Patents

Literature

54results about How to "Guaranteed push" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

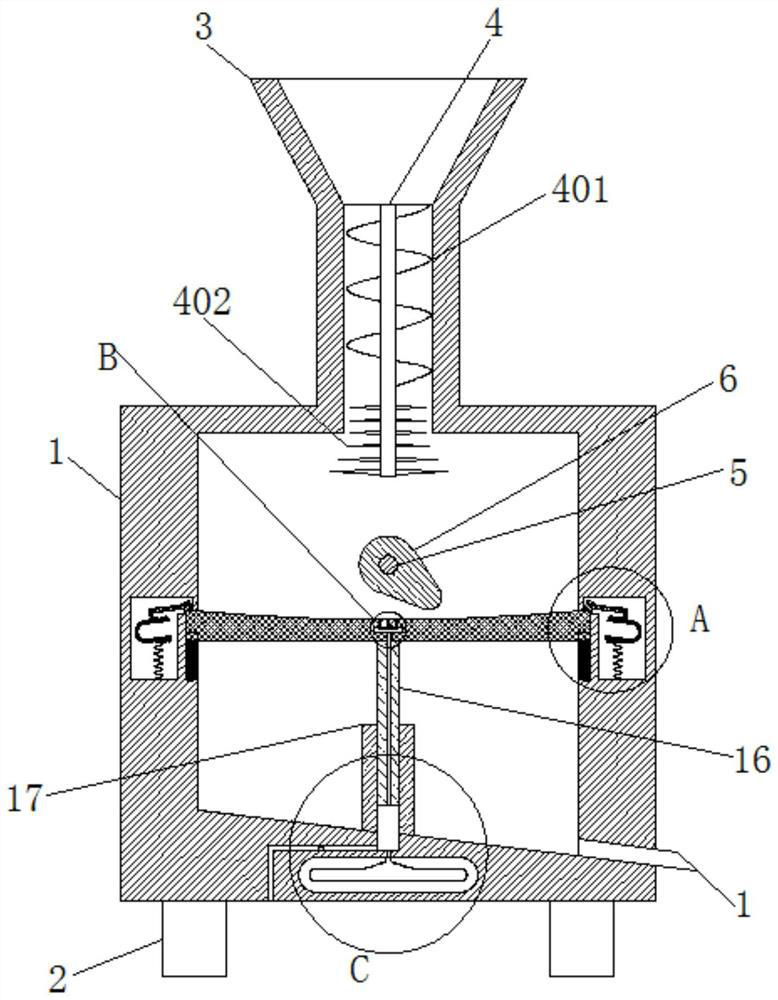

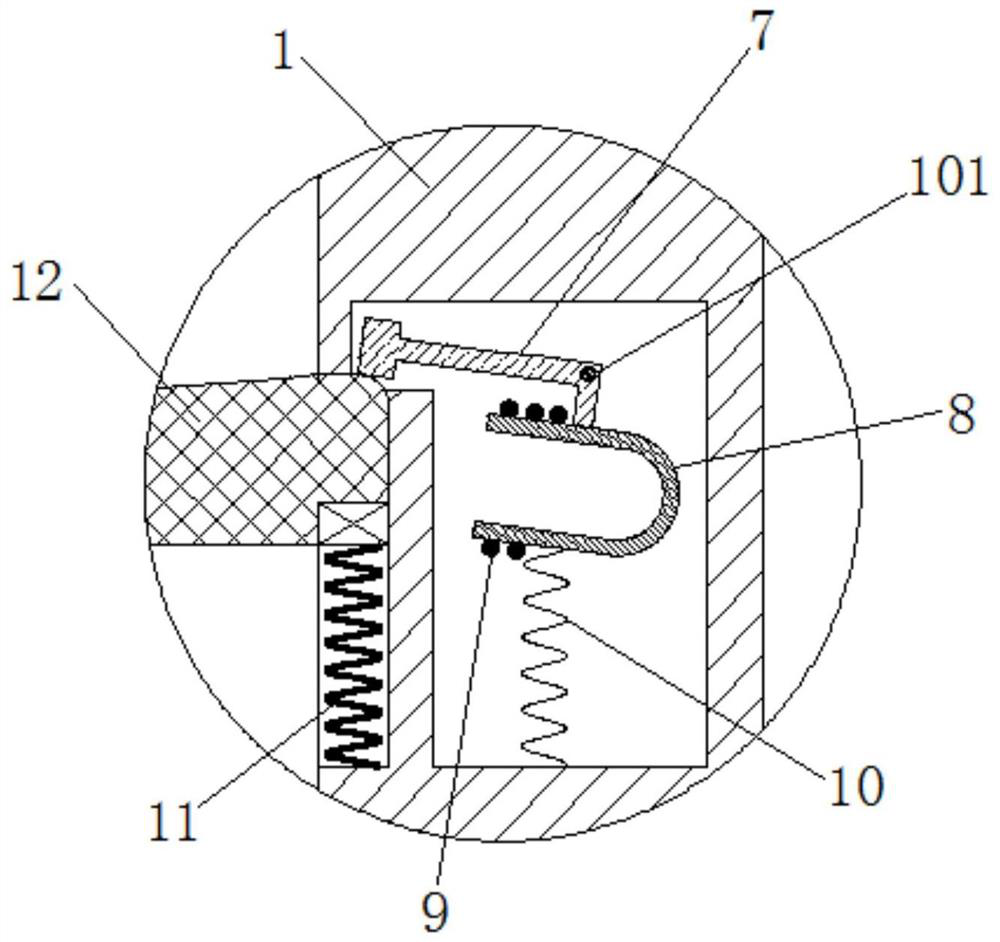

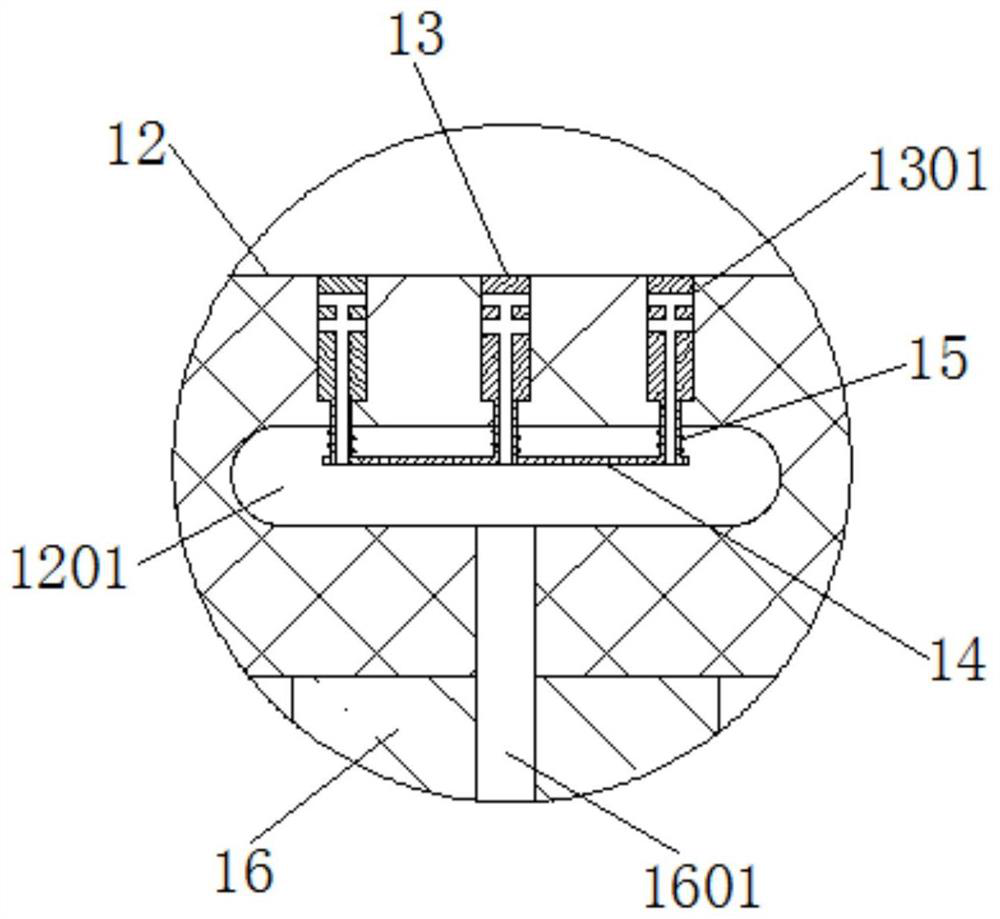

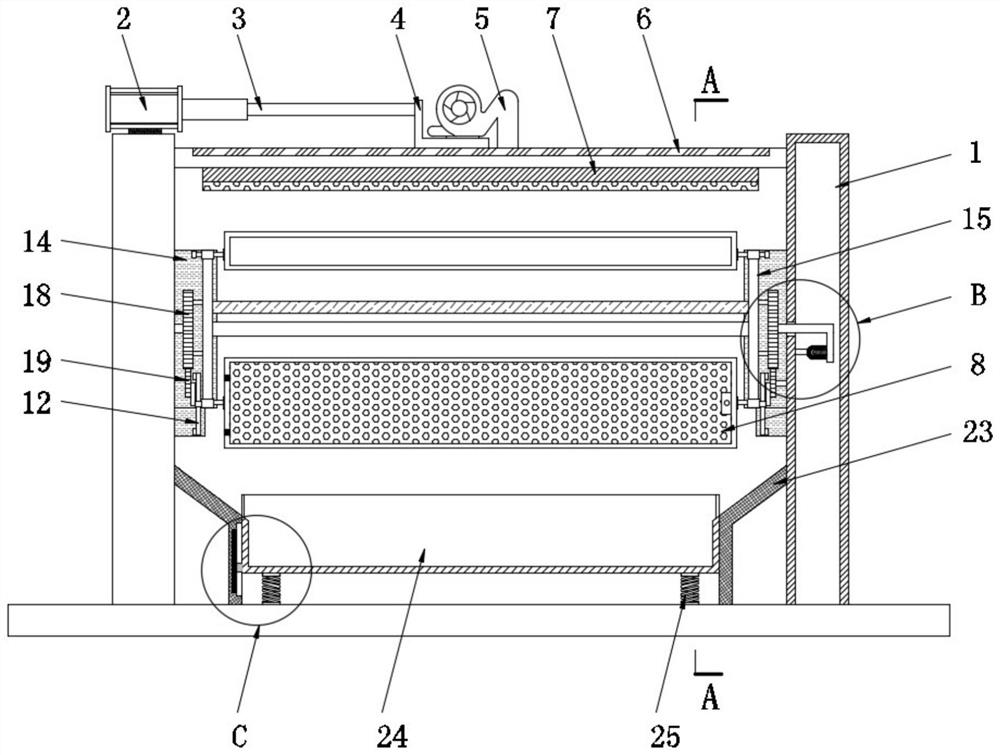

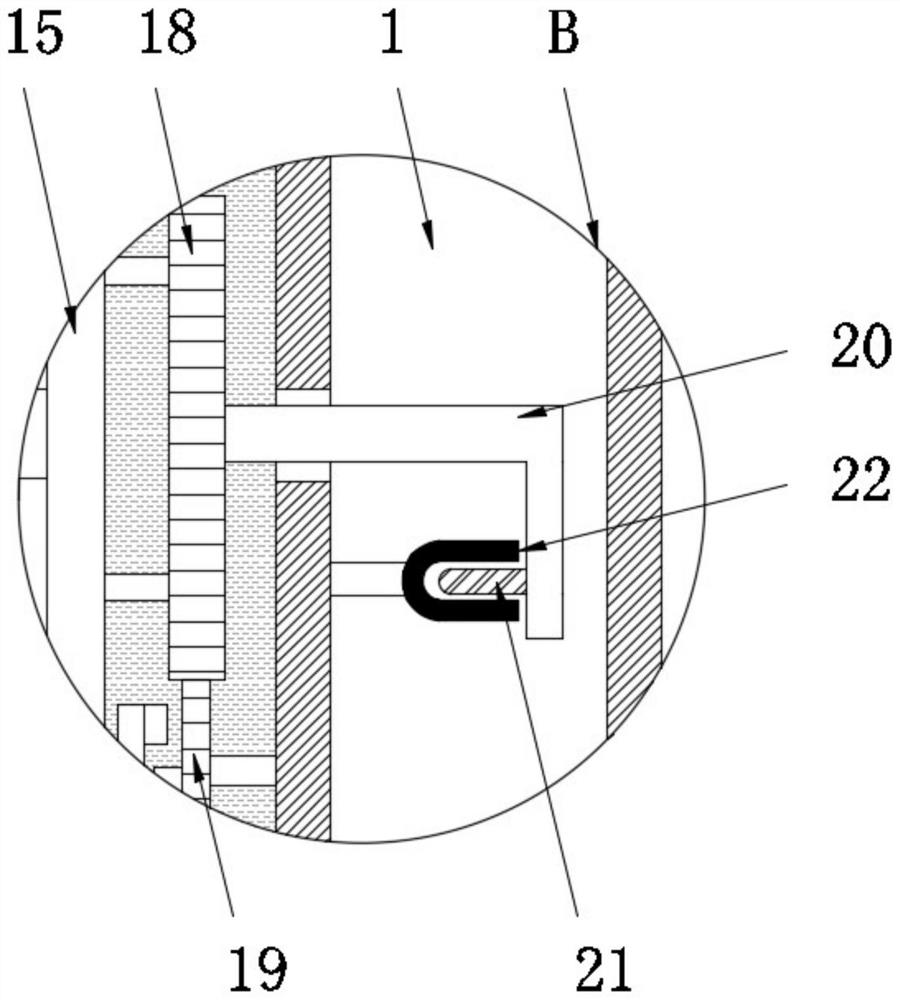

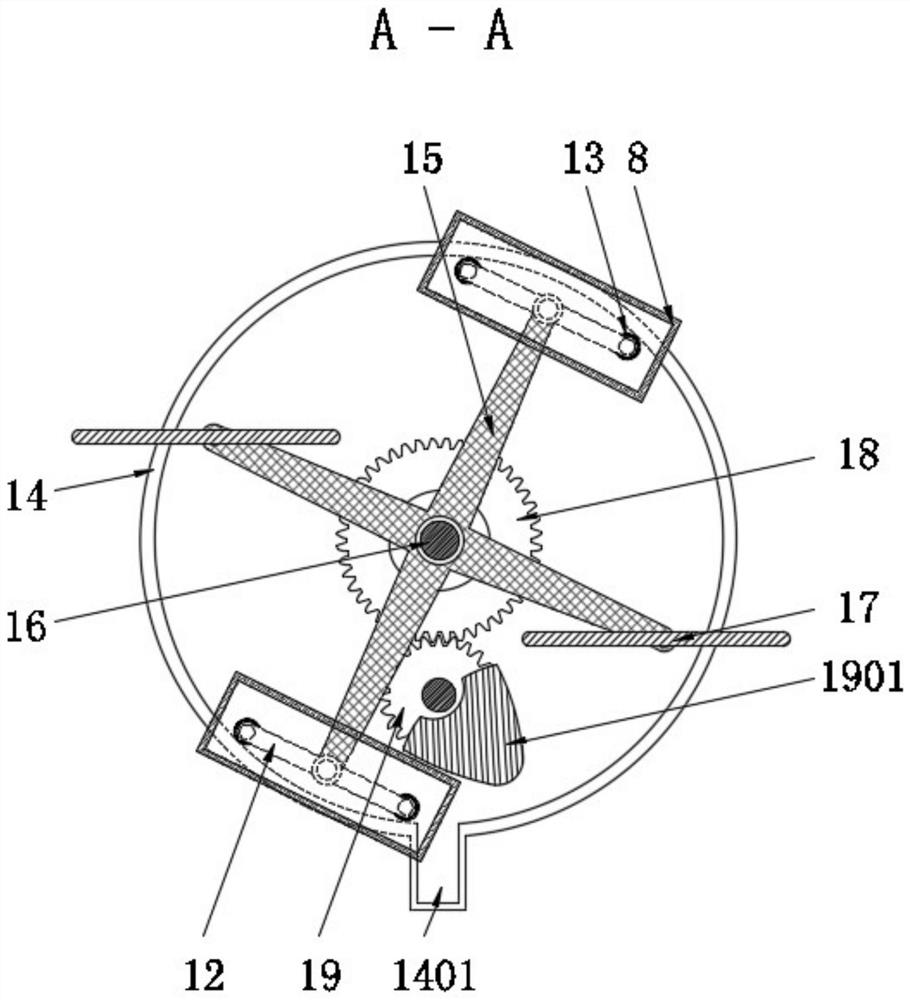

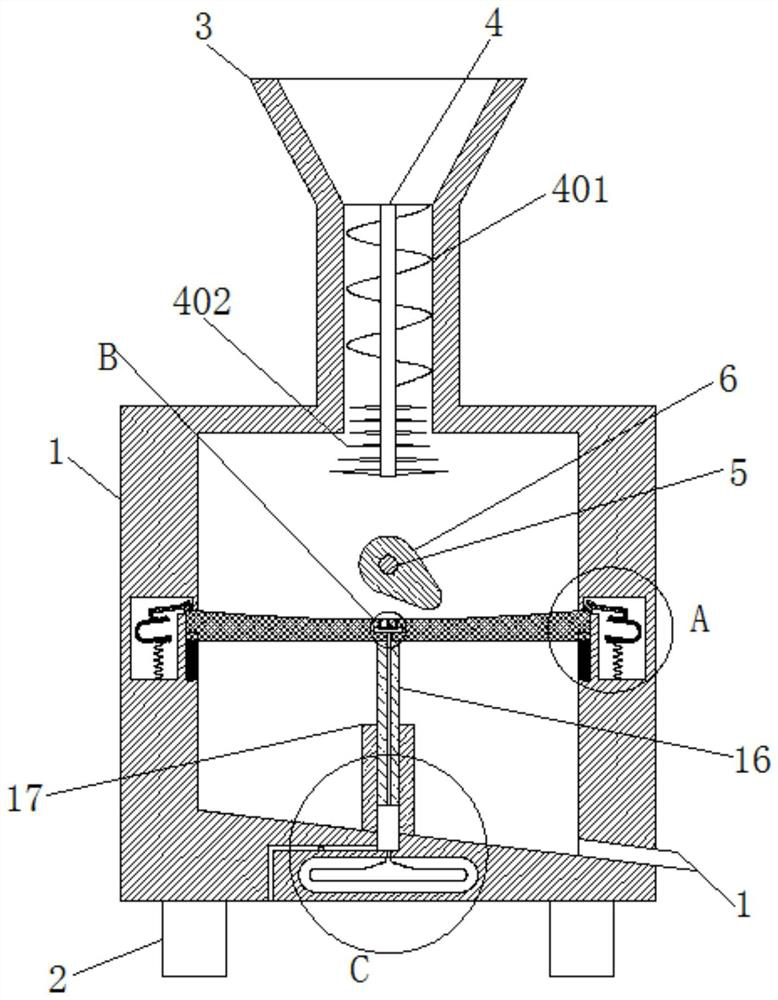

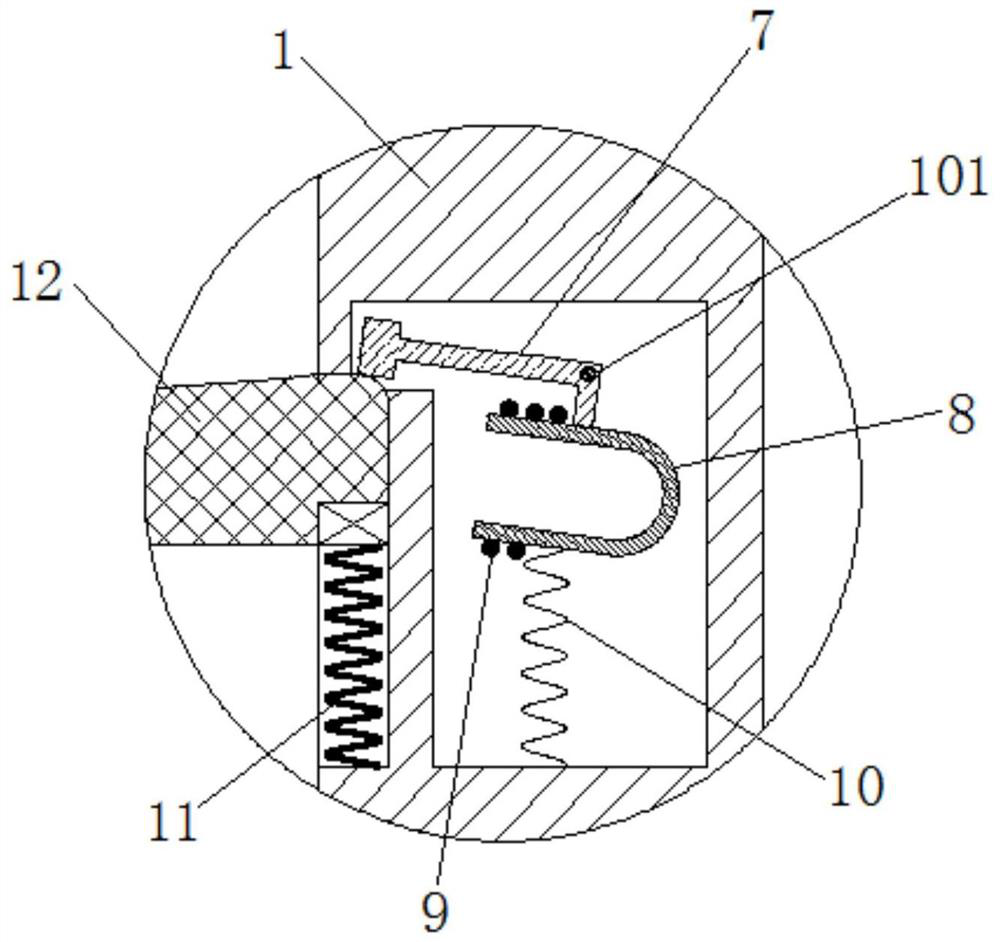

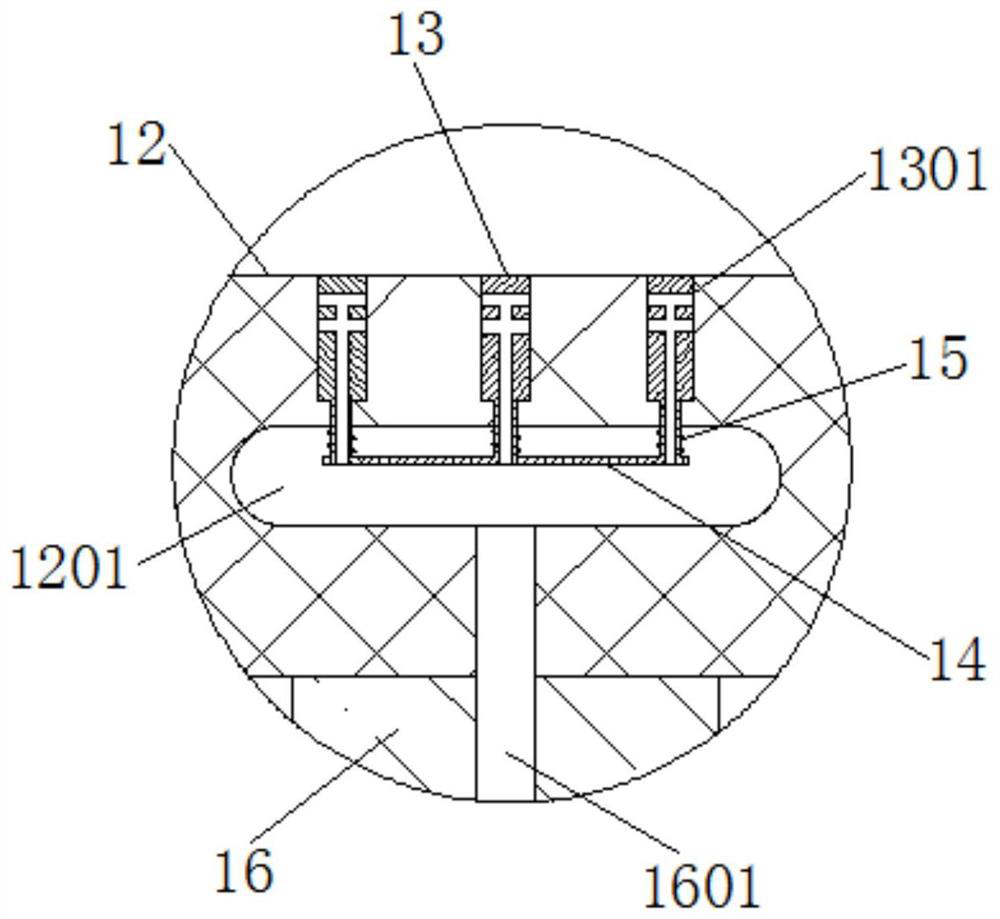

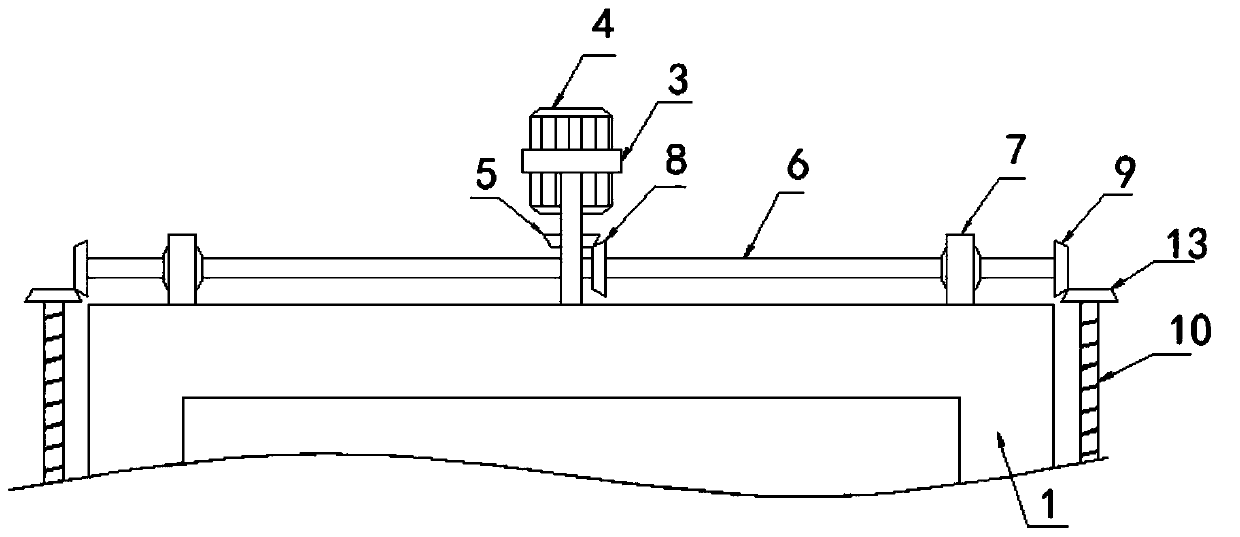

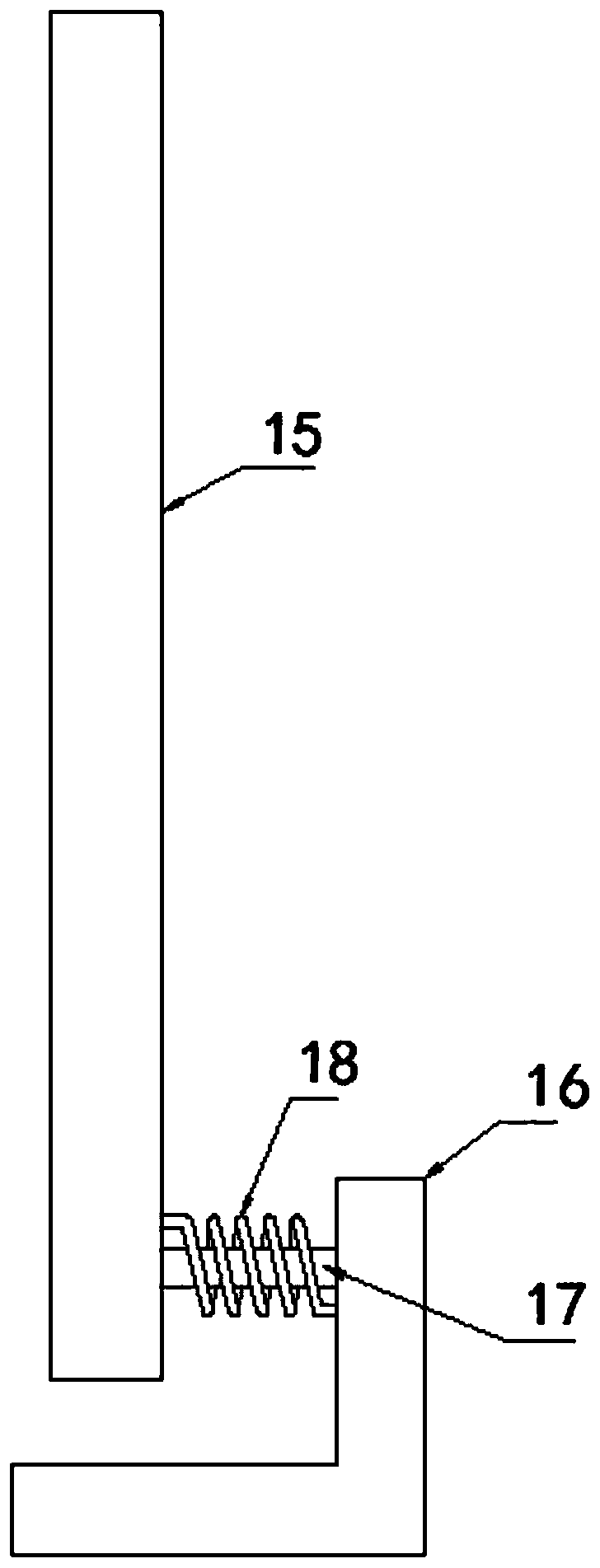

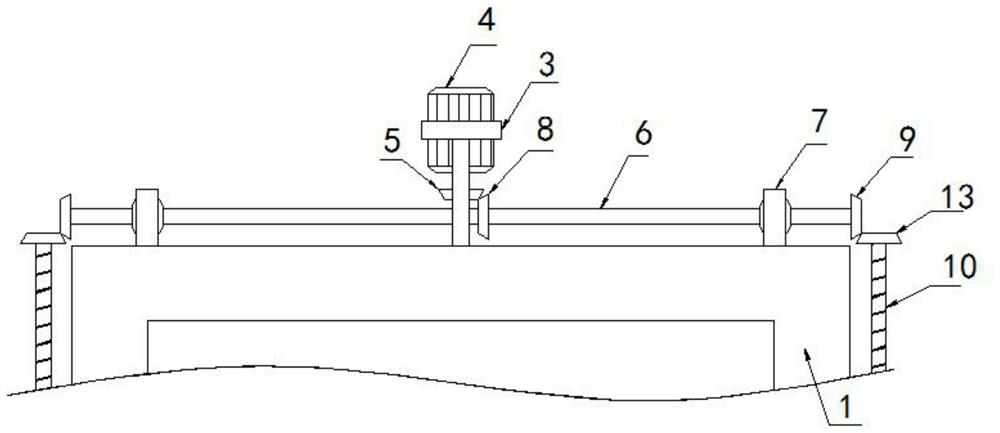

Automatic sand screening device for building material synthesis production and sand screening method thereof

