Self-locking mechanism capable of preventing slide retreating and self-locking and unlocking method of self-locking mechanism

A technology of limiting mechanism and self-locking, applied in the field of self-locking mechanism to prevent travel position retreat, can solve the problems of reduced product quality, travel position backward, poor product dimensional accuracy, etc., and achieve the effect of maintaining production progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below.

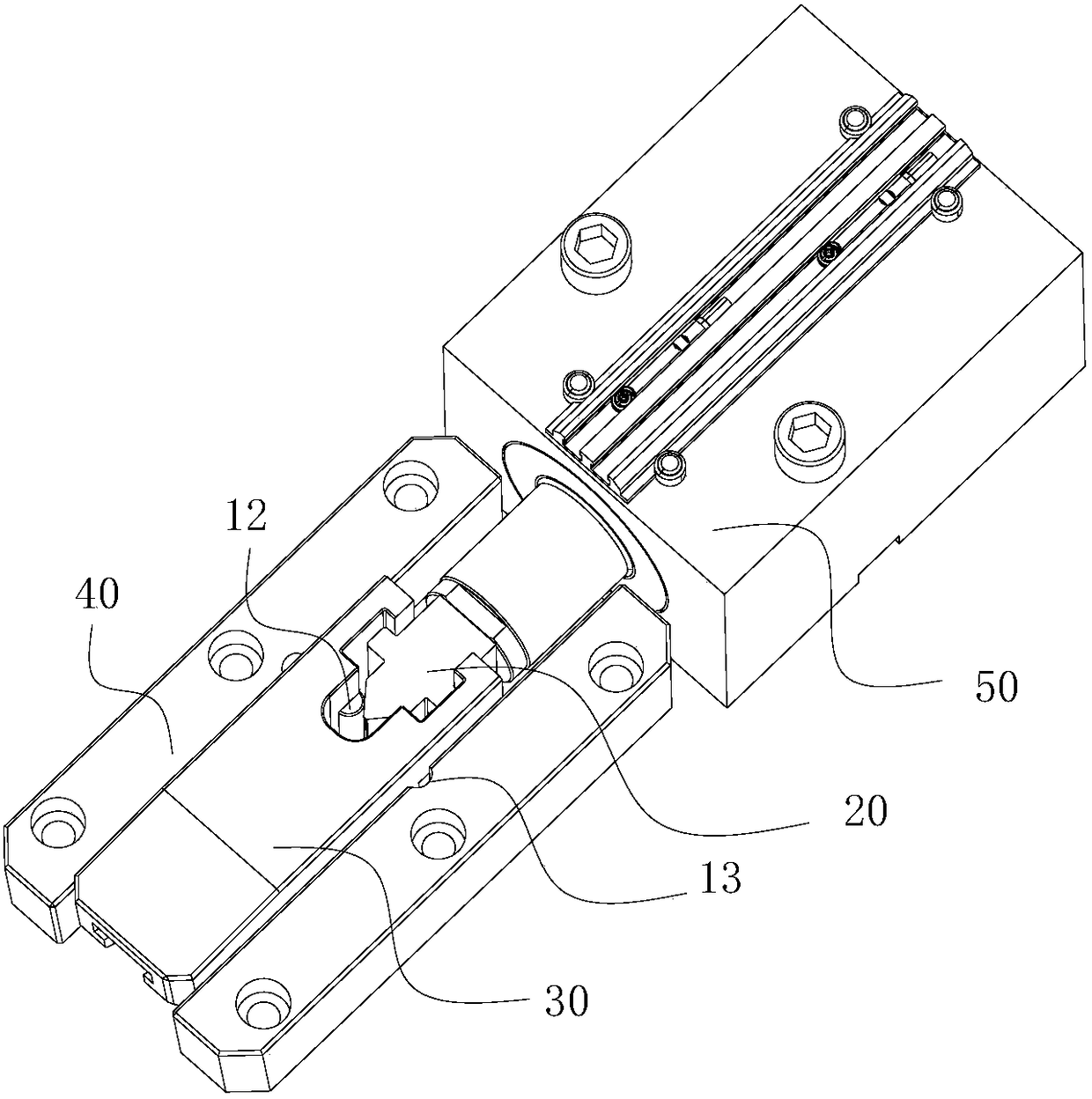

