Rotor mechanism of twister

A twister and twisting technology, which is applied in the direction of textiles and papermaking, can solve the problems of unequal length difference, equality and uniformity of inner and outer yarns, and the inability to reliably guarantee tension, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

