High-strength anti-corrosion fireproof brake cable

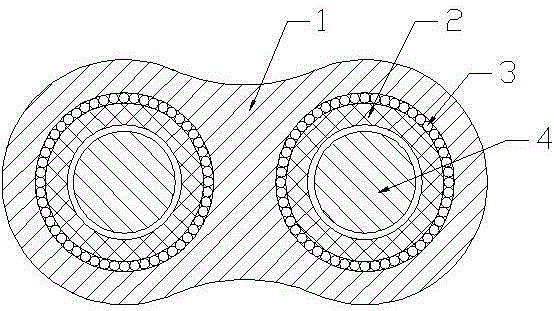

A high-strength brake line technology, which is applied to linear motion axes, bicycle accessories, bicycle brakes, etc., can solve problems such as insufficient friction and support, loose brakes, and high safety hazards, and achieve increased friction and support. Strong, not easy to slide relative to each other, guarantee the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1, put 35 parts of polyvinyl alcohol and 23 parts of potassium sorbate into the reactor and mix them. The mixing time is 1.5 hours, the mixing temperature is 40 degrees, and the mixing speed is 90 r / min. After mixing, 16 parts of dispersant are added , continue to stir for 20 minutes, then add 8 parts of talcum powder, 7 parts of resole phenolic resin and 4 parts of microencapsulated red phosphorus. Can.

Embodiment 2

[0041] Example 2, put 37 parts of polyvinyl alcohol and 25 parts of potassium sorbate into the reactor and mix them. The mixing time is 1.5 hours, the mixing temperature is 40 degrees, and the mixing speed is 90 r / min. After mixing, add 14 parts of dispersant , continue to stir for 20 minutes, then add 13 parts of talcum powder, 7 parts of resole phenolic resin and 4 parts of microencapsulated red phosphorus. Can.

Embodiment 3

[0042] Example 3, 33 parts of polyvinyl alcohol and 21 parts of potassium sorbate were mixed in the reactor, the mixing time was 1.5 hours, the mixing temperature was 40 degrees, the mixing speed was 90 r / min, and 18 parts of dispersant were added after the mixing , continue to stir for 20 minutes, then add 14 parts of talcum powder, 9 parts of resole phenolic resin and 5 parts of microencapsulated red phosphorus, the mixing temperature is 50 degrees, the mixing speed is 110r / min, until the mixing is uniform, naturally cool to room temperature Can.

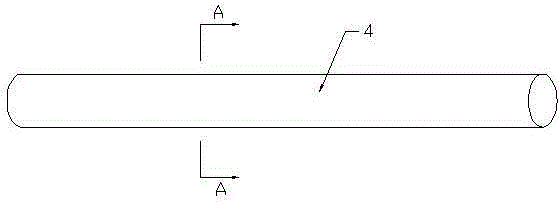

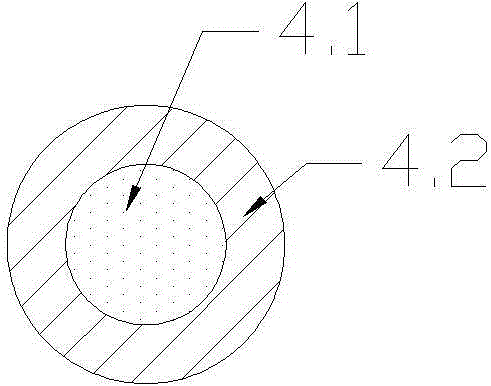

[0043] The brake line body 4 of the present invention is molded at one time. In the process of preparing the brake line body, the head of the extruder passes through a bundle of continuous carbon fibers, and the molten resin layer 4.2 coming out of the extruder is tightly coated. The brake line body 4 is made on the carbon fiber core wire group 4.1.

[0044] The diameter of the carbon fiber core wire group 4.1 can be controlled b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com