Cable harness vulcanization method

A cable harness and cable technology, applied in home appliances, other home appliances, household components, etc., can solve problems such as leaking wires, eccentric wiring harnesses, etc., and achieve the effects of avoiding bending, solving eccentric vulcanization, and solving uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

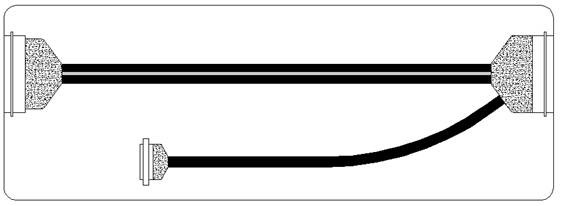

[0022] Embodiment 1: The wire harness of this embodiment has no branch structure.

[0023] First, use a steel rod with a diameter equal to that of the wire harness to make an under-vulcanized sleeve. Cover the steel rod with vulcanized rubber and heat and vulcanize it. Stop heating when it is not fully vulcanized. The vulcanized rubber forms an under-vulcanized sleeve on the surface of the steel rod, and then The undervulcanized casing is cut open and stripped from the rod. Cut the undervulcanized sleeve axially along a straight line.

[0024] The cable is straightened out through one-time forming tooling. The one-time forming tooling includes a slot plate and connectors at both ends. There is a straight slot in the center of the slot plate. There are notches at both ends of the straight slot. The notch slots are positioned along the side walls and bottom of both sides. The slot, the connector is installed at the notch, and after the connector is put into the notch, there is ...

Embodiment 2

[0025] Embodiment 2: The wiring harness of this embodiment has a branch structure

[0026] Use one-time forming tooling to position through the flange grooves of each connector, and design one-time forming tooling, including the slot plate and connectors. There are two positioning slots on the slot plate, one straight slot and one inclined slot. The distance between the positioning grooves of each connector flange is fixed, and the width of the middle wire harness groove is equal to the diameter of the wire harness. After the first connector is made and the glue is stacked, the second and third connectors are made. The cable semi-finished product starts from the first end and puts the connector and wire harness into the one-time forming tool step by step. When placing the second and third end connectors, push the connector back to place the flange plate in the groove of the positioning flange plate, and the second end is connected. The connector is used to install the branch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com