Patents

Literature

35results about How to "Guaranteed equal length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

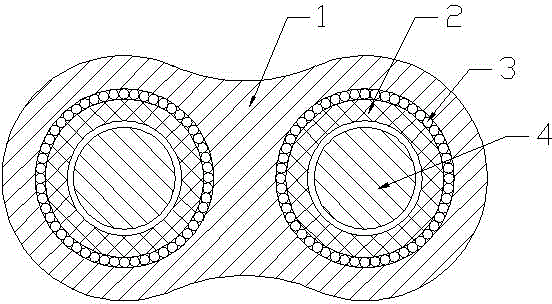

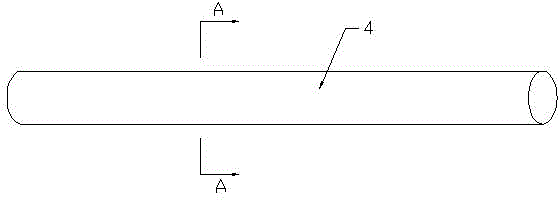

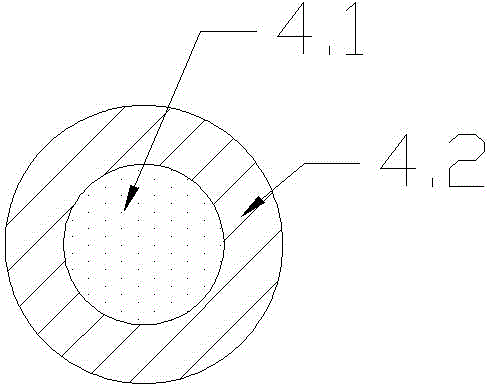

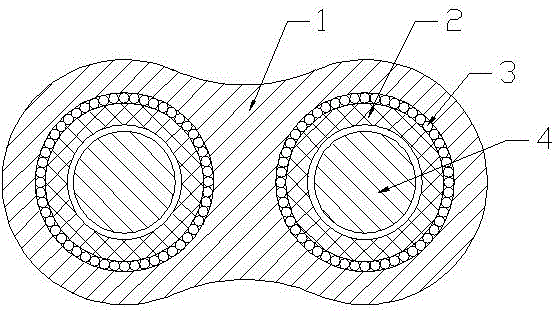

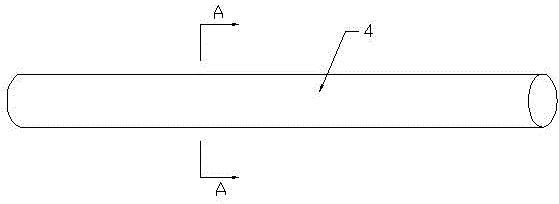

Wear-resistant brake line

InactiveCN105697511AEasy to shapeLight in massCoatingsShaft for linear movementFiberWeather resistance