ActiveCN112474311AAvoid settingTo achieve the effect of automatic disintegrationSievingScreeningMaterial synthesisReciprocating motion

Owner:GUIZHOU QINENG THERMAL INSULATION MATERIAL ENG CO LTD

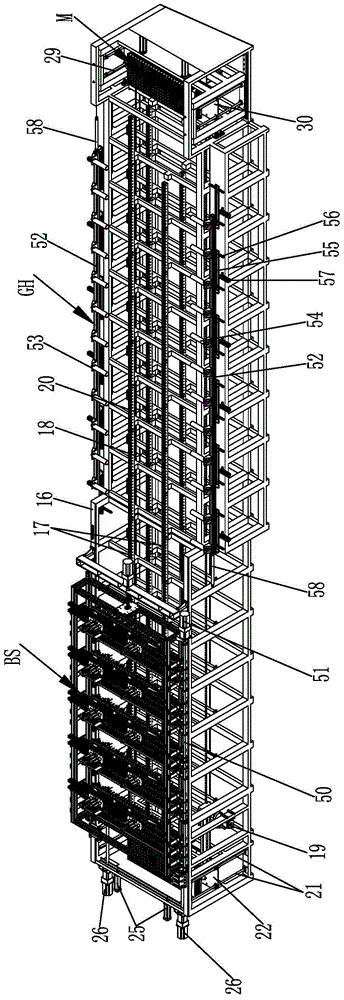

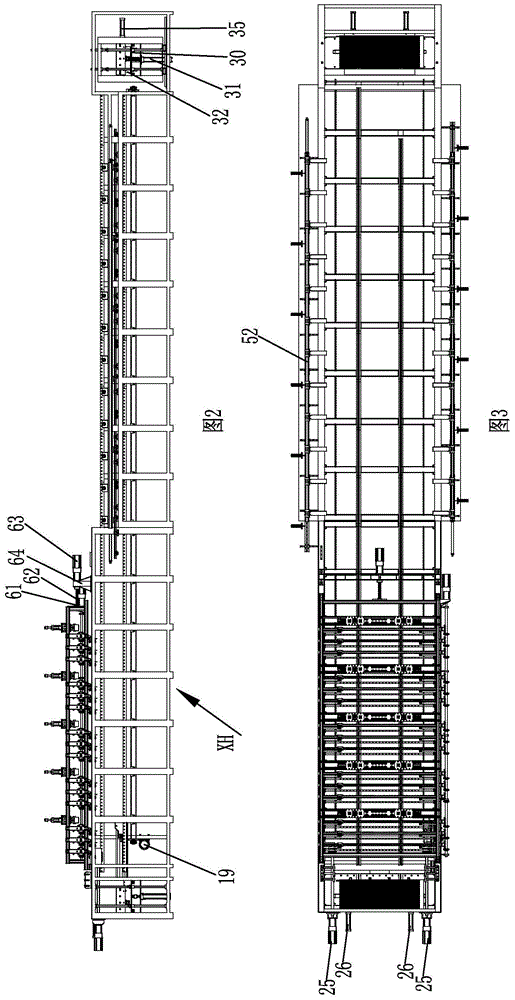

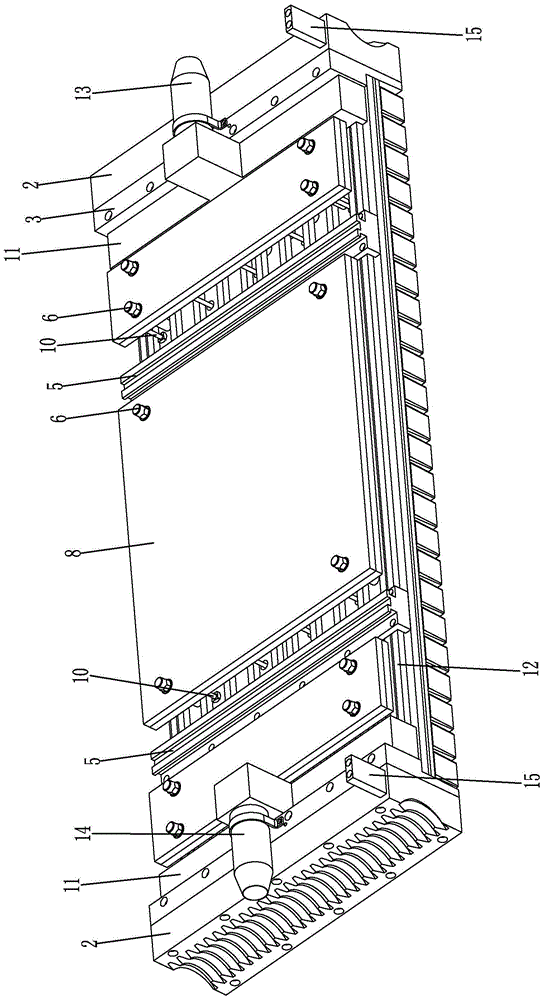

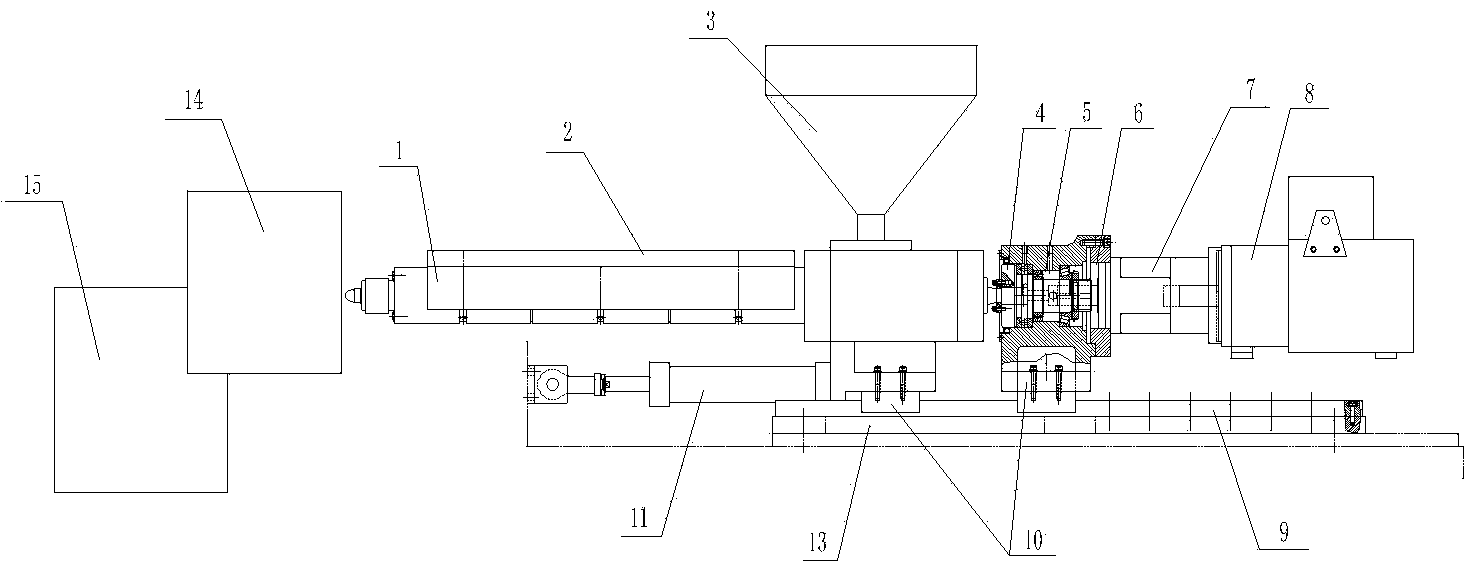

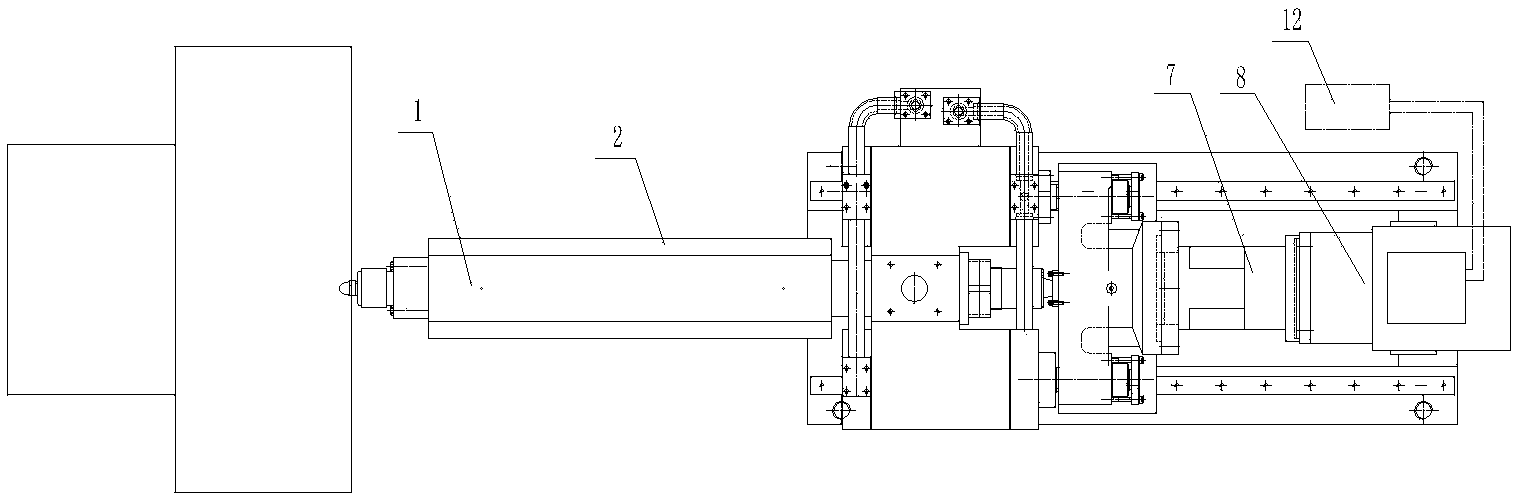

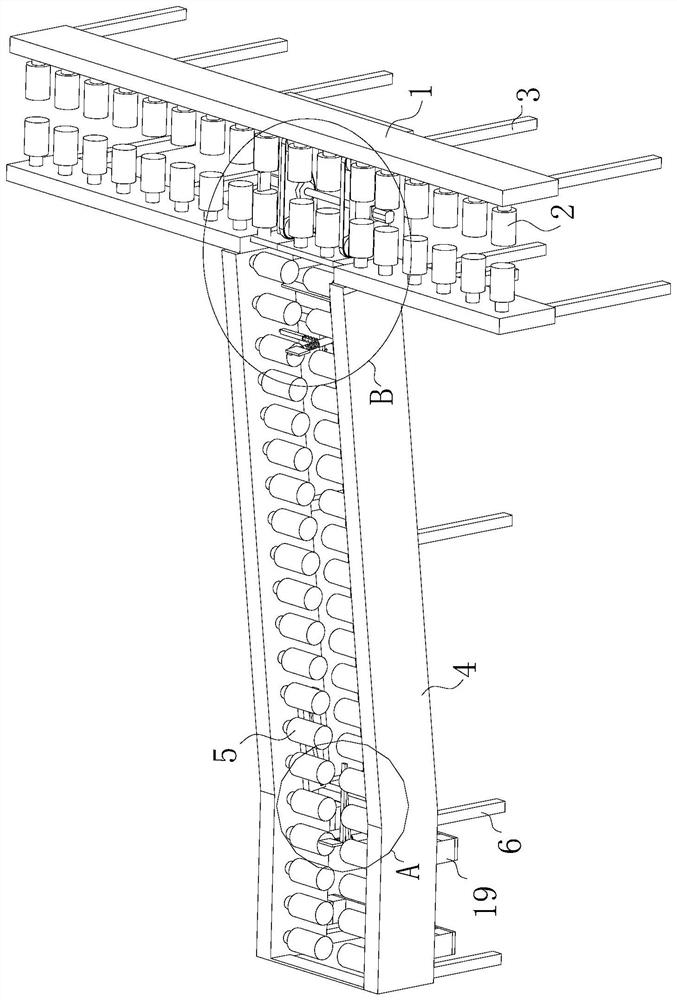

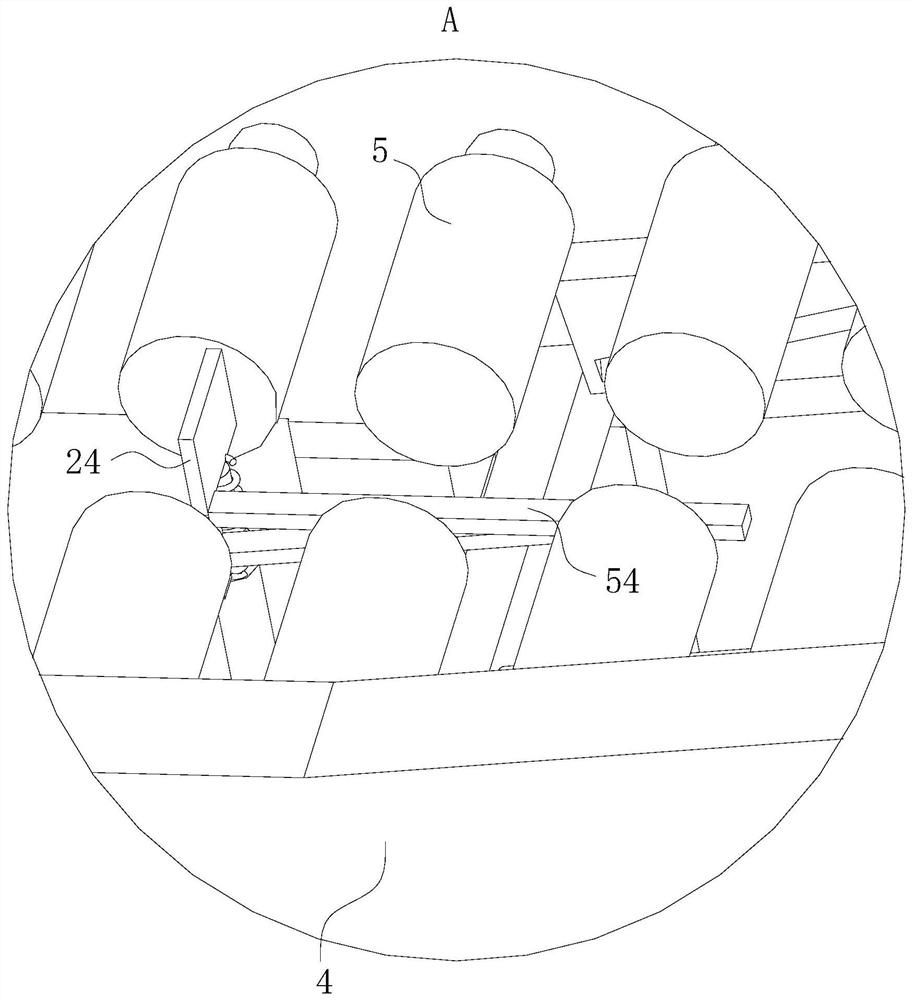

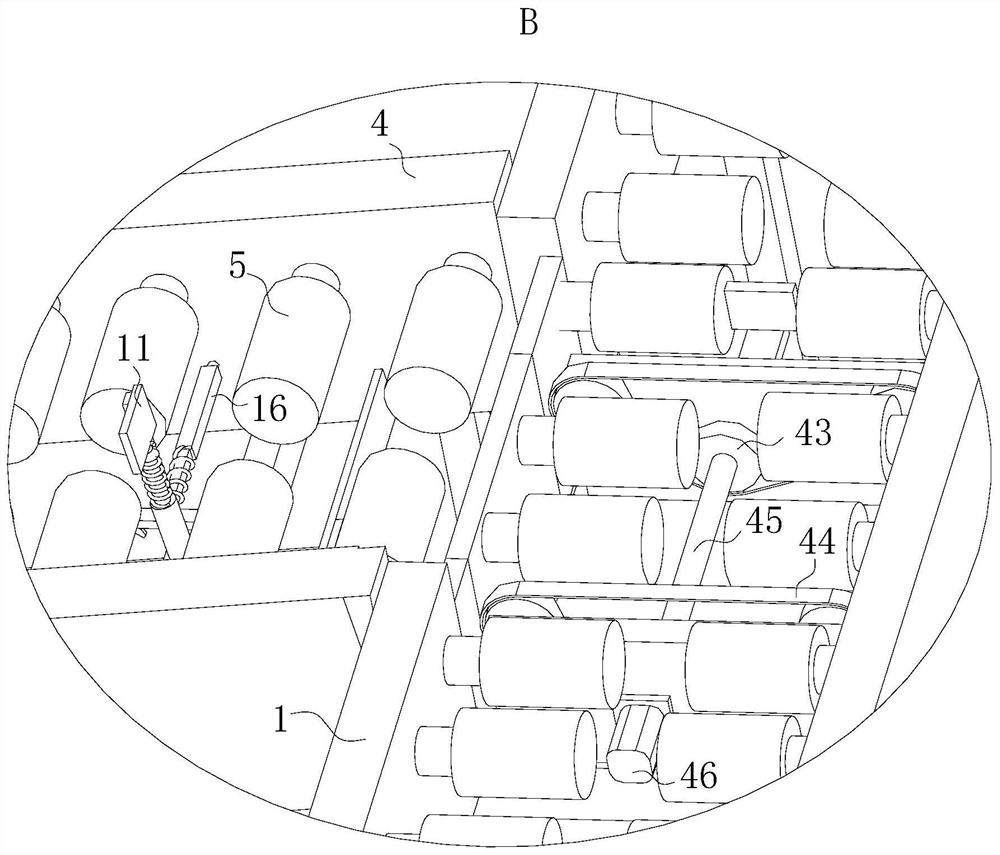

Composite material grid production apparatus

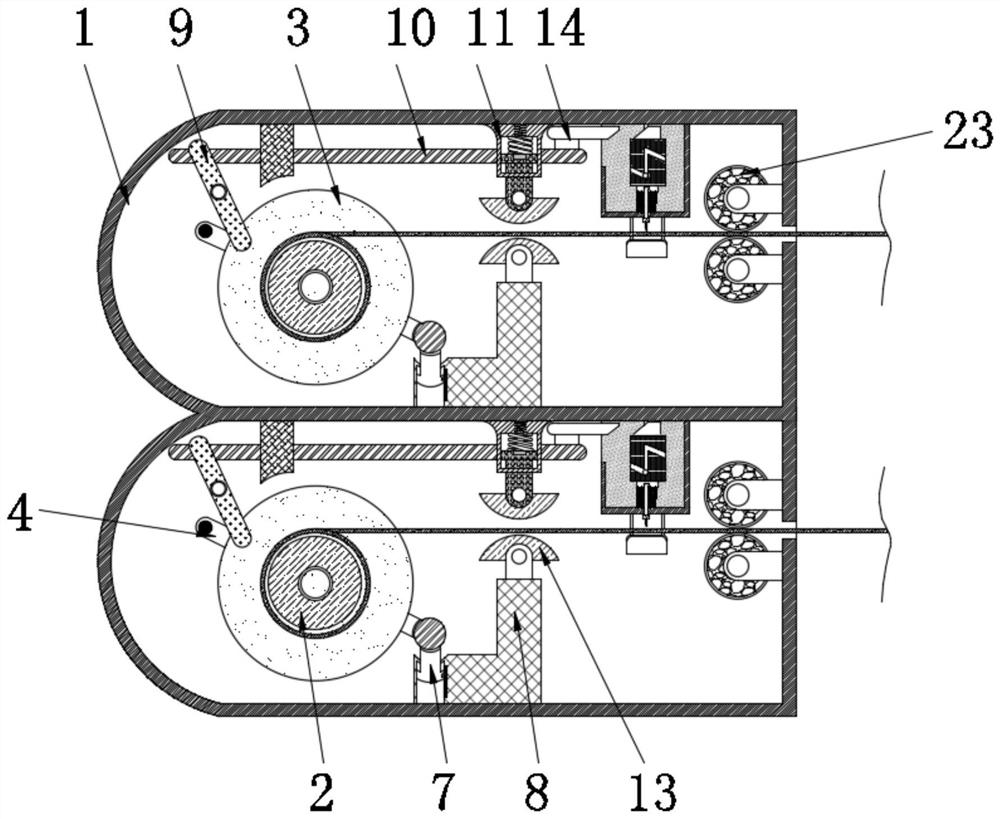

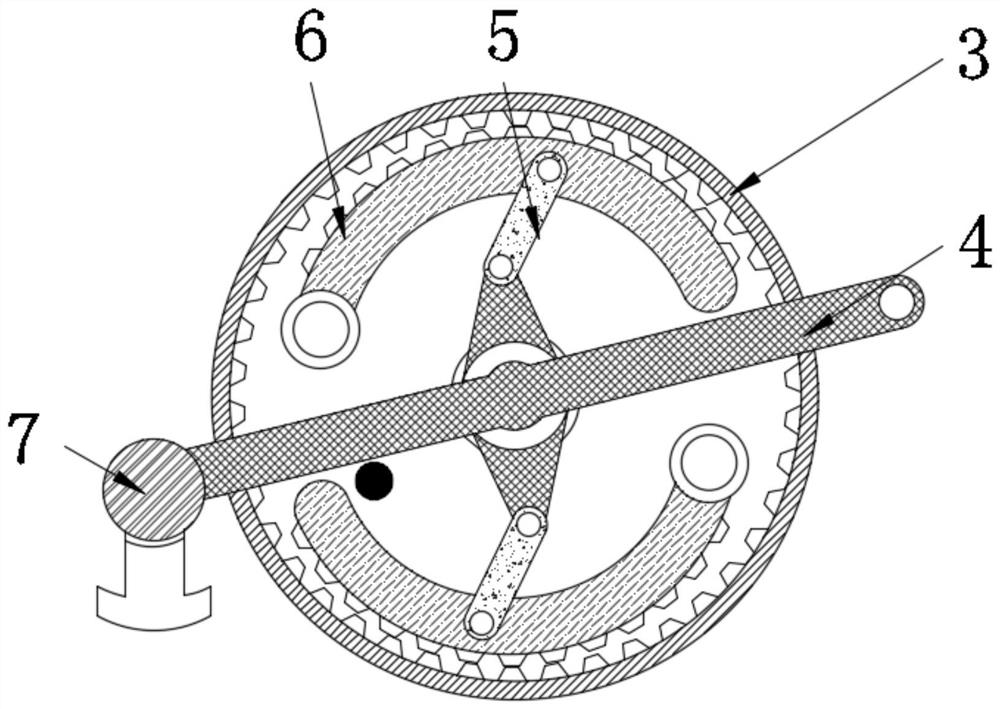

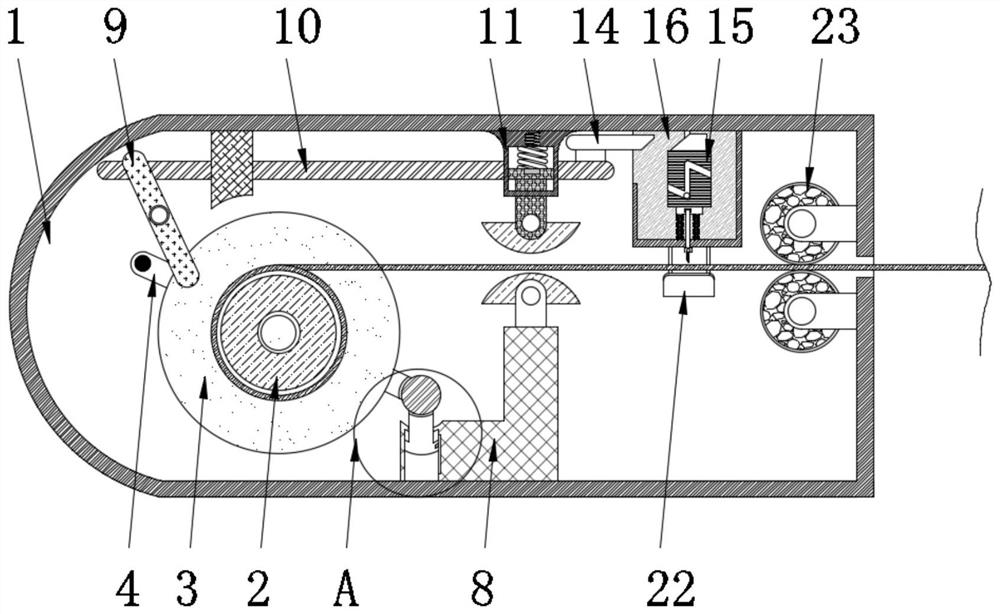

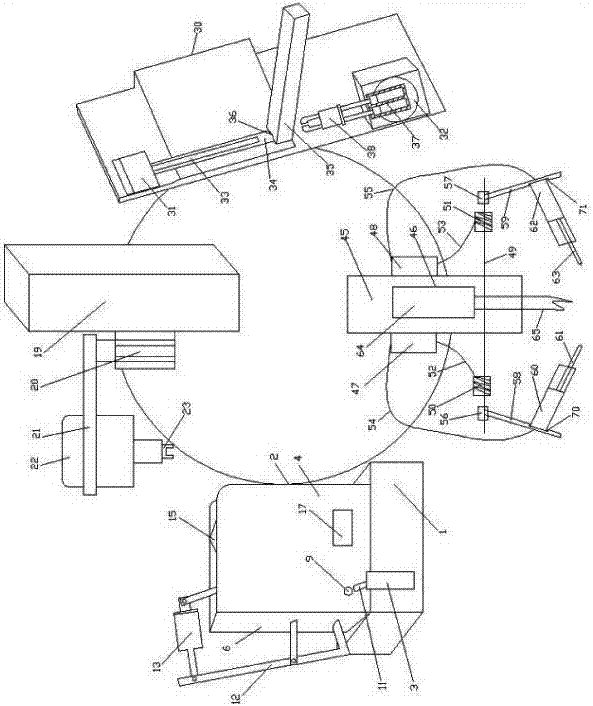

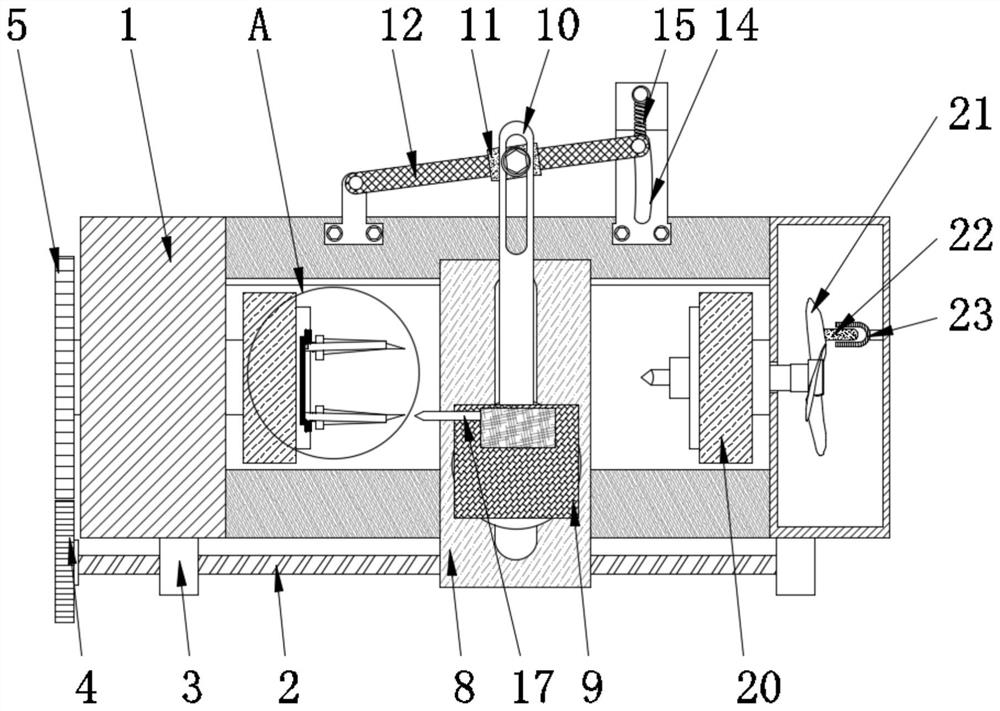

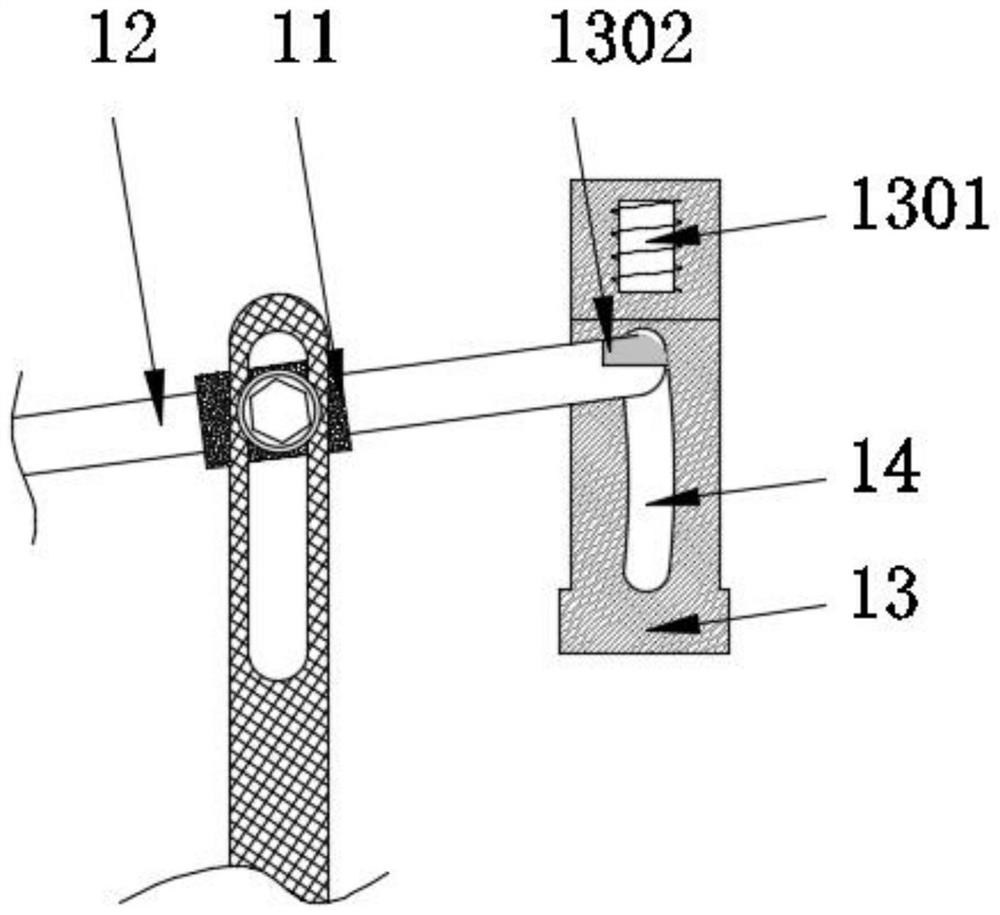

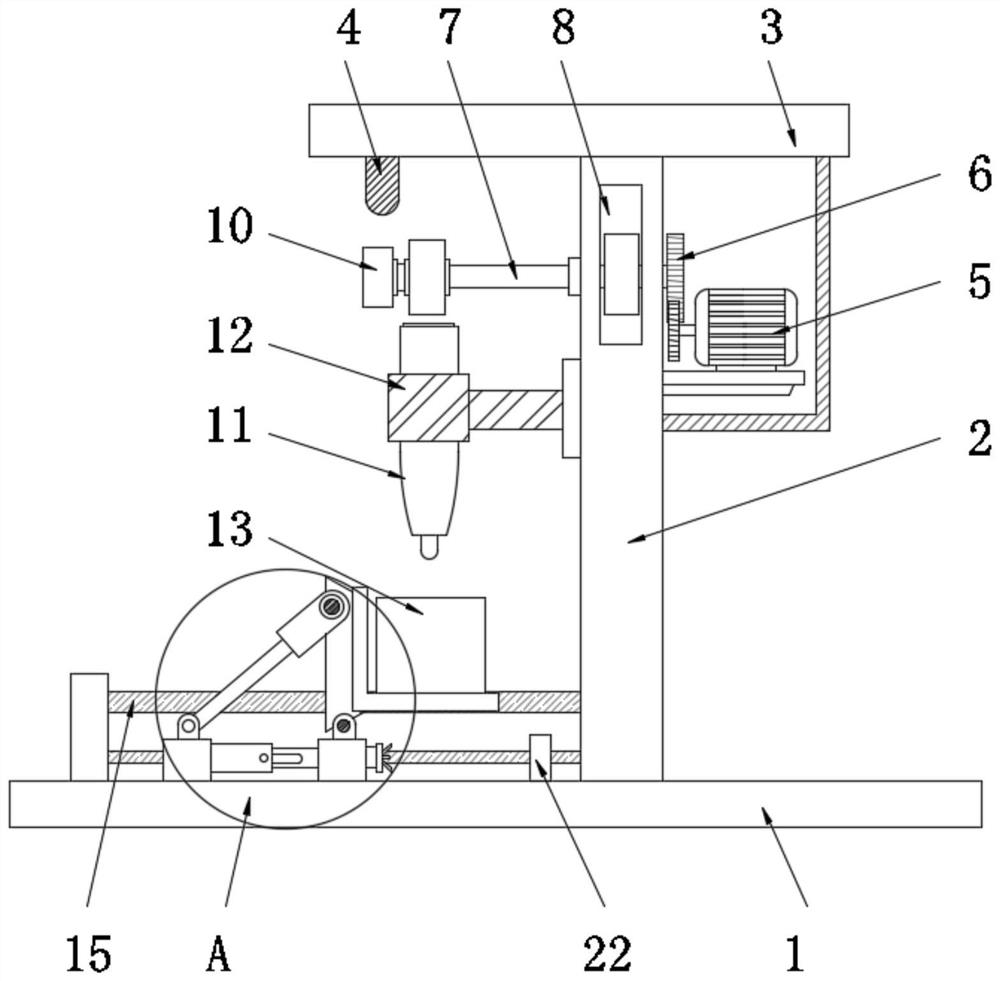

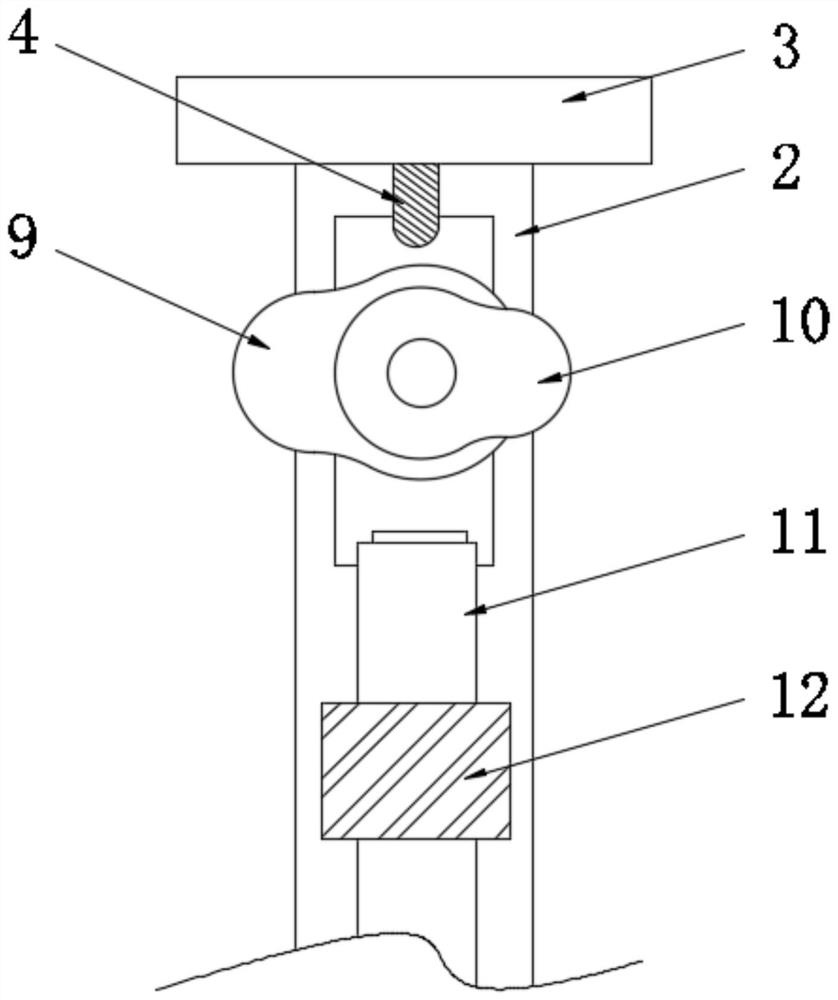

The invention discloses a composite material grid production apparatus. The apparatus comprises a die, a die circulating moving device, a yarn distribution device and a curing device, and the die circulating moving device is used to realize circulating movement of the die; the yarn distribution device and the curing device are arranged on the upper layer platform of a frame from left to right, and the yarn distribution device is used for distributing fiber cloth in the fiber adhesion tank of the die; and the curing device is used for heat curing of a grid in the fiber adhesion tank to mold the grid, and the molded grid is demolded through a demolding and die guiding mechanism in the die circulating moving device. All devices in the composite material grid production apparatus mutually cooperate to form an inseparable organic integral body, so manufacturing and demolding of the composite material grid can be completed, thereby artificial grid production is substituted.

Owner:NANTONG JOSSON NEW MATERIAL TECHNOLOGY CO LTD

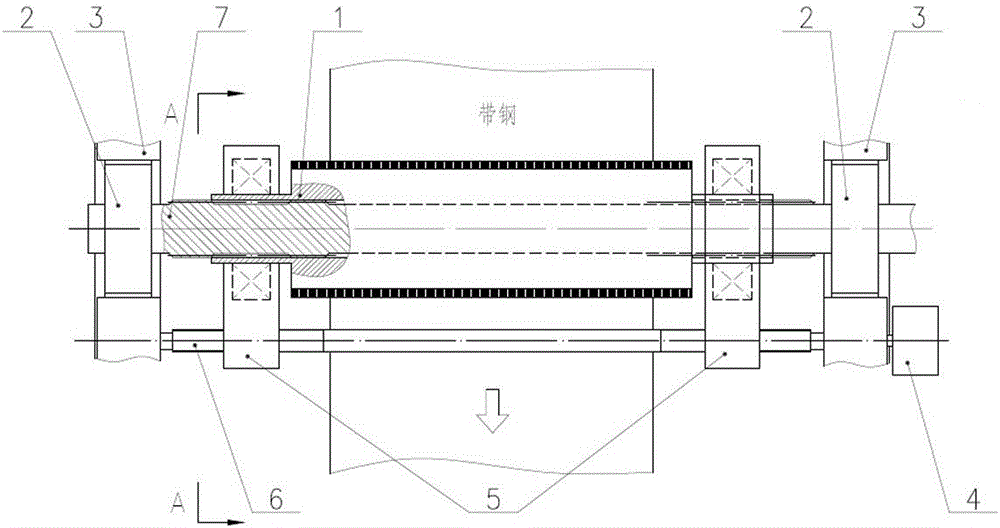

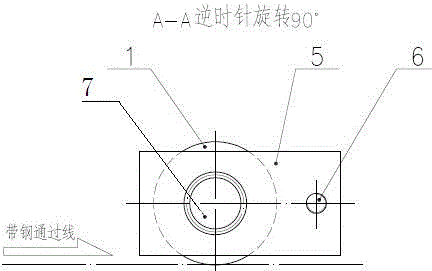

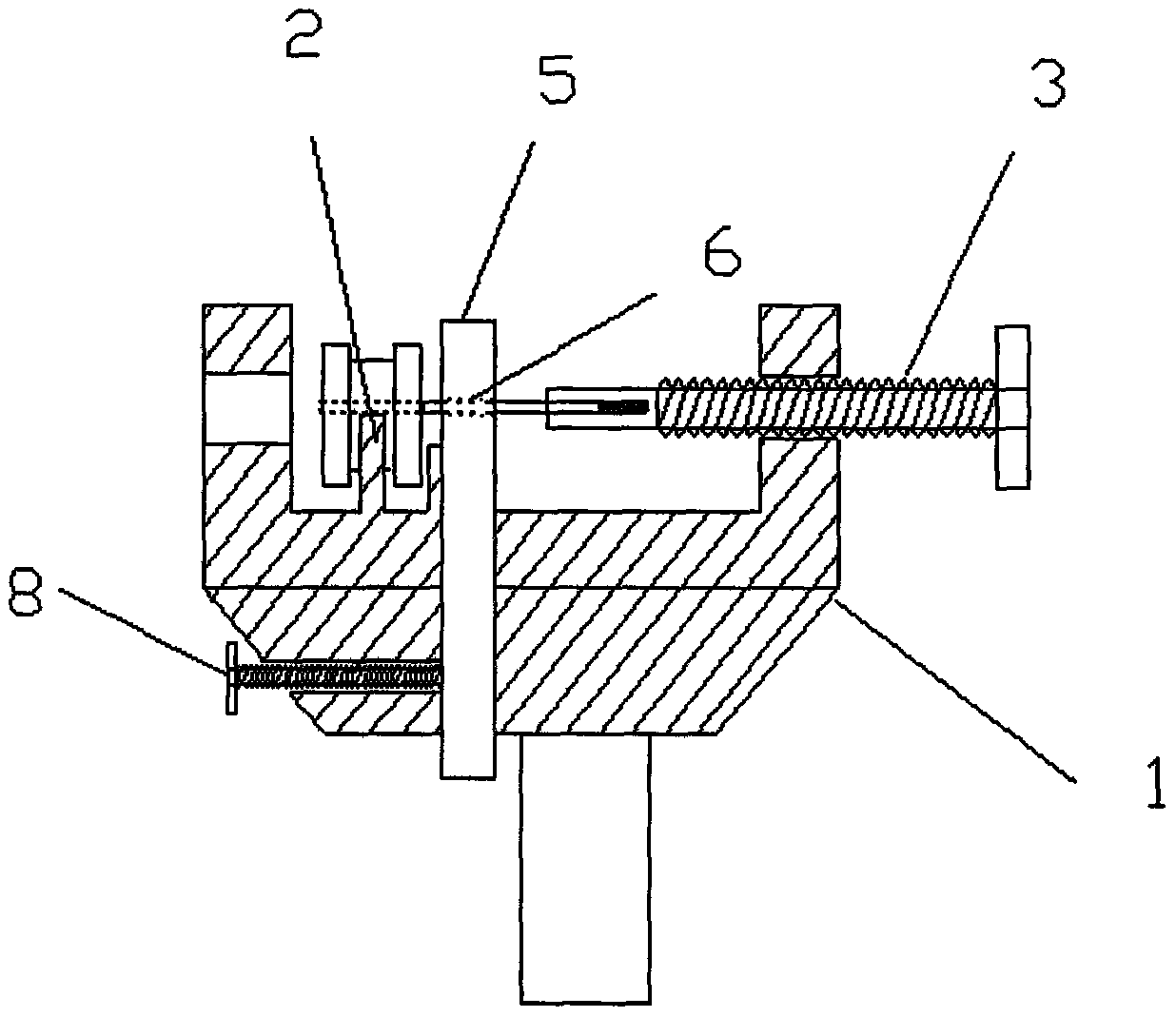

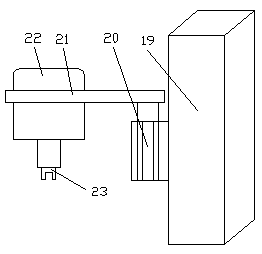

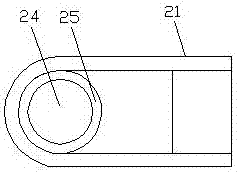

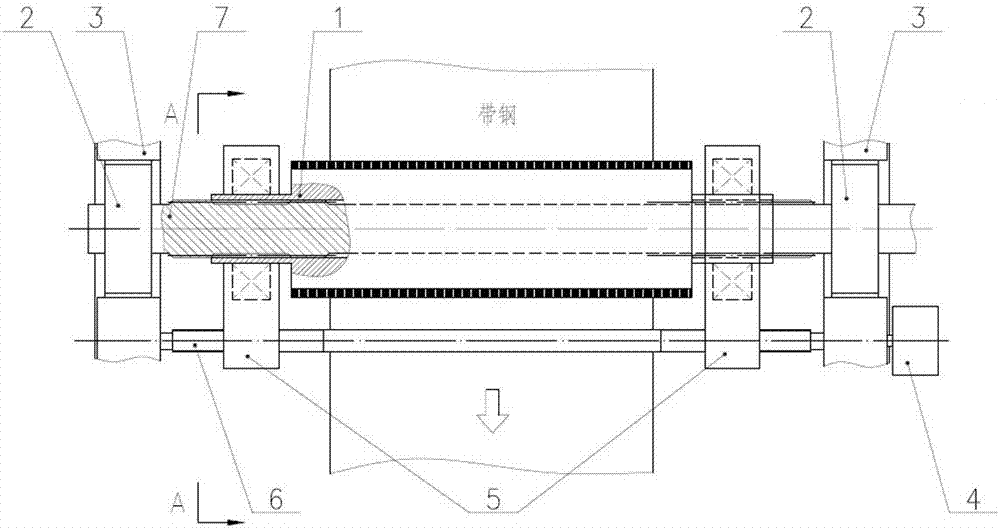

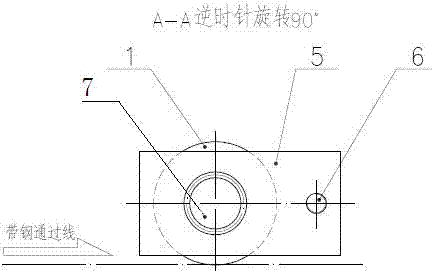

Brush roller with double bearing pedestals

ActiveCN105750247AExtended service lifeSimple structureCleaning using toolsReciprocating motionFixed bearing

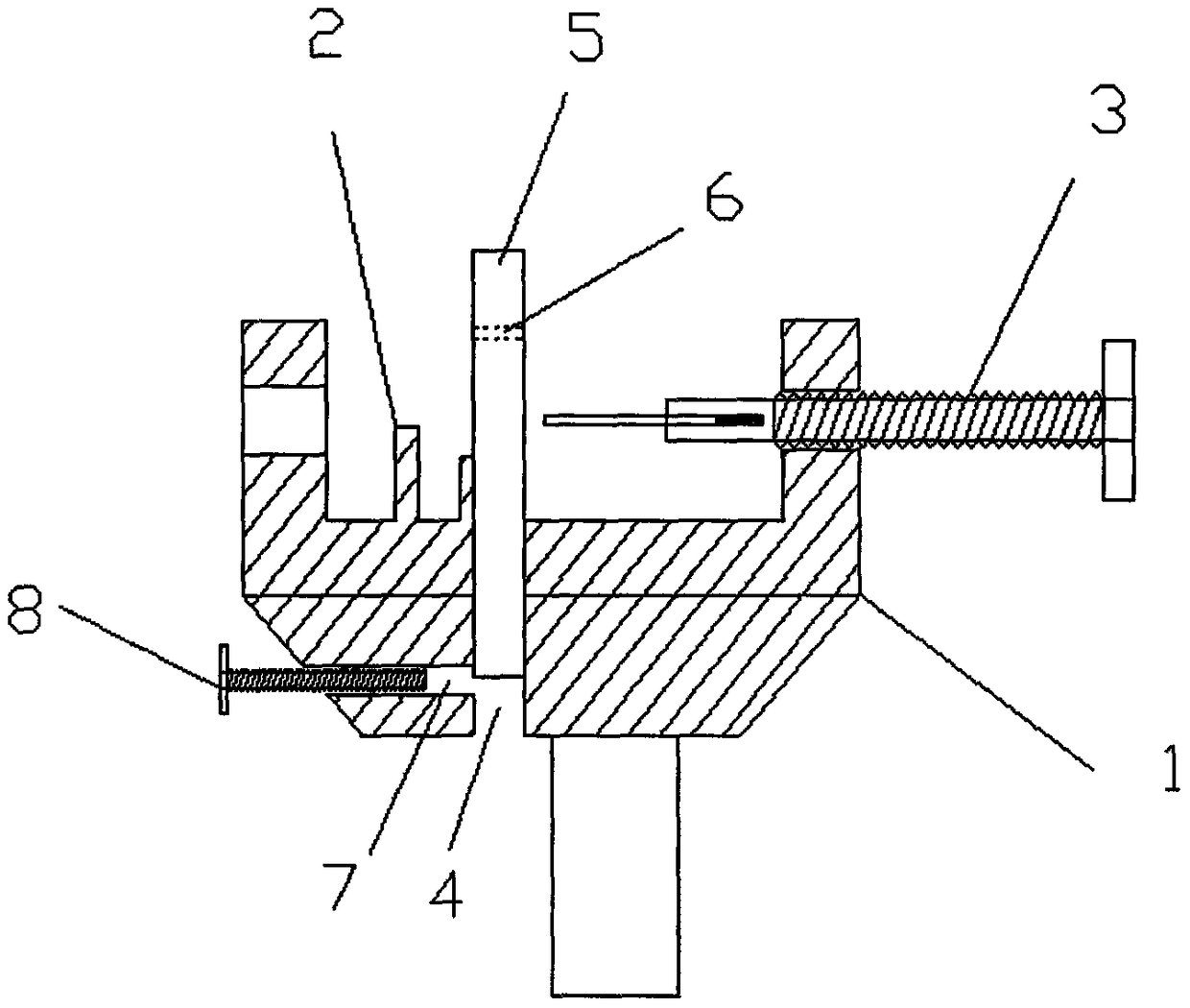

The invention relates to a brush roller with double bearing pedestals.The brush roller comprises a brush roller shaft and a brush roller cylinder.Bristles are arranged on the brush roller cylinder.The brush roller shaft is sleeved with the brush roller cylinder and matched and connected with the brush roller cylinder through spline.The two ends of the brush roller shaft penetrate out of the brush roller cylinder and are arranged on the fixed bearing pedestals respectively.The two fixed bearing pedestals are arranged on machine frames respectively.The two ends of the brush roller cylinder are arranged on the movable bearing pedestals respectively.A lead screw penetrates through the two movable bearing pedestals in a matched mode to be parallel to the brush roller shaft.One end of the lead screw is arranged on one machine frame, and the other end of the lead screw penetrates through the other machine frame and is connected with a drive mechanism.The drive mechanism can drive the movable bearing pedestals and the brush roller cylinder through the lead screw to reciprocate axially.All the bristles of the brush roller can make uniform contact with belt steel, and the brush roller is simple in structure and low in cost.

