Three-strand straight twisting machine and three-strand yarn directly twisted into wire method

A technology of direct twisting machine and twisted yarn, which is applied in the field of direct twisting machine, can solve the problems that large overfeed rollers cannot be braked, cannot obtain small air rings, wear and thin friction plates, etc., so as to improve adjustment accuracy and reduce workshop noise , to prevent the effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

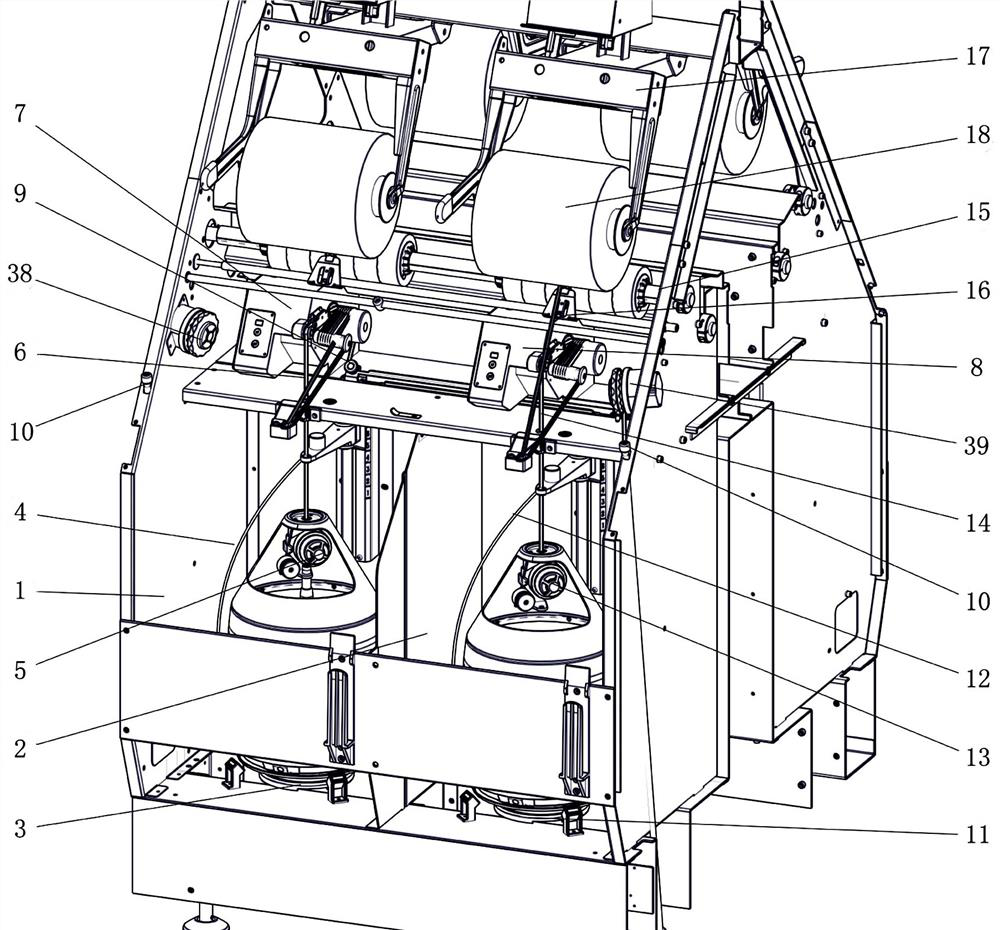

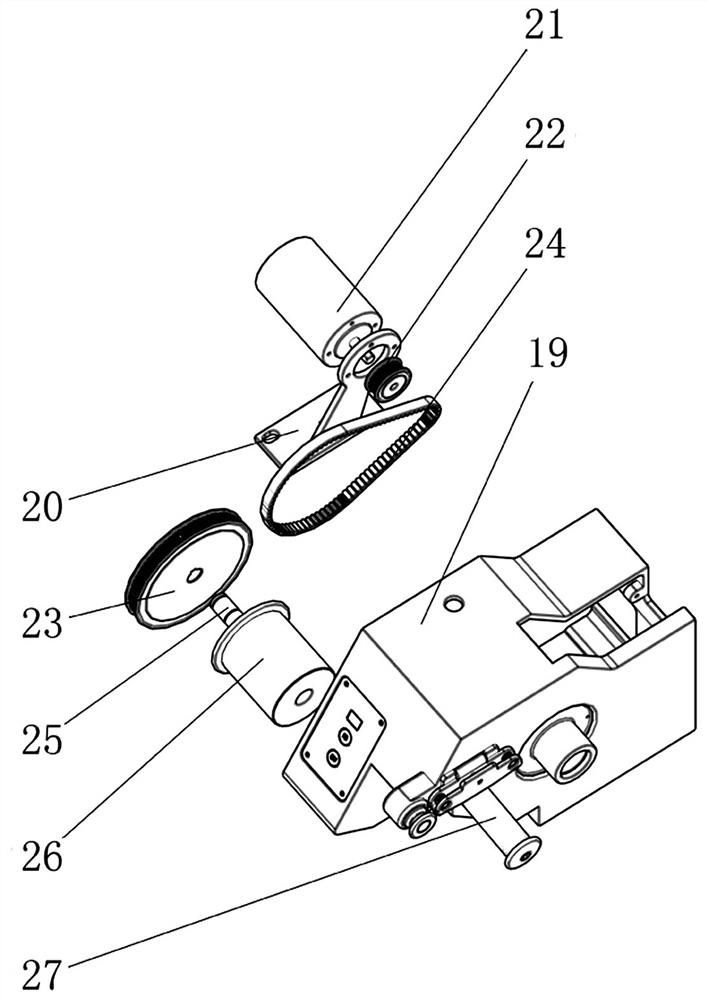

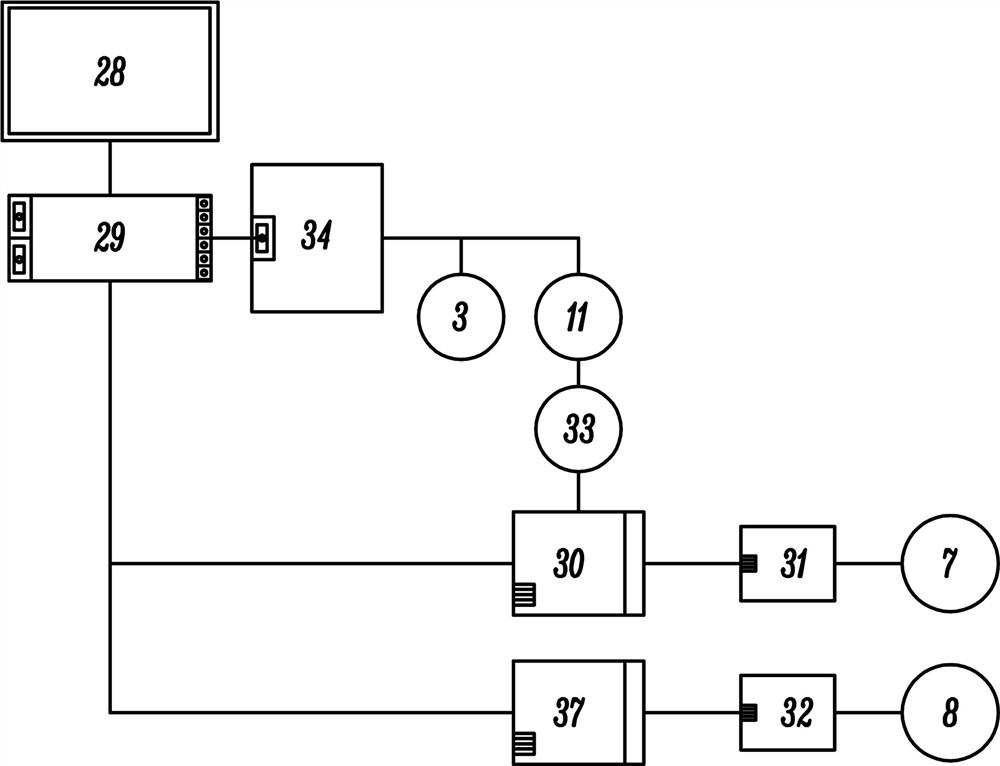

[0043] Such as figure 1 , 2 Among them, a three-strand straight twisting machine, including two-strand twisting spindle position 1 and three-strand twisting spindle position 2, two strands of raw silk are sent to two-strand twisting spindle position 1, one of which enters two-strand twisting and twisting assembly 3 and passes through high-speed The rotating two-twisting twisting assembly 3 is thrown out to form a two-twisting outer yarn balloon 4, which is twisted with one two-twisting inner yarn 5, and the two-twisting inner yarn 5 after twisting at the two-twisting spindle position 1 is After the first overfeed assembly 7 is wound n turns, it is delivered to the outer yarn long tube 10 of the three-strand twisting spindle position 2 through the wire guide device 9, and then delivered to the three-strand twisting assembly 11 to form a three-strand twist outer yarn balloon 12, which is combined with the three-strand twisting assembly 11. The twisted inner yarn 13 is twisted t...

Embodiment 2

[0060] A method for directly twisting the three-strand filaments of the above-mentioned three-strand direct twisting machine into a thread, comprising the following steps:

[0061] S1. The single-strand raw silk is fed to the two-twisting spindle position 1, and the high-speed rotating two-strand twisting assembly 3 will throw the raw silk as the outer yarn to form a two-twisted outer yarn balloon 4, and combine it with the two-twisted outer yarn Two strands of twisted inner yarn 5 of spindle position 1 are twisted to become two strands of twisted yarn 6;

[0062] S2. After the two-ply twisted yarn 6 is wound n turns on the first overfeed assembly 7, it is transported to the three-ply twisting spindle position 2 through a wire guide device 9 comprising multiple sets of guide wheels;

[0063] S3, the two-ply twisted yarn 6 is fed into the three-ply twisted twisting assembly 11 from the outer yarn long tube 10 of the three-ply twisted spindle position 2 as the outer yarn of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com