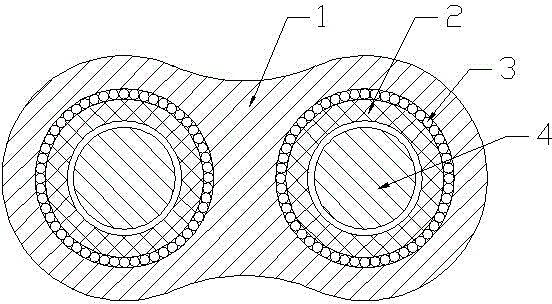

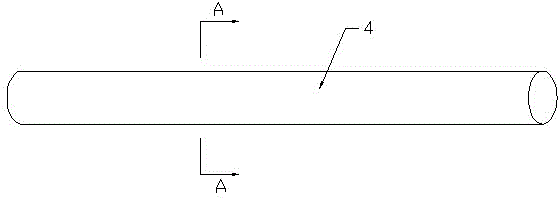

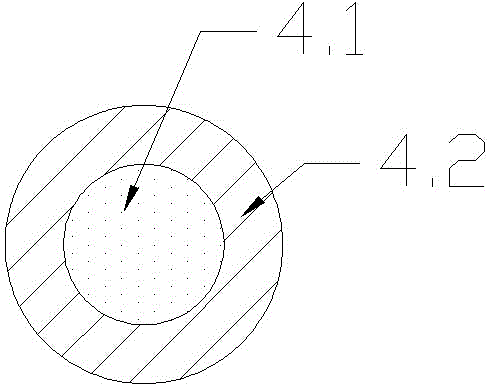

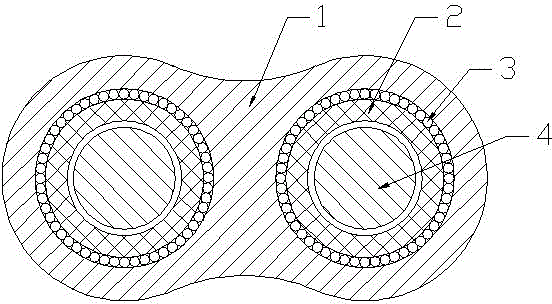

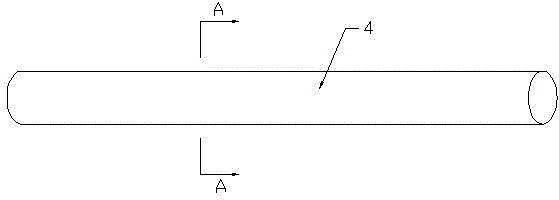

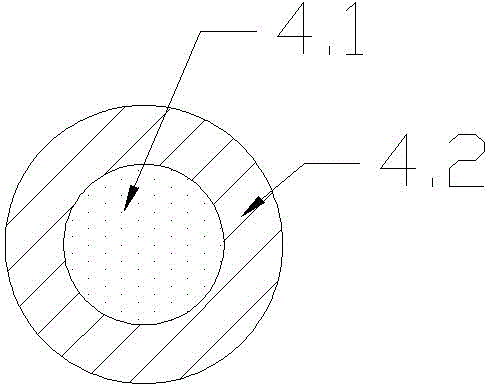

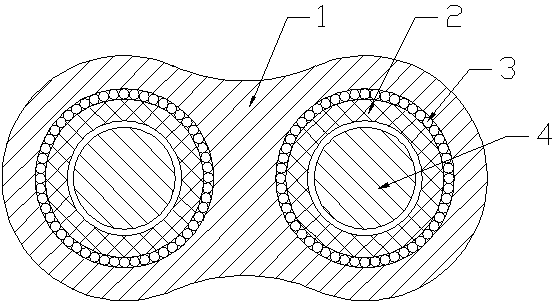

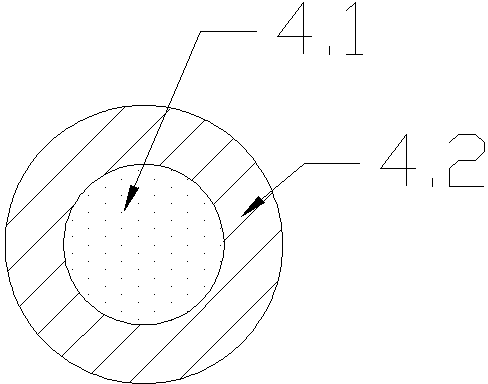

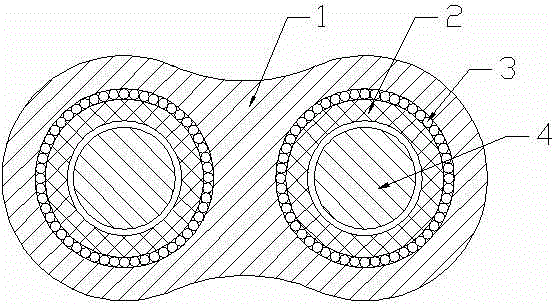

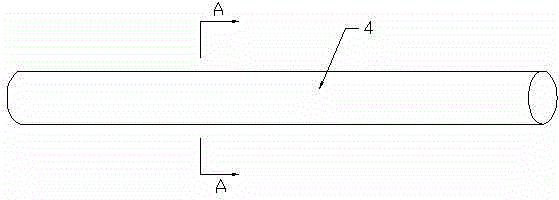

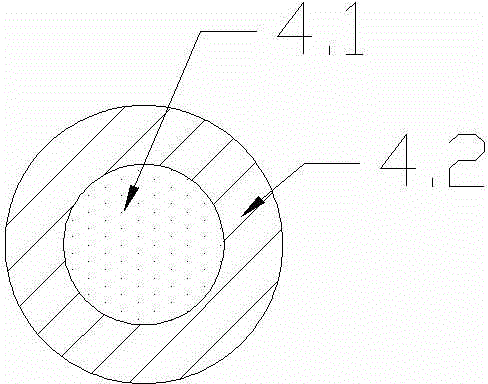

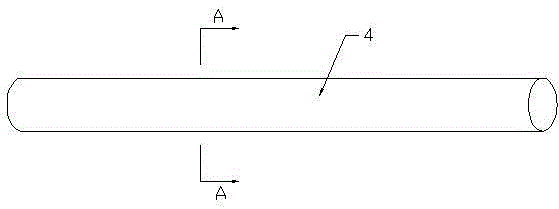

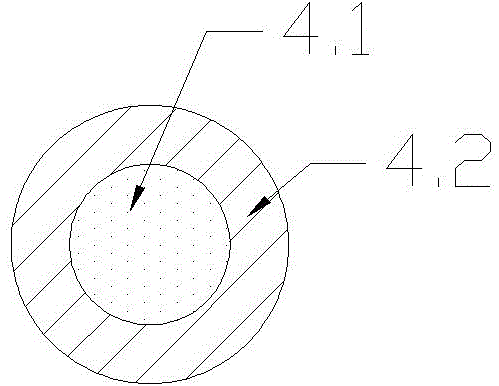

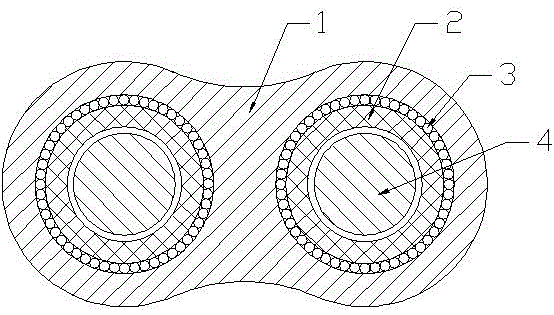

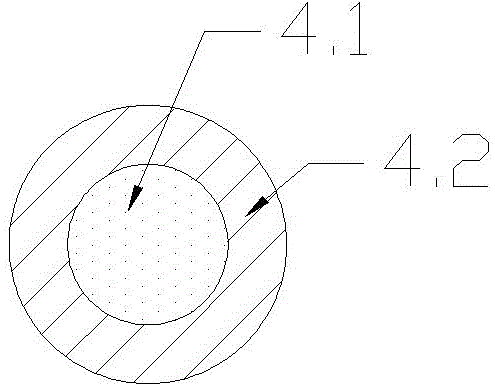

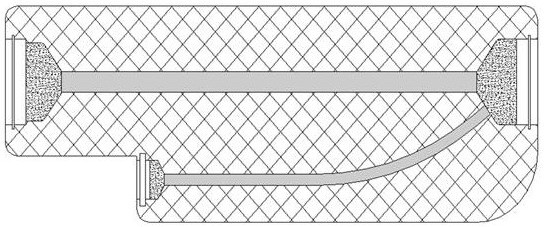

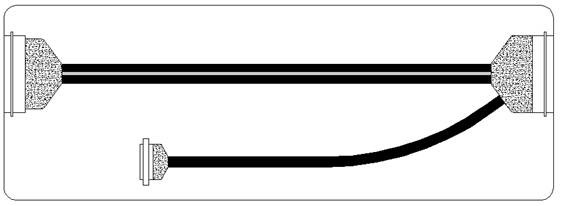

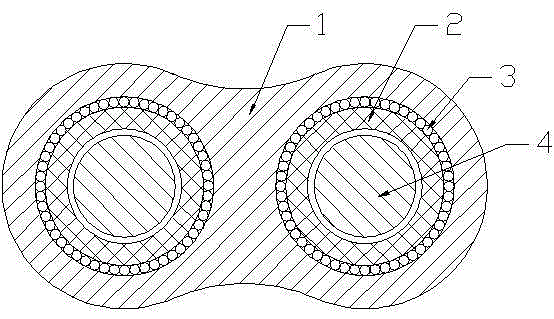

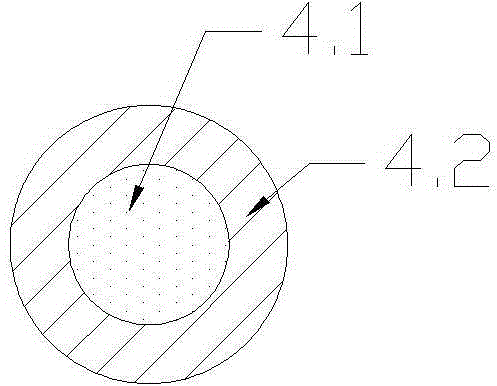

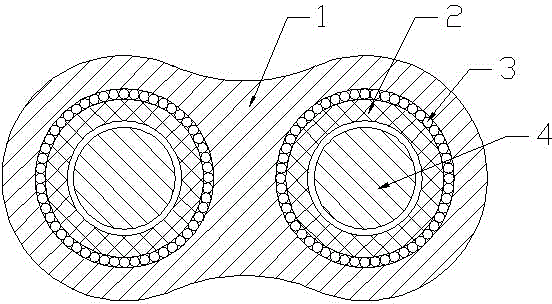

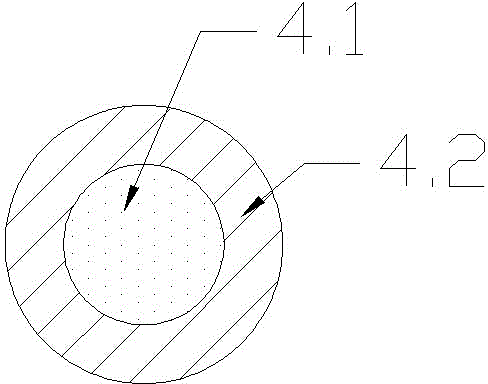

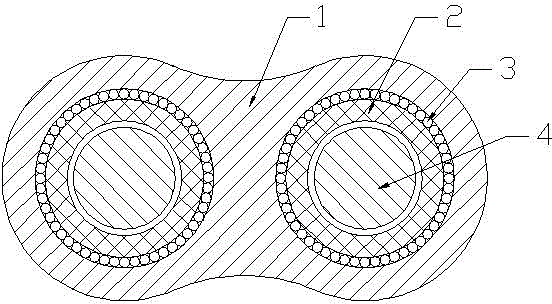

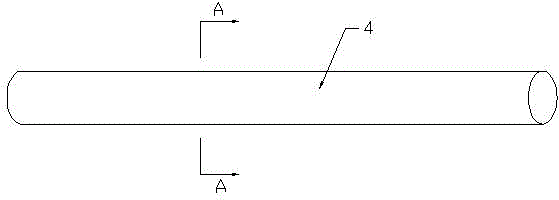

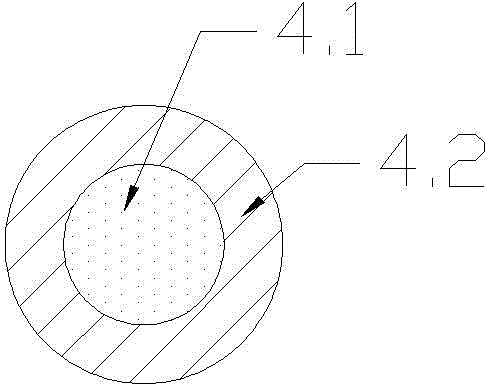

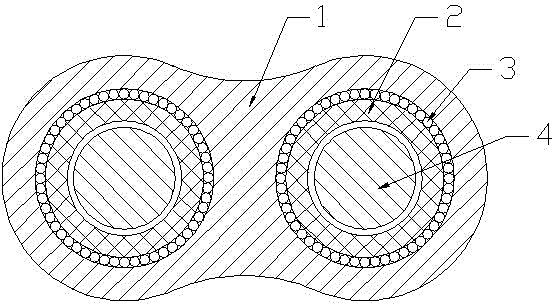

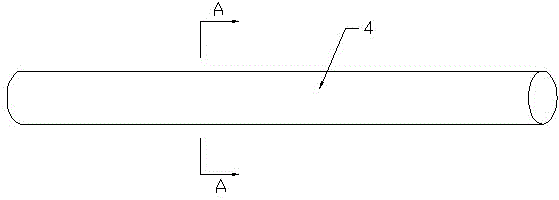

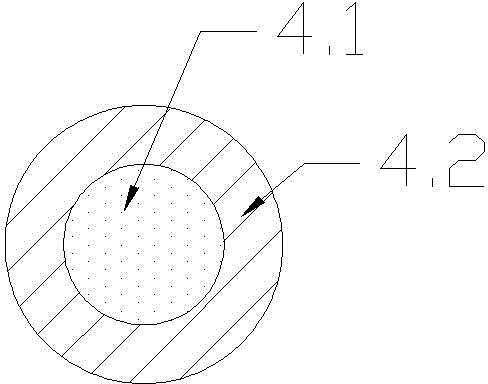

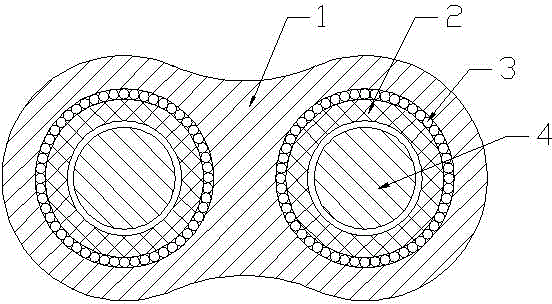

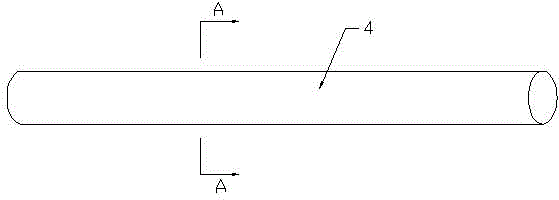

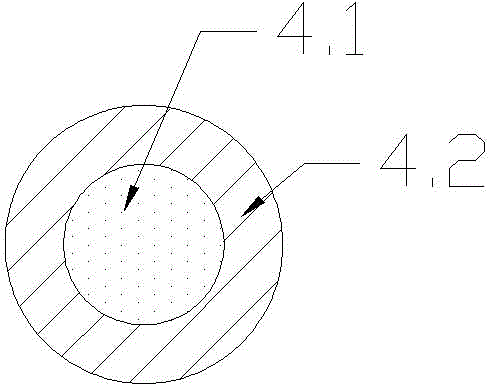

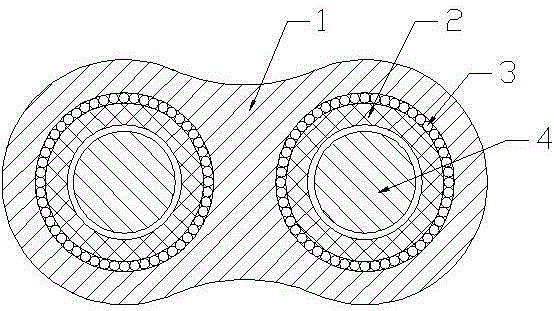

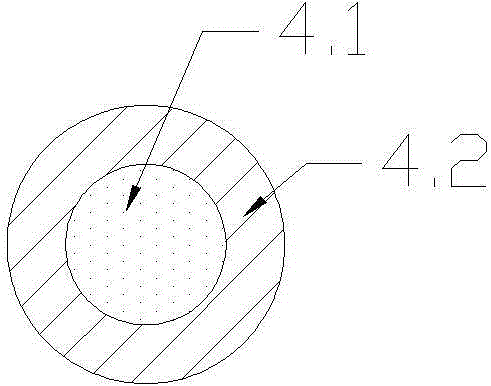

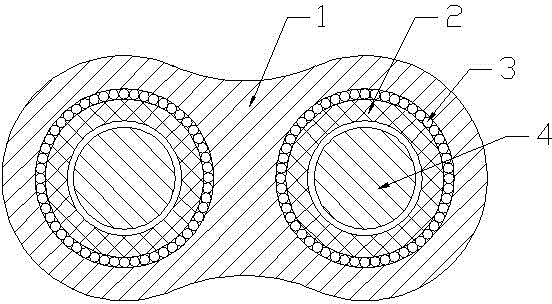

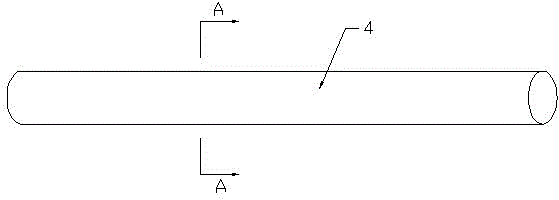

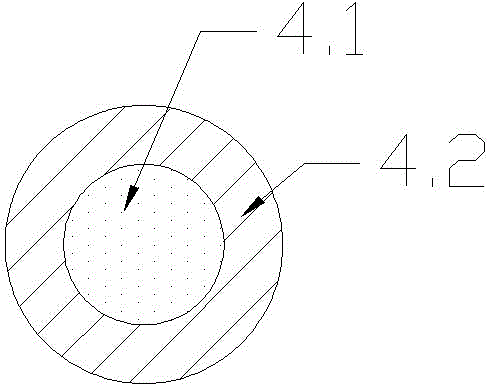

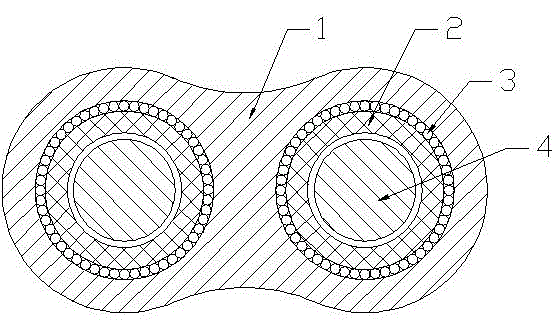

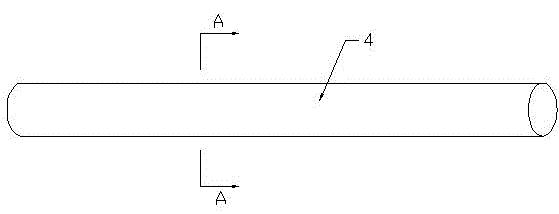

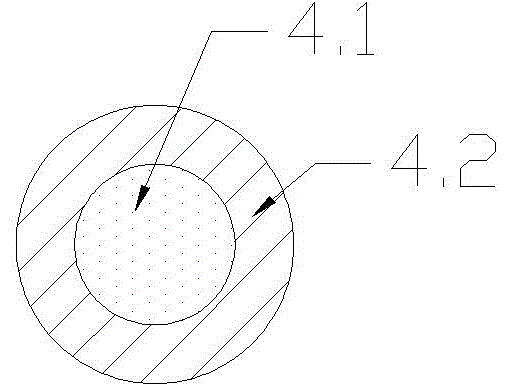

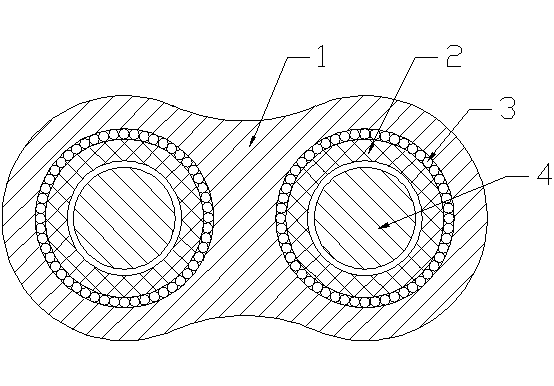

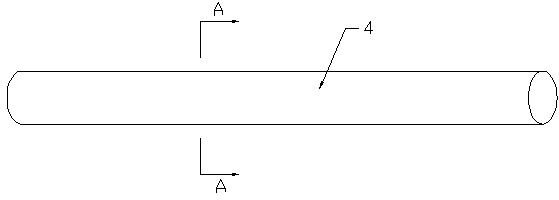