Owner:WISDRI ENG & RES INC LTD

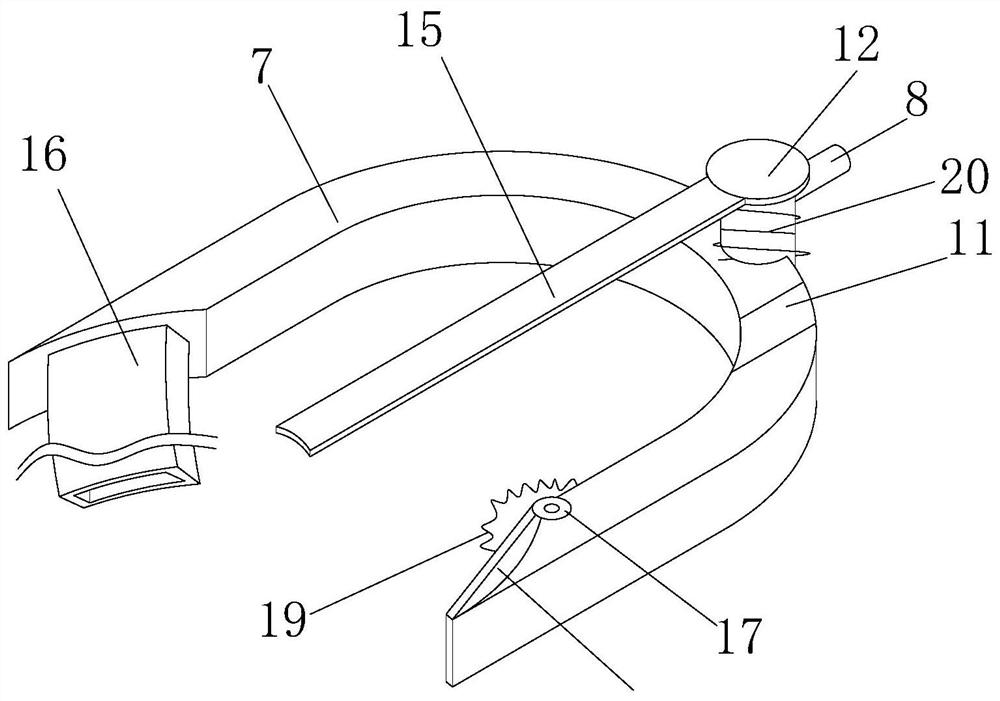

Automatic cutting-off device in textile fabric winding process

InactiveCN112064188ANeat cutting effectRealize automatic cut offWeft knittingTextile selvedgesRolling-element bearingStructural engineering

The invention provides an automatic cutting-off device in a textile fabric winding process. A round wheel is slidably mounted in a mounting plate, an inclined groove is formed in the surface of the round wheel, a bottom block is mounted at the bottom of the round wheel through a rolling bearing, and a compression spring is fixedly connected between the lower surface of the bottom block and the lower wall of the interior of the mounting plate; and connecting rods are fixedly mounted on the front surface and the rear surface of the bottom block, and a cutter is fixedly mounted between every twoadjacent connecting rods. The diameter of a fabric on the outer surface of a winding roller is larger and larger, thus a movable rod is driven to move leftwards, based on a lever principle, the movable rod drives a transverse rod to slide rightwards in a top seat, when the push block moves rightwards, the round wheel is pressed by an inclined face to move downwards in the mounting plate, meanwhile, through design of the inclined groove and a protruding column, the round wheel is driven to rotate clockwise by a certain distance, the connecting rod on the lower surface of the bottom block and the cutters are driven to move downwards together, the textile fabric is cut off on the upper surface of a cutter holder, and therefore the purpose of automatic cutting in the winding process is achieved.

Owner:梁春惠

Simple chain intercepting tool

Owner:蔡法成

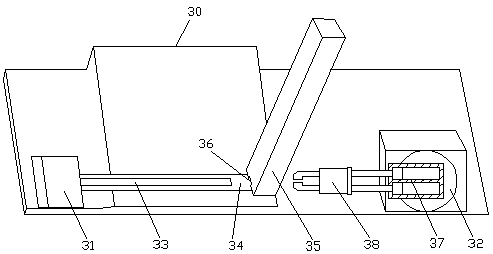

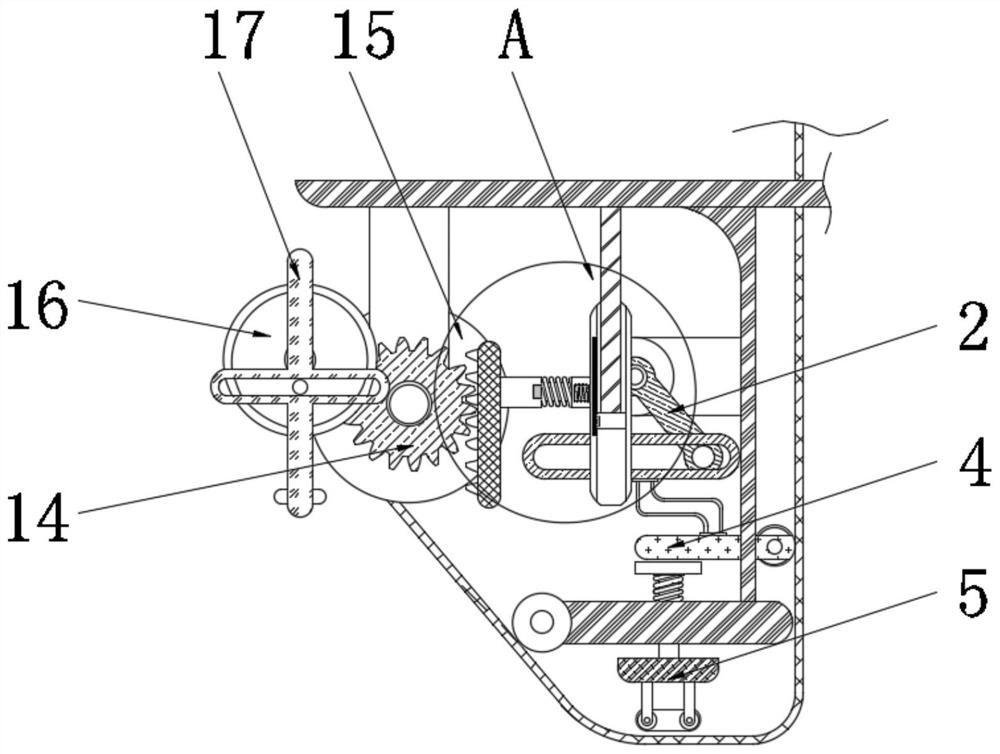

Plasticized material receiving structure of injection blow molding machine

The invention relates to a plasticized material receiving structure of an injection blow molding machine. The plasticized material receiving structure comprises a frame, wherein an injection molding part is arranged on the frame, a forming part is arranged beside the injection molding part, and the injection molding part comprises a plasticized screw rod, a housing arranged outside the plasticized screw rod, and a driving device used for driving the plasticized screw rod to rotate; a moving device for driving the injection molding part to move is arranged below the injection molding part, and a rotating device used for automatically transferring products is arranged in an outlet of the forming part. By adopting the structure, the improved driving device and a servo motor are used, so that the plasticized position can be smoothly fed; the moving device is adopted, so that the plasticized position can be smoothly pushed; the rotating device is adopted, so that the automatic feed of the machine can be guaranteed so as to enable the automation to be realized, the working efficiency can be improved, manpower resources are saved, the abrasion is reduced, and safety accidents are reduced.