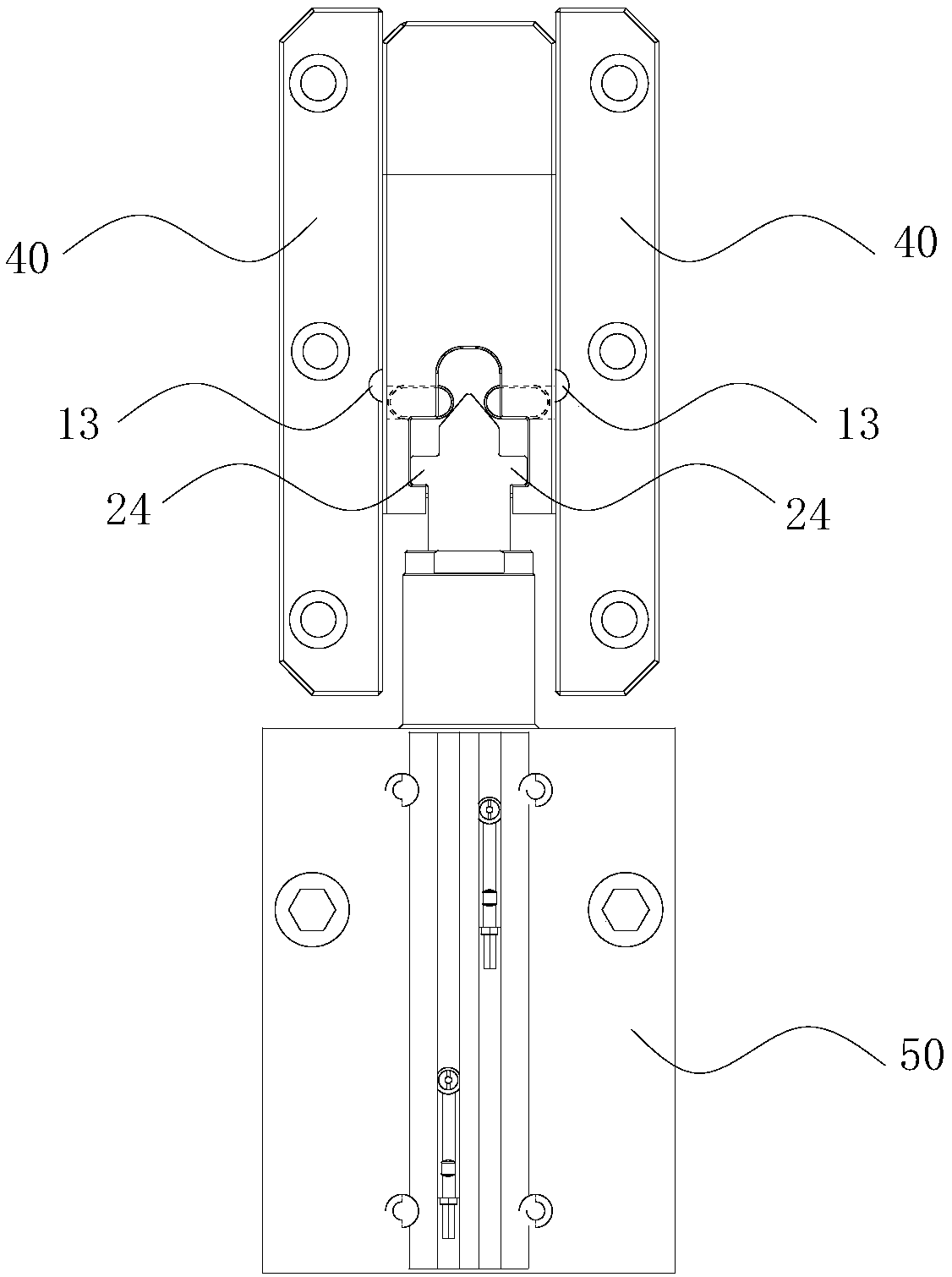

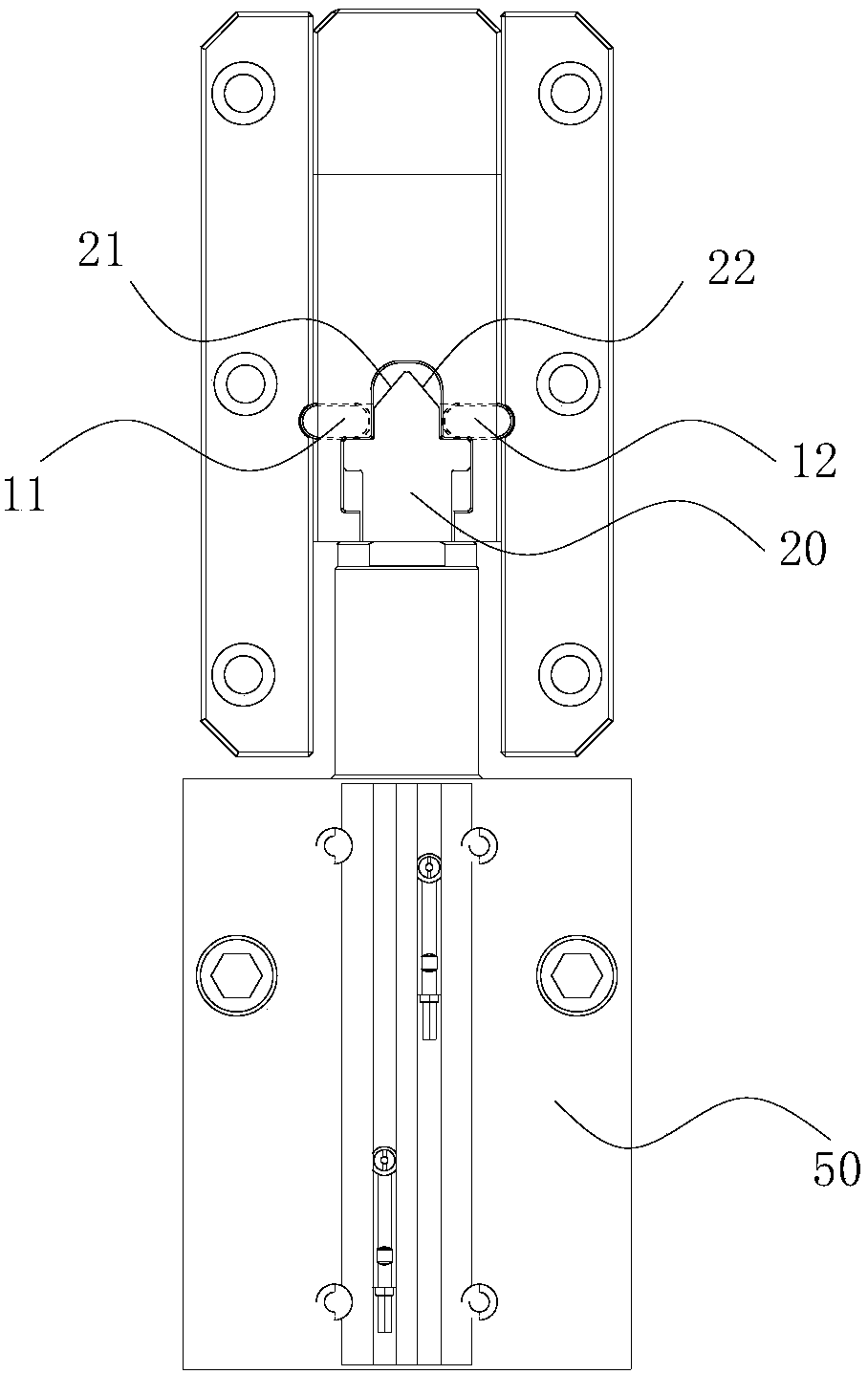

[0047] Such as Figure 1 to Figure 4 The shown self-locking mechanism for preventing row position backward includes row position push plate 30, fixed plate 40, limit mechanism 10, top block 20 and driving oil cylinder 50, and fixed plate 40 is placed on both sides of row position push plate 30, The end of the row position push plate 30 has a self-locking groove 31, the limit mechanism 10 is located inside the self-locking groove 31, the top block 20 is located at the notch of the self-locking groove 31, and the top of the top block 20 has an inclined top surface and a limit surface 23 , the limiting surface 23 is located below the inclined top surface, and the driving cylinder 50 is connected with the top block 20 to drive the movement of the top block 20;

[0048] The limiter mechanism 10 comprises a first limiter 11, a second limiter 12 and a limiter slot 13, the first limiter 11 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com