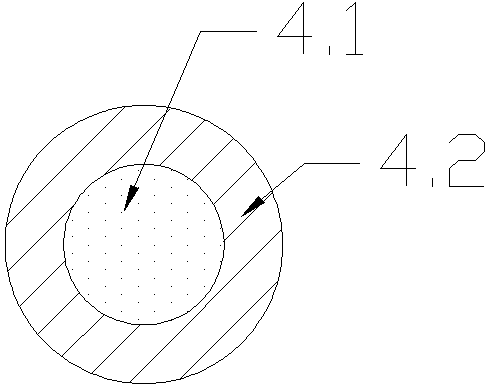

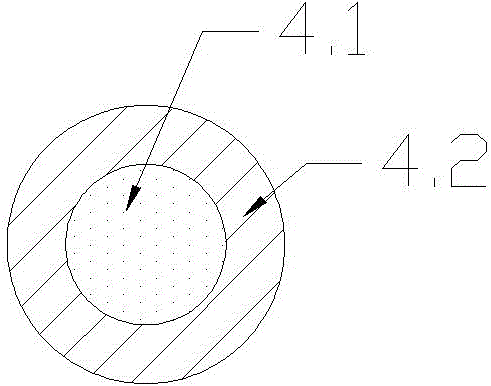

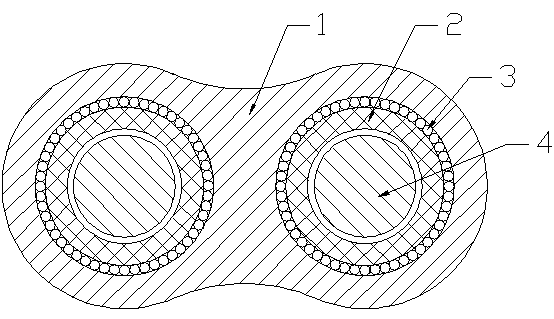

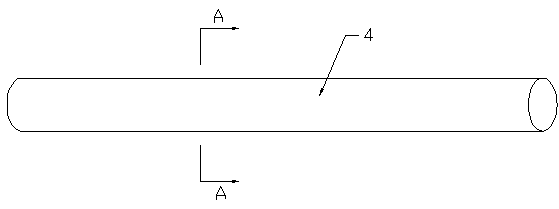

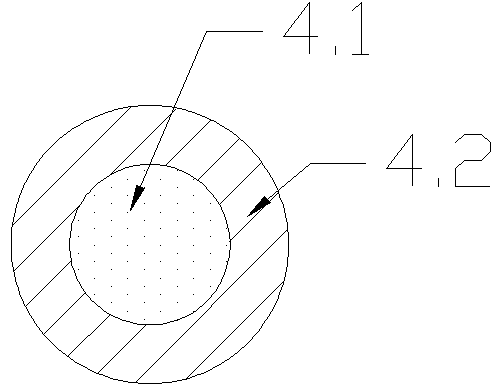

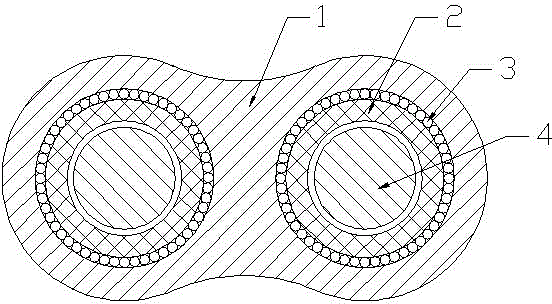

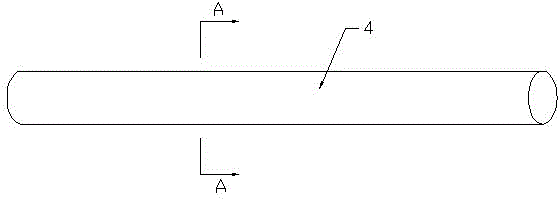

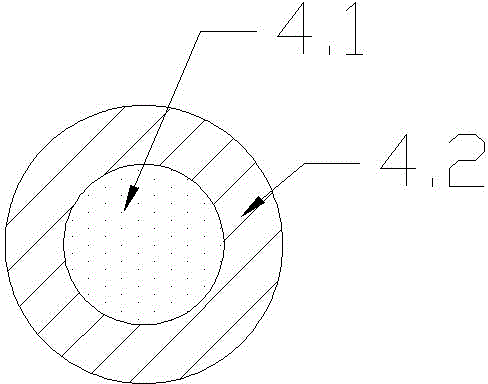

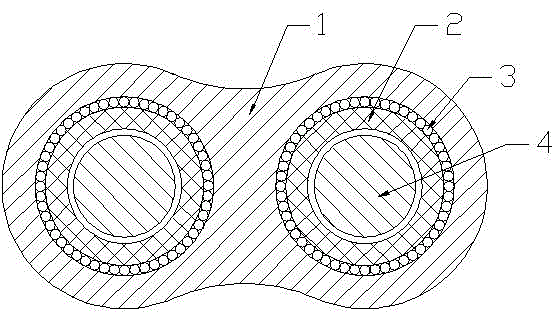

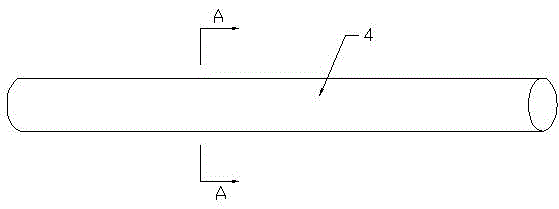

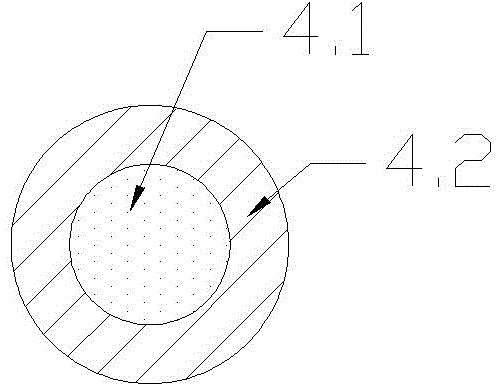

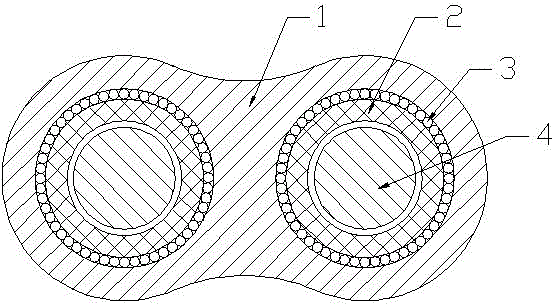

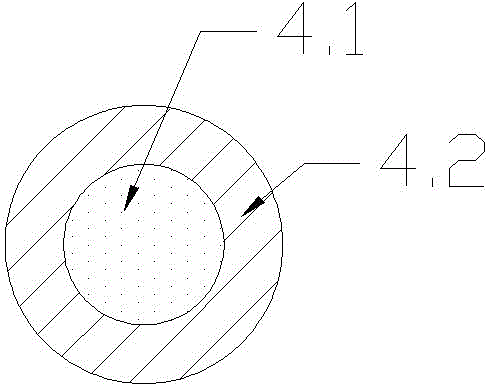

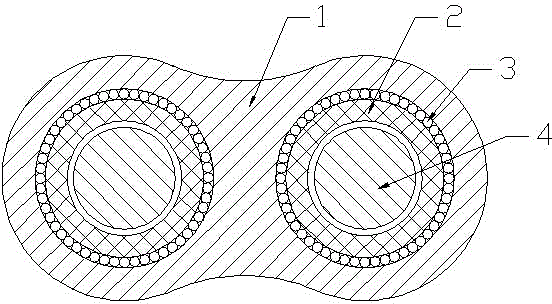

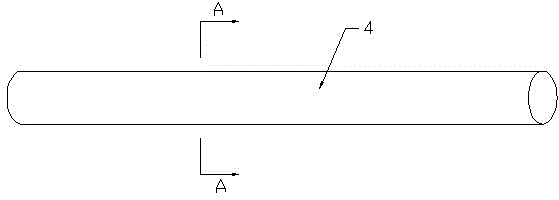

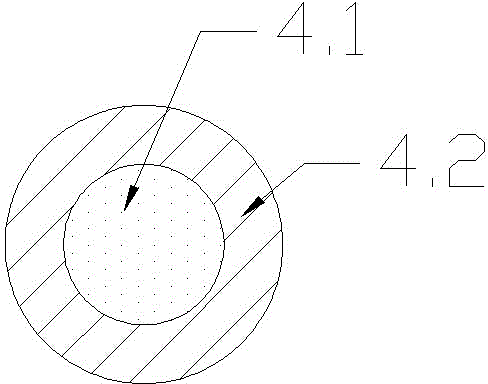

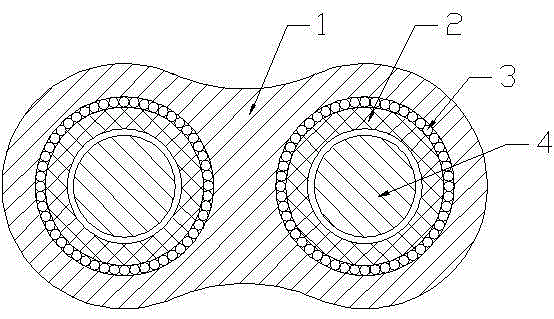

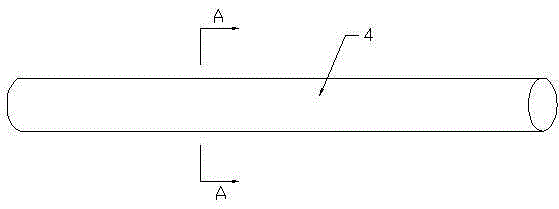

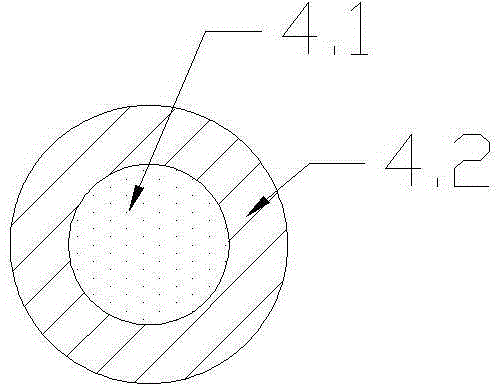

The present invention relates to a wear-resistant brake line which comprises an outer cladding layer (1), two lining tubes (2) side by side disposed in parallel and two metal wire groups (3), a brake line body (4) comprises an inner layer carbon fiber core line group (4.1 ) and an outer layer wear-resistant coating (4.2). The lining tubes can ensure two brake lines are equal in length so as to ensure that two brake line bodies are uniformly forced in braking; the brake line body is simple in molding, light in weight, chemical-resistant, good in weather resistance and low in cost of production; the wear-resistant brake line effectively increases the frictional force and the support force between the lining tubes and the cladding layer, the lining tubes and the cladding layer are less prone to relative sliding, and the used effect of the brake system can be ensured.

