High-strength wear-resistant brake cable

A high-strength brake line technology, applied to linear motion axes, bicycle accessories, bicycle brakes, etc., can solve problems such as insufficient friction and support, wear, and loose brakes, etc., to increase friction and support , to ensure driving safety, and to ensure the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

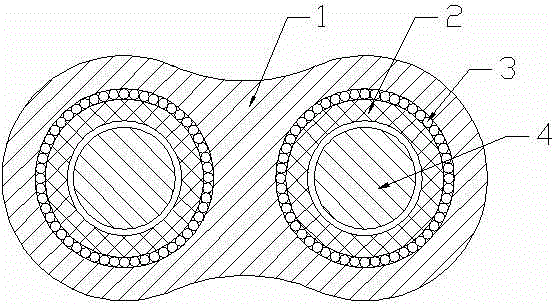

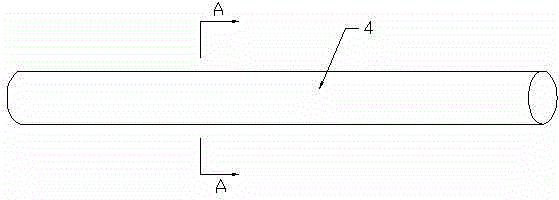

[0034] see Figure 1-4 , the present invention relates to a high-strength wear-resistant brake line, comprising an outer cladding 1, two liner tubes 2 arranged side by side in parallel and a metal wire group 3, the lengths of the two liner tubes 2 are equal, and the liner tube 2 A brake line body 4 is arranged inside, and the metal wire group 3 includes a plurality of metal wires, the metal wires are closely arranged on the outer wall of the inner liner 2, the length direction of the metal wires is consistent with the axial direction of the inner liner 2, and a plurality of The metal wire is bent in a spiral shape along its length (similar to a twisted steel wire rope). The metal wire group 3 has 15 to 25 metal wires, preferably 21 wires. The outer cladding 1 is coated on Wire group 3 outside.

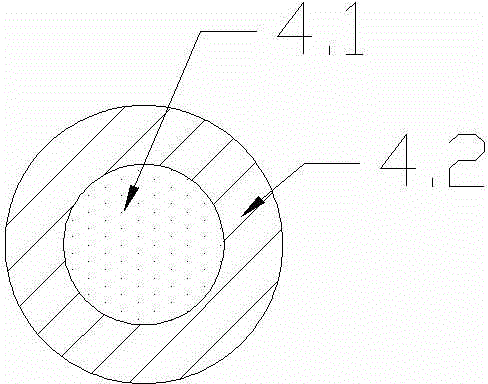

[0035] The brake line body 4 includes an inner carbon fiber core wire group 4.1 and an outer layer resin layer 4.2. The carbon fiber core wire group 4.1 is composed of multiple bundle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com