Plasticized material receiving structure of injection blow molding machine

An injection blowing machine and injection molding technology, which is applied in the field of injection blowing machine plasticizing and receiving structure, can solve the problems of waste of resources, unstable movement, waste of energy, etc., and achieve the effects of improving work efficiency, reducing safety accidents, and saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

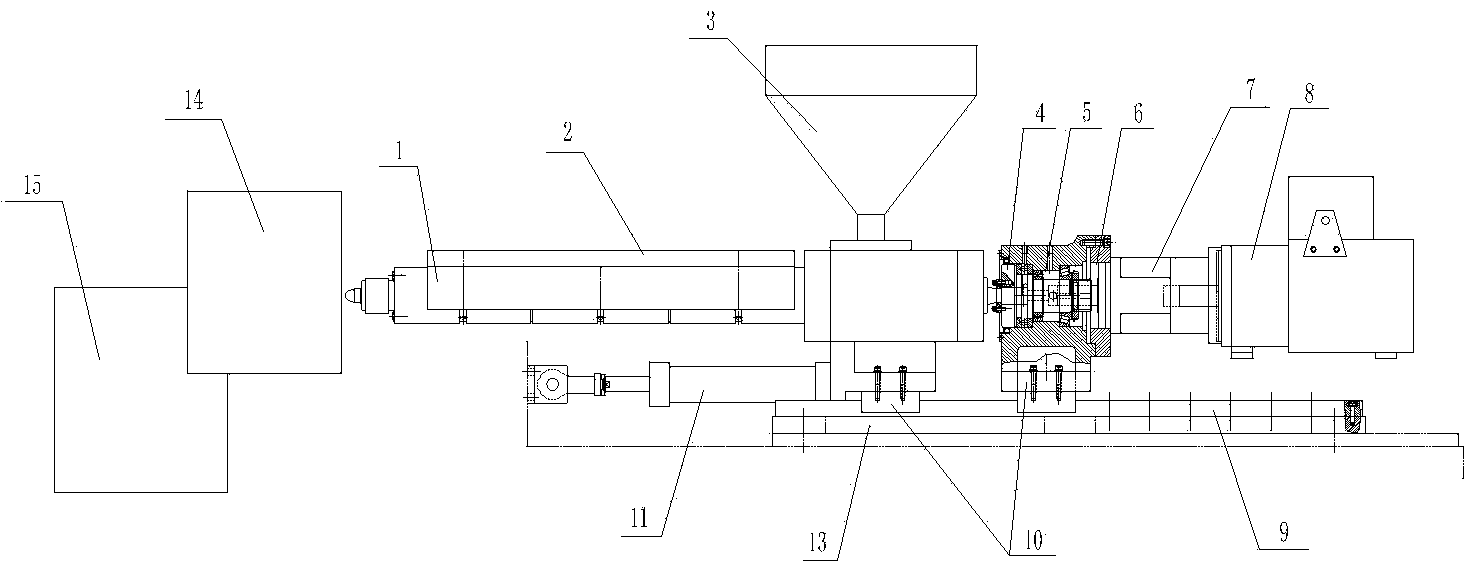

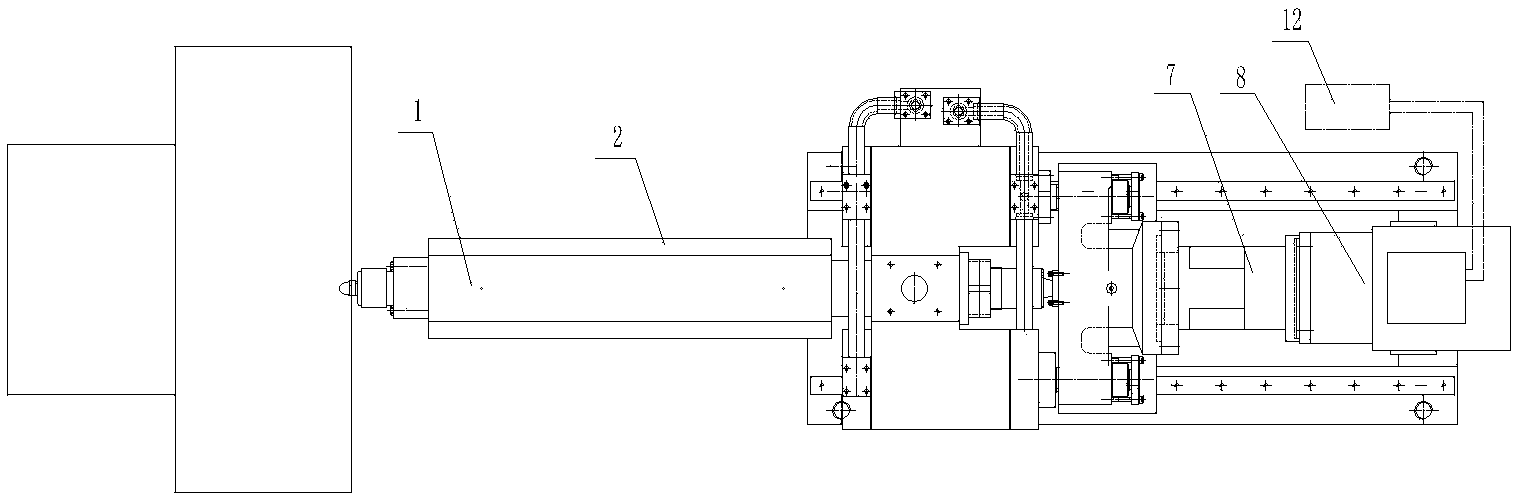

[0018] Such as Figure 1 ~ Figure 4 A kind of injection blowing machine plasticization receiving structure shown, comprises frame, is provided with injection molding part on described frame, and described