Owner:李士清

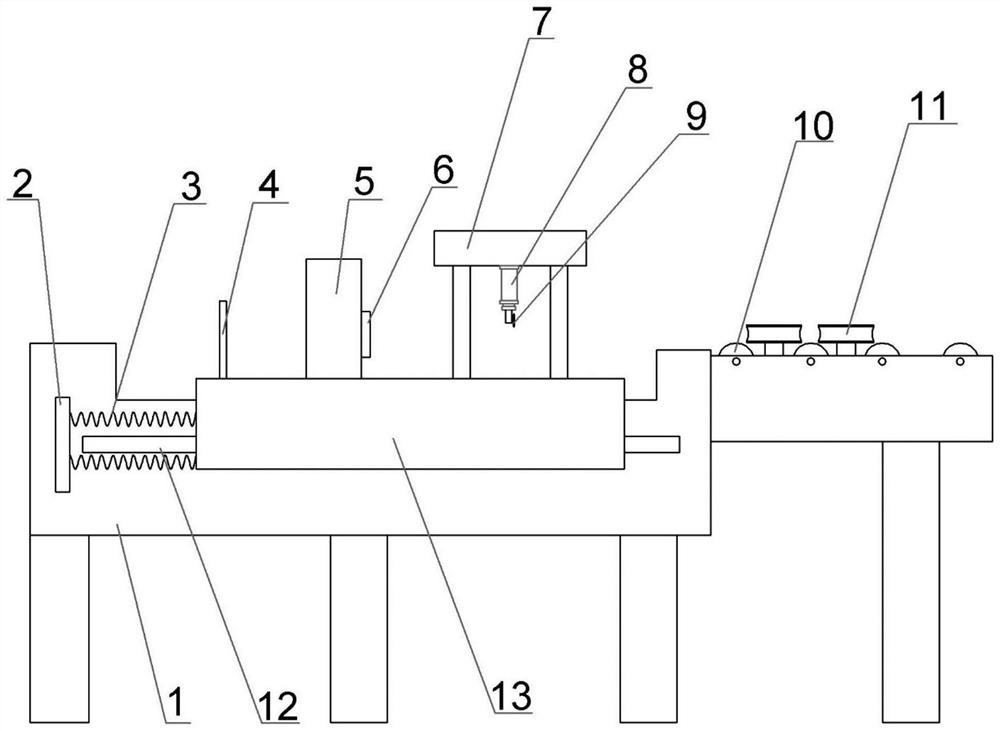

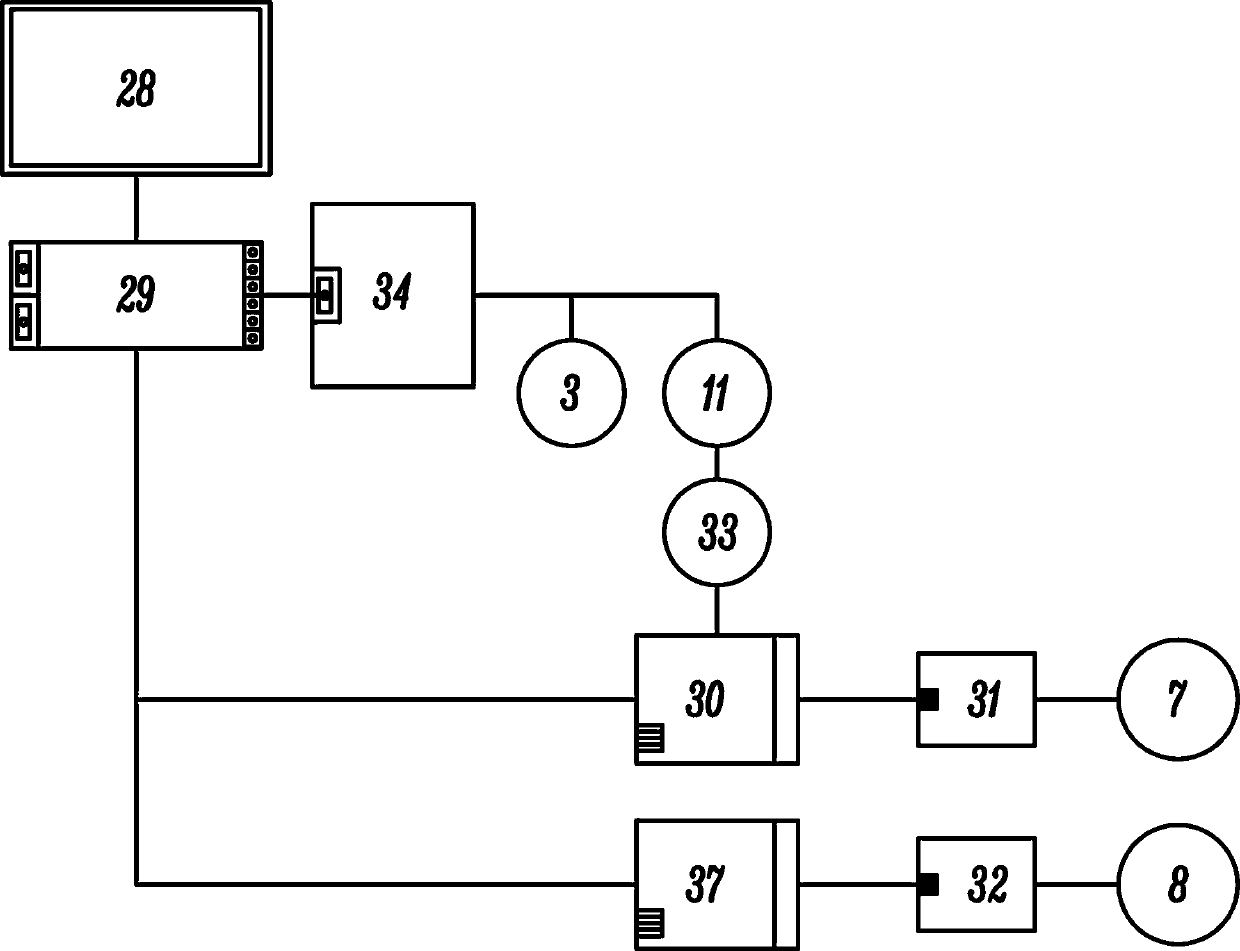

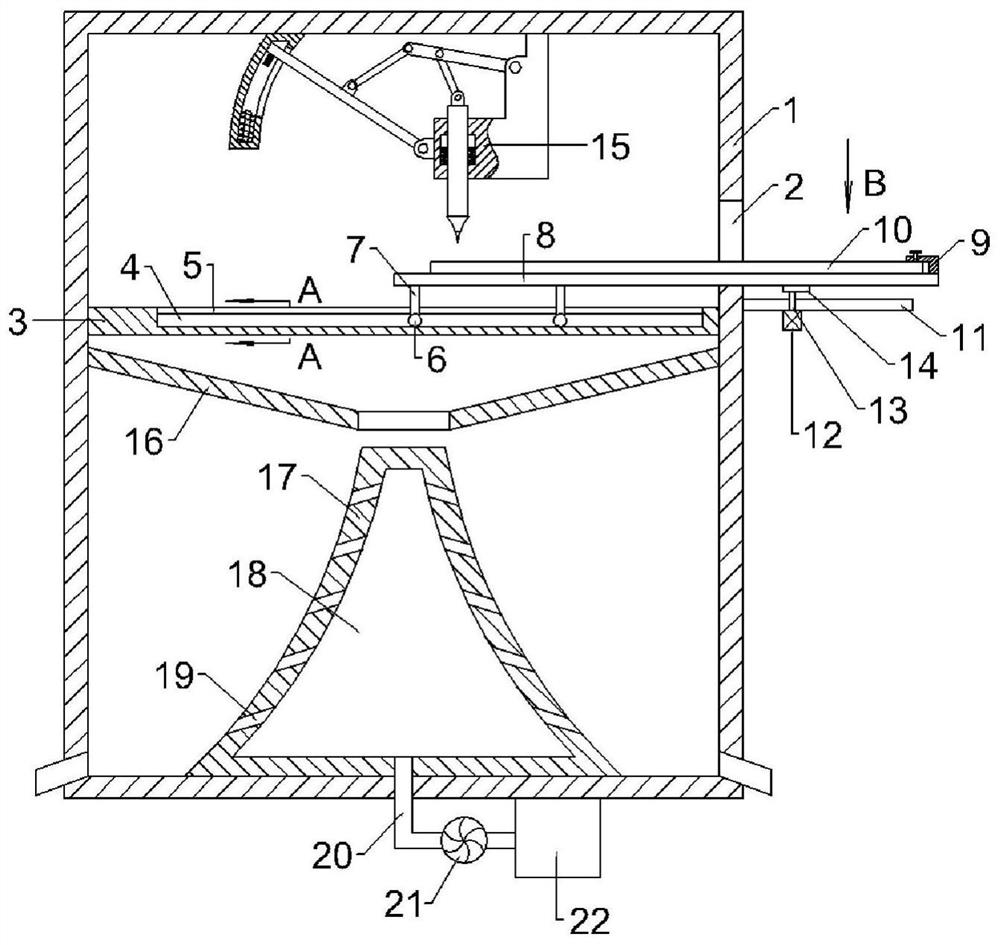

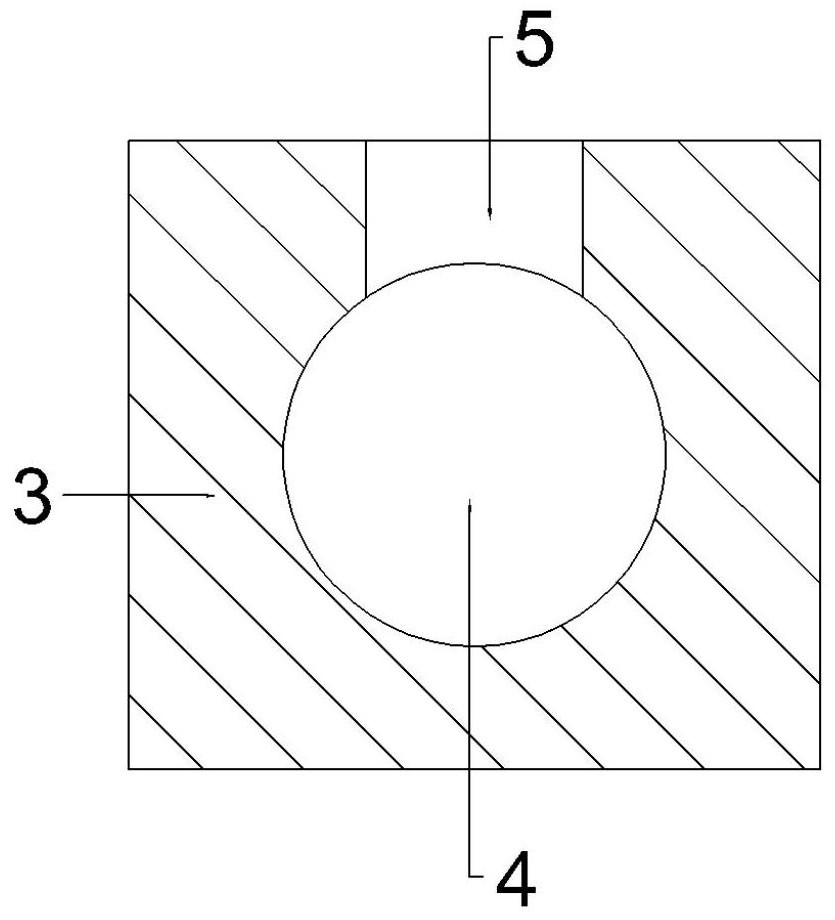

Automobile part cutting device

PendingCN114083037AGuaranteed smoothGuaranteed equal lengthHybrid vehiclesShearing machinesMotor vehicle partStructural engineering

The invention belongs to the technical field of automobile production devices, and particularly discloses an automobile part cutting device which comprises a rack and a cutting structure. A feeding structure is arranged on the rack; and the device further comprises a fixing unit and an elastic connecting piece. The feeding structure is located at one end of the rack, a positioning structure is arranged at the other end of the rack and comprises a positioning support and a positioning plate, the positioning support is slidably connected with the rack, the positioning plate is vertically arranged and fixedly connected with the positioning support, the cutting structure is located on the positioning support, and a triggering unit for triggering the cutting structure is further arranged on the rack. The fixing unit is arranged on the positioning frame and used for fixing the automobile parts. Two ends of the elastic connecting piece are respectively connected with the rack and the positioning frame. When the device is used for cutting the automobile parts, the cut automobile parts can be guaranteed to be equal in length, and the end openings of the cut parts can be guaranteed to be flat.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

