure 1 As shown, the structure of the hasp includes a lock body 11 and a lock tongue 12 arranged on the lock body 11 , the lock body 11 can rotate around a pin shaft 111 , and the lock tongue 12 can rotate on the lock body 11 . Hasp also includes a fastening groove 13 corresponding to dead bolt 12, and fastening groove 13 and lock body 11 are respectively installed on different components.

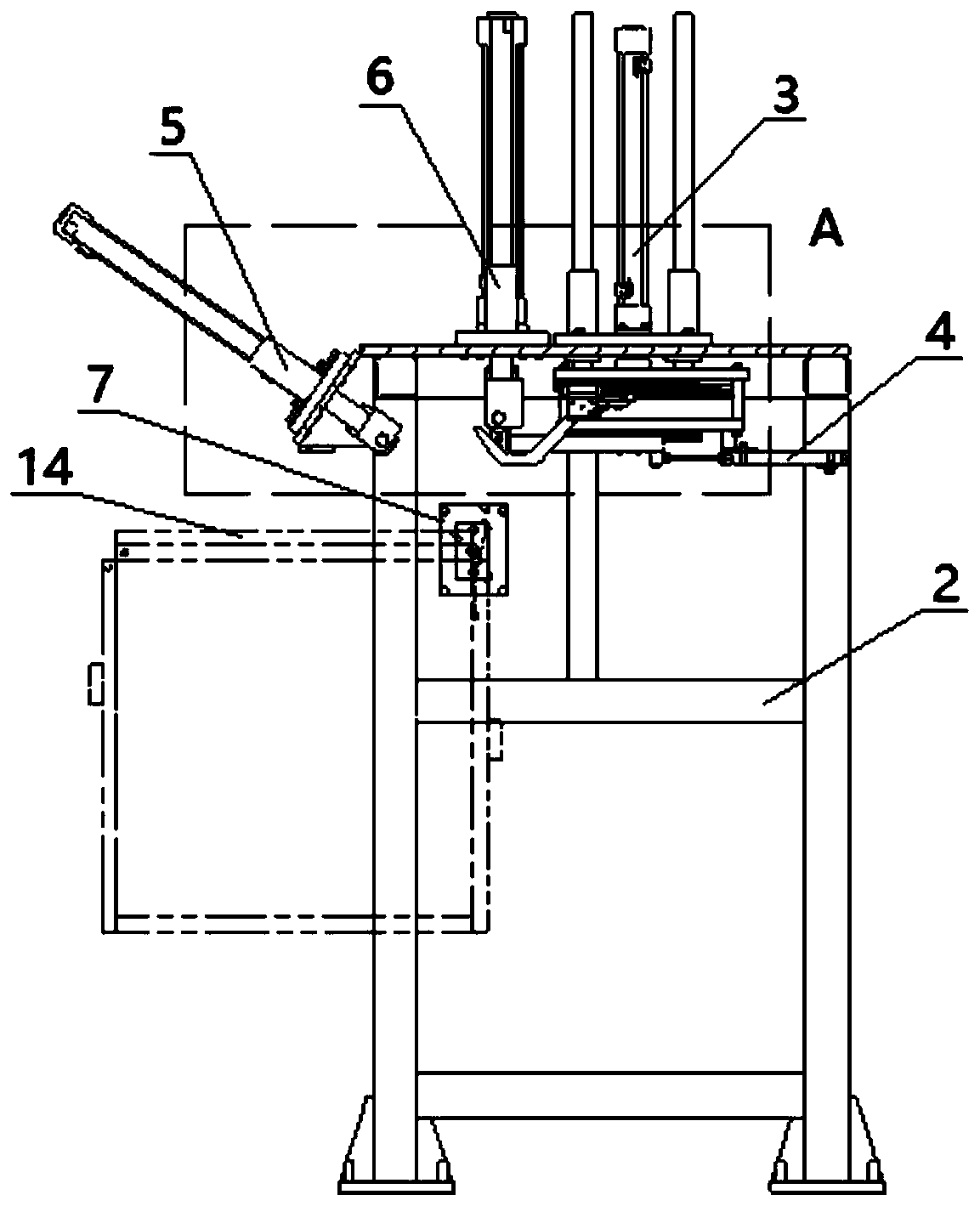

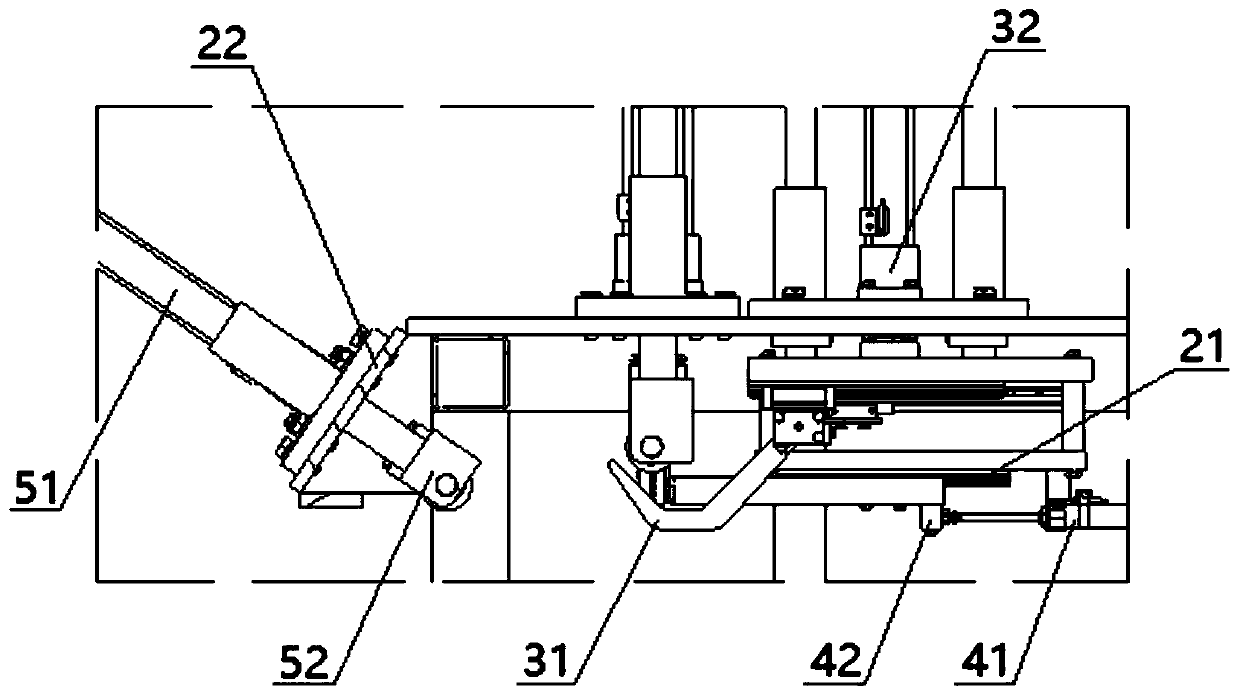

[0032] Please refer to Figure 2-5 , the present embodiment provides a hasp automatic fastening device, including a console 2, a hasp lifting device 3 is arranged on the console 2, a bolt adjusting device 4 is arranged below the hasp lifting device 3, and a hasp lifting device 3 A hasp fastening device 6 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com