Owner:张家港市联鑫塑料机械有限公司

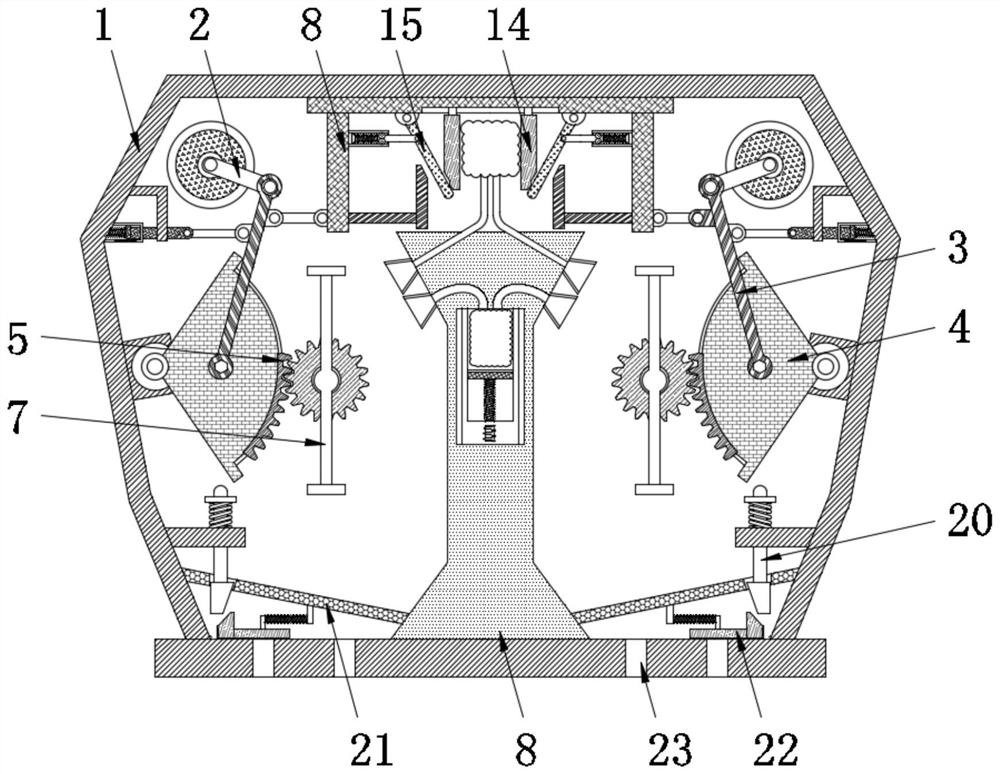

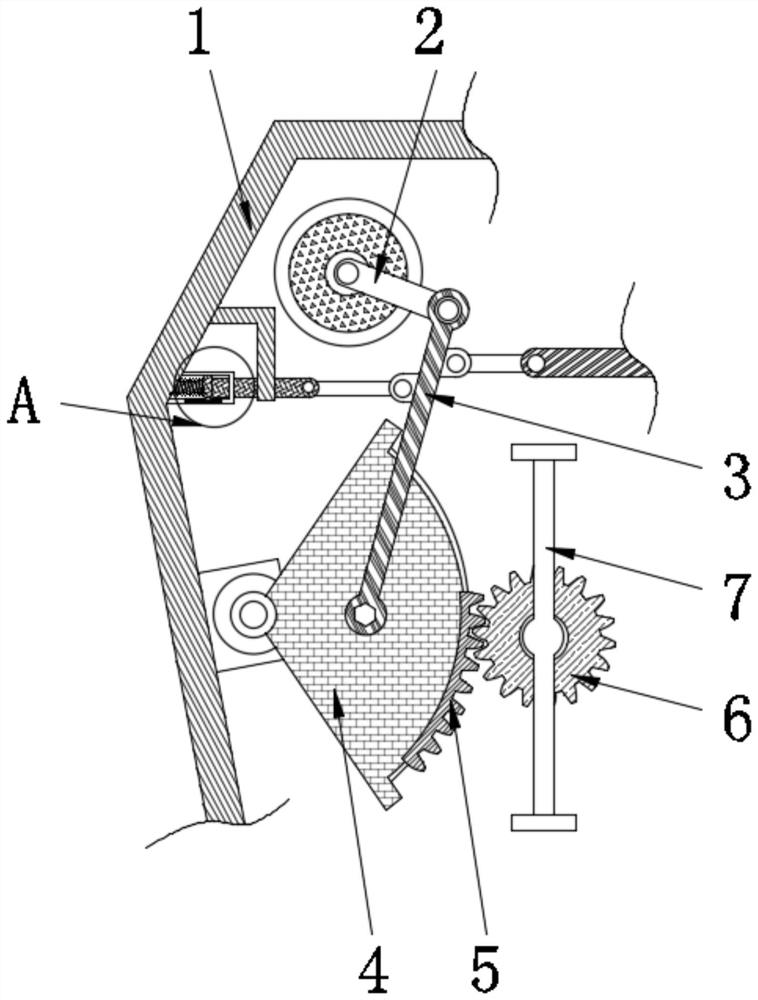

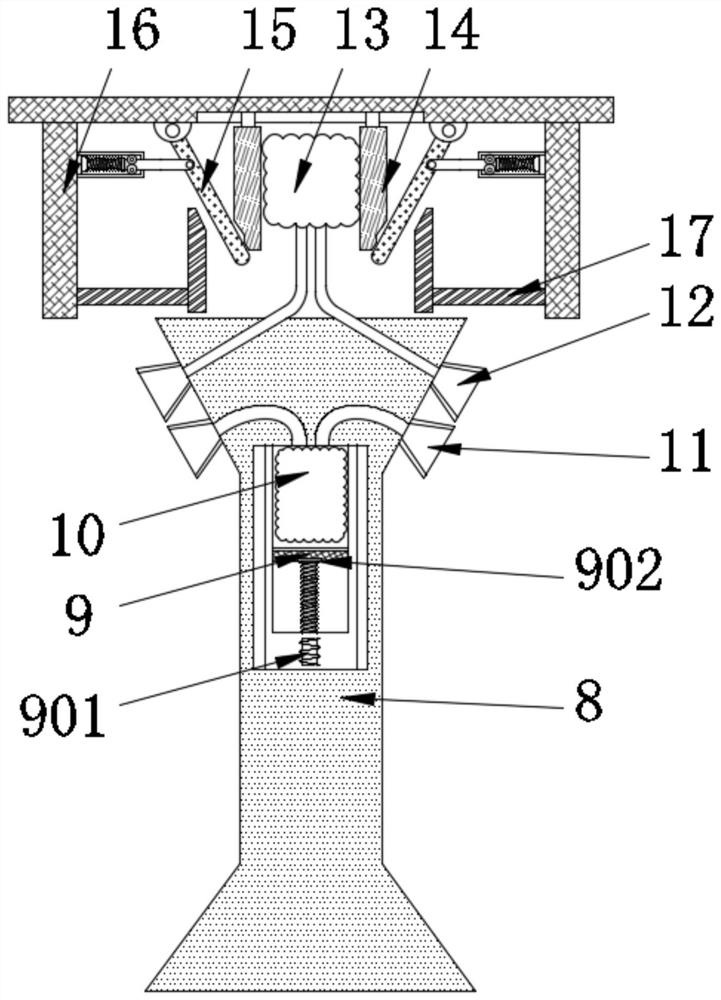

Centrifugal vegetable drying device with uniform dehydration function

ActiveCN111838715AAvoid colliding with each otherGuaranteed pushFood treatmentAgricultural engineeringStructural engineering

The invention provides a centrifugal vegetable drying device with a uniform dehydration function. A groove is formed in the lower part of a bearing seat, transmission shafts are fixedly installed between adjacent main frames, air deflectors are fixedly installed on the peripheries of the main frames, large gears are fixedly installed on the outer sides of the main frames, pinions are meshed with the lower portions of the large gears, shifting blocks are fixedly installed on the surfaces of the inner sides of the pinions, and supporting rods are fixedly installed in the centers of the right surfaces of the large gears. An air guide plate is blown to rotate by an air heater, a material box between the main frames and a transmission shaft rotate together, and the main frame drives the large gear and the pinion to rotate in a meshed mode. When the shifting block on the inner side of the pinion makes contact with an idler wheel on a connecting rod, the connecting rod and the idler wheel arepressed into the groove in the bearing seat, and therefore the whole material box is turned over, the situation that the quality of vegetables is damaged due to long-time single-face drying is prevented, the drying efficiency of the vegetables is improved, and the drying degree and the dehydration degree of the vegetables are the same.

Owner:山东庄超食品有限公司

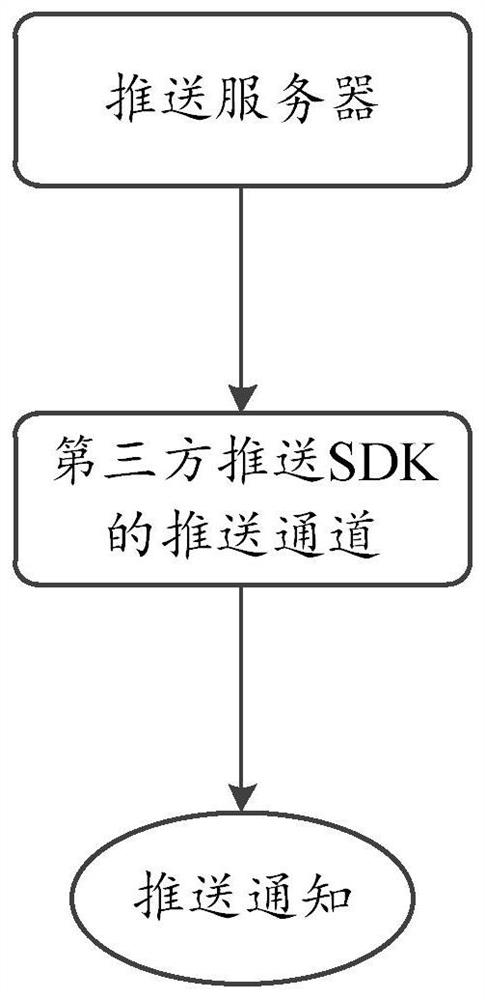

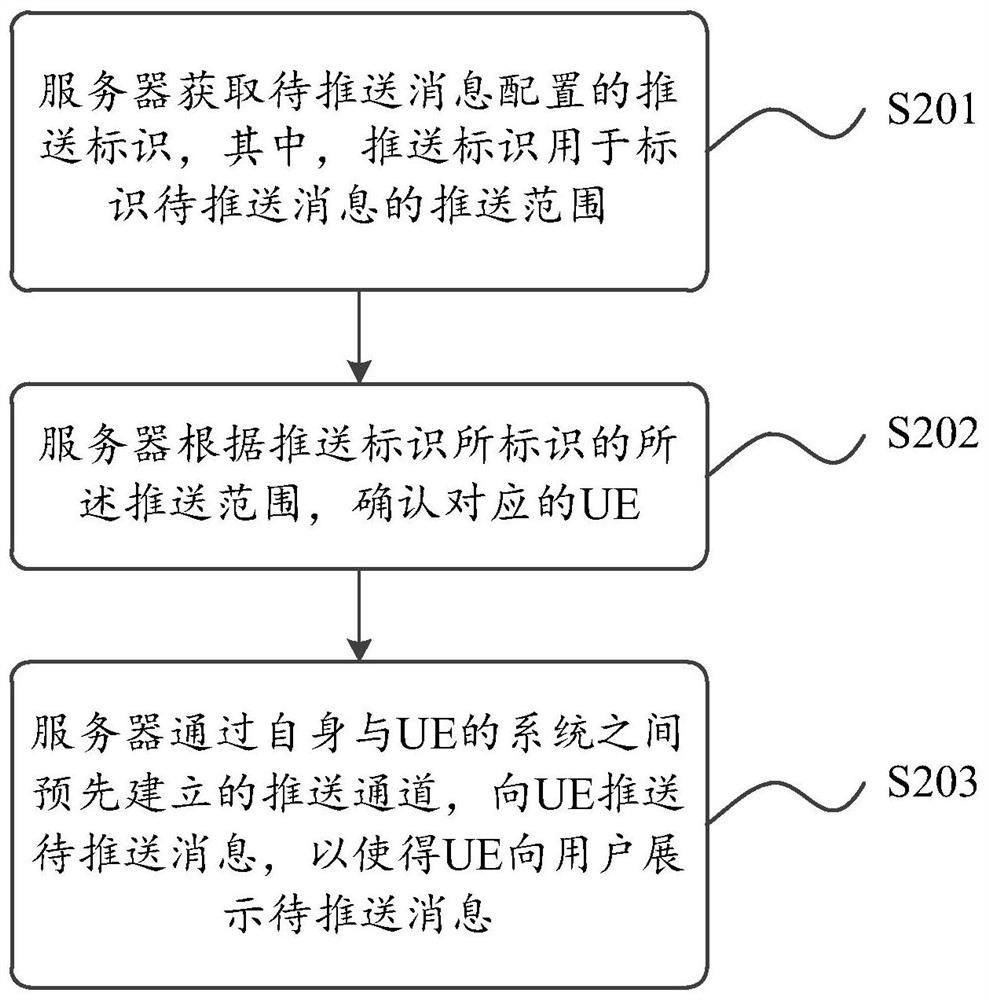

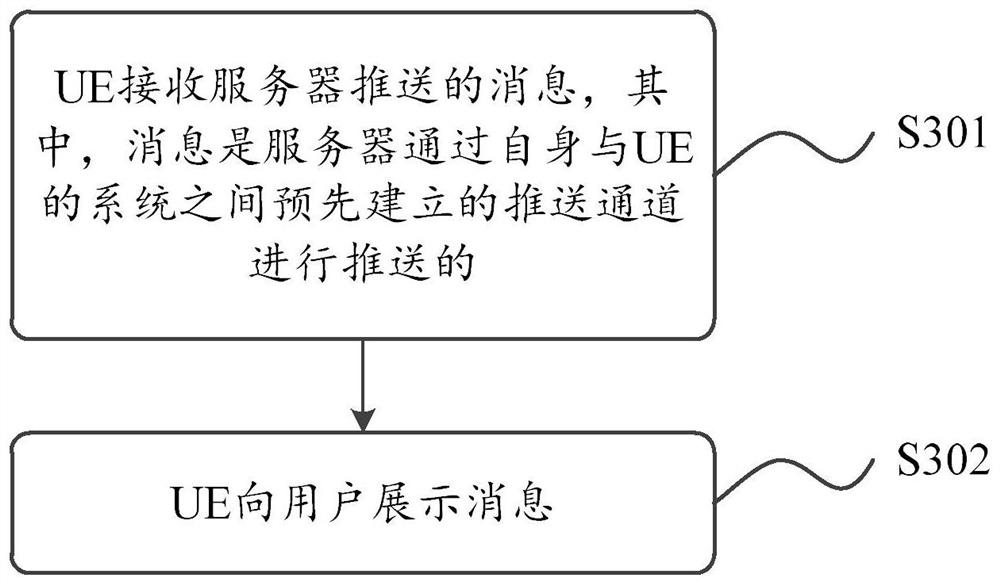

Message pushing method and device

PendingCN112231552AGuaranteed pushImprove push success rateDigital data information retrievalAdvertisementsComputer networkEngineering

The invention provides a message pushing method and device, which are used for pushing a message through a pushing channel established between a server and a system of UE; because the pushing channelis a pushing channel of a system level, the pushing channel has the characteristic of stable starting, and the normal pushing of the message can be guaranteed. The message pushing method provided by the invention comprises the steps that a server acquires a pushing identifier configured for a to-be-pushed message, and the pushing identifier is used for identifying a pushing range of the to-be-pushed message; the server confirms the corresponding UE according to the pushing range identified by the pushing identifier; the server pushes the to-be-pushed message to the UE through a push channel pre-established between the server and the system of the UE, and therefore the UE displays the to-be-pushed message to the user.

Owner:武汉木仓科技股份有限公司

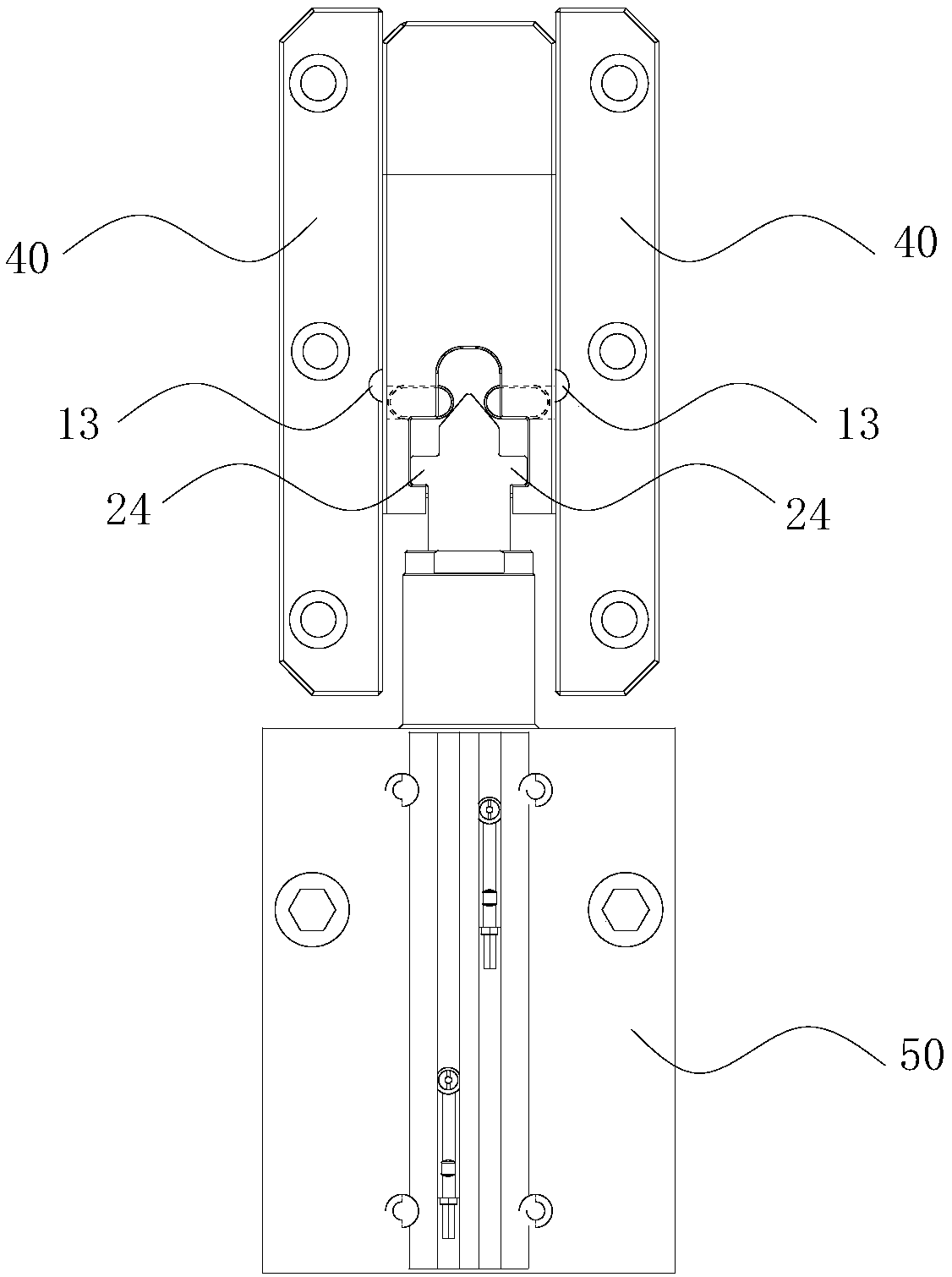

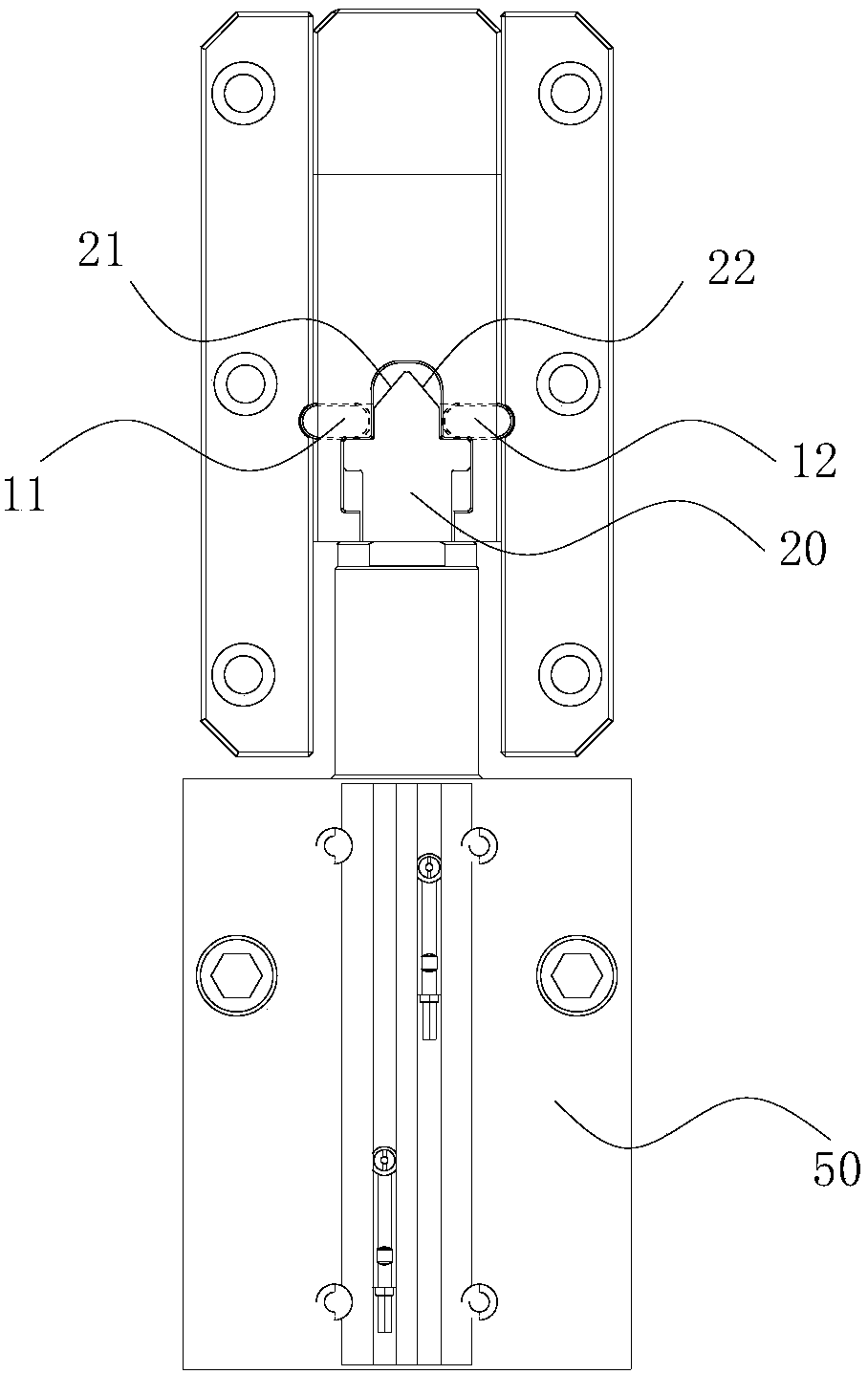

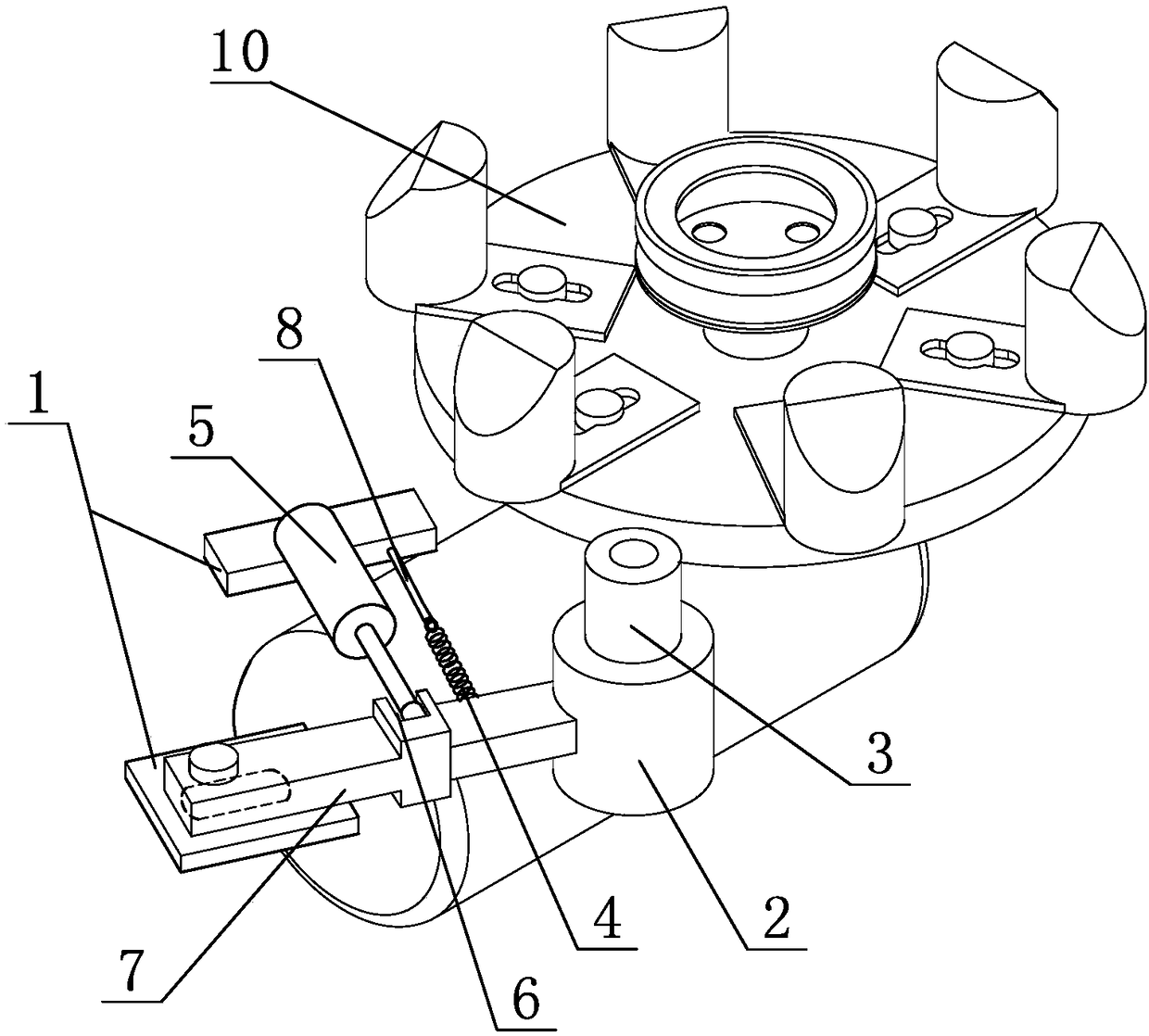

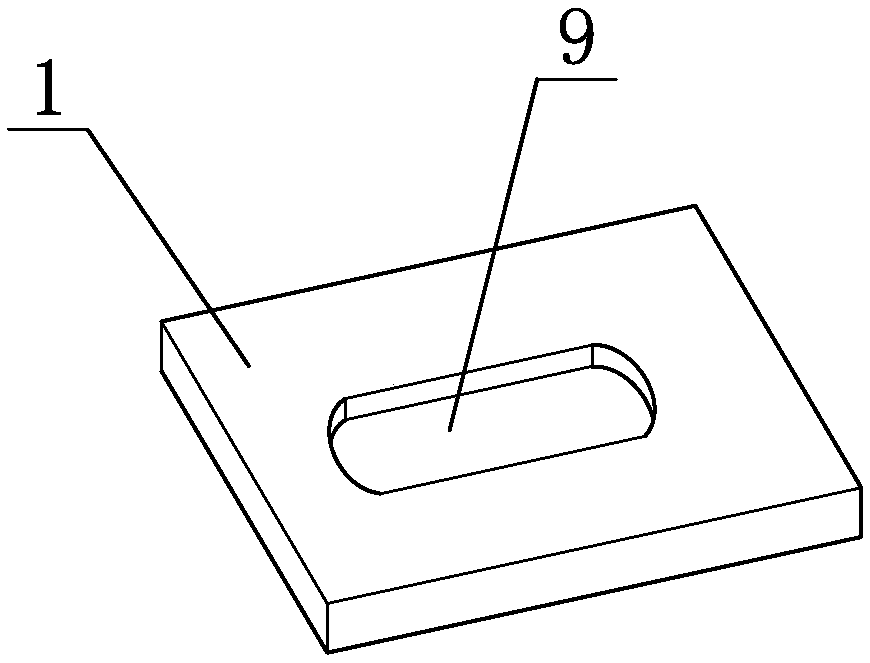

Installation method of blade

InactiveCN108177215AQuick take outHigh degree of automationRotary cutting toolsAutomationEngineering

The invention discloses an installation method of a blade. The installation method of the blade belongs to the technical field of cutter processing and preparing, and is characterized by comprising the following steps of a, placing a cutter body on a cutter clamping device; b, downwards moving an inserting plate of a cutter body alignment device, inserting the inserting plate into an inserting slot of the cutter body, rotating a stepping motor to drive the inserting plate to rotate, enabling the inserting slot of the cutter body to align at a placement position of a blade of a next process, upwards moving the inserting plate, and separating the inserting plate from the inserting slot; and c, pushing the blade out through a blade pushing air cylinder of a blade placement device, rotating the air cylinder to drive a double-shaft air cylinder to rotate clockwise at 90 degrees, clamping the pushed-out blade through a parallel clip on the double-shaft air cylinder, then anticlockwise rotating the blade at 90 degrees, and inserting the blade into the inserting slot of the cutter body. The installation method of the blade provided by the invention not only can be used for quickly aligningan installation position, corresponding to the blade, of the cutter body inserting slot, but also can be used for quickly taking the blade out for installing the blade, and is high in automation degree without the need for manual intervention, good in safety and high in efficiency.