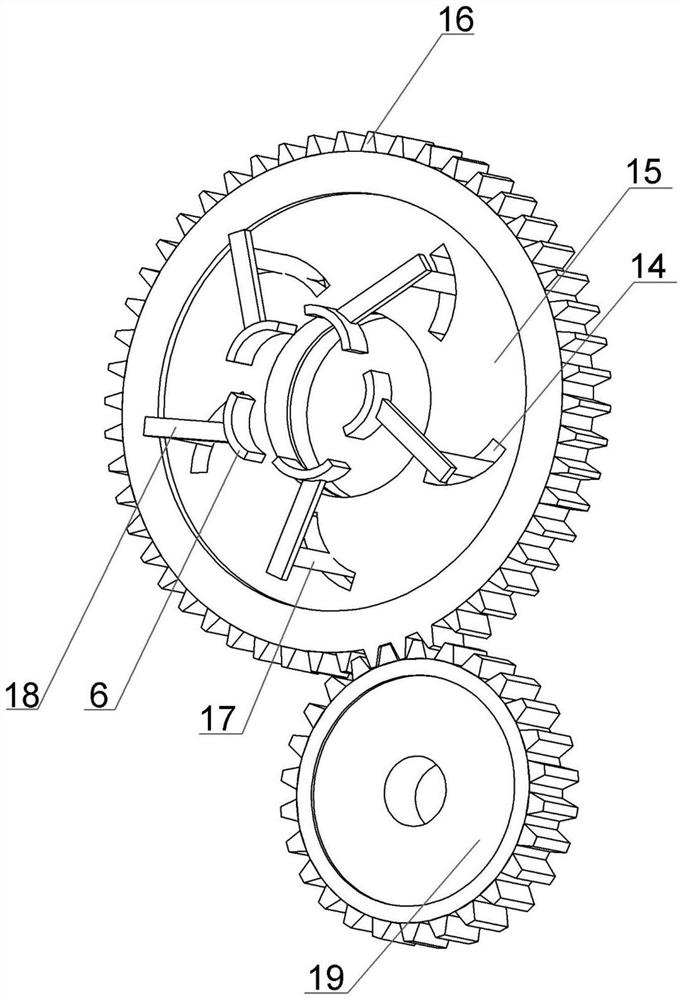

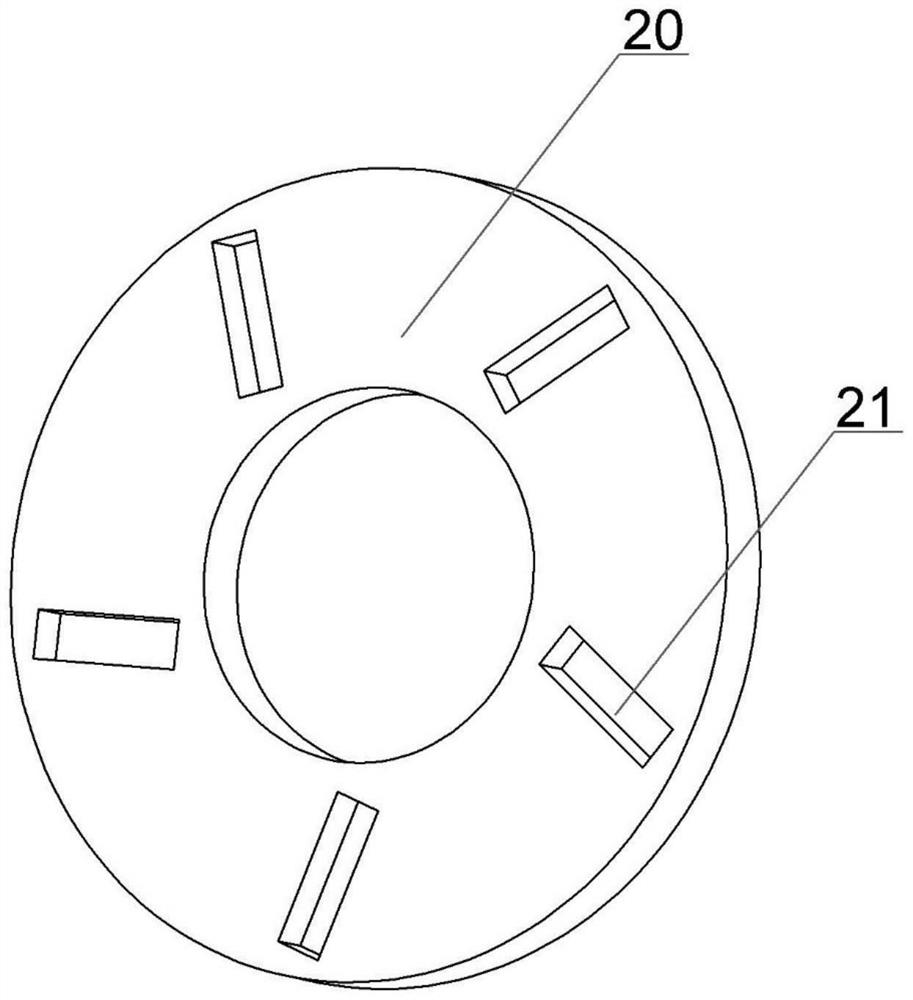

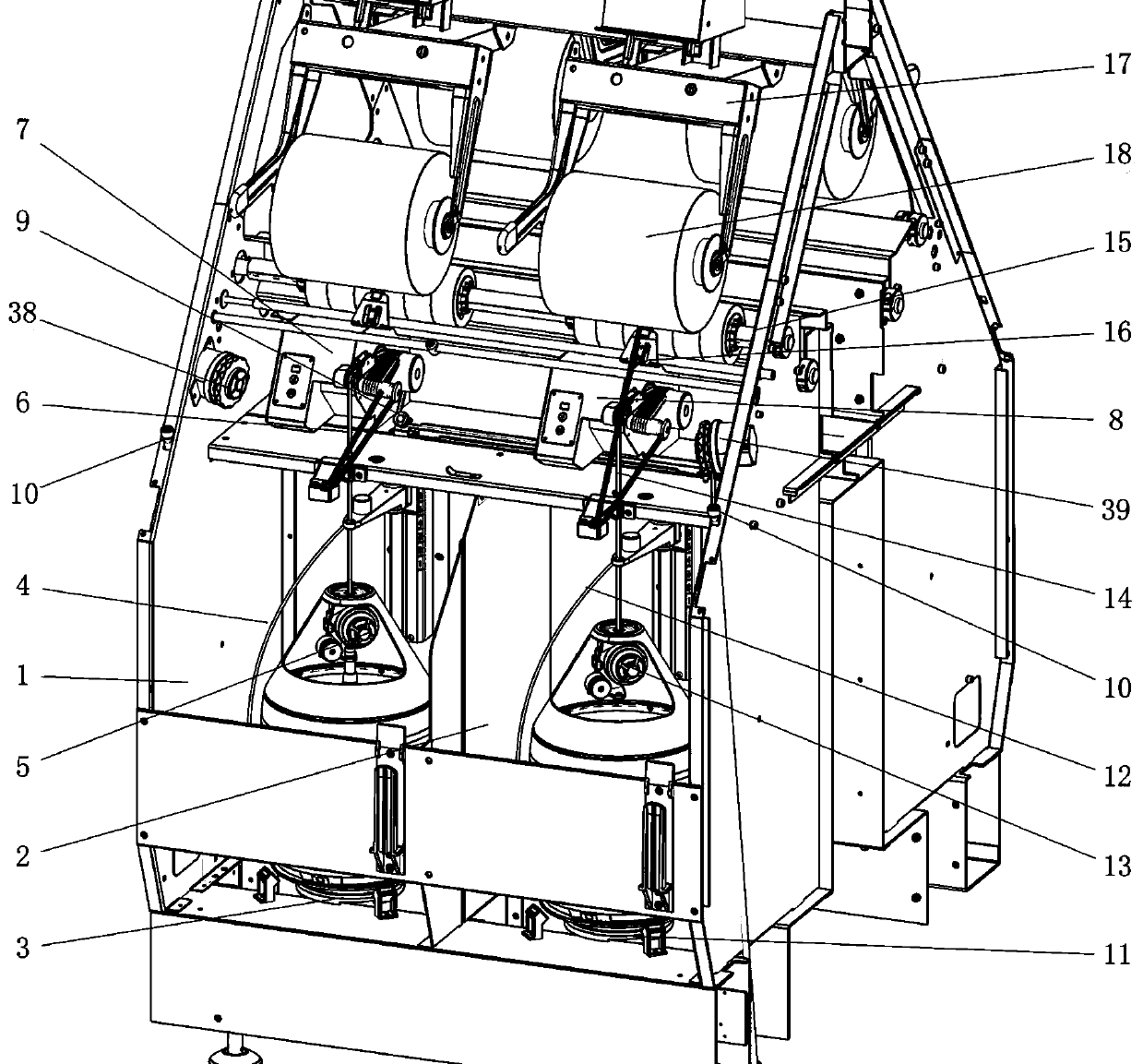

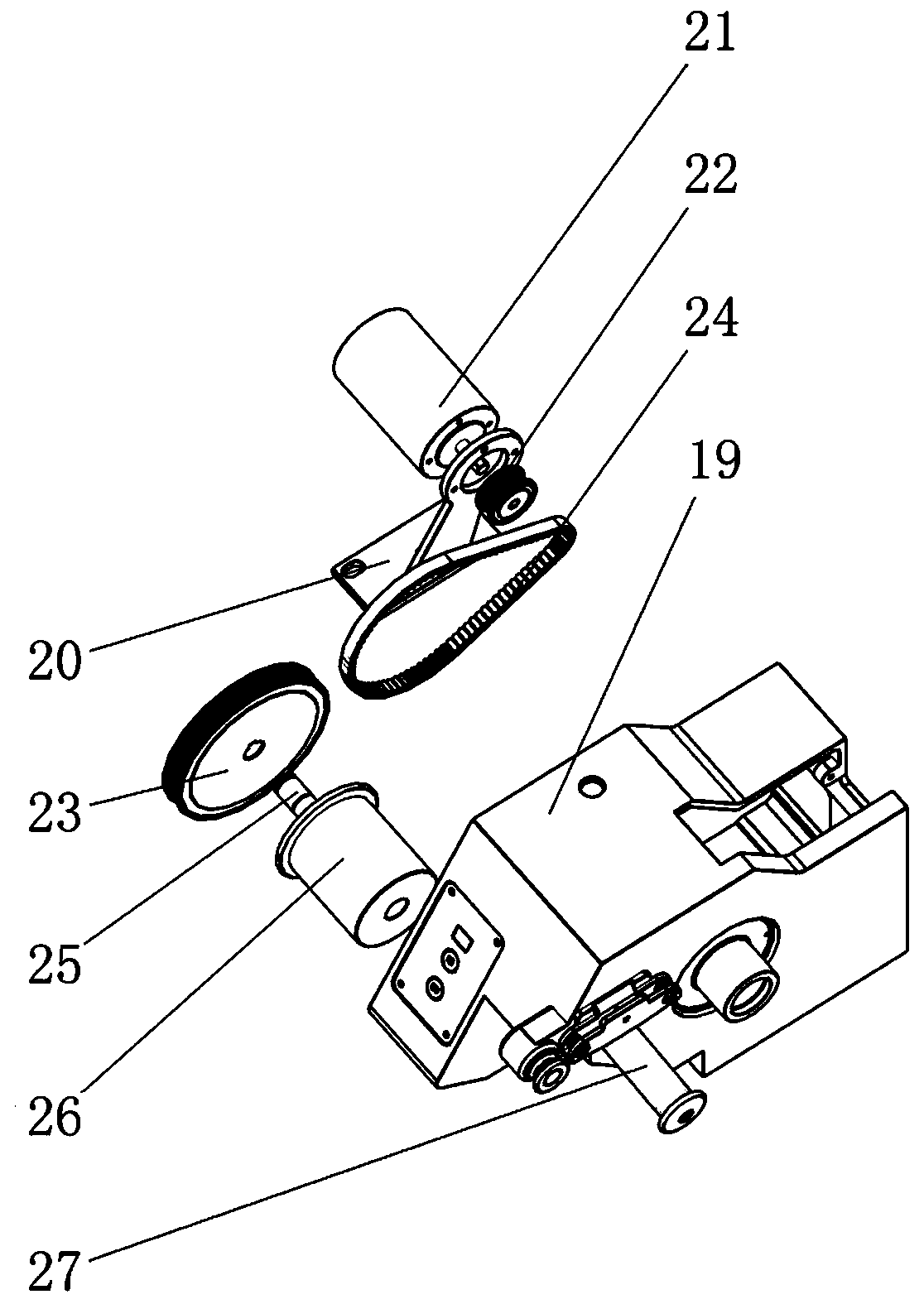

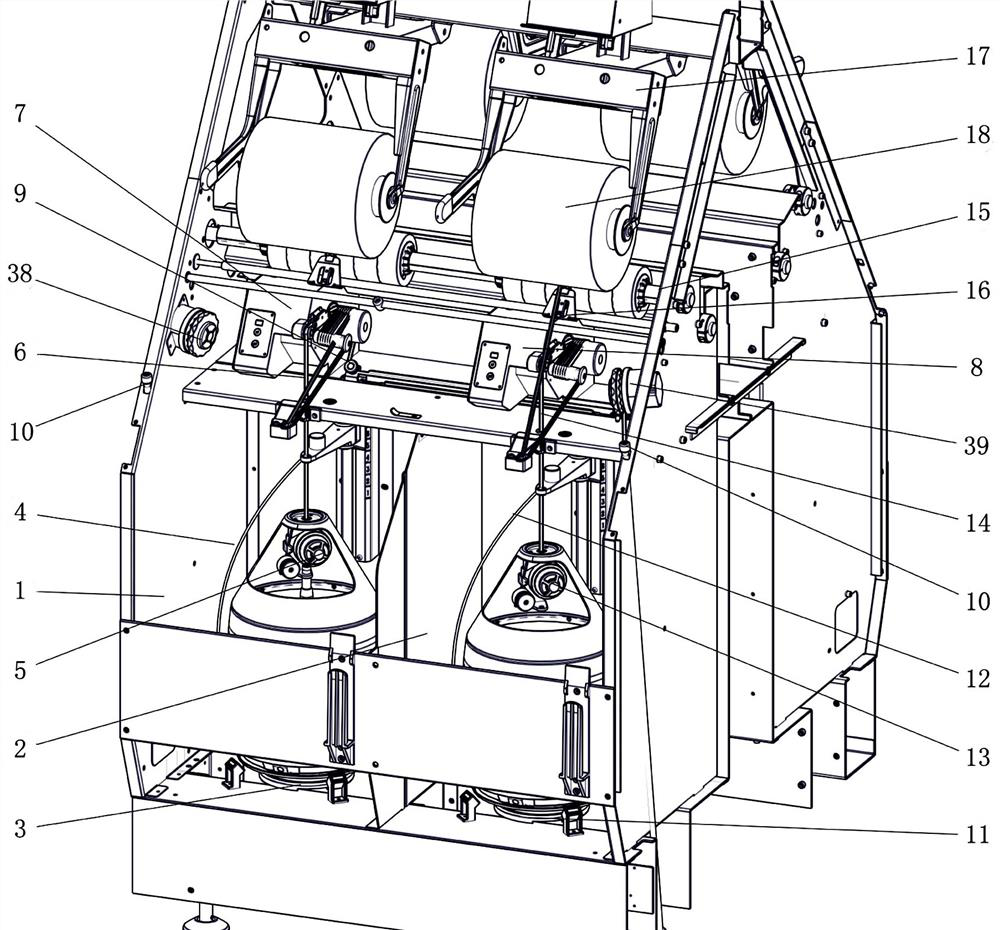

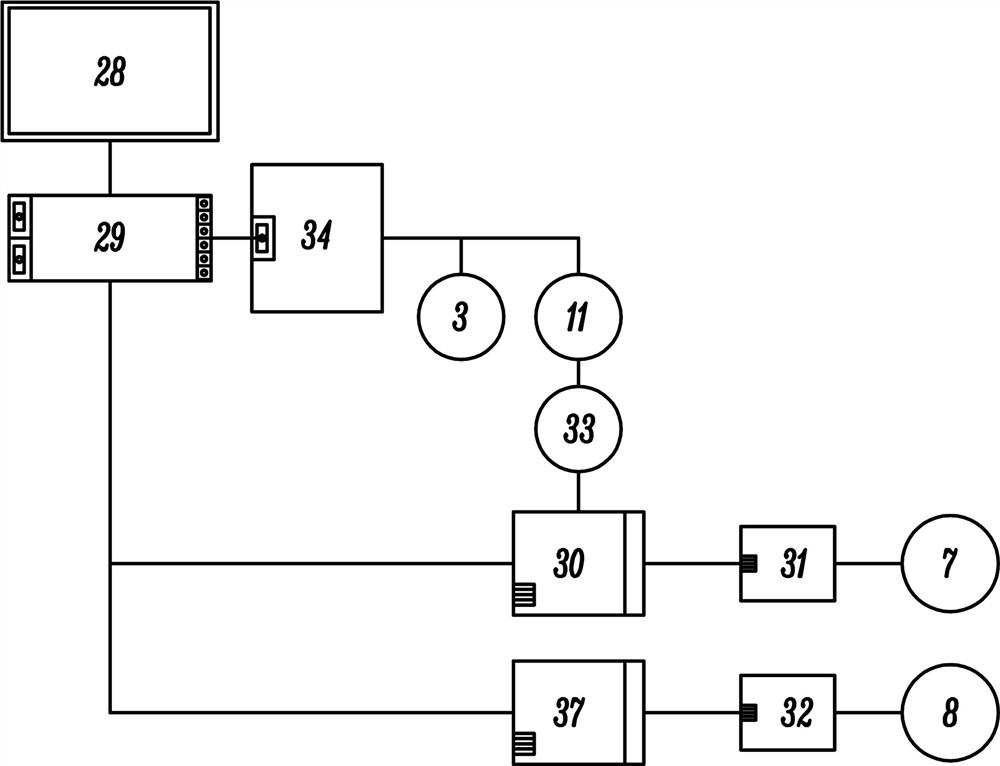

Three-strand direct twisting machine and method for directly twisting three yarns into thread

ActiveCN110552088AAvoid interferenceImprove packaging qualityContinuous wound-up machinesYarnEngineering

The invention provides a three-strand direct twisting machine and a method for directly twisting three yarns into a thread. The three-strand direct twisting machine comprises a two-strand twisting spindle position and a three-strand twisting spindle position, according to the method, two twisting yarns twisted by the two-strand twisting spindle position are wound n circles on a first overfeeding assembly, then conveyed to an outer yarn long pipe of the three-strand twisting spindle position through a yarn guiding device, then conveyed to a three-strand-twisted twisting assembly to form a three-strand-twisted outer yarn air ring, and twisted with a three-strand-twisted inner yarn into a three-strand-twisted yarn, and the three-strand-twisted yarn is conveyed for finished product package; the size of the three-strand-twisted outer yarn air ring is controlled according to the overfeeding speed of the first overfeeding assembly. The three-strand direct twisting machine and the method for directly twisting the three yarns into the thread overcome the interference of the speed of an overfeeding assembly in the prior art to the shape of the three-strand-twisted outer yarn air ring, so that the stable energy-saving small air ring can be obtained; the twisting yarn conveying speed of the first overfeeding assembly and second overfeeding assembly can be independently adjusted to match the winding speed of the three-stranded-twisted yarn to obtain the ideal package density and improve the quality of the finished product package.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

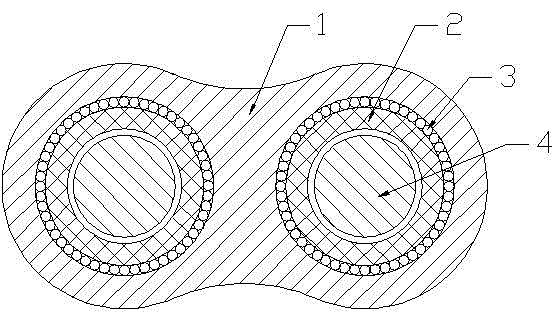

High-strength abrasion-resistant brake cable

InactiveCN104482031AEasy to shapeLight in massBrake actuating mechanismsShaft for linear movementFiberWeather resistance

The invention relates to a high-strength abrasion-resistant brake cable. The abrasion-resistant brake cable comprises an outer cladding layer (1), two inner lining pipes (2) arranged in parallel side by side, and two metal wire sets (3), wherein a brake cable body (4) comprises an inner carbon fiber core wire set layer (4.1) and an outer resin layer (4.2), one end of an outer sleeve (5) is arranged on the outer cladding layer (1), and the other end of the outer sleeve is outwards extended in the axial direction of the outer cladding layer (1) and is arranged on the brake cable body (4). According to the high-strength abrasion-resistant brake cable, the lining pipes can ensure the equal length of the two brake cables, so as to ensure that the two brake cable bodies are stressed uniformly when in braking; meanwhile, the brake cable body can be molded simply, has light weight, and has chemical corrosion resistance and good weather resistance and is low in production cost; the friction force and the supporting force between the lining pipe and the outer cladding layer can be effectively increased, the lining pipe and the outer cladding layer cannot easily slip relatively, the using effect of the braking system is ensured, and the outer sleeve can effectively prevent the end joint of the brake cable from being abraded partially.