injection molding part is provided with molding part 14, and described injection molding part comprises plasticizing screw rod 1. The outer casing 2 of the plasticizing screw 1 and the driving device for driving the plasticizing screw 1 to rotate. A moving device for the injection part is provided under the injection part, and a device for automatically transferring products is provided at the exit of the molding part 14. Rotary device 15.

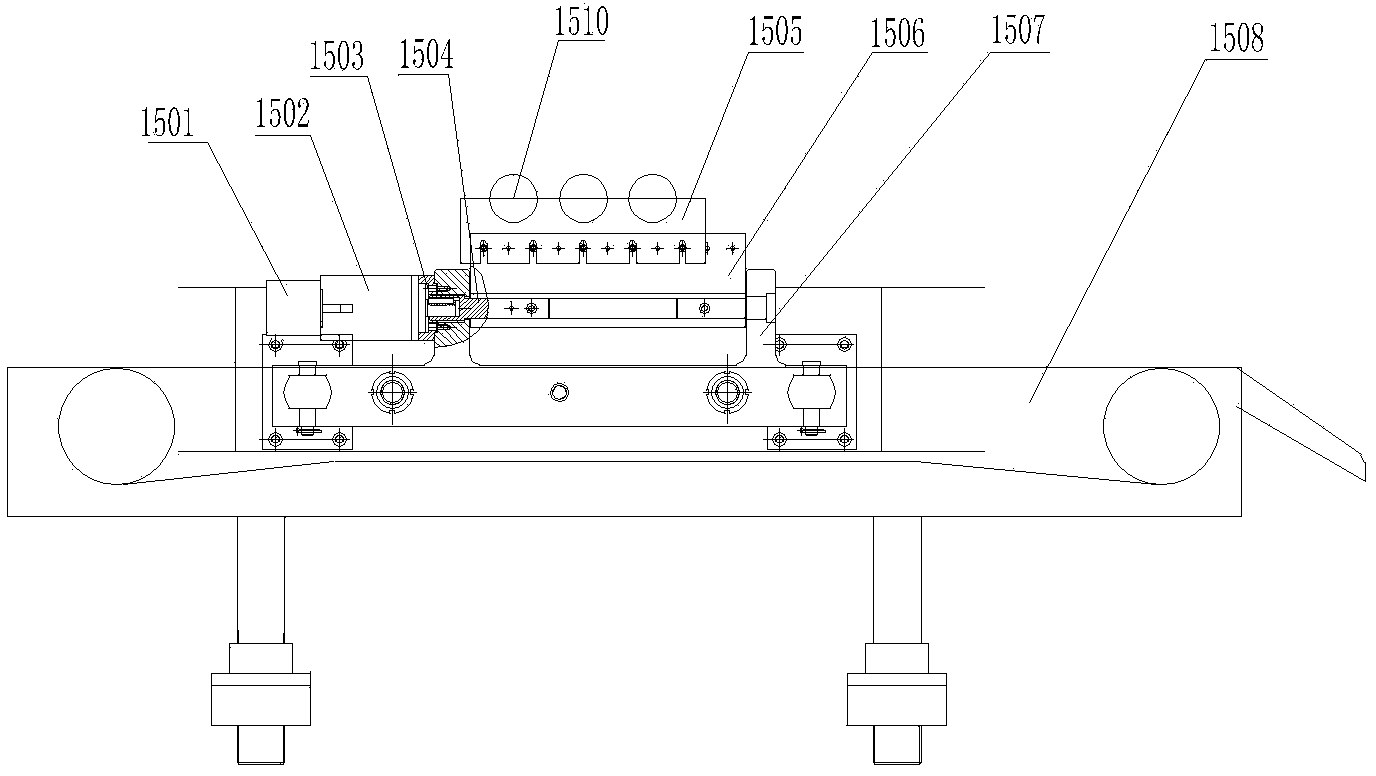

[0019] The rotating device includes a push hydraulic cylinder 1509 arranged on the frame of the injection blowing machine. A fixed mount 1507 is arranged on the head of the hydraulic cylinder shaft of the push hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com