Owner:成都恒成工具股份有限公司

Trolley capable of achieving safe pushing on slope

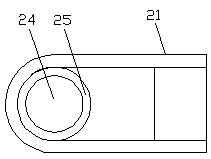

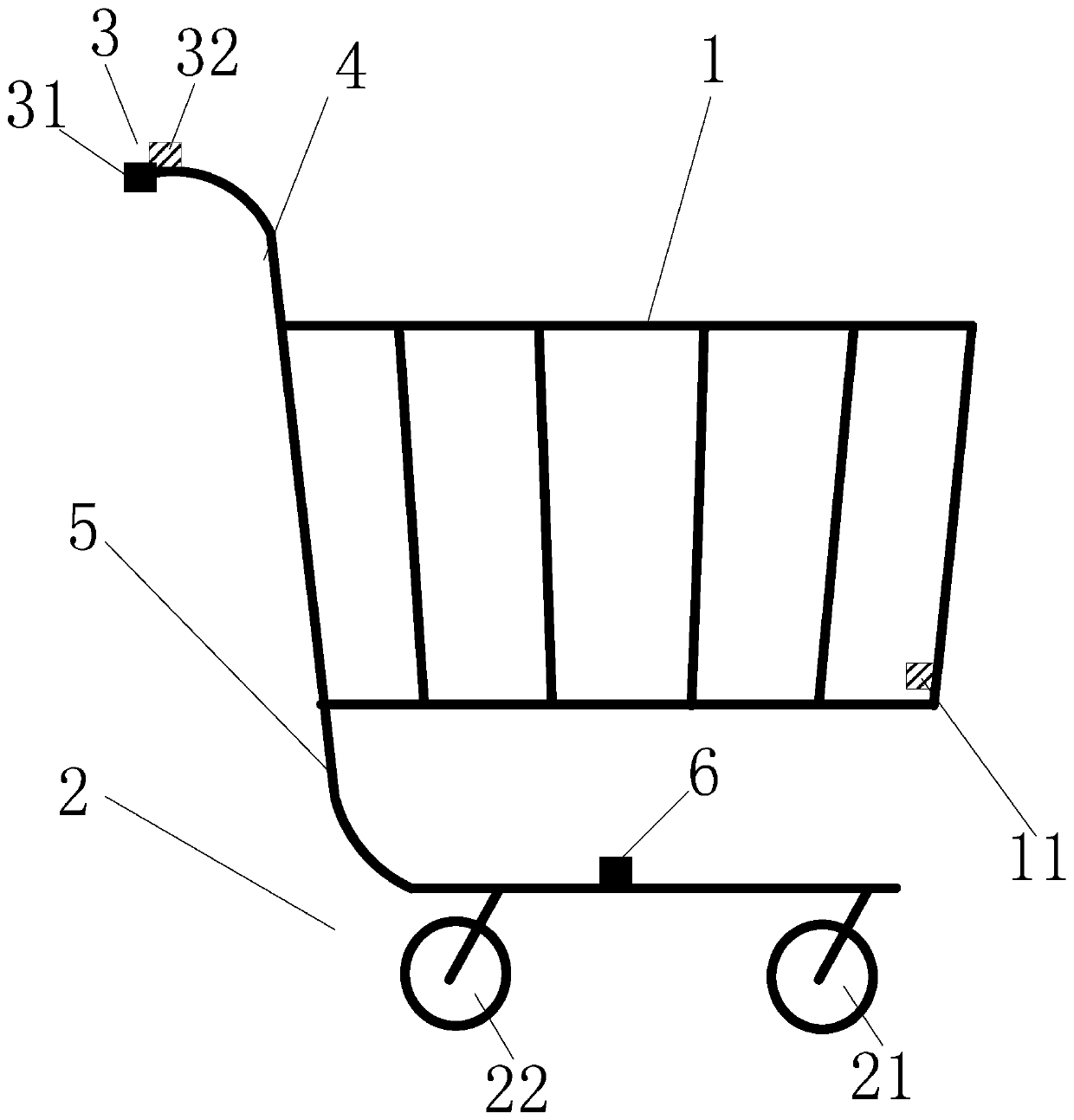

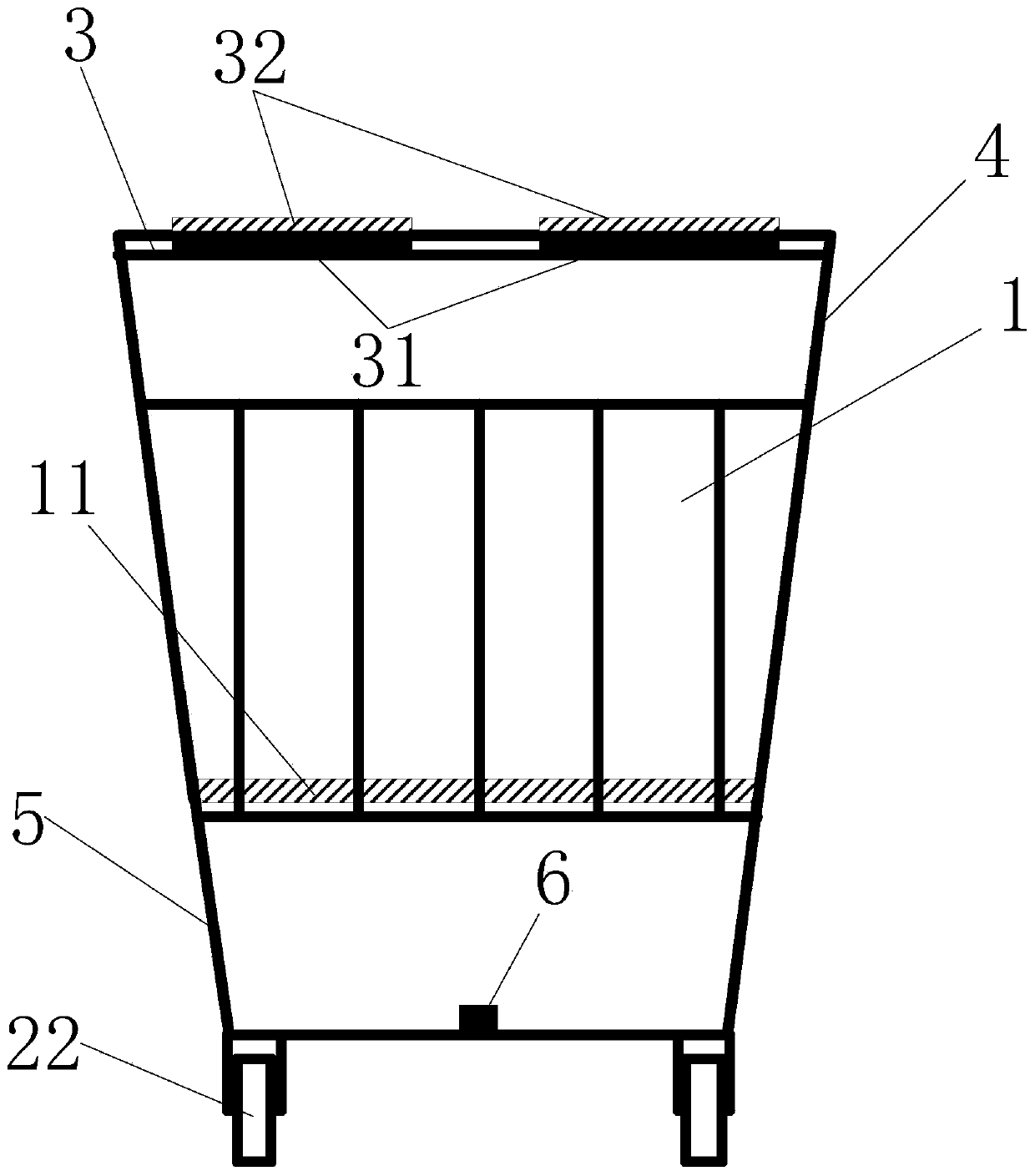

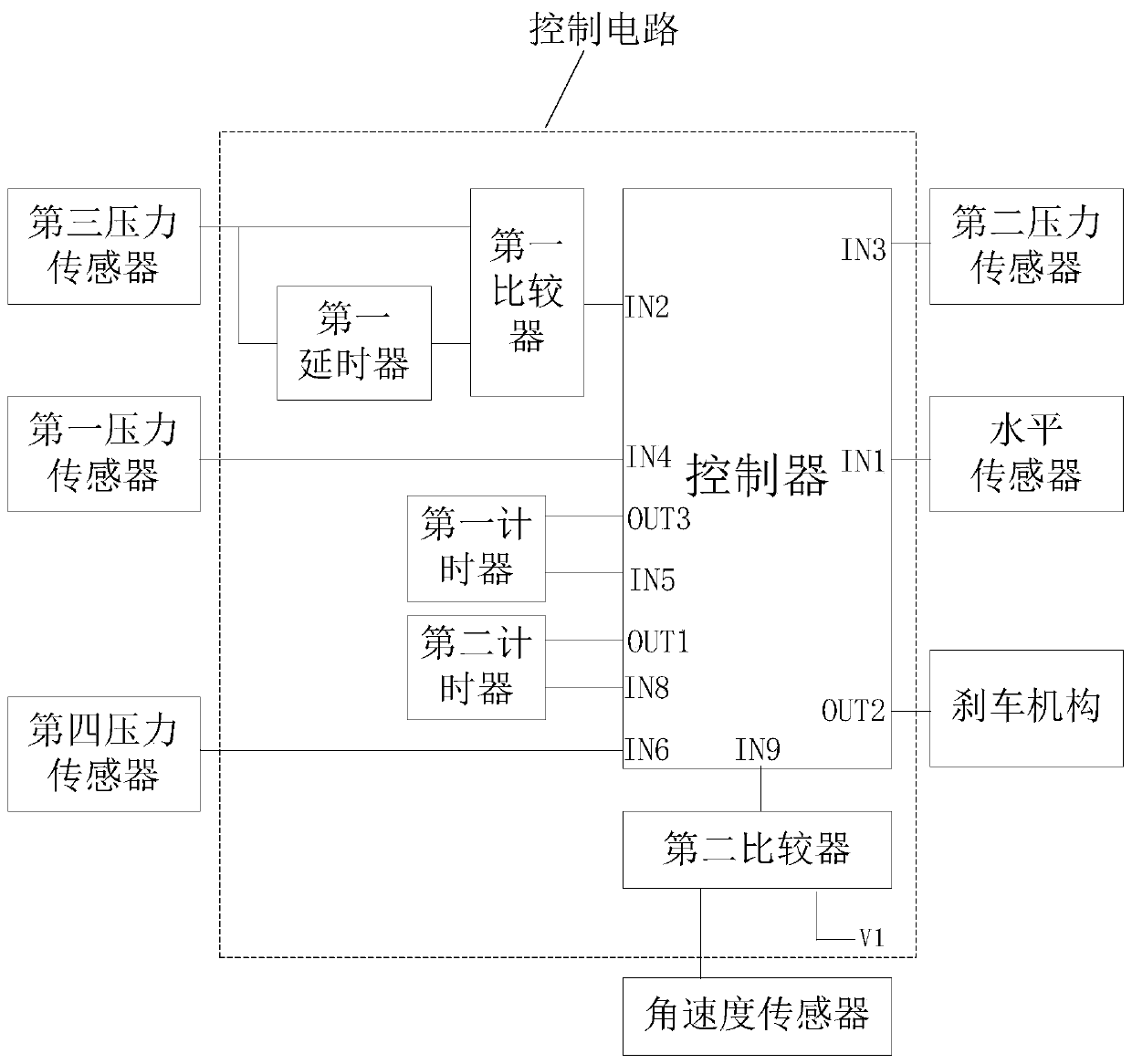

PendingCN110356456AImprove securityEnsure safetyMeasurement devicesHand carts with multiple axesEngineeringControl circuit

The invention provides a trolley capable of achieving safe pushing on a slope. Front wheels of the trolley are correspondingly provided with brake mechanisms; first pressure sensors are arranged on one side, facing towards a user, of a handle; a second pressure sensors are arranged on the upper surface of the handle; a third pressure sensor is arranged on a front side baffle of a frame body; a horizontal sensor is further arranged on the trolley; when the horizontal sensor detects that the trolley is inclined and the third pressure sensor detects that pressure applied by articles in the framebody on the front side baffle is increased, a control circuit determines that the trolley descends along the slope and judges whether the second pressure sensors detect pressure; if so, the control circuit determines that the user holds the handle and controls the brake mechanism to perform progressive braking till the brake mechanisms achieve complete braking; and when the first pressure sensor detects the pressure, the control circuit determines that the user pushes the trolley, and controls to reduce a braking force of the brake mechanisms by a level.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

An automatic high-precision sand screening device for synthetic production of building materials

ActiveCN111215322BAvoid settingTo achieve the effect of automatic disintegrationSievingScreeningMaterial synthesisReciprocating motion

Owner:博兴兴博城建投资集团有限公司

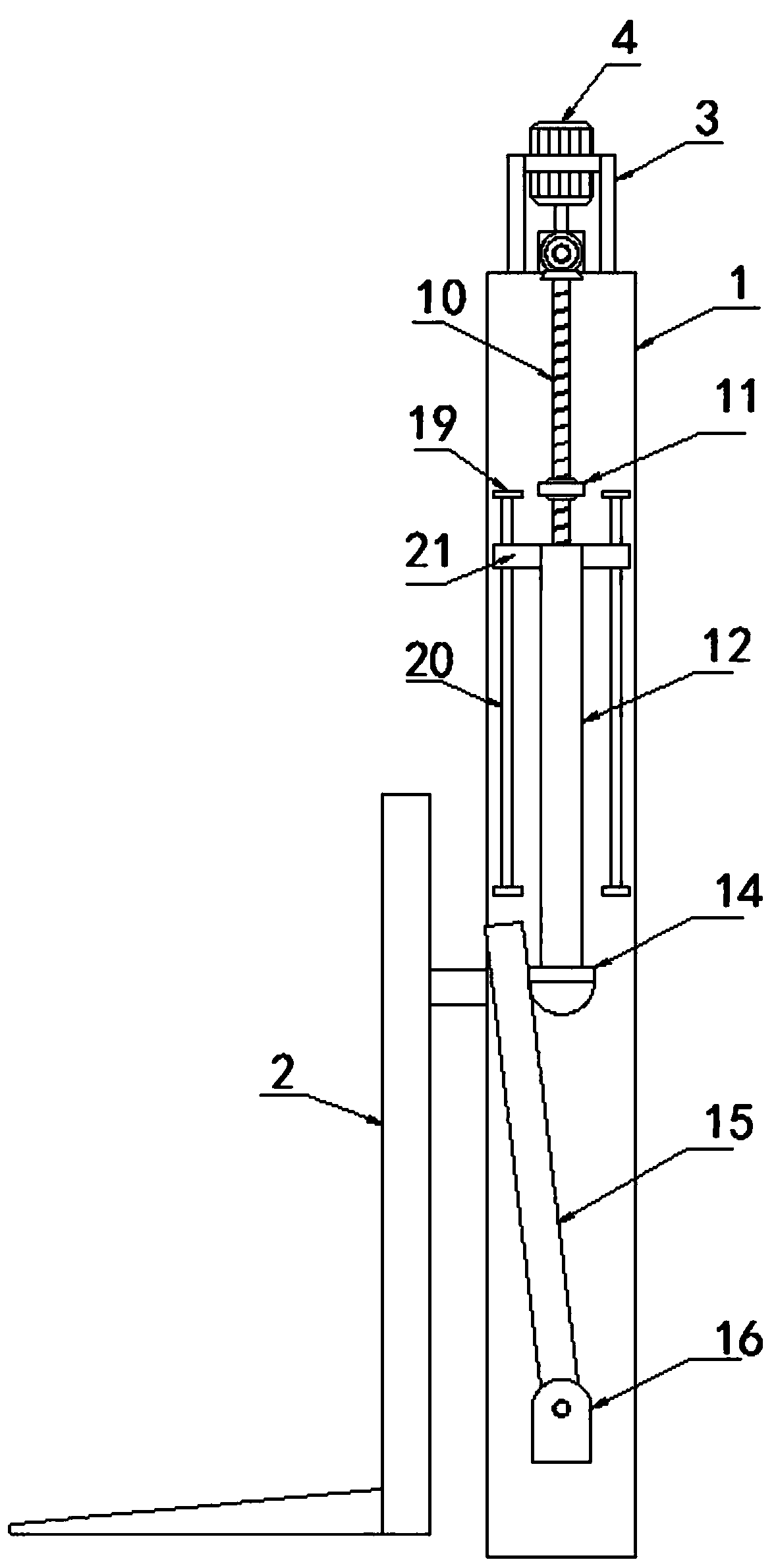

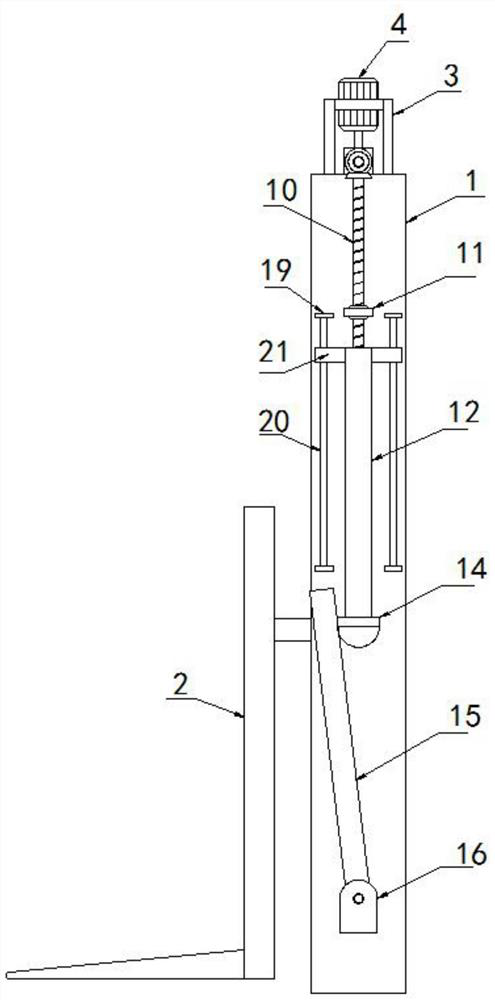

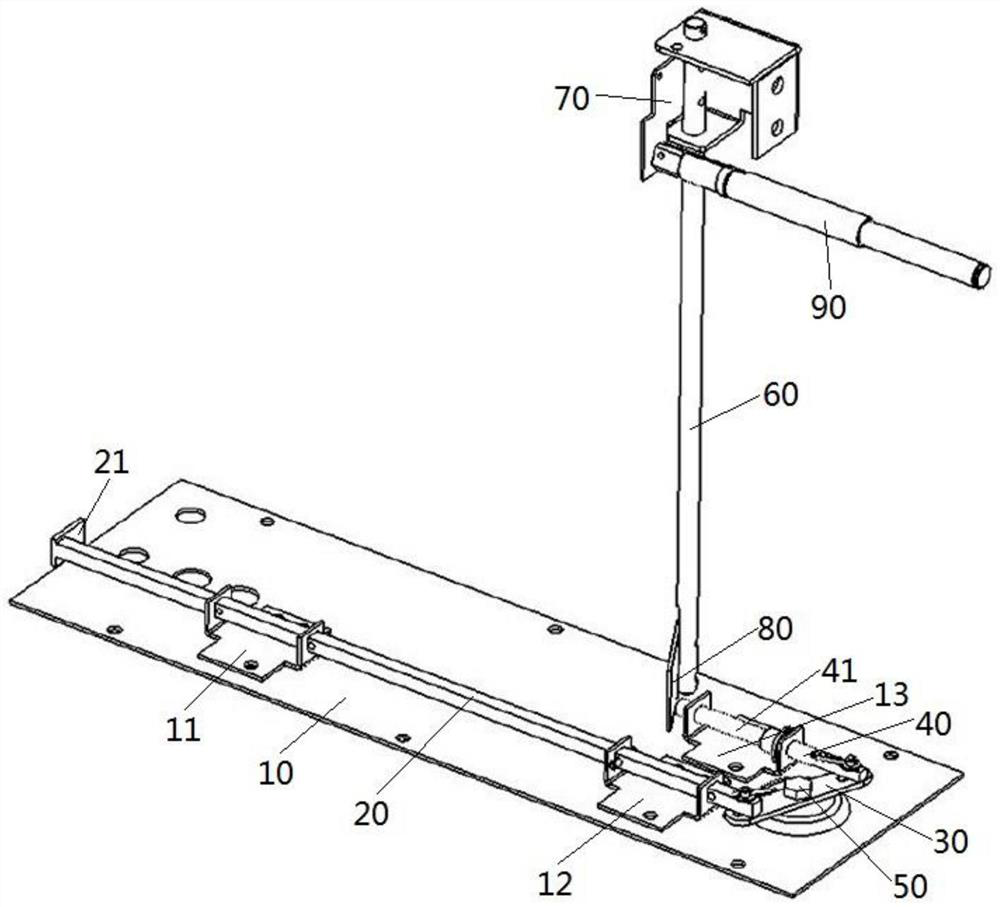

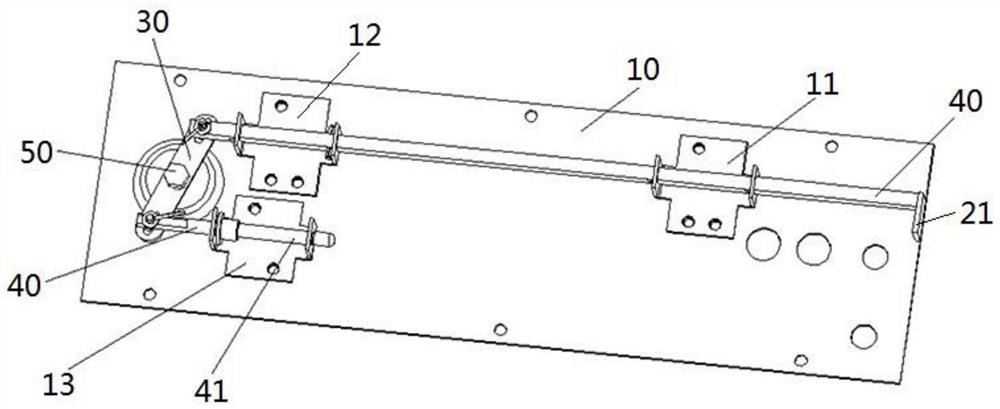

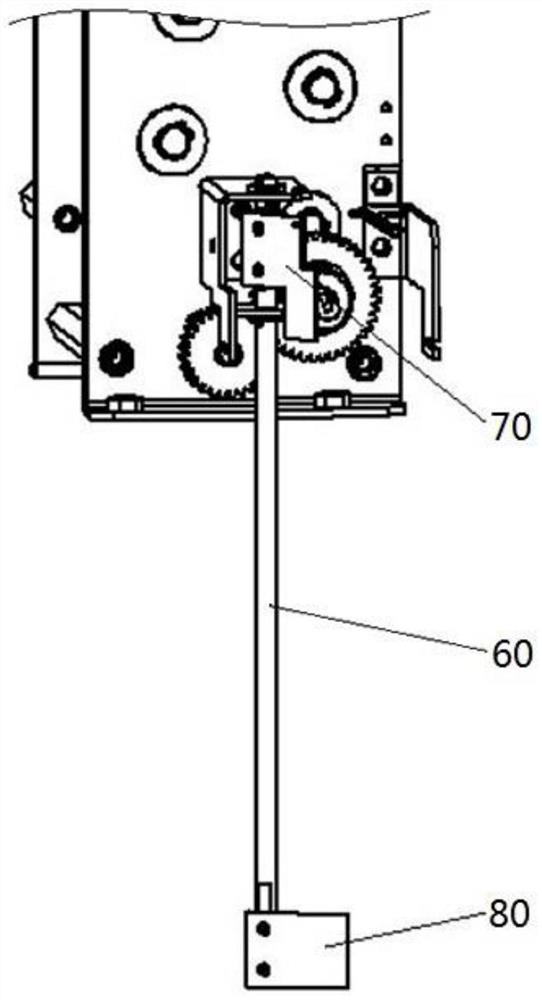

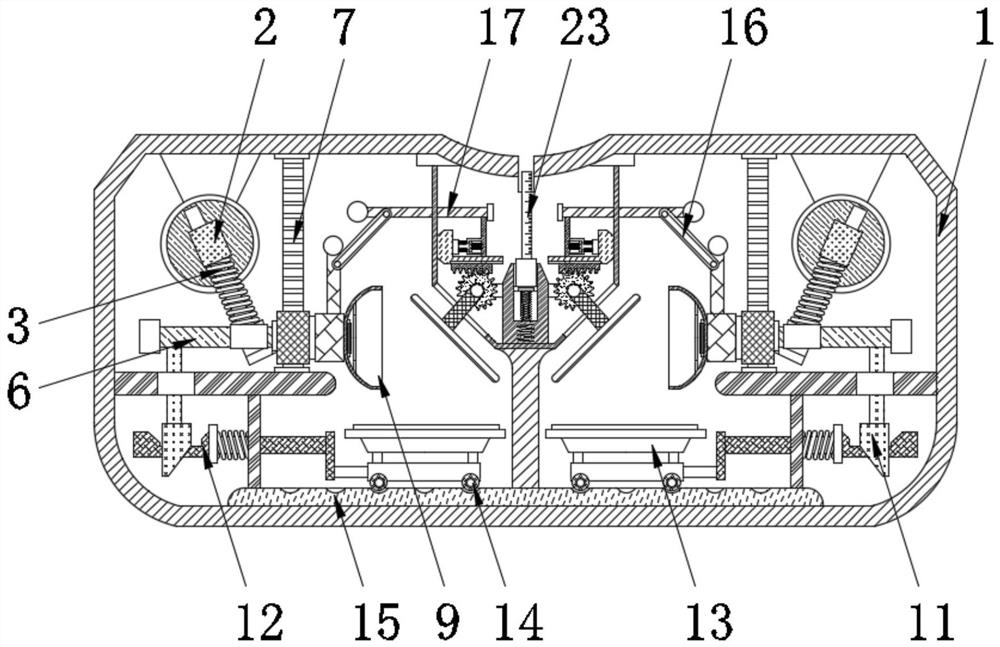

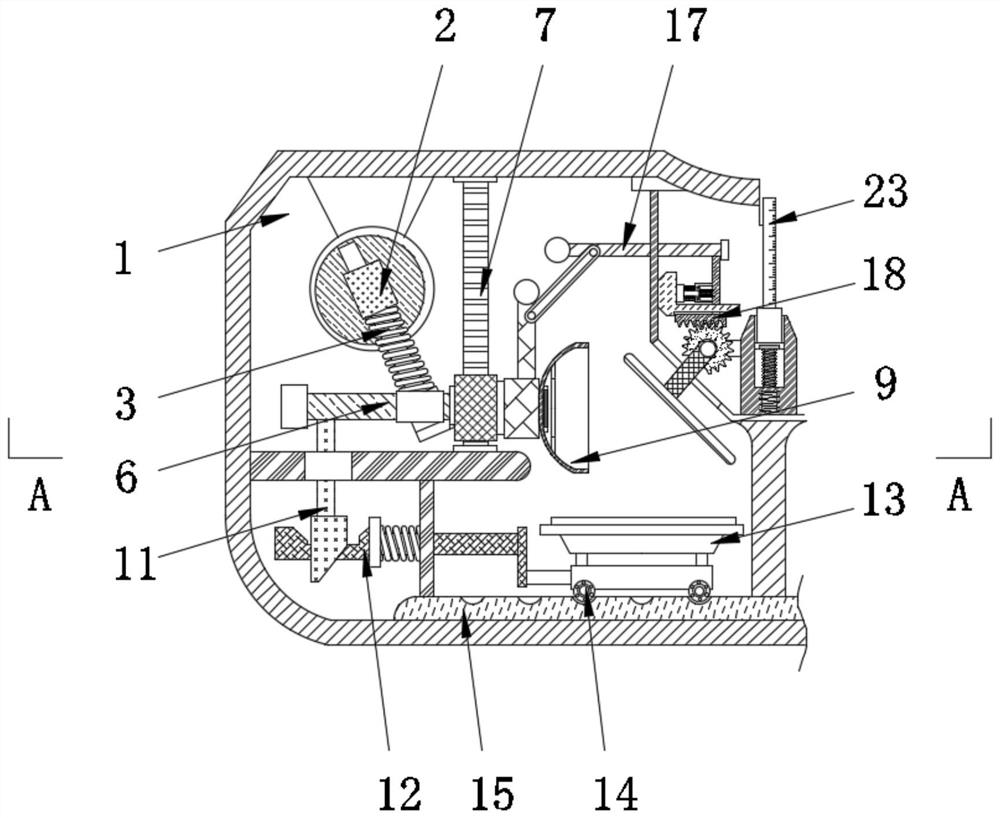

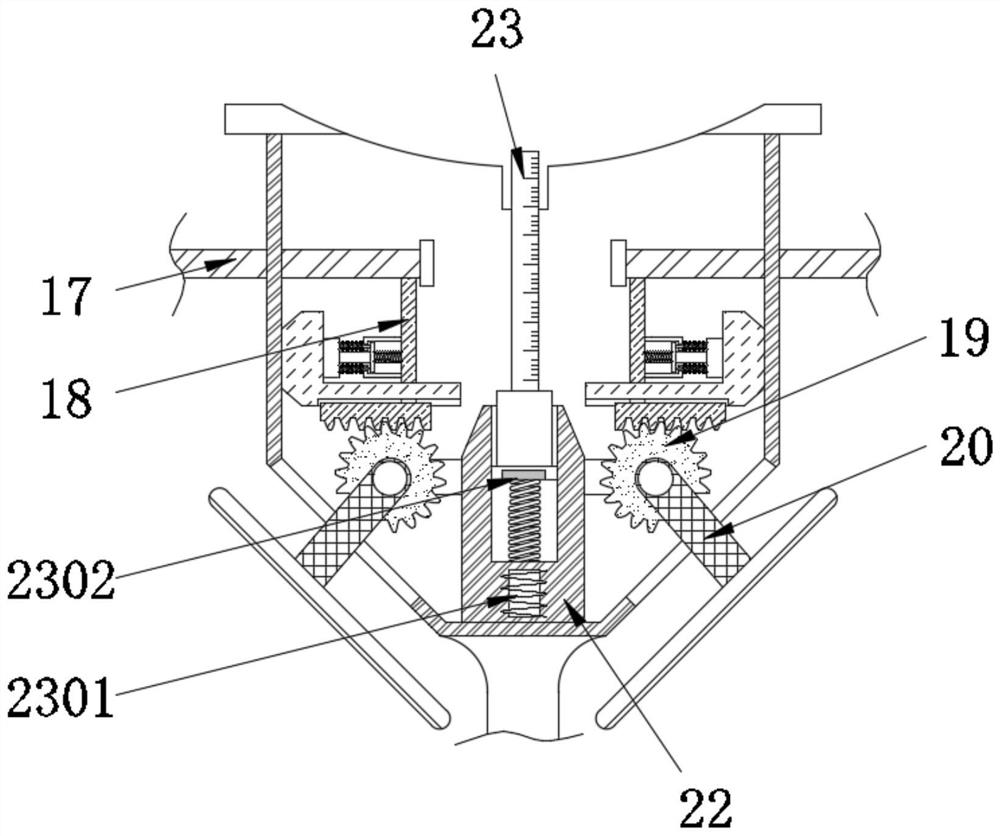

Manipulator pushing device for forklift

ActiveCN110963449AGuaranteed re-use phenomenonGuaranteed pushLifting devicesDrive shaftRolling-element bearing