Owner:JIANGYIN HENGDA VEHICLES FITTING

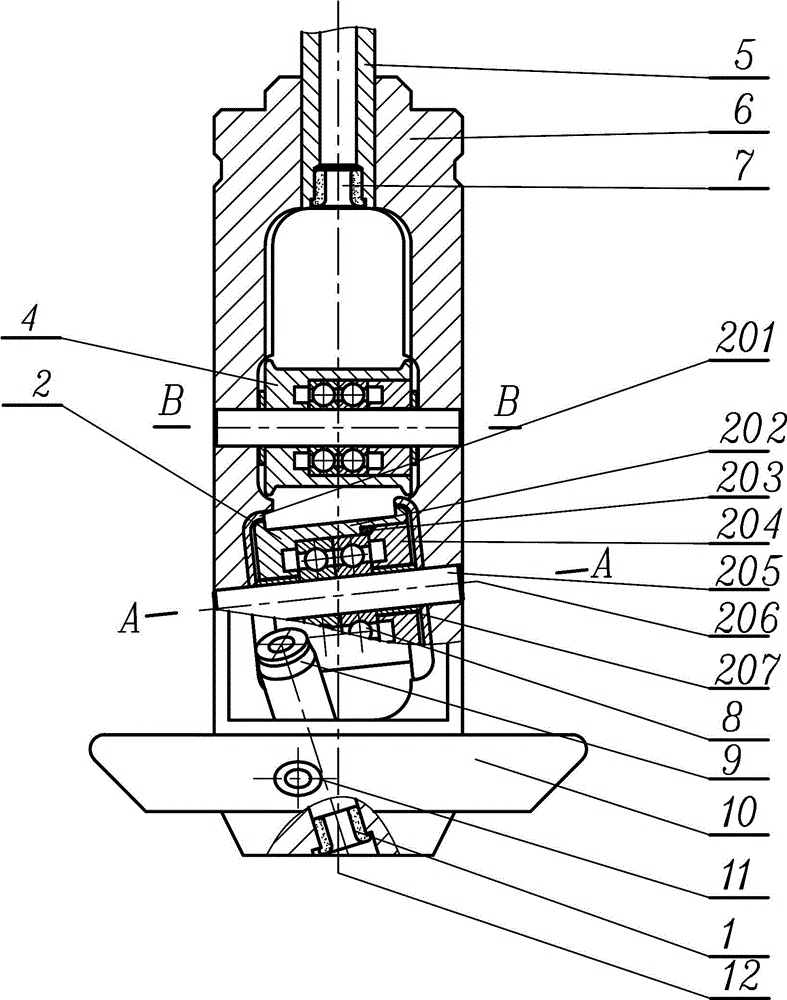

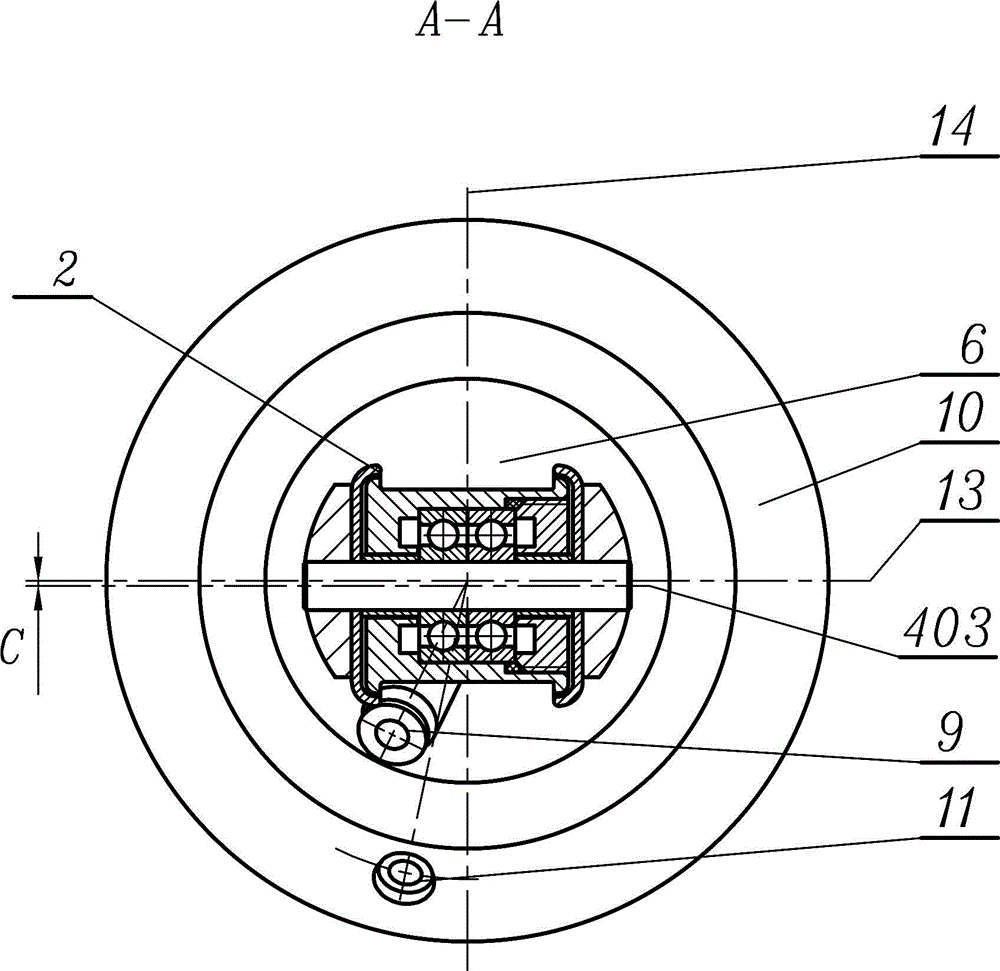

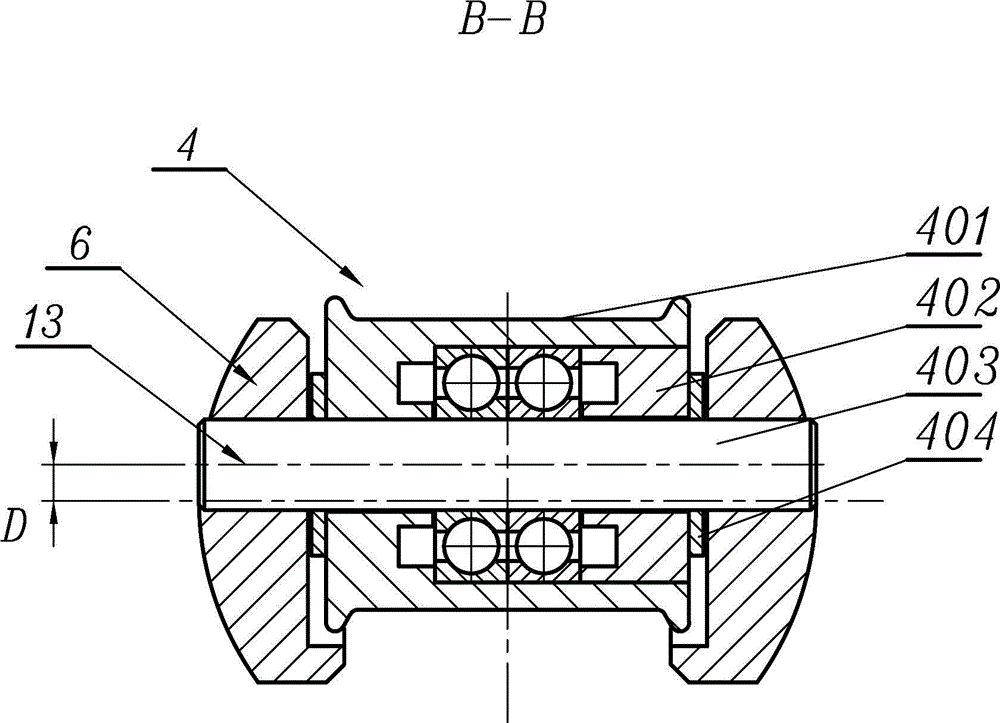

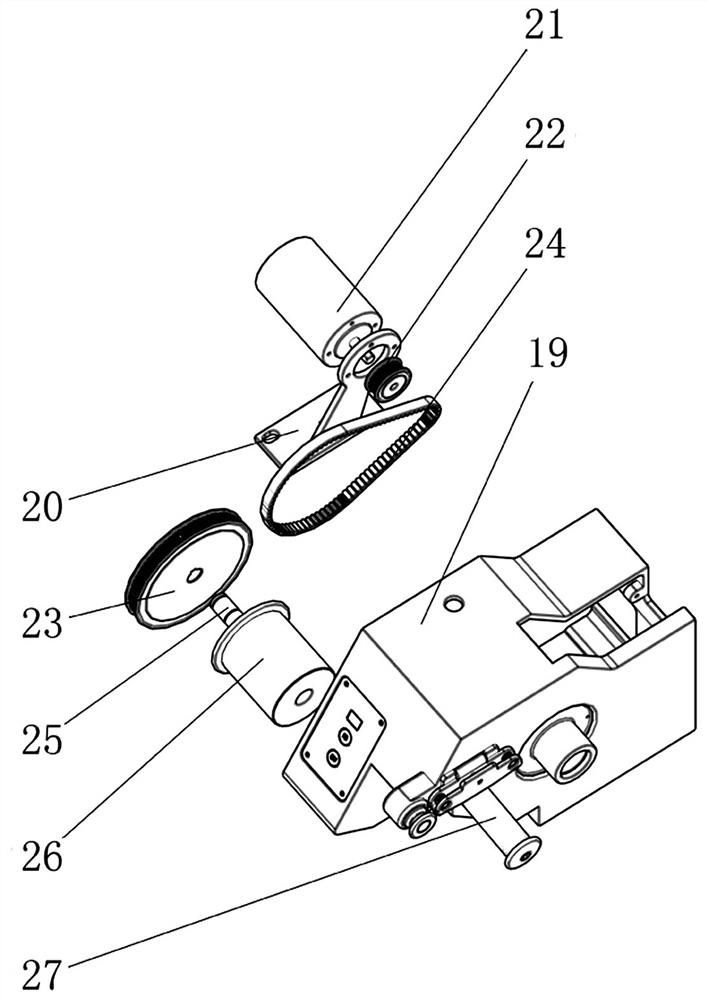

Rotor mechanism of twister

The invention discloses a rotor mechanism of a twister. The upper part of a rotor frame is fixedly connected with a guide chase tube. The lower part of the rotor frame is fixedly connected with a balance disk. The balance disk is provided with a first porcelain ring and the rotor frame is internally provided with a second porcelain ring. The bottom end surface of the rotor frame is provided with a third porcelain ring. A first roller and a second roller are arranged at the hollow part of the rotor frame and are positioned closer to the lower part of the rotor frame. The first roller is positioned below the second roller. The diameter of the first roller is larger than the diameter of the second roller. The axis of the first roller is at an included angle relative to the horizontal plane. According to the technical scheme of the rotor mechanism of the twister, based on a built-in double-roller structure, the inner and outer yarns of two strands of tension fluctuation are wound onto the built-in double-roller structure for multiple cycles, so that the unequal-length difference between the tensions of inner and outer yarns is minimized and unified before the twisting process. Therefore, after the stranding process, the unequal-length difference between inner and outer yarns becomes smaller.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

Antioxidative brake cable with good braking effect

InactiveCN104948566AGood weather resistanceEasy to shapeBrake actuating mechanismsShaft for linear movementFiberCarbon fibers

The invention relates to an antioxidative brake cable with a good braking effect, which comprises an outer cladding layer (1), two inner lining pipes (2) which are arranged in parallel side by side, and two metal wire groups (3), wherein each brake cable body (4) comprises an inner layer carbon fiber core wire group (4.1) and an outer layer resin layer (4.2); one end of each outer sleeve pipe (5) is arranged on the outer cladding layer (1); the other end of each outer sleeve pipe extends outwards along the axial direction of the outer cladding layer (1) and is arranged on the corresponding brake cable body (1); and the surface of the outer cladding layer (1) is coated with an antioxidative coating. The antioxidative brake cable with the good braking effect has the advantages that the molding is simple; the mass is light; chemical corrosion resistance and weather resistance are good; the production cost is low; the stresses of the brake cable bodies are uniform; and since the surface of the outer cladding layer is coated with the antioxidative coating, the normal use of the brake cable is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

High-strength brake cable

InactiveCN104358773AGuaranteed equal lengthEven by forceShaft for linear movementCycle brakesFiberCarbon fibers

The invention relates to a high-strength brake cable which comprises an outer cladding layer (1), two side-by-side parallel lining tubes (2) and two metal wire groups (3), wherein each brake cable body (4) comprises a carbon fiber core wire group (4.1) on the inner layer and a resin layer (4.2) on the outer layer; one end of an outer sleeve (5) is arranged on the outer cladding layer (1); the other end of the outer sleeve (5) extends outwards along the outer cladding layer (1) axially and is arranged on a corresponding brake cable body (4). The high-strength brake cable has the advantages that due to the adoption of the lining tubes, the two brake cable bodies are equal in length, so as to be uniform in stress during braking; moreover, the brake cable bodies are simple to form, light in weight, high in chemical resistance and weather resistance, and low in production cost; according to the brake cable, the friction force and support force between the lining tubes and the outer cladding layer are effectively increased, so that the lining tubes and the outer cladding layer cannot slide easily relative to each other to ensure the using effect of a brake system; the outer sleeves can effectively prevent abrasion of end joint parts of the brake cable.

