Centrifugal vegetable drying device with uniform dehydration function

A drying device and centrifugal technology are applied in the field of centrifugal evenly dehydrated vegetable drying devices, which can solve the problems of easy collision and damage, affecting the quality of vegetables, and excessive drying of vegetables, so as to improve the drying efficiency and prevent the quality of vegetables. Destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

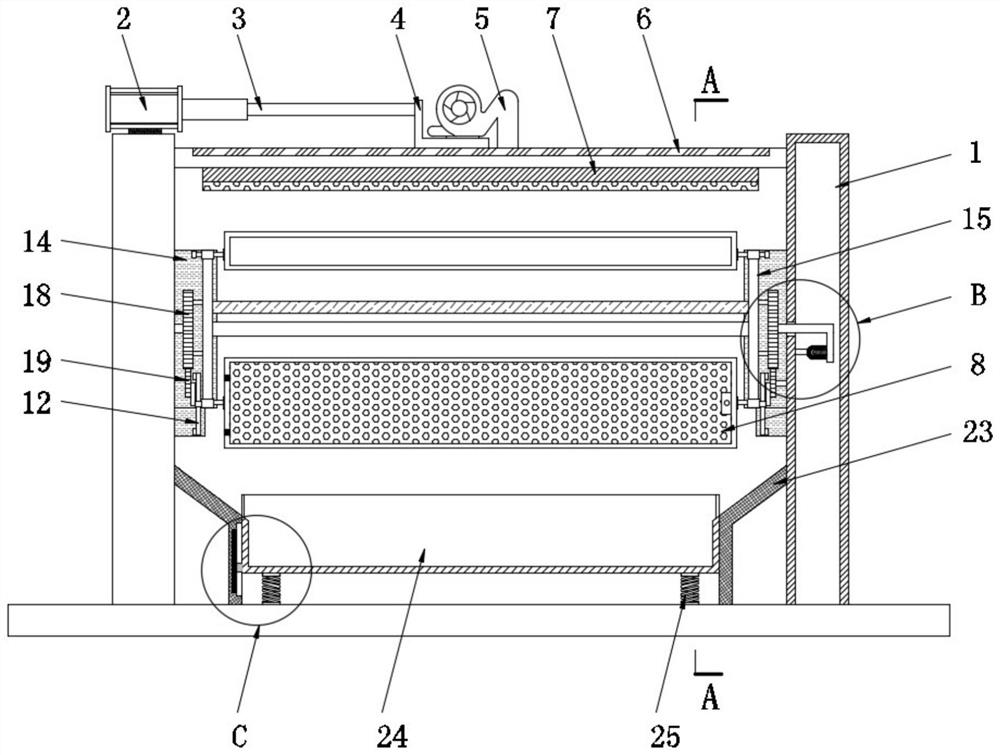

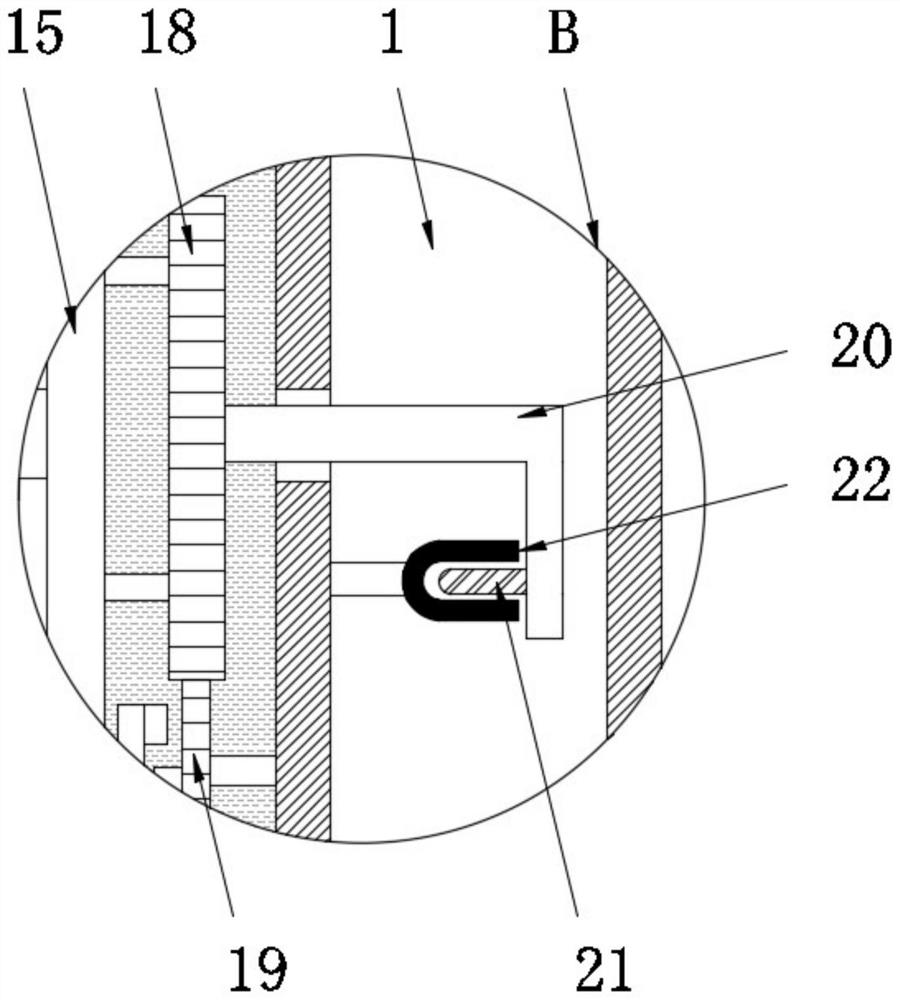

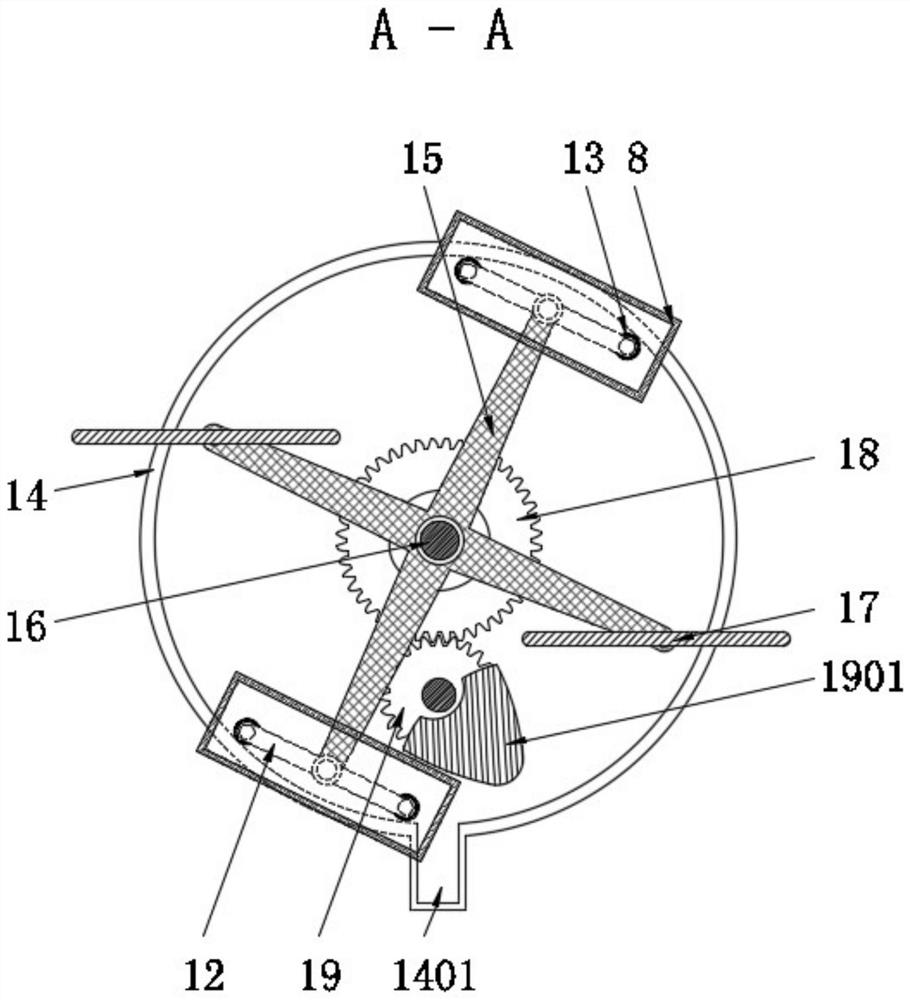

[0022] The invention provides a centrifugal uniform dehydration vegetable drying device, as attached figure 1 to attach Figure 5 Shown: including the dehydration chamber 1, the upper surface of the left end of the dehydration chamber 1 is fixedly installed with the cylinder 2, the output end of the cylinder 2 is fixedly installed with the telescopic column 3, the right end of the telescopic column 3 is fixedly installed with the sliding seat 4, and the upper surface of the sliding seat 4 A hot air blower 5 is fixedly installed on the surface, and the sliding seat 4 is slidably installed inside the guide rail 6, and the guide rail 6 is arranged on the upper surface of the cylinder 2. Through holes are evenly opened on the surface, and the hot air blower 5 transmits the hot air to the dehydration chamber 1 through the through holes in the air delivery pipe 7, blows the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com