The invention relates to the technical field of forklifts, and discloses a manipulator pushing device for a forklift, which comprises a rack and a pallet fork, wherein the pallet fork is arranged on the left side wall of the rack; a fixed frame is fixedly arranged at the top of the rack; a driving motor is fixedly arranged at the top of the fixed frame; a rotating shaft is fixedly arranged at theoutput end of the driving motor; a first bevel gear is fixedly arranged at the lower end of the rotating shaft; a transmission shaft is transversely arranged at the top of the rack; two first bearingseats which are distributed left and right are fixedly arranged at the top of the rack; first rolling bearings are fixedly arranged in the two first bearing seats correspondingly; the two sides of theshaft wall of the transmission shaft are rotationally arranged on the two first bearing seats through the first rolling bearings correspondingly; a second bevel gear is fixedly arranged on the shaftwall of the transmission shaft; the first bevel gear and the second bevel gear are arranged in a meshed mode; and third bevel gears are arranged at the two ends of the transmission shaft correspondingly. According to the manipulator pushing device for the forklift, goods can be automatically pushed out of the pallet fork, the goods and the pallet fork do not need to be carried away together, and practicability is high.

Owner:青州市佳百乐国际贸易有限公司

A manipulator pushing device for forklift

ActiveCN110963449BGuaranteed re-use phenomenonGuaranteed pushLifting devicesEngineeringStructural engineering

Owner:青州市佳百乐国际贸易有限公司

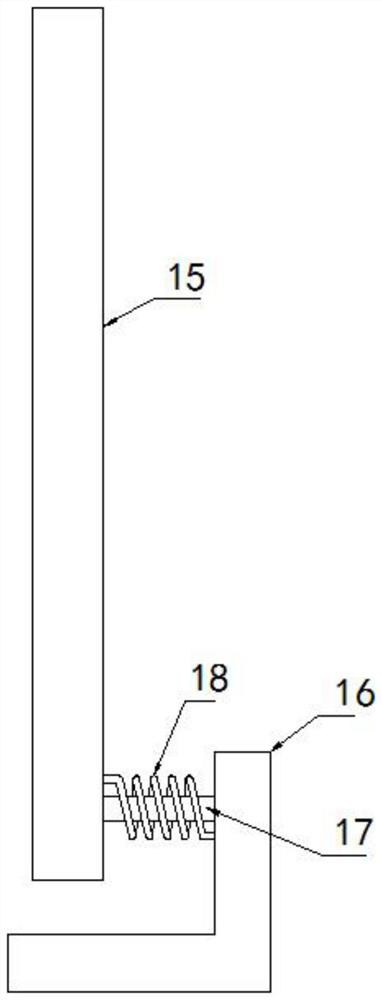

Self-locking mechanism capable of preventing slide retreating and self-locking and unlocking method of self-locking mechanism

The invention discloses a self-locking mechanism capable of preventing slide retreating and a self-locking and unlocking method of the self-locking mechanism. The self-locking mechanism capable of preventing slide retreating comprises a slide push plate, fixed plates, a limiting mechanism, an ejection block and a driving mechanism, the fixed plates are arranged on the two sides of the slide push plate, the tail end of the slide push plate is provided with a self-locking groove, the limiting mechanism is located inside the self-locking groove, the ejection block is located in a groove opening of the self-locking groove, the top of the ejection block is provided with an inclined top face and a limiting face, the limiting face is located below the inclined top face, the driving mechanism is connected with the ejection block and drives the ejection block to move, self-locking of the limiting mechanism can be achieved, the position of the slide push plate can be locked effectively, slide push plate retreating caused by too large injection molding pressure is prevented, the defects of too much glue, flashing, trimming and the like are prevented, and the quality of an injection molding product is guaranteed.

Owner:欧唐科技(深圳)有限公司

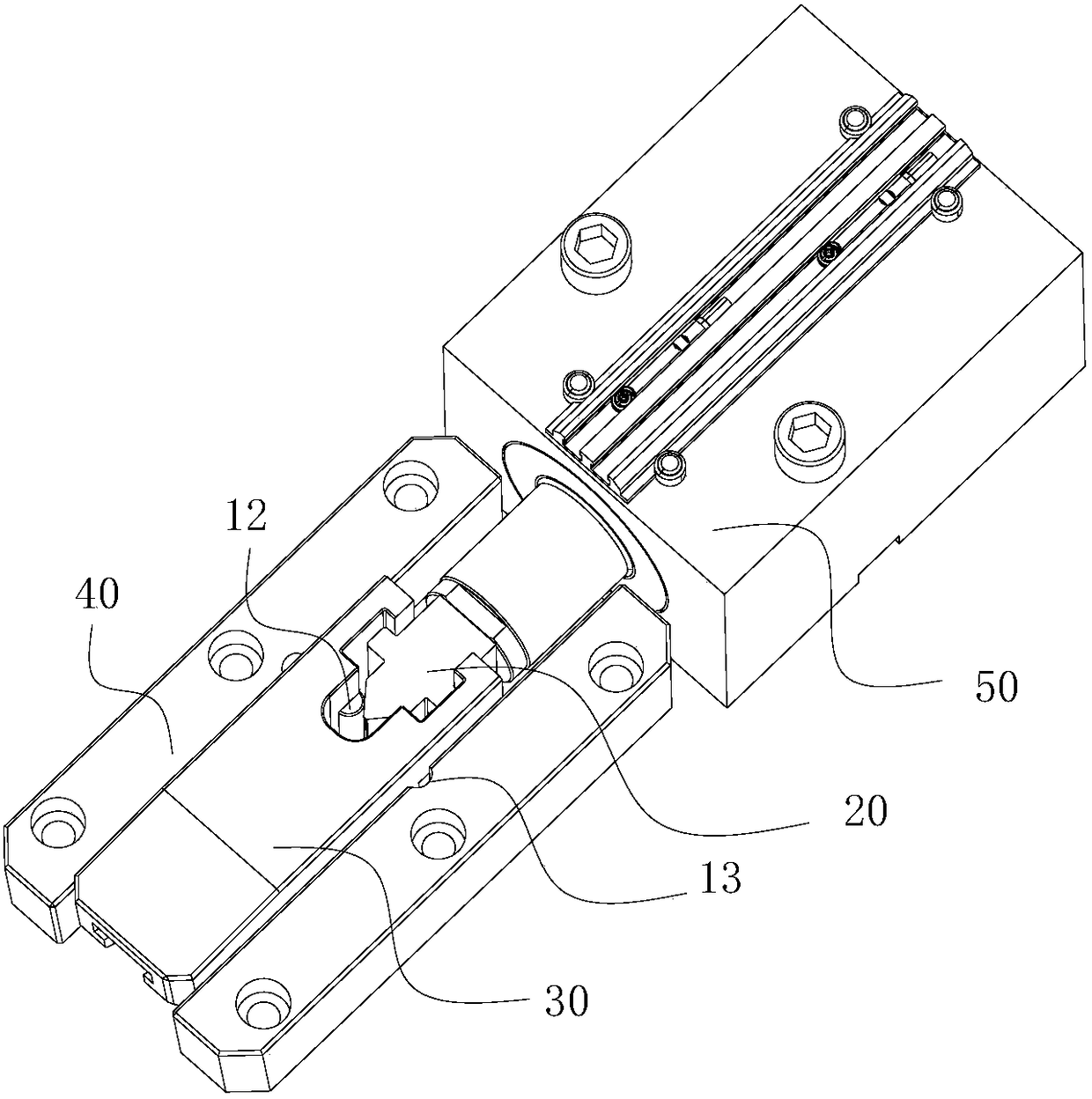

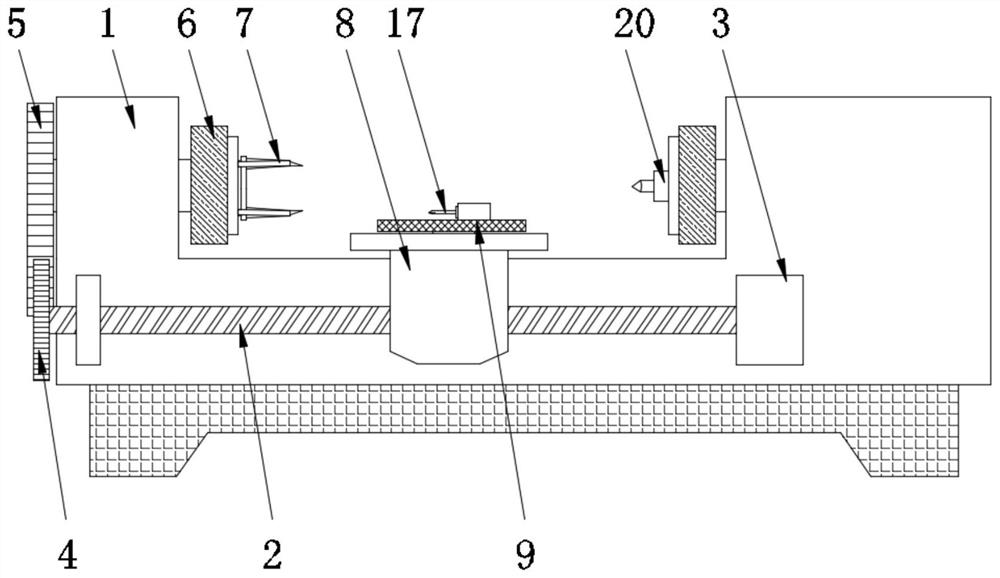

Tool manufacturing equipment

ActiveCN107962266AImprove push efficiencyReduce weightMetal working apparatusSolder feeding devicesEngineeringMachining

The invention discloses tool manufacturing equipment, and belongs to the field of tool machining and manufacturing. The tool manufacturing equipment is characterized in that a tool body pushing devicecomprises an installation base, and a tool body storage bin and a tool pushing cylinder are fixed to the installation base; a tool body alignment device comprises a support, a lifting cylinder is fixed to the support, a supporting frame is fixed to the lifting cylinder, and a stepping motor is fixed to the supporting frame; a blade installation device comprises a fixed base, a blade pushing cylinder and a rotating cylinder are arranged on the fixed base, a double-shaft cylinder is fixed to the rotating cylinder, and a parallel clamp is fixed to the double-shaft cylinder; and a blade welding device comprises a vertical base, an electromagnetic heater is fixed to the vertical base, a first wire feeder is fixed to one side of the vertical base, and a second wire feeder is fixed to the otherside of the vertical base. According to the tool manufacturing equipment, tool bodies can be conveyed continuously, a tool body insertion groove can be rapidly aligned with the installation position corresponding to a blade, and the blade can be taken out rapidly to be installed; and the contact portions of the blade and the tool body can be welded from the two sides at the same time, and the welding uniformity and the welding effect are ensured.

Owner:雅安恒成精密刀具有限公司

Automatic production machine operating path simulation auxiliary device

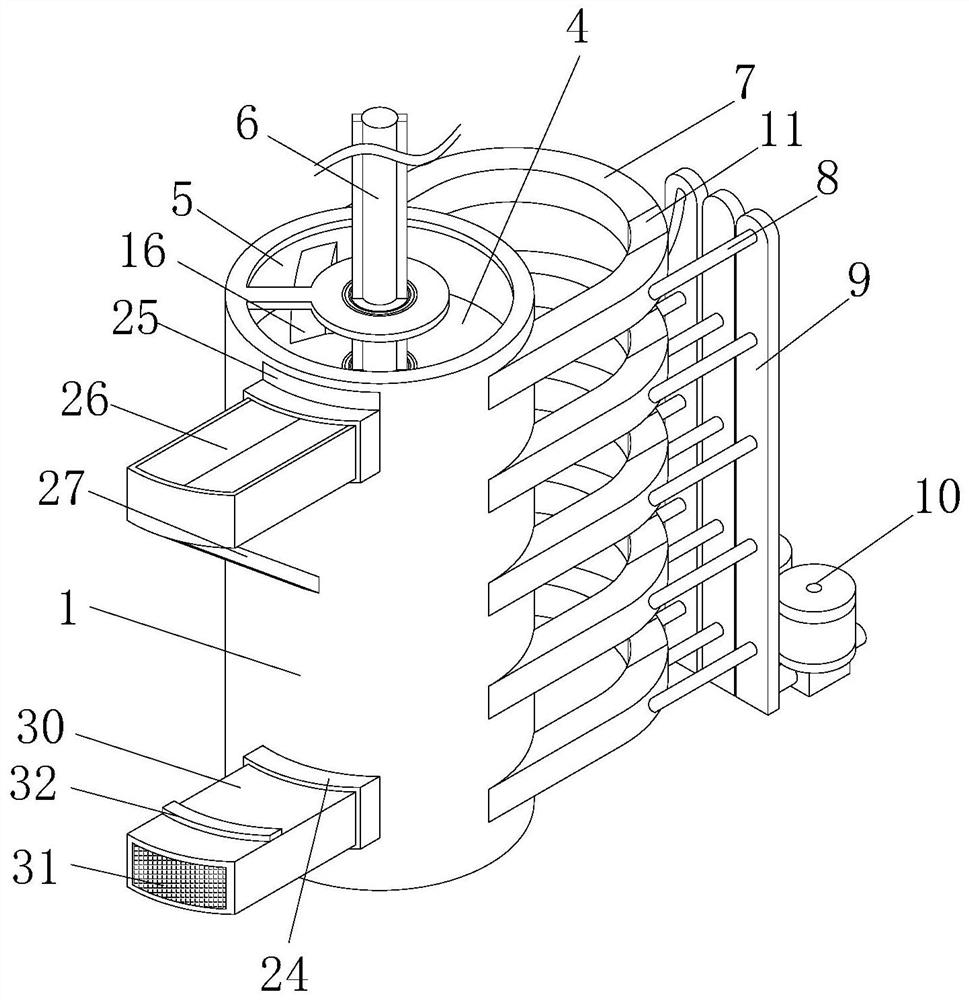

InactiveCN111823008AGuaranteed magnetic field pushGuaranteed pushOther manufacturing equipments/toolsCircular discMachine parts

The invention provides an automatic production machine operating path simulation auxiliary device. A variable resistor is arranged at the joint between a disk and a fixture. A corresponding metal sheet is arranged in the position, located at the left end of the fixture, of the surface of the variable resistor. A moving seat is slidably mounted in the position, on the right side of the fixture, ofthe upper surface of a working table. A moving table is slidably mounted on the upper surface of the moving seat. A supporting plate is fixedly mounted on the rear surface of the moving table. A machined part is mounted inside the fixture. According to machined part with different diameters, the fixture is driven to move to adjust the positions of the metal sheet and the variable resistor and further adjust the resistance value of the variable resistor connected with a circuit, and the current in a first coil connected with the variable resistor in series is adjusted to ensure that a magneticfield generated by the first coil pushes a first magnet and pushes the right end of a path lever to go down in a sliding hole. Accordingly, the operating path in the machining process is changed, anddifferent operating paths can be adjusted according to the sizes of machined parts.

Owner:黄海涛

Rebound method concrete compressive strength detection device

InactiveCN111912727AReduce laborPrevent movementInvestigating material hardnessMagnetMechanical engineering

The invention provides a rebound method concrete compressive strength detection device, the tail end of a support rod is movably mounted at the top of a stress seat, a sleeve is fixedly mounted on theright surface of the stress seat, a push rod is slidably mounted in the sleeve, and a magnet is arranged at the left end of the push rod. A corresponding coil is arranged on the left side of the magnet and located in the stress base, and a movable base is fixedly installed at the right end of the push rod. After the rebound apparatus is recovered by using an internal spring, the positions of themetal sheet and the variable resistor are adjusted by moving the moving plate upwards in the supporting plate, and the resistance value of the variable resistor connected into a circuit is adjusted, so that the current in the coil connected with the variable resistor in series is adjusted, and a magnetic field generated by the coil pushes the magnet; the push rod and the movable seat are guaranteed to move rightwards in the guide rail rod, and the movable seat drives the clamping seat to rotate at the top end of the supporting rod while moving rightwards, so that the test block is turned overanticlockwise, and the purpose of turning over the test block is achieved.

Owner:尹逊新

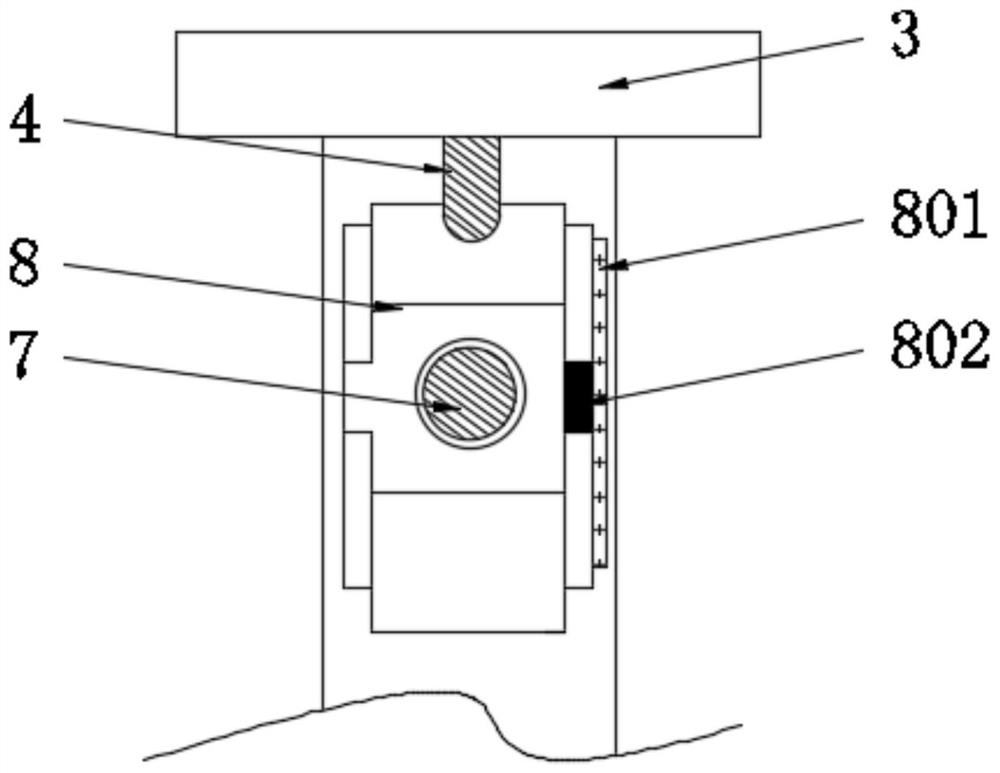

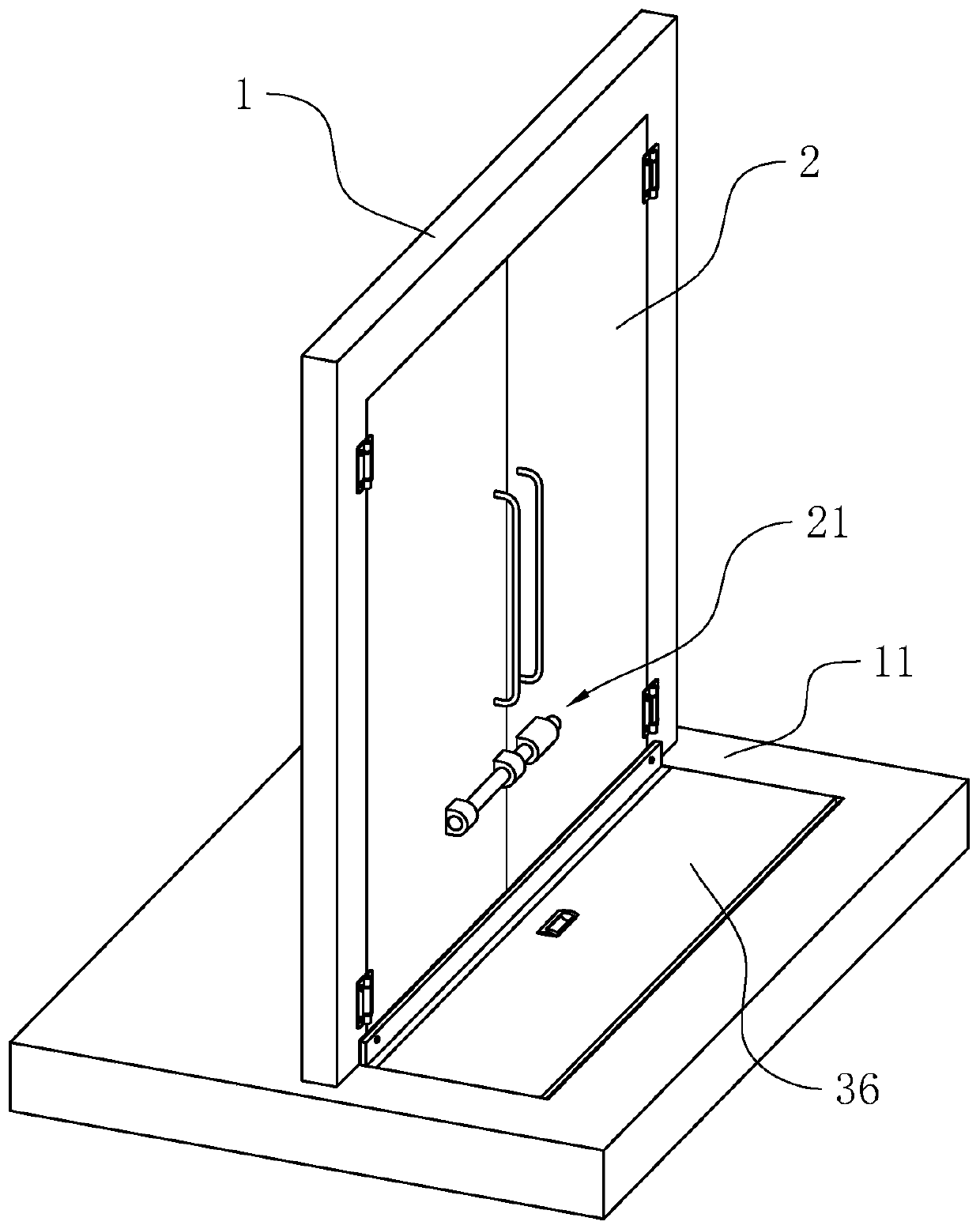

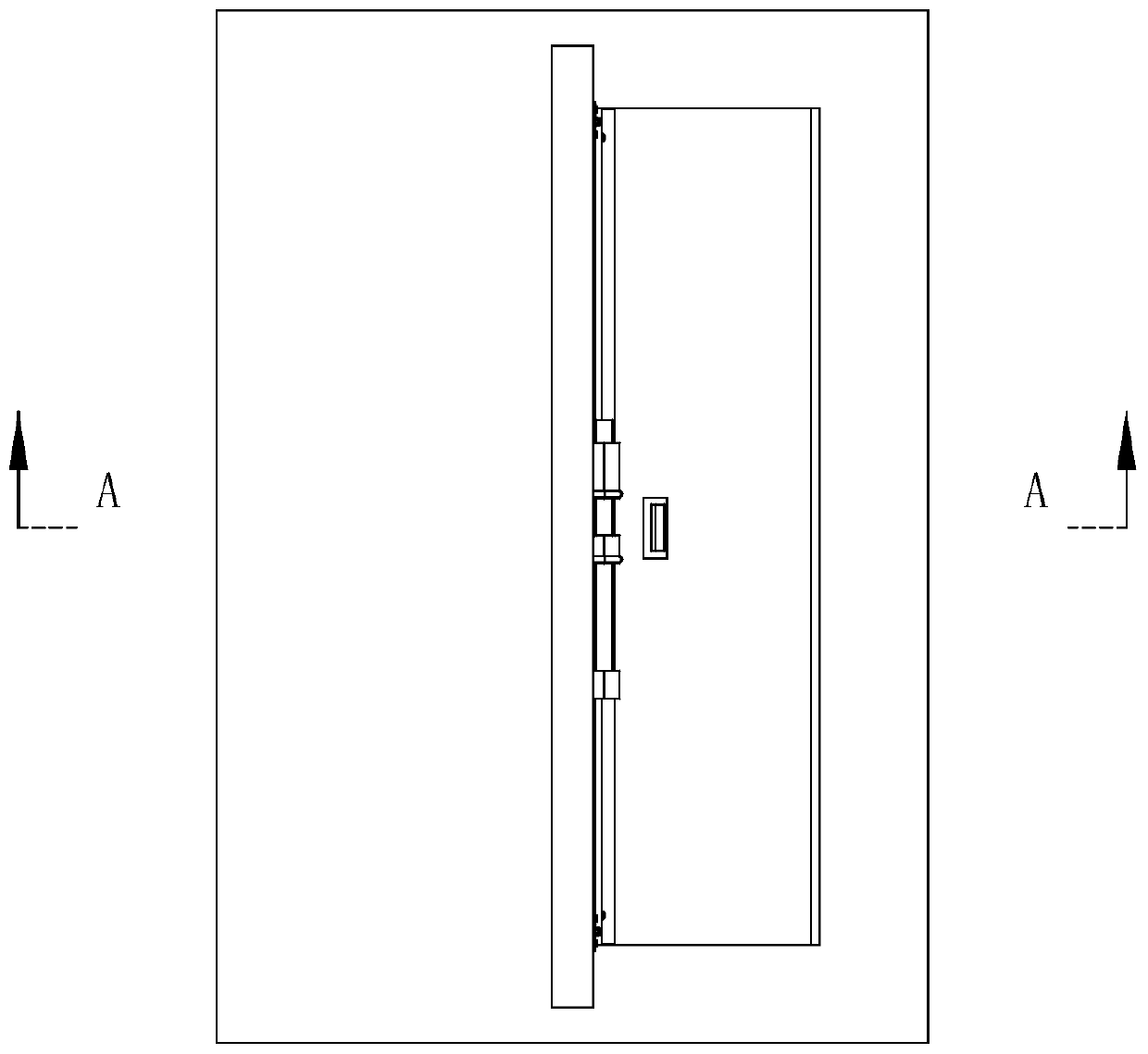

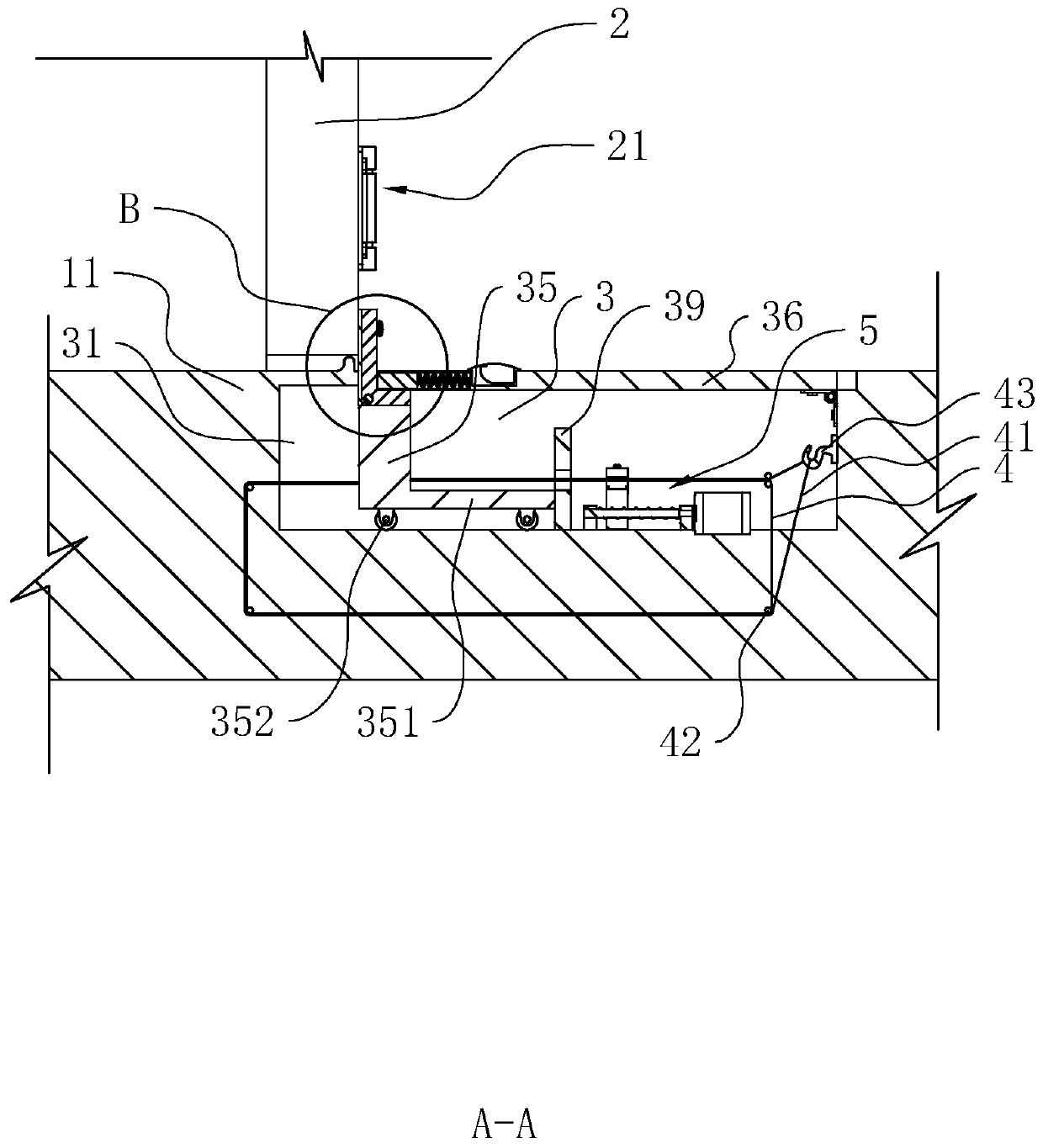

A double-leaf civil air defense door structure with living threshold

ActiveCN108571266BEasy to assemble and disassembleImprove sealingSills/thresholdSealing arrangementsEngineeringMechanical engineering