Owner:JIANGYIN HENGDA VEHICLES FITTING

High-strength wear-resistant brake cable

InactiveCN104912904AEven by forceSimple moldingShaft for linear movementCycle brakesWeather resistanceWear resistant

The invention relates to a high-strength wear-resistant brake cable. The brake cable comprises an outer covering layer (1), two lining pipes (2) which are arranged in parallel side by side, and two metal wire groups (3); each brake cable body (4) comprises a carbon fiber core wire group (4.1) in an inner layer and a resin layer (4.2) in an outer layer; one end of each outer casing pipe (5) is arranged on the outer covering layer (1), and the other end of each outer casing pipe (5) extends outwards along the axial direction of the outer covering layer (1) and is arranged on the corresponding brake cable body (4); the end part of each brake cable body (4) is provided with an annular belt (6), and the surface of the outer covering layer (1) is coated with a wear-resistant coating layer. The high-strength wear-resistant brake cable has the advantages of simple forming, light weight, chemical corrosion resistance, good weather resistance, wear resistance, low cost of production, uniform stress of the brake cable bodies, and safe driving.

Owner:JIANGYIN HENGDA VEHICLES FITTING

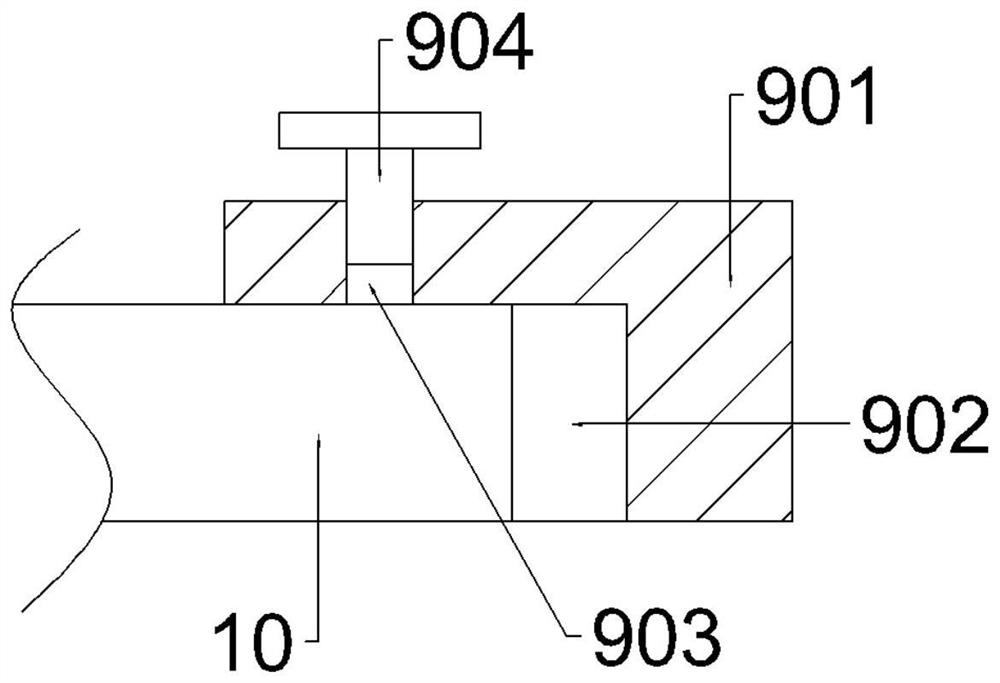

A device for processing medicinal materials based on the principle of intermittent equidistant feeding

ActiveCN110154102BAchieve fixationGuaranteed equal lengthDrying gas arrangementsMetal working apparatusMedicinal herbsStructural engineering

The invention provides a device for processing medicinal materials based on the principle of intermittent equidistant feeding, which includes a casing, an opening is opened on the right side wall of the casing, and a long support column is fixedly connected inside the casing, There is a supporting cavity inside the elongated supporting column, and a moving channel is opened on the elongated supporting column on the upper side of the supporting cavity. Two supporting balls are arranged inside the supporting cavity, and the upper side of the supporting ball is fixed. A ball bracket is connected, the ball bracket extends upward through the moving channel, the tops of the two ball brackets are fixedly connected with a mobile bearing plate, the mobile bearing plate extends through the opening toward the outside of the casing, the right end of the mobile bearing plate The fixed connection has a fixing piece. The present invention has the following beneficial effects: first, the right part of the medicinal material is located in the clamping groove, and then the screw knob is turned, and the spiral knob moves downward and clamps the medicinal material, thereby realizing the fixing of the medicinal material, and the medicinal material will move with the carrying plate Exercise together.

Owner:黑龙江福久堂中药饮片有限责任公司

High-temperature-resistant braking device for bicycle

InactiveCN105526239AEasy to shapeLight in massShaft for linear movementCycle brakesFiberCarbon fibers

The invention relates to a high-temperature-resistant braking device for a bicycle. The high-temperature-resistant braking device comprises an outer coating layer (1), two inner liner pipes (2) which are in parallel arranged side by side and two metal wire sets (3), wherein each brake cable body (4) comprises a carbon fiber core set (4.1) in an inner layer and a resin layer (4.2) in an outer layer; an endless loop built belt (5) is arranged at the end parts of the brake cable bodies (4); a high-temperature-resistant coating is arranged on the surface of the outer coating layer (1). According to the high-temperature-resistant braking device for the bicycle, disclosed by the invention, the inner liner pipes are arranged, so that the situation that the two brake cables are in the same length is guaranteed, and the situation that the two brake cable bodies are uniformly stressed when the bicycle is braked is guaranteed; besides, the brake cable body is simple to form, light in weight, high in chemical resistance, high in weather resistance, low in production cost and high in the safety of the brake cable; the high-temperature-resistant coating is arranged on the surface of the outer coating layer, so that the brake cable is effectively protected, and the normal use of the brake cable is guaranteed.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Anti-oxidation brake cable high in strength

InactiveCN105020245AEasy to shapeLight in massShaft for linear movementCycle brakesFiberCarbon fibers

The invention relates to an anti-oxidation brake cable high in strength. The anti-oxidation brake cable comprises a wrapping layer (1), two parallel liner pipes (2) arranged side by side and two metal wire sets (3). A brake cable body (4) comprises an inner carbon fiber core wire set (4.1) and an outer resin layer (4.2). One end of an outer sleeve pipe (5) is arranged on the wrapping layer (1), and the other end of the outer sleeve pipe (5) extends outwards in the axial direction of the wrapping layer (1) and is arranged on the brake cable body (4). An annular belt (6) is arranged at one end of the brake cable body (4), and the surface of the wrapping layer (1) is coated with an anti-oxidation coating. The anti-oxidation brake cable high in strength is easy to form, low in weight, resistant to chemical corrosion, good in weather fastness and low in production cost and enables running to be safe, and the brake cable body is evenly stressed; the surface of the wrapping layer is provided with the anti-oxidation coating, and normal use of the brake cable is guaranteed.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Cable harness vulcanization method

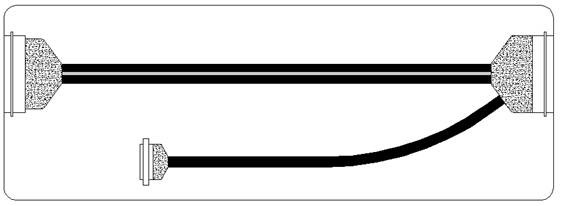

ActiveCN112109248BAvoid bendingSolve the problem of vulcanization eccentricityDomestic articlesVulcanizationEngineering

The invention discloses a vulcanization method for a cable harness. First, the vulcanized rubber is coated on a steel rod for heating and vulcanization, and the heating is stopped when the complete vulcanization state is not reached. The sleeve is peeled off from the steel rod, and finally the vulcanized sleeve is put on the cable harness and heated to complete the vulcanization. The invention can solve the problems of uneven encapsulation and uneven stress and deformation of the wire harness, and completely solves the problem of the vulcanization eccentricity of the cable wire harness from the technological method.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Antiseptic and fireproof brake cable good in braking effect

InactiveCN105351342AGuaranteed equal lengthEven by forceRoad vehiclesShaft for linear movementFiberWeather resistance

The invention relates to an antiseptic and fireproof brake cable good in braking effect. The antiseptic and fireproof brake cable comprises a wrapping layer (1), two liner tubes (2) arranged in parallel side by side, and two metal wire sets (3). Brake cable bodies (4) comprise carbon fiber core wire sets (4.1) on the inner layers and resin layers (4.2) on the outer layers. One ends of outer casing pipes (5) are arranged on the wrapping layer (1), and the other ends of the outer casing pipes (5) extend outwards in the axial direction of the wrapping layer (1) and are arranged on the brake cable bodies (4). An antiseptic and fireproof coating is arranged on the surface of the wrapping layer (1). The antiseptic and fireproof brake cable good in braking effect is easy to form, low in mass, resistant to chemical corrosion, good in weather resistance, low in production cost and even in stress of the brake cable bodies. The antiseptic and fireproof coating is arranged on the surface of the wrapping layer, and therefore the brake cable is effectively protected, and normal use of the brake cable is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Brake cable

InactiveCN104369829AEasy to shapeLight in massShaft for linear movementCycle brakesFiberWeather resistance

The invention relates to a brake cable. The brake cable comprises an outer packaging layer (1), two parallel lining pipes (2) which are arranged side by side and two metal wire sets (3); a brake cable body (4) comprises a carbon fiber core wire set (4.1) on the inner layer and a resin layer (4.2) on the outer layer; according to the brake cable, the lining pipes ensure that two brake cable bodies are equal in length; and it is ensured that in the brake process, the two brake cable bodies are evenly stressed; meanwhile, the brake cable bodies are easy to form, light, resistant to chemical corrosion, good in weather resistance, and low in production cost. According to the brake cable, friction force and supporting force between the lining pipes and the outer packaging layer can be effectively increased; relative sliding is not prone to happening to the lining pipes and the outer packaging layer; and the use effect of a brake system is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Corrosion-resisting brake line high in strength

InactiveCN104948563AGuaranteed equal lengthEven by forceShaft for linear movementCycle brakesFiberSurface layer

The invention relates to a corrosion-resisting brake line high in strength. The brake line comprises an outer cladding (1), two liner pipes (2) which are arranged in parallel in a side-by-side manner and two metal wire sets (3), and a brake line body (4) comprises a carbon fiber core wire set (4.1) of an inner layer and a resin layer (4.2) on an outer layer; one end of an outer casing pipe (5) is arranged on the outer cladding (1), and the other end of the outer casing pipe (5) extends outwards in the axial direction of the outer cladding (1) and is arranged on the brake line body (4); an annular belt (6) is arranged at the end of the brake line body (4), and the surface of the outer cladding (1) is coated with an anti-corrosion layer; and the anti-corrosion layer comprises a binding bottom layer and an anti-corrosion surface layer. According to the corrosion-resisting brake line high in strength, the brake line body is uniform in stress; meanwhile, the brake line body is simple to form, light in mass, resistant to chemical corrosion, good in weather fastness, low in production cost and high in safety; and the brake line effectively resists corrosion, and the service life of the brake line is prolonged.

Owner:JIANGYIN HENGDA VEHICLES FITTING

High-strength weather-proof brake cable

InactiveCN104389889AEasy to shapeLight in massBrake actuating mechanismsShaft for linear movementFiberCarbon fibers

The invention relates to a high-strength weather-proof brake cable. The high-strength weather-proof brake cable comprises an outer cladding layer (1), two lining pipes (2) arranged in parallel side by side and two metal wire groups (3), wherein each brake cable body (4) comprises an inner carbon fiber core cable group (4.1) and an outer resin layer (4.2); one end of an outer sheath pipe (5) is arranged on the outer cladding layer (1); the other end of the outer sheath pipe (5) axially extends outwards and is arranged on each brake cable body (4); an annular belt (6) is arranged at the end of each brake cable body (4). According to the high-strength weather-proof brake cable, two brake cable bodies are uniformly stressed during braking; meanwhile, the brake cable bodies are simple to mold, light in mass, chemical corrosion-resistant, high in weather resistance and low in production cost; the lining pipe and the outer cladding layer of the brake cable has small possibility of sliding relative to each other, so that the use effect of a brake system is ensured; the outer sheath pipe can be used for effectively protecting the abrasion of a connector part of the end of the brake cable; the riding safety is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Abrasion-resistant brake cable

InactiveCN105626668AEasy to shapeLight in massBrake actuating mechanismsShaft for linear movementFiberCarbon fibers

The invention relates to an abrasion-resistant brake cable. The abrasion-resistant brake cable comprises an outer covering layer (1), two lining pipes (2) and two metal wire sets (3), wherein the two lining pipes (2) are arranged side by side and in parallel. Each brake cable body (4) comprises a carbon fiber core wire set (4.1) on the inner layer and a resin layer (4.2) on the outer layer. An annular belt (5) is arranged at the end of each brake cable body (4). According to the abrasion-resistant brake cable, the effect that the two brake cable bodies (4) are as long as each other is guaranteed through the lining pipes, and thus the effect that the stress of the two brake cable bodies is uniform during braking is guaranteed; meanwhile, the brake cable bodies are easy to form, low in weight, resistant to chemical corrosion, good in weather resistance and low in production cost; the friction force and supporting force between the lining pipes and the outer covering layer of the brake cable are effectively increased, relative sliding between the lining pipes and the outer covering layer is unlikely to happen, and the using effect of a brake system is guaranteed; the annular belts at the ends of the brake cable bodies are used for fixing the brake cable bodies to a handle, so that the brake cable is prevented from being separated from the handle, and the traveling safety is guaranteed.

Owner:李士清

High-strength anti-corrosion fireproof brake cable

InactiveCN105202005AEasy to shapeLight in massBrake actuating mechanismsShaft for linear movementFiberCarbon fibers

The invention relates to a high-strength anti-corrosion fireproof brake cable including an outer wrapping layer (1), two parallel lining pipes (2) which are arranged side by side, and two metal wire sets (3); each brake cable body (4) comprises a carbon fiber core wire set (4.1) on the inner layer and a resin layer (4.2) on the outer layer; one end of an outer casing pipe (5) is arranged on the outer wrapping layer (1), the other end of the outer casing pipe (5) extends outwards along the axial direction of the outer wrapping layer (1) and is arranged on the brake cable bodies (4); an annular belt (6) is arranged at the end part of each brake cable body (4), and the surface of the outer wrapping layer (1) is provided with a anti-corrosion fireproof coating layer. The high-strength anti-corrosion fireproof brake cable has the advantages of simple molding, light mass, chemical corrosion resistance, good weather resistance, low production cost, and safe driving, and allows the brake cable bodies to be uniform in stress; the surface of the outer wrapping layer is provided with the anti-corrosion fireproof coating layer, so that the brake cable is effectively protected, and the normal use of the brake cable is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Weather-proof brake cable

InactiveCN104482030AGuaranteed equal lengthEven by forceBrake actuating mechanismsShaft for linear movementFiberWeather resistance

The invention relates to a weather-proof brake cable. The weather-proof brake cable comprises an outer cladding layer (1), two inner lining pipes (2) arranged in parallel side by side, and two metal wire sets (3), wherein a brake cable body (4) comprises an inner carbon fiber core wire set layer (4.1) and an outer resin layer (4.2), and the end part of the brake cable body (4) is provided with a ring-shaped belt (5). According to the weather-proof brake cable, the lining pipes can ensure the equal length of the two brake cables, so as to ensure that the two brake cable bodies are stressed uniformly when in braking; meanwhile, the brake cable body can be molded simply, has light weight, and has chemical corrosion resistance and good weather resistance and is low in production cost; the friction force and the supporting force between the lining pipe and the outer cladding layer can be effectively increased, the lining pipe and the outer cladding layer cannot easily slip relatively, the using effect of the braking system is ensured, the ring-shaped belt at the end part of the brake cable body is used for fixing the brake cable body and a handle, the brake cable cannot be separated from the handle, and the traffic safety is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Brake device of bicycle

The invention relates to a brake device of a bicycle. The brake device of the bicycle comprises an outer cladding layer (1), two lining pipes (2) which are arranged side by side in parallel and two metal wire groups (3). Each brake cable body (4) comprises a carbon fiber core wire group (4.1) at the inner layer and a resin layer (4.2) at the outer layer. An endless belt (5) is arranged at the end portion of each brake cable body (4). An oxidation resistant coating is coated on the surface of the outer cladding layer (1). According to the brake device of the bicycle, the two brake cable bodies are guaranteed to be in same length through the lining pipes, and the two brake cable bodies are guaranteed to be balance in stress; at the same time, the brake cable bodies are simple in molding, light in mass, resistant to chemical attack, good in weather fastness, low in production cost, good in brake effect and high in the security of the brake cables; the oxidation resistant coating is coated on the surface of the outer cladding layer, and the normal use of the brake cables is guaranteed.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Cable harness vulcanization method

ActiveCN112109248ASolve uneven laggingSolve vulcanization eccentricityDomestic articlesComposite materialMechanical engineering

The invention discloses a cable harness vulcanization method. The cable harness vulcanization method comprises the following steps of that vulcanized rubber is coated on a steel bar, heating and vulcanizing are carried out, heating is stopped when a complete vulcanization state is not reached, the vulcanized rubber forms an under-vulcanized sleeve pipe on the surface of the steel bar, the under-vulcanized sleeve pipe is cut off and stripped from the steel bar, finally, the vulcanized sleeve pipe sleeves a cable harness, and heating is carried out to finish vulcanization. According to the cableharness vulcanization method, the problems of non-uniform rubber coating and non-uniform stress deformation of wire harness can be solved, and the problem of vulcanization eccentricity of the cable wire harness is thoroughly solved from the aspect of a process method.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

High-strength brake cable

InactiveCN104358771AEasy to shapeLight in massShaft for linear movementCycle brakesFiberWeather resistance

The invention relates to a high-strength brake cable which comprises an outer wrapping layer (1), two parallel lining pipes (2) and two metal wire sets (3); each brake cable body (4) comprises an inner carbon fiber core wire set (4.1) and an outer resin layer (4.2); one end of an outer sleeve pipe (5) is arranged on the outer wrapping layer (1), and the other end of the outer sleeve pipe axially extends outwards along the outer wrapping layer (1) and is arranged on the brake cable body (4); an annular belt (6) is arranged at the end part of the brake cable body (4). According to the high-strength brake cable, two brake cable bodies are uniformly stressed and are easy to form, light in weight, resistant to chemical corrosion, good in weather resistance and low in production cost; the lining pipes and the outer wrapping layer of the brake cable are difficult to slide relatively, so that the use effect of a brake system is guaranteed; the outer sleeve pipe is capable of effectively protecting a connector part at the end part of the brake cable from being worn, thereby guaranteeing the driving safety.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Three-strand straight twisting machine and three-strand yarn directly twisted into wire method

ActiveCN110552088BAvoid interferenceImprove packaging qualityContinuous wound-up machinesYarnEngineering

The invention provides a three-ply direct twisting machine and a method for directly twisting three-ply filaments into a thread, including two-ply twisting spindles and three-ply twisting spindles, and the two-ply twisted yarn twisted by the two-ply twisting spindles is fed in the first overfeed After the component is wound n times, it is transported to the long outer yarn tube of the three-ply twisting spindle through the wire guide device, and then transported to the three-ply twisting assembly to form a three-ply twist outer yarn balloon, which is twisted with the three-ply twist inner yarn to form a three-ply twist yarn , conveyed to the finished package; at the overfeed speed of the first overfeed assembly, the size of the three-ply twisted outer yarn balloon is controlled. The invention overcomes the interference of the speed of the overfeeding assembly in the prior art on the shape of the three-ply twisted outer yarn balloon, can obtain a stable energy-saving small balloon, and the speed of the twisted yarn conveyed by the first overfeeding assembly and the second overfeeding assembly It can be independently adjusted to match the winding speed of the three-ply twisted yarn to obtain the ideal package density and improve the quality of the finished package.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

Anticorrosive bicycle brake apparatus

InactiveCN105065424AEasy to shapeLight in massMolten spray coatingShaft for linear movementFiberSurface layer

The invention relates to an anticorrosive bicycle brake apparatus. The apparatus comprises an outer cladding (1), two liner tubes (2) arranged in parallel and side by side, and two metal wire groups (3), each of brake cable bodies (4) comprises a carbon fiber core cable group (4.1) as an inner layer and a resin layer (4.2) as an outer layer, the end portion of each of the brake cable bodies (4) is provided with an annular belt (5), the surface of the outer cladding (1) is coated with an anticorrosive layer, and the anticorrosive layer comprises a bonding bottom layer and an anticorrosive surface layer. The anticorrosive bicycle brake apparatus has the advantages of simple molding, light weight, chemical corrosion resistance, good weatherability, low production cost and high safety; the force bearing of the two brake cable bodies is uniform in the brake process; sliding of liner tubes relative to the outer cladding is difficult, so the use effect of a brake system is guaranteed; and brake cables can effectively resist corrosion, so the service life is prolonged.

Owner:JIANGYIN HENGDA VEHICLES FITTING

High-temperature-resistant brake cable with good brake effect

The invention relates to a high-temperature-resistant brake cable with a good brake effect. The high-temperature-resistant brake cable comprises an outer cladding (1), two lining tubes (2) and two metal wire groups (3), wherein the two lining tubes (2) are arranged side by side and in parallel; a brake cable body (4) comprises a carbon fiber core wire group (4.1) serving as an inner layer and a resin layer (4.2) serving as an outer layer; one end of an outer sleeve (5) is arranged on the outer cladding (1), and the other end of the outer sleeve (5) outwards extends along the axial direction of the outer cladding (1) and is arranged on the brake cable body (4); and the surface of the outer cladding (1) is provided with a high-temperature-resistant coating. The high-temperature-resistant brake cable with the good brake effect is simple in molding, light in weight, resistant to chemical corrosion, good in weather resistance and low in production cost, and the stress of the brake cable body is uniform; and the surface of the outer cladding is provided with the high-temperature-resistant coating, so that the brake cable is effectively protected, and the normal use of the brake cable is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

High-strength high-strength wear-resistant brake line

InactiveCN105697515AEasy to shapeLight in massBrake actuating mechanismsShaft for linear movementDriving safetyWeather resistance

The present invention relates to a high-strength wear-resistant brake line which comprises an outer cladding layer (1), two lining tubes (2) side by side disposed in parallel and two metal wire groups (3), a brake line body (4) comprises an inner layer carbon fiber core line group (4.1) and an outer layer resin layer (4.2), one end of an outer sleeve tube (5) is arranged on the outer cladding layer (1), the other end of the outer sleeve tube (5) extends axially outwardly along the outer cladding layer (1), and is arranged on the brake line body (4), and the end portion of the brake line body (4) is provided with an endless belt (6). The two brake line bodies are uniformly forced when in a brake; the brake line body is simple in molding, light in weight, chemical-resistant, good in weather resistance and low in cost of production; the lining tubes and the cladding layer are less prone to relative sliding, and the used effect of the brake system can be ensured, the outer sleeve tube (5) can effectively protect an end connector part of the brake line from being worn, and driving safety is ensured.

Owner:李士清

High-strength acid-resistant brake cable

InactiveCN105545926AGuaranteed equal lengthEven by forcePolyurea/polyurethane coatingsPolyether coatingsFiberWeather resistance

The invention relates to a high-strength acid-resistant brake cable. The high-strength acid-resistant brake cable comprises an outer covering layer (1), two inner lining tubes (2) parallelly arranged side by side and two metal wire sets. Each brake cable body (4) comprises an inner-layer carbon fiber core wire set (4.1) and an outer-layer resin layer (4.2). One end of an outer sleeve (5) is arranged on the outer covering layer (1), and the other end of the outer sleeve (5) extends outwards in the axial direction and is arranged on the brake cable bodies (4). The ends of the brake cable bodies (4) are provided with an annular belt (6). The surface of the outer covering layer (1) is provided with an acid-resistant coating. The high-strength acid-resistant brake cable is easy to form, light in mass, resistant to chemical corrosion, good in weather resistance and low in production cost, traffic safety is achieved, and stress borne by the brake cable bodies is uniform; the surface of the outer covering layer is provided with the acid-resistant coating, so that the brake cable bodies are protected effectively, and normal using of the brake cable is ensured.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Abrasion-resistant brake apparatus of bicycle

The invention relates to an abrasion-resistant brake apparatus of a bicycle. The abrasion-resistant brake apparatus comprises an outer cladding (1), two lined pipes (2) and two metal wire groups (3); the lined pipes (2) are parallelly arranged side by side; each brake cable body (4) comprises a carbon fiber core wire group (4.1) and a resin layer (4.2) which are respectively arranged on the inner layer and outer layer of the brake cable body (4); a circular belt (5) is arranged at the end part of each brake cable body (4); the surface of the outer cladding (1) is coated with an abrasion-resistant coating material. The abrasion-resistant brake apparatus has the advantages that the brake cable body is uniform in stress, simple to form, light in quality, resistant to chemical corrosion, high in weatherability, resistant to abrasion and low in production cost; the friction force and support force between the lined pipes and the outer cladding are effectively increased, so that the relative sliding possibilities of the lined pipes and the outer cladding are low, and the using effect of a brake system is guaranteed; the circular belts arranged at the end parts of the brake cable bodies are used for fixing the brake cable bodies with handles, so that the brake cable bodies are prevented from coming away from the handles, and the riding safety is guaranteed.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Brake cable

InactiveCN104454933AEasy to shapeLight in massShaft for linear movementCycle brakesFiberWeather resistance

The invention relates to a brake cable. The brake cable comprises an outer cladding (1), two lining tubes (2) arranged in parallel and two metal wire groups (3), wherein a brake cable body (4) comprises an inner carbon fiber core wire group (4.1) and an outer resin layer (4.2); and an annular belt (5) is arranged at the end part of the brake cable body (4). According to the brake cable, two brake cables are equal in length and uniformly stressed during braking by virtue of the lining tubes; the brake cable body has the advantages of simple molding, light mass, chemical corrosion resistance, good weather resistance and low production cost; the friction and supporting force between the lining tubes and the outer cladding can be effectively improved, and the lining tubes and the outer cladding cannot easily perform relative sliding, so that the using effect of a brake system is guaranteed; the annular belt arranged at the end part of the brake cable body is used for fixing the brake cable body and a handle, so that the brake cable cannot separate from the handle, and the traffic safety is guaranteed.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Corrosion-resistant brake cable with good braking effect

InactiveCN105299024AGood weather resistanceEasy to shapeShaft for linear movementCycle brakesFiberCarbon fibers

The invention relates to a corrosion-resistant brake cable with a good braking effect. The corrosion-resistant brake cable with the good braking effect comprises an outer cladding layer (1), two inner lining tubes (2) arranged in parallel and side by side and two metal wire groups (3), wherein a brake cable body (4) comprises an inner-layer carbon fiber core wire group (4.1) and an outer resin layer (4.2); one end of an outer sleeve (5) is arranged on the outer cladding layer (1), and the other end of the outer sleeve (5) extends outwards in the axial direction of the outer cladding layer (1) and is arranged on the brake cable body (4); the surface of the outer cladding layer (1) is coated with a corrosion-resistant layer; the corrosion-resistant layer comprises an adhesive bottom layer and a corrosion-resistant face layer. According to the corrosion-resistant brake cable with the good braking effect, the brake cable body is uniformly stressed; meanwhile, the brake cable is easy to form, light, resistant to chemical corrosion, good in weather resistance and braking effect and low in production cost; the outer sleeve can effectively protect a joint part at the end of the brake cable from abrasion; besides, the brake cable can effectively resist corrosion and the service life of the brake cable is prolonged.

Owner:JIANGYIN HENGDA VEHICLES FITTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com