Automobile part cutting device

A technology for auto parts and cutting devices, which is applied in the direction of shearing devices, attachments of shearing machines, motor vehicles, etc., and can solve the problems of affecting the cutting accuracy of metal rods, low quality, and inability to guarantee auto parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

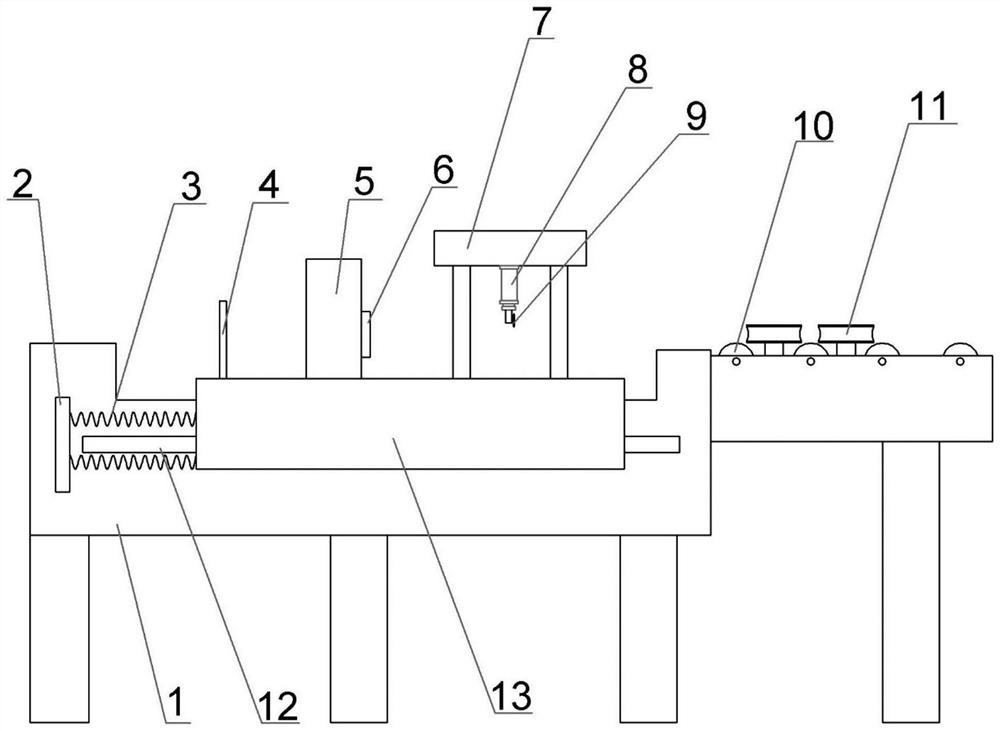

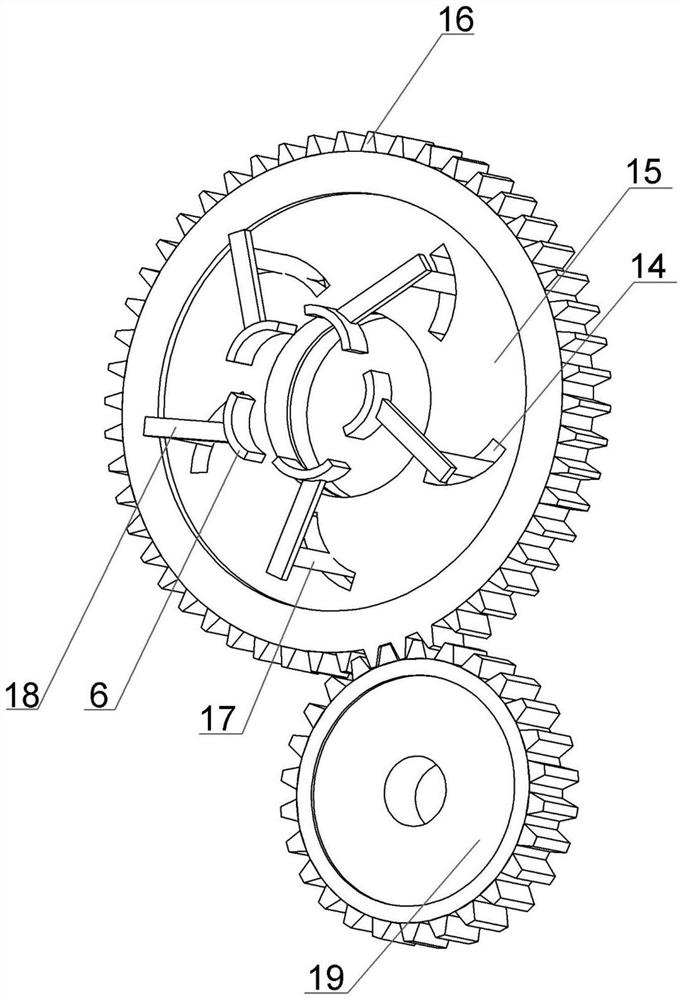

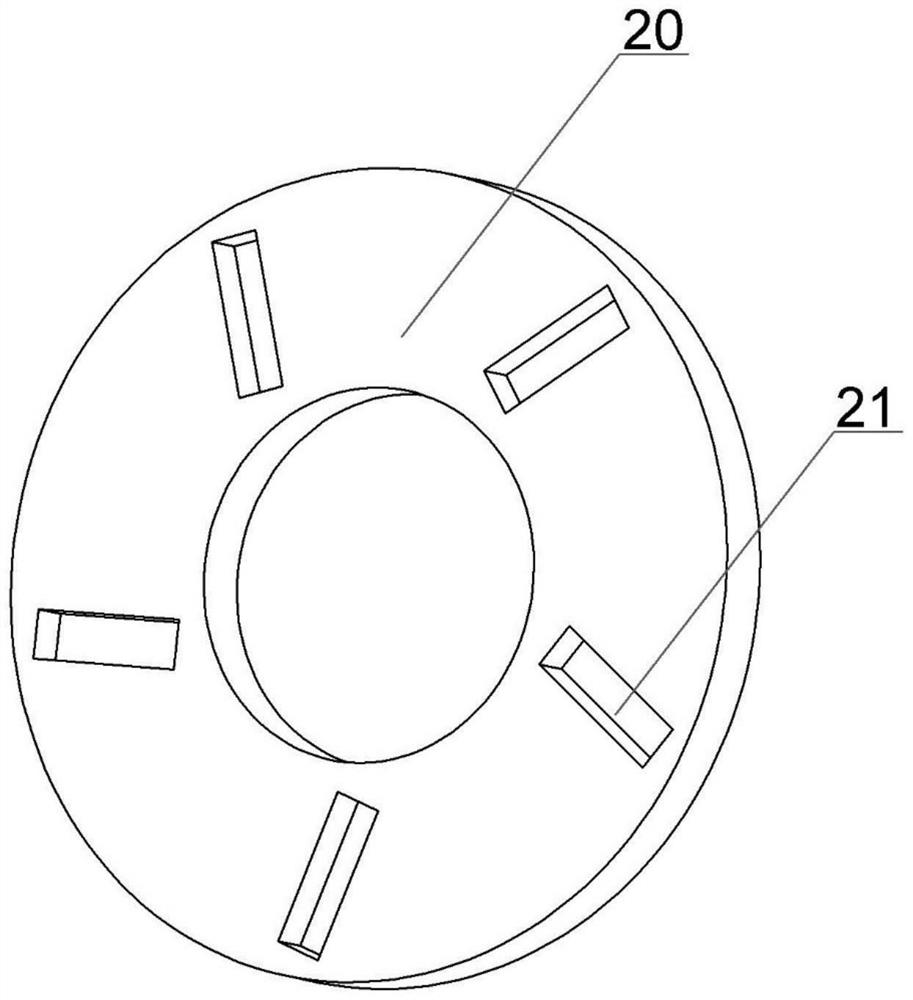

[0023] This embodiment is basically as attached Figure 1-5 Shown: a kind of auto part cutting device, comprises frame 1 and cutting structure, frame 1 in this embodiment refers to the main structure that supports and connects this device, is provided with feeding structure and fixing unit on frame 1, The feeding structure is located at one end of the rack 1 . Specifically, the feeding structure includes a power part and a plurality of rotating rollers 10, and the power part in this embodiment may use a motor. A plurality of turning rollers 10 are respectively connected with the frame 1 in rotation; a plurality of turning rollers 10 are arranged in parallel; on both sides of the frame 1, a plurality of vertically arranged traction rollers 11 are respectively arranged, and the traction rollers 11 are vertically arranged and connected to the machine frame. The frame 1 is connected in rotation, and the traction roller 11 is driven to rotate by a motor. The connection mode betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com