The invention discloses a movable threshold type double-leaf civil protection door structure and relates to the field of protection equipment. The structure comprises two protection doors, wherein a turnover groove is formed in the ground, a movable threshold is rotationally connected in the turnover groove, and the movable threshold comprises a sealing plate and an abutting plate perpendicularlyfixed on one side edge of the sealing plate; an accommodating groove is formed on the peripheral wall of the turnover groove, a shifting block is arranged in the accommodating groove, a main pull cordis arranged in the accommodating groove, two ends of the main pull cord are connected to two ends of the shifting block respectively, guide wheels are arranged on two sides of the shifting block, andthe main pull cord winds around the guide wheels and is in a tightened state; a pull assembly for pulling the main pull rope back and forth is arranged on one side of the shifting block; when the pull assembly pulls the main pull cord and drives the shifting block to move, the shifting block turns over the movable threshold and allows the sealing plate to abut against one side of each protectiondoor and the wall of the turnover groove, and then, the shifting block is supported on the lower side of the abutting plate. The threshold state is switched through turnover of the movable threshold,so that the movable threshold is more convenient to mount and dismount.

Owner:浙江富腾人防设备有限公司

sorting equipment for logistics

ActiveCN111661602BAvoid damageAvoid collisionLoading/unloadingConveyor partsLogistics managementEconomic benefits

The invention discloses a sorting equipment for logistics in the technical field of logistics sorting, which includes a main chain, a secondary chain, a sorting part and a buffer part. The inside of the first side plate is fixedly connected with the first rotating roller, the sorting part is arranged inside the chain body of the main chain, and the auxiliary chain is arranged on the left side of the main chain, and the auxiliary chain includes the first and rear symmetrically distributed Two side plates, the insides of the two second side plates are fixedly connected with the second rotating roller, and the interior of the chain body of the secondary chain is provided with a buffer; the present invention is provided with a buffer, and the first stop in the buffer With the cooperation of the bottom plate and the second baffle plate, the fragile items can be smoothly transferred to the pick-up place, avoiding the problem of the fragile items being dumped or the collision between two fragile items under the action of inertia, thus reducing the impact on the fragile items. The damage of broken products improves the company's economic benefits.

Owner:杭州特翌智科技有限公司

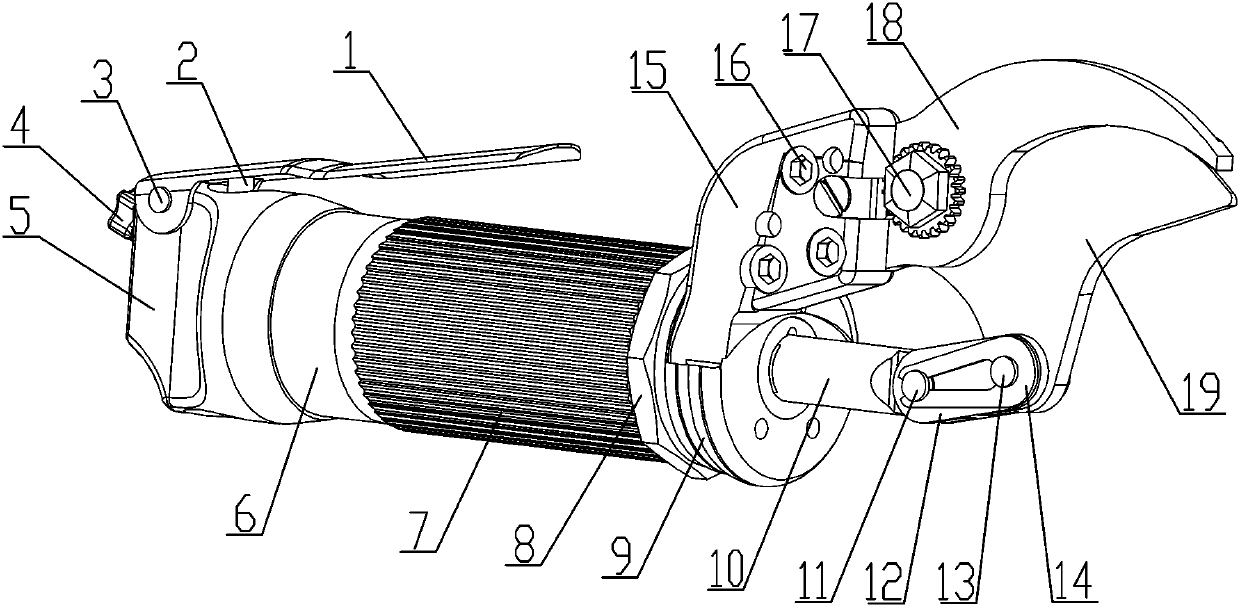

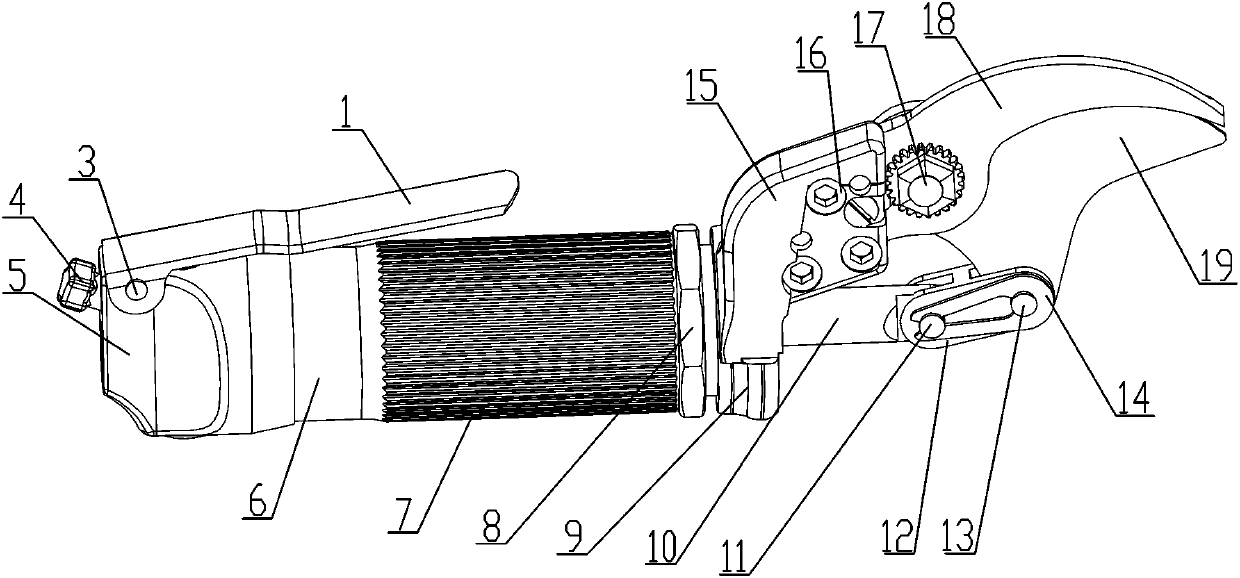

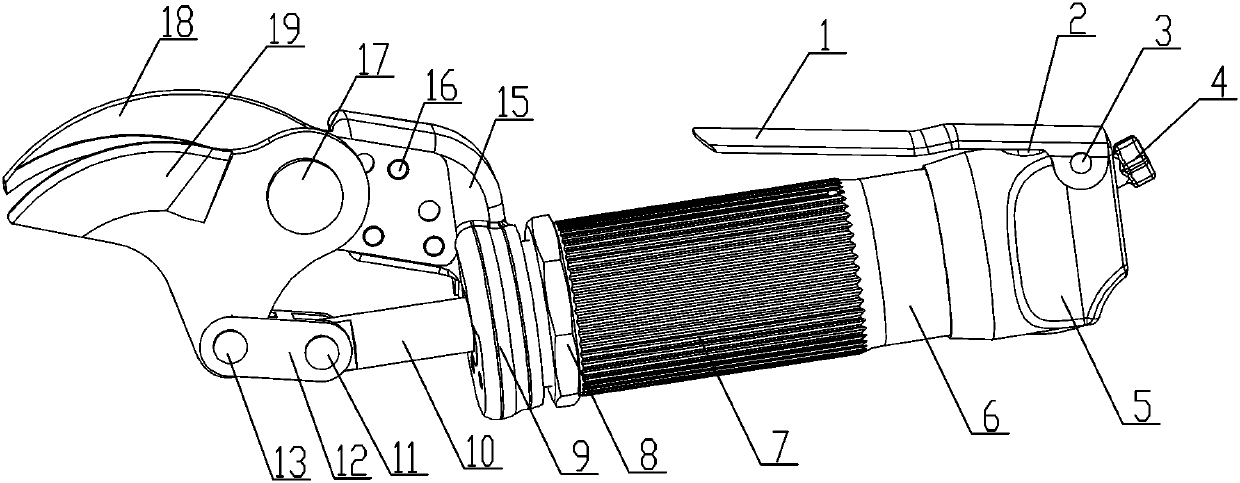

Optical fiber shearing tool and operating method

ActiveCN110531464AImprove work efficiencyReduce labor intensityCoupling light guidesHigh pressureHigh pressure gas

The invention provides an optical fiber shearing tool and operating method. A tailstock is fixedly installed at the tail part of a handheld barrel, and an end cap is locked and fixed at the head partof the handheld barrel via a round nut; a piston cavity is arranged in the handheld barrel, a piston body is matched and installed in the piston cavity in a sliding manner; the piston body is fixedlyconnected with a piston rod arranged in the piston cavity; a push rod is connected with the other end of the piston rod; the push rod penetrates through the end cap; the push rod is hinged and connected with the bottom end of a movable blade via a link mechanism; the movable blade is hinged to a fixed blade via a rotation shaft; the fixed blade is fixedly installed on a blade mounting base via a blade fixing bolt; the blade mounting base is fixed on the top of the end cap; and a control valve rod used for controlling high-pressure air to enter is installed in the tailstock. The shearing tool adopts a high-pressure air source as a power source, adopts the link mechanism to drive the blades to act, and thus finally achieves shearing operation.

Owner:YICHANG POWER SUPPLY CO OF STATE GRID HUBEI ELECTRIC POWER CO LTD

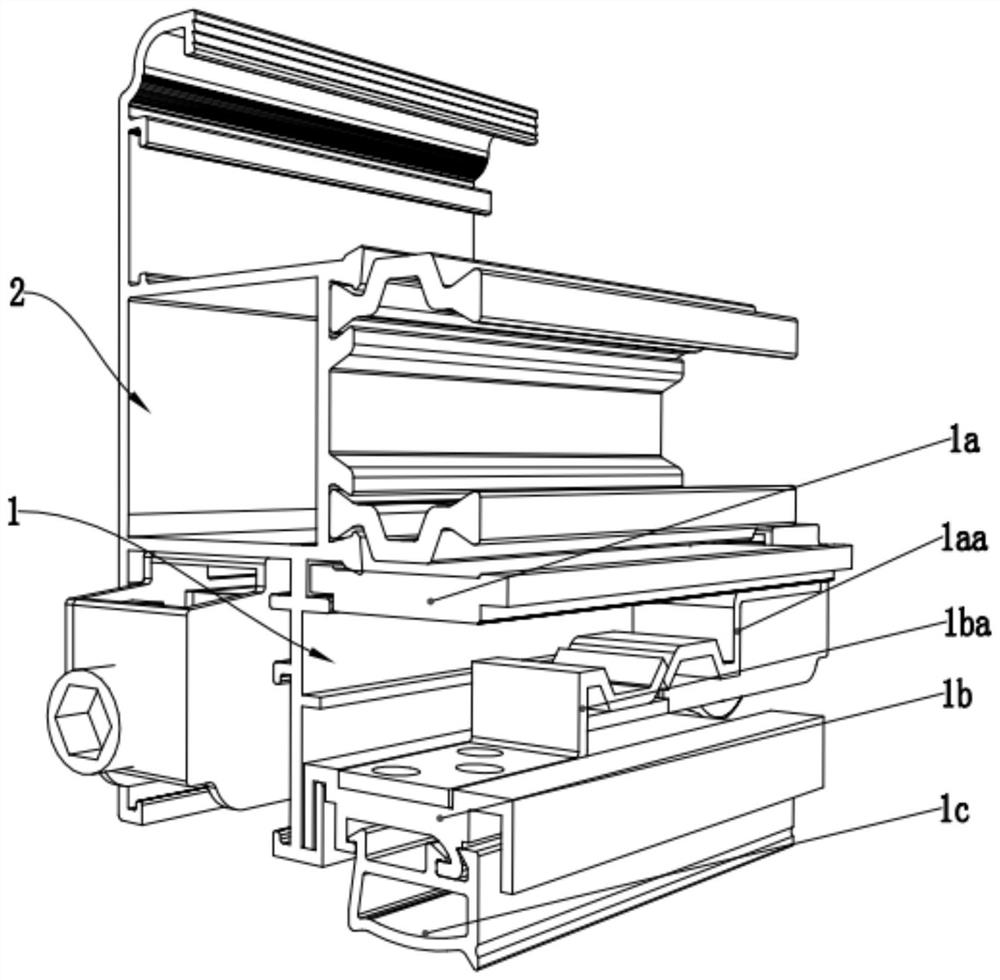

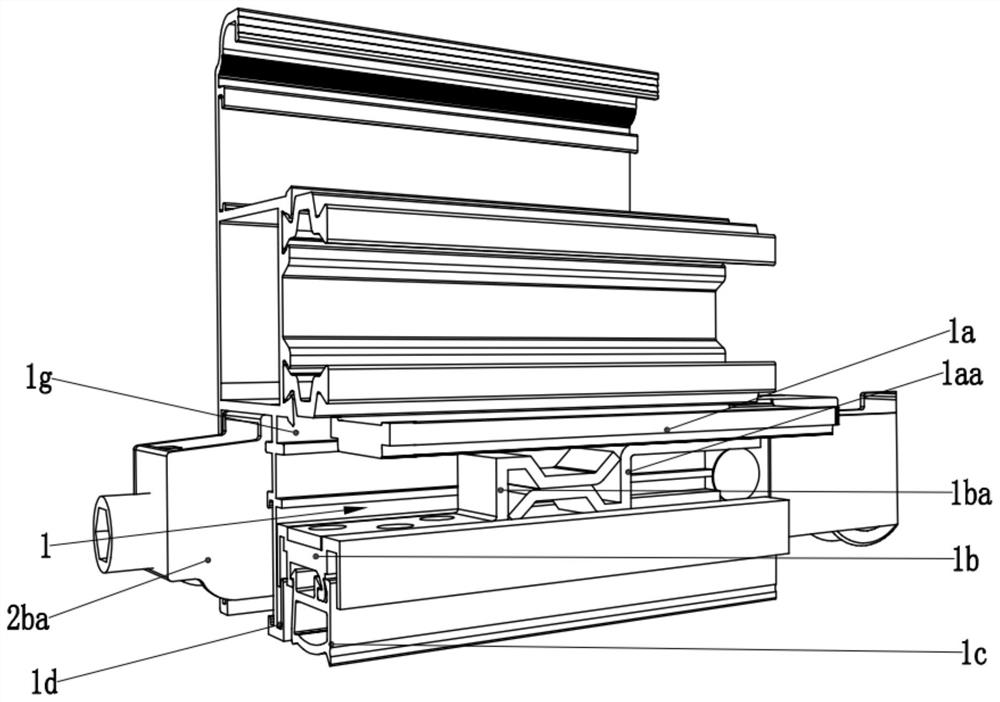

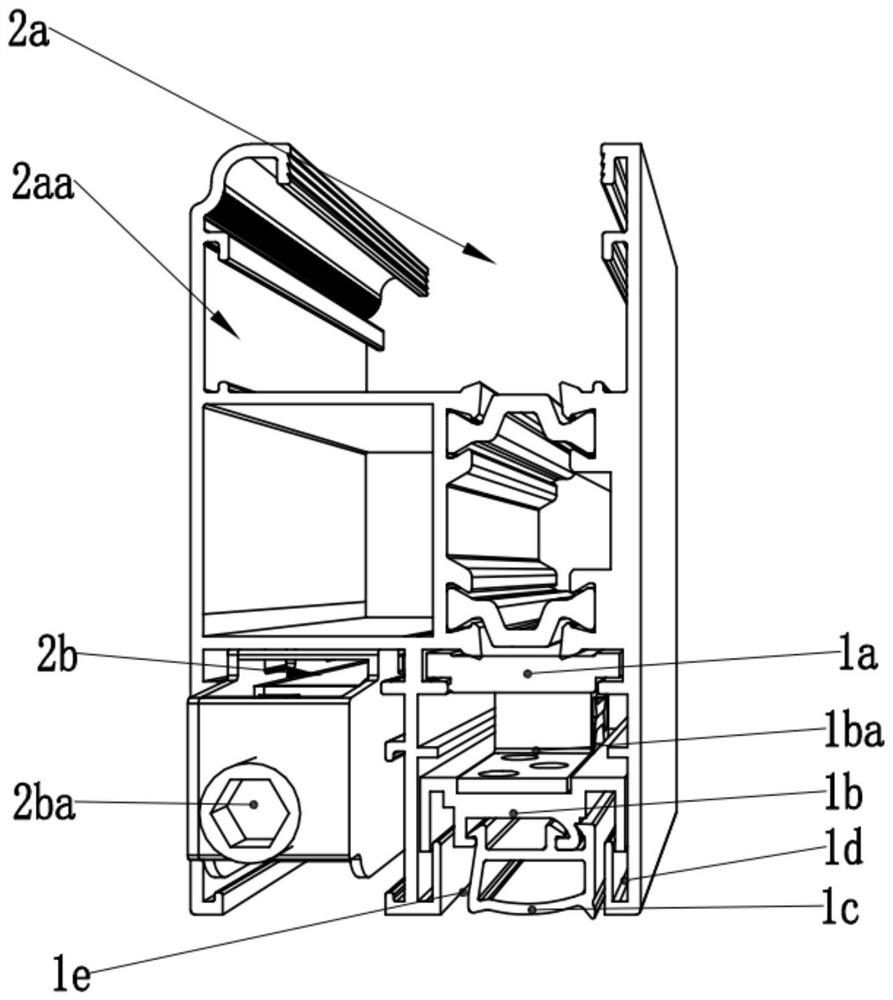

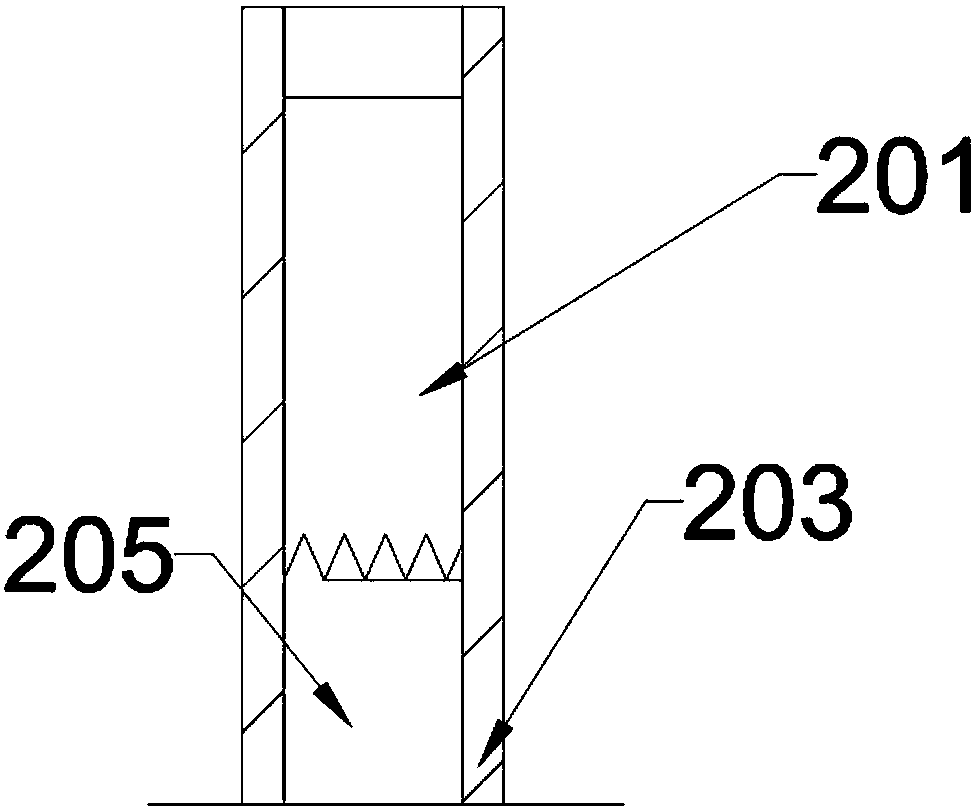

High-airtightness magnetically-attracted closed sliding window structure

PendingCN112814532ASolve the shortcomings of insufficient sealingGuaranteed pushSealing arrangementsWing arrangementsSlide windowClassical mechanics

The invention provides a high-airtightness magnetically-attracted closed sliding window structure. The high-airtightness magnetically-attracted closed sliding window structure is characterized by comprising an airtight mounting part, wherein the airtight mounting part is provided with a sliding connecting piece, a driving connecting piece and a sealing strip; the driving connecting piece is mounted in a lifting groove; the sealing strip is mounted on the driving connecting piece; the sealing strip protrudes out of the airtight mounting part; a first buckling piece is mounted on the sliding connecting piece; a second buckling piece is mounted on the driving connecting piece; and the sliding connecting piece can slide on the airtight mounting part and applies thrust to the first buckling piece to enable the first buckling piece to slide towards the second buckling piece. Through the fitting of a mounting box and a window frame track, the defect of insufficient airtightness of a sliding window is overcome, so that the gas and liquid sealing capacity and the noise reduction capacity of the sliding window are further improved, the sliding window can be suitable for more environments, and the adaptability of the sliding window is greatly improved.

Owner:广东鑫阳泰金属科技有限公司

Environment-friendly double-sided paint spraying equipment for interior and exterior of automobile door

InactiveCN112221778AReduce workloadGuaranteed pushLiquid spraying apparatusIndustrial engineeringSpray painting

The invention provides environment-friendly double-sided paint spraying equipment for the interior and exterior of an automobile door. The bottom end of a connecting plate is movably connected with amovable rod, a fan-shaped plate is fixedly installed at the bottom end of the movable rod, a positioning column is arranged below the fan-shaped plate and inside a processing bin, the positioning column penetrates through the interior of a through plate, a corresponding water baffle is arranged below the positioning column, and through holes are formed in the lower surface of the water baffle andin the inner wall of the processing bin. The movable rod drives the fan-shaped plate to swing to the outer side, the fan-shaped plate gradually moves downwards, after the fan-shaped plate presses thepositioning column to move downwards, the water baffle is driven to move towards the inner side at the same time by utilizing the design of an inclined plane, so that the through holes are shielded, the inner paint can flow out through the through holes through the through plate to be collected, the whole structure is used for spraying paint on the inner surface and the outer surface, and meanwhile, different through holes are opened to collect the paint, so that the two different kinds of paint are prevented from being mixed while being collected, the environment-friendly benefit is achieved,and meanwhile, the resource utilization rate is improved.

Owner:杭州芥蒂电子商务有限公司

Edge grinding device for hot pot blank

PendingCN109382721AEasy to put inAvoid pulling forceEdge grinding machinesGrinding drivesEngineeringMechanical engineering

The invention discloses an edge grinding device for a hot pot bank. The device comprises a frame and a grinding motor provided with a grinding wheel; the grinding motor is hinged on the frame by a bracket; the frame is further provided with a cylinder capable of abutting against the bracket; the cylinder is used for pushing the bracket to make the grinding wheel away from a positioning fixture; atension spring is arranged between the frame and the bracket; the tension spring is used for pulling the bracket to make the grinding wheel abut against the edge of the pot blank. According to the technical scheme of the device, by setting the grinding wheel and the tension spring on the frame, during the grinding process, the grinding wheel can tightly adhere to the edge of the pot blank, and a handle can push the grinding motor away from the positioning fixture to prevent the handle from interfering with the grinding motor.

Owner:包倩秋

Environment-friendly dip dyeing device with good dyeing effect for garment fabric

InactiveCN112981791AGuaranteed pushQuality impactLiquid/gas/vapor treatment machines driving mechanismsTextile treatment rollersCircular discGear wheel

The invention provides an environment-friendly dip dyeing device with the good dyeing effect for a garment fabric. A gear disc is meshed with the outer surface of a vertical plate frame; a winding roller is fixedly mounted on the rear surface of the gear disc; a disc is meshed with the outer surface of the gear disc; a moving frame is slidably mounted on the front surface of the disc; a swing rod is attached to the bottom end of moving frame; and the bottom end of the swing rod is attached to the upper surface of a piston plate. When the gear disc rotates, the disc is driven to rotate at the same time; the disc drives the moving frame to pull the swing rod upwards, and the bottom end of the swing rod extrudes the piston plate, so that dye in a storage barrel is pushed into a dye box; and when a hot pressing roller moves to the bottommost end, a pressing wheel rod is extruded to press and convey a fabric into the dye box, and the fabric on the surface of the pressing wheel rod is immersed in the dye in the dye box by utilizing pressure, so that the pressing wheel rod drives the fabric to be rolled and dyed, the dye can be uniformly and fully absorbed, and the effect of ensuring the dyeing quality is achieved.

Owner:梓逸(广州)母婴用品有限公司

Cabinet door interlocking device and switch cabinet using same

The invention relates to a cabinet door interlocking device and a switch cabinet using the cabinet door interlocking device, the cabinet door interlocking device comprises a transmission shaft, the transmission shaft is provided with a shielding part used for shielding a switch operation shaft, an elastic reset piece is arranged between the shielding part and a switch, a base is installed on a middle partition plate, and a push rod and an ejector rod which extend in parallel are assembled on the base in a guiding mode. The push rod is provided with a stress end; a reversing component of which two ends are respectively connected with or in pushing fit with the ejector rod and the push rod is arranged between the ejector rod and the push rod; the transmission shaft is provided with a transmission part, the transmission part is located between the ejector rod and the cabinet door in the moving direction of the ejector rod, the ejector rod is in pushing fit with or connected with the transmission part so as to push the transmission part to act in the direction where the cabinet door is located when the cabinet door is closed, and the transmission shaft drives the shielding part to move in the direction of avoiding the switch operation shaft. The technical problems that in the prior art, when the distance between the cabinet door and the switch is long, the lengthened driving part is prone to causing the cabinet door of the switch cabinet to be opened or closed inconveniently, and the driving part is prone to bruise operators can be solved.

Owner:PINGGAO GRP

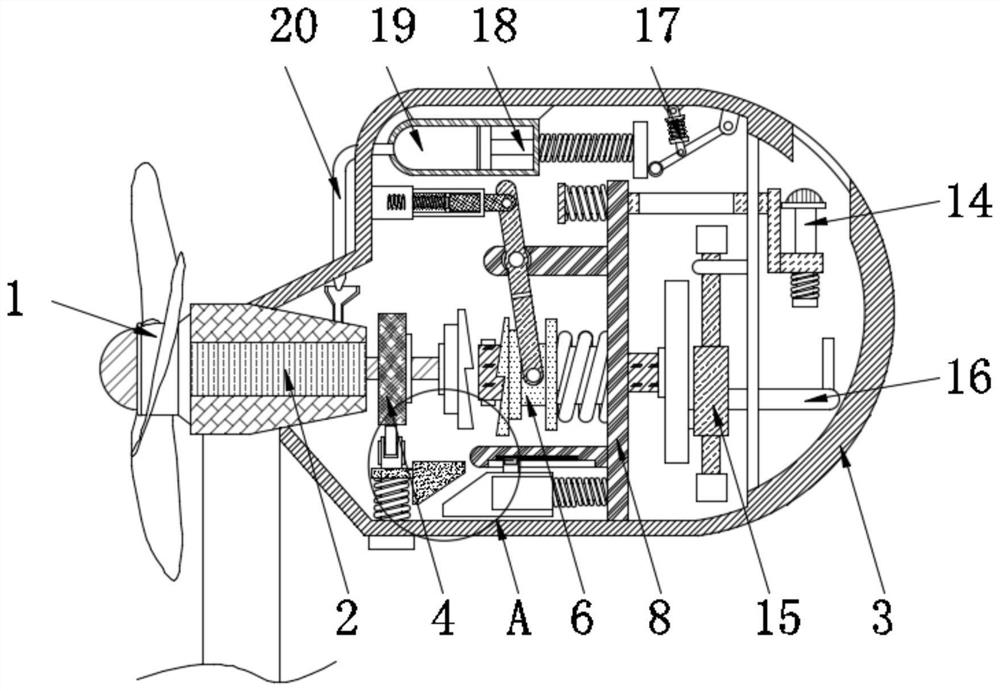

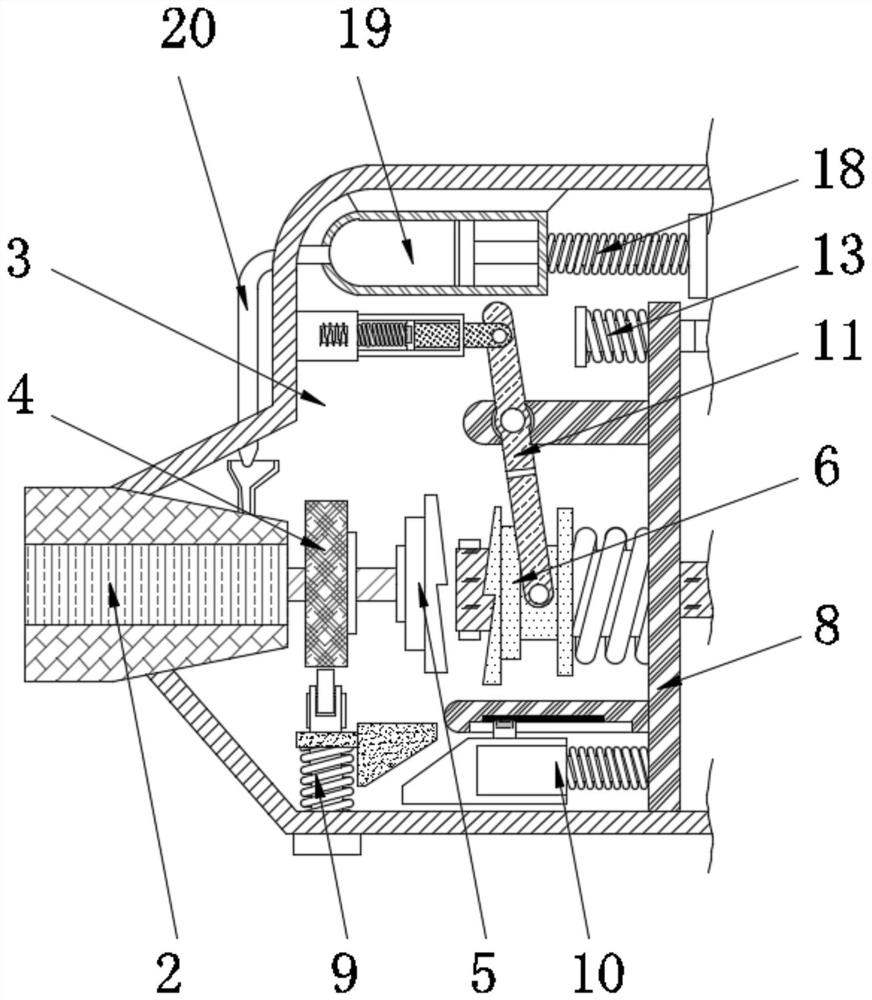

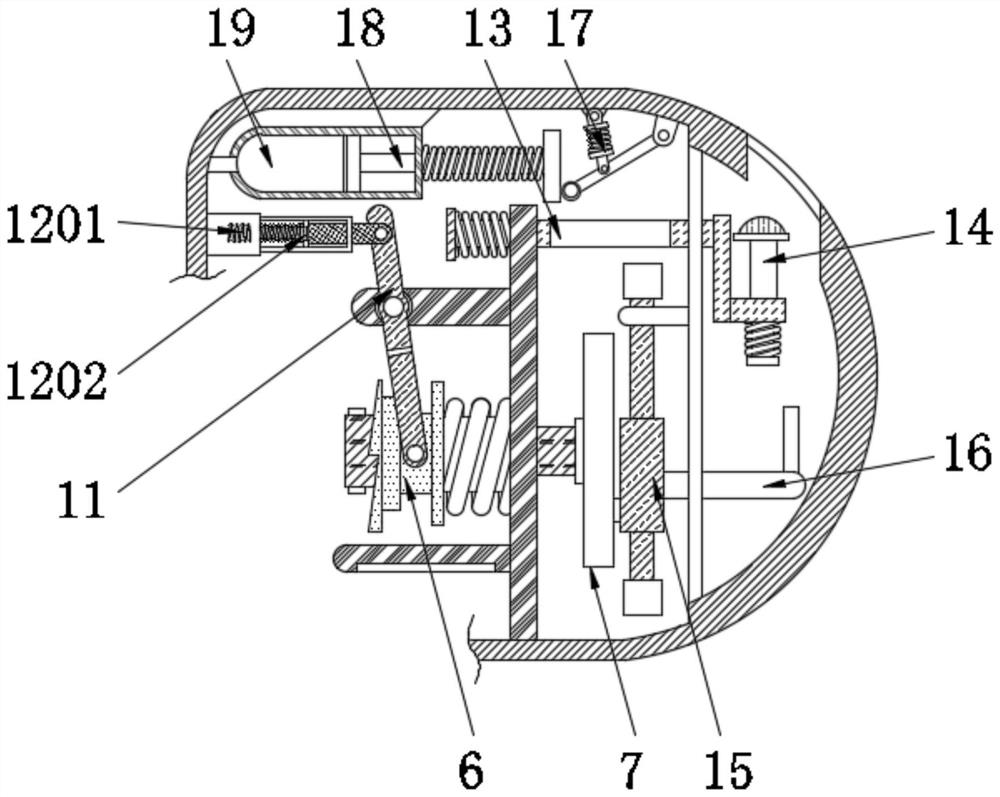

Automatic detection oil injection device for bearing in wind engine

InactiveCN112856195AGuaranteed pushGuaranteed magnetic field pushTurbinesBearing componentsImpellerEngineering

The invention provides an automatic detection oil injection device for a bearing in a wind engine. A transmission rod is arranged in a right chuck, a moving plate is arranged on the right surface of the transmission rod, an auxiliary rod is fixedly mounted on the right surface of the moving plate, and an elastic frame is movably mounted at the position, above the moving plate, on the inner wall of a shell. A piston plate is attached to the bottom end of the elastic frame, the piston plate is installed in an oil storage barrel in a sliding manner, and a dropper is fixedly installed at the position, above a wind wheel shaft, on the outer surface of the oil storage barrel. After a right chuck is engaged with a left chuck, an impeller rod rotates and drives the transmission rod to rotate at the same time, when the transmission rod drives the moving plate to move upwards, after the moving plate extrudes the elastic frame, the elastic frame pushes the piston plate to move in the oil storage barrel, and lubricating oil in the oil storage barrel drips into the wind wheel shaft through the dropper. Thus, the automatic oil injection detection function in the operation process of the wind engine is achieved, manual automatic oil injection is not needed, and the service life of the wind engine is prolonged.

Owner:陈艳艳

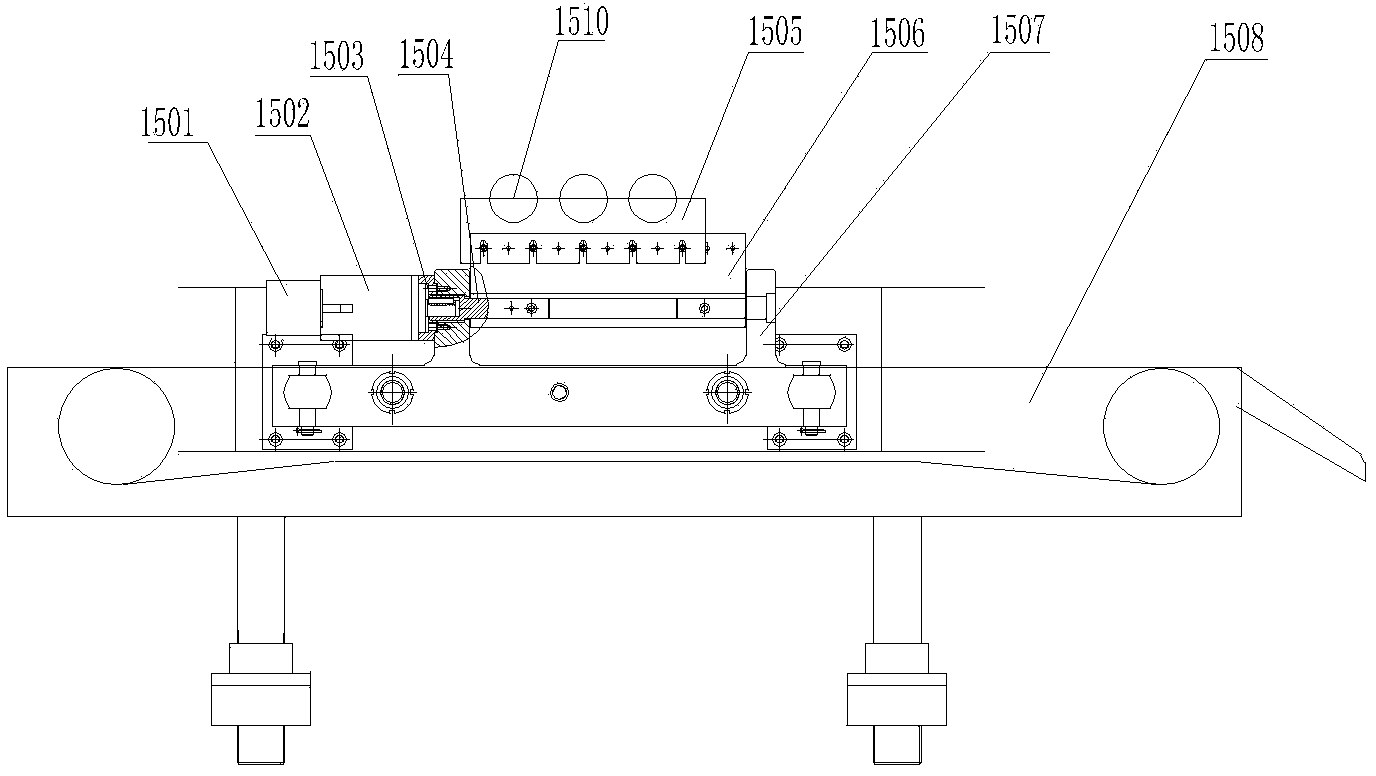

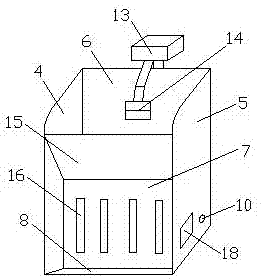

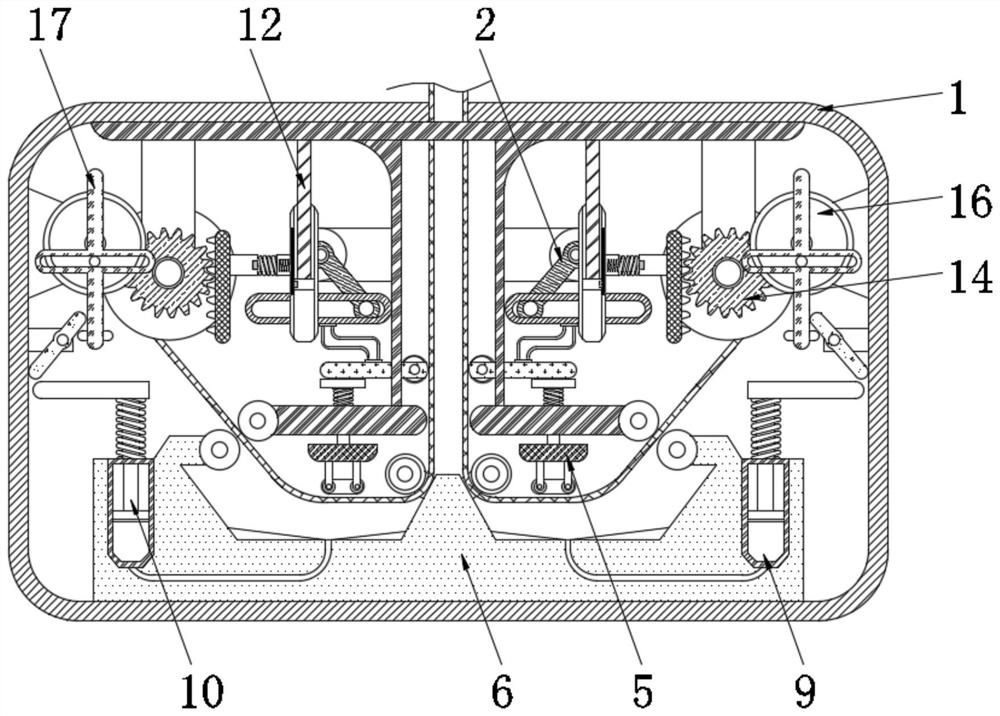

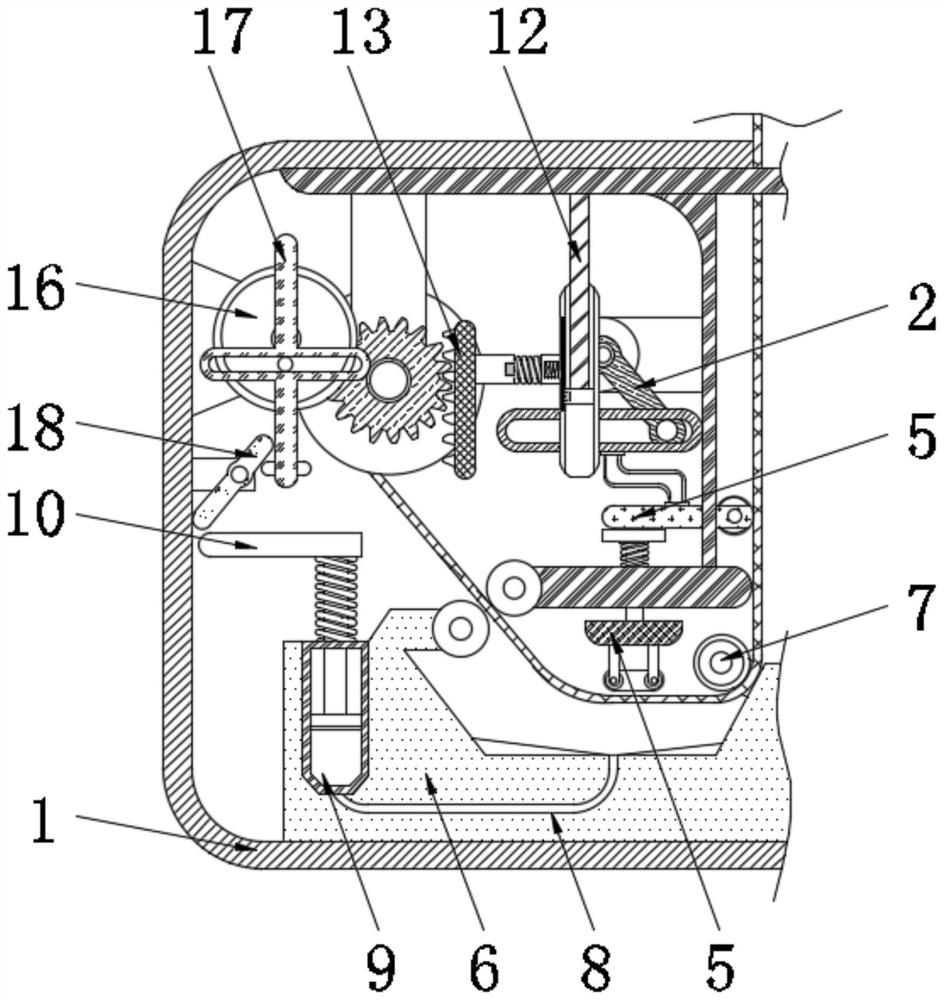

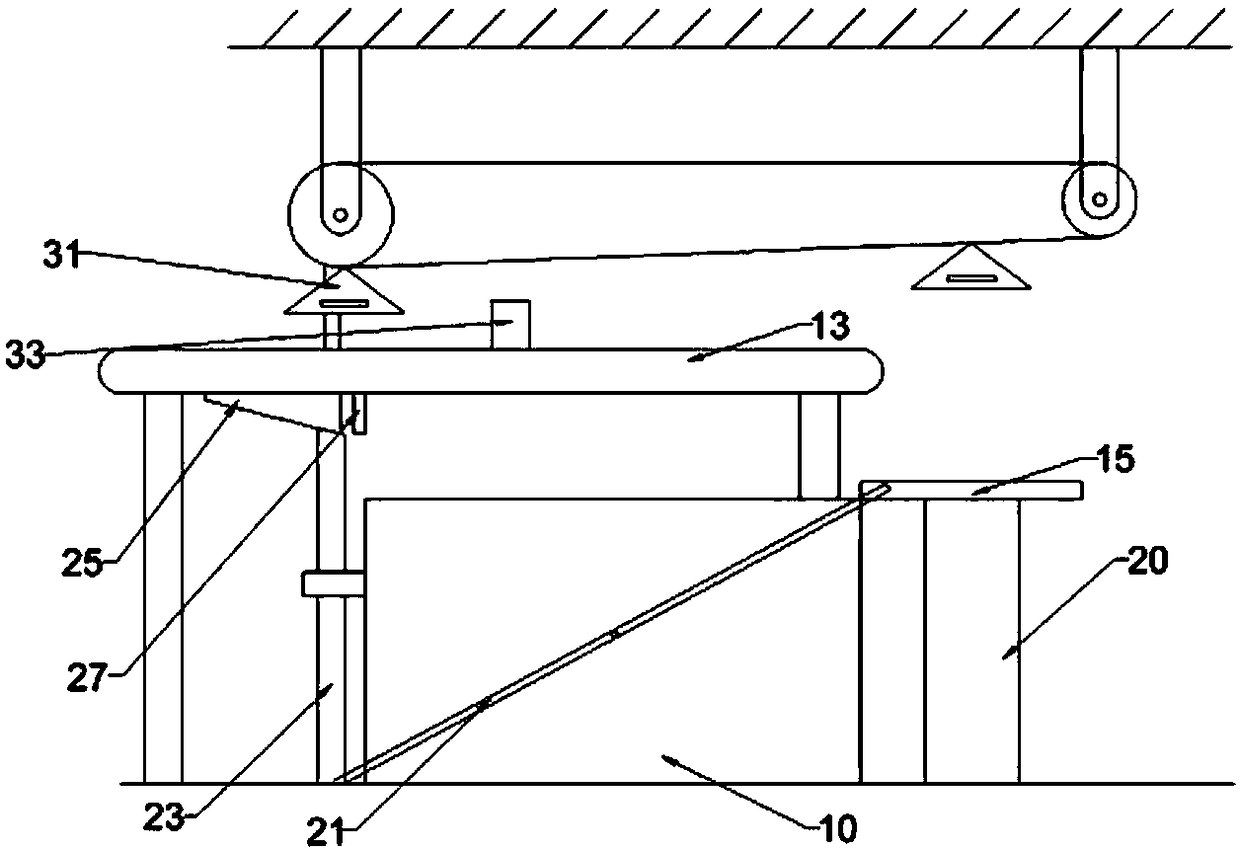

Feeding system of automatic production line

InactiveCN108526338AImprove feeding efficiencyGuaranteed pushMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention relates to the field of automatic material receiving and feeding devices, in particular to a feeding system of an automatic production line. The feeding system of the automatic production line comprises a placement box and a conveying belt, wherein plates are placed in the placement box; the conveying belt conveys the plates and comprises a rack; the placement box is provided with asupporting mechanism capable of pushing the plates to move upwards; a pushing mechanism is arranged in front of a feeding end of the conveying belt and comprises a rotating shaft capable of rotating,a sleeve and a pushing plate; the lower end of the sleeve is connected with the rotating shaft; the upper end of the sleeve is connected with the pushing plate; the rotating shaft can drive the sleeveto move vertically; the sleeve is connected with a push block through a connecting mechanism; the push block is positioned on the side, which is away from the pushing mechanism, of the placement box;the push block is slidably connected to the lower surface of the rack; when the sleeve moves upwards, the connecting mechanism pulls the push block to move away from the pushing plate; when the sleeve moves downwards, the connecting mechanism pushes the push block to move towards the pushing plate; a grabbing mechanism is arranged above the pushing mechanism and comprises a driving belt and a grabbing piece; and the grabbing piece can make contact with the pushing plate and can grab the plates on the pushing plate.

Owner:宁波高新区神台德机械设备有限公司

Device for detecting brightness of liquid crystal display by using light reflection method

InactiveCN112985771AAccurate detectionGuaranteed pushTesting optical propertiesLiquid-crystal displayLiquid crystal

The invention provides a device for detecting the brightness of a liquid crystal display by using a light reflection method. A supporting rod is slidably mounted in a rotating plate, a movable plate is fixedly mounted at the bottom end of the supporting rod, the movable plate is movably mounted on the rear surface of a push seat, the push seat is connected to the outer surface of a supporting column in a sleeving manner, the supporting column is slidably mounted on the outer surface of a sliding rod, and an ejector rod is fixedly mounted on the inner end surface of the supporting column. When the rotating plate rotates, the movable plate at the top end of the supporting rod is driven to rotate, the movable plate drives the push seat to slide in the supporting column, and meanwhile, the supporting column slides in the sliding rod, so that the supporting column is driven to move up and down on the surface of the sliding rod, after the supporting column moves upwards, an inserting rod at the bottom is separated from a reset rod, and the reset rod pulls a clamping table to move, so that the reflection angle between the liquid crystal display and a reflection lens and the reflection angle between the liquid crystal display and a condensation cover are kept perpendicular all the time, brightness detection between different distances of the liquid crystal display is completed through a light reflection method, and detection is more accurate.

Owner:广州高航科技有限公司

An automatic food purification device

ActiveCN113333379BSave waterImprove cleaning efficiencyDrying gas arrangementsCleaning using liquidsBiotechnologyWater resources

The invention relates to the technical field of food purification, and discloses an automatic food purification device, which includes a purification cylinder with a hollowed-out interior, a spring A is fixedly connected to the bottom surface of the purification cylinder, and a support plate is fixedly connected to the top of the spring A, and the support plate adopts Magnet material, the support plate is inserted into the inner wall of the purification cylinder, the top surface of the support plate is placed with a filling plate, the top surface of the filling plate is opened with a hole, and the hole is connected with a cylindrical outer wall on the left and right sides through a rotating bearing. There is a rectangular protruding insertion rod. The top surface of the purification cylinder is provided with holes and is in a nested relationship with the insertion rod. The top surface of the purification cylinder is provided with through holes. The outer wall of the purification cylinder is fixedly connected with five U-shaped liquid pipe, through the setting of the material holding plate, the material holding plate can automatically change the position in the purification cylinder according to the weight of the raw material, so that the device can change the injection amount of clean water according to the direct raw material amount, so as to save water resource benefits.

Owner:杭州温理科技有限公司

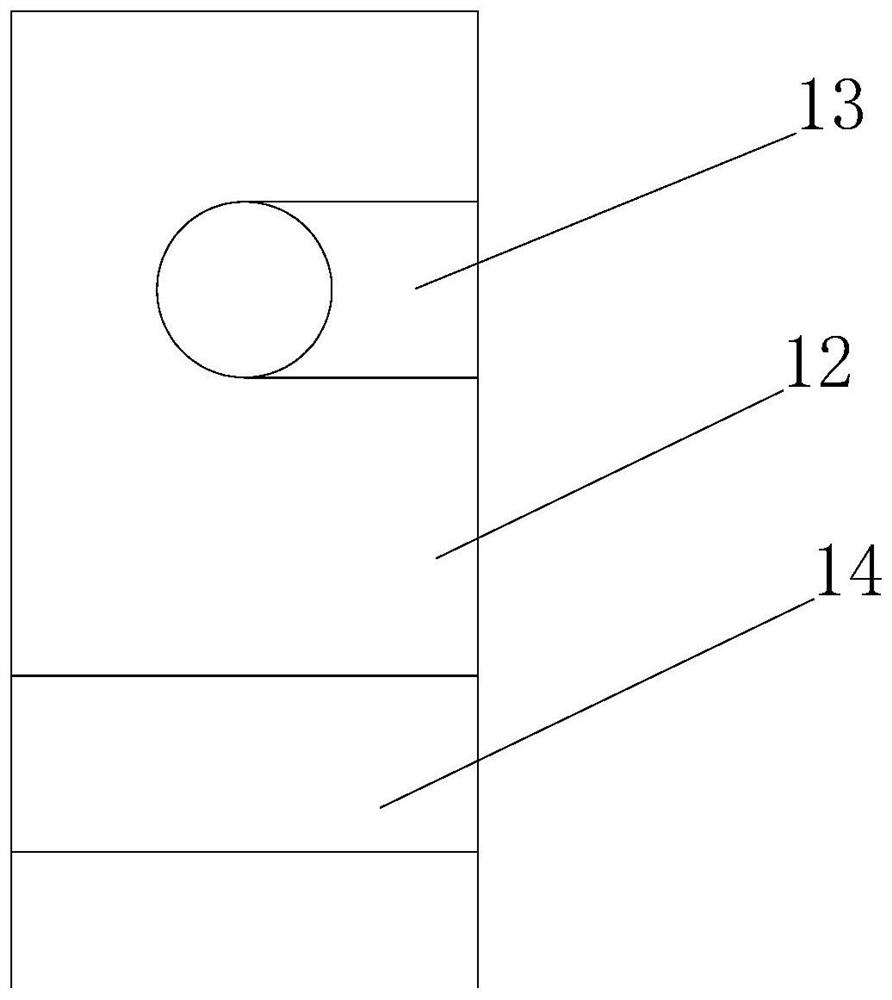

Brush roll with double bearing housing

The invention relates to a brush roller with double bearing seats, which includes a brush roller shaft and a brush roller cylinder. The brush roller cylinder is provided with bristles. The brush roller cylinder is sleeved on the brush roller shaft and connected to each other through splines. The brush roller The two ends of the shaft pass through the brush roller and are each set on a fixed bearing seat. The two fixed bearing seats are each set on a frame. The two ends of the brush roller are each set on a movable bearing seat. The screws pass through the two moving bearing seats and are parallel to the brush roller shaft. One end of the screw is set on one frame, and the other end passes through another frame and is connected to the driving mechanism. The driving mechanism can be driven by the screw The mobile bearing seat and brush roller move reciprocally along the axial direction. All the bristles of this brush roller can evenly contact the strip steel, and it has a simple structure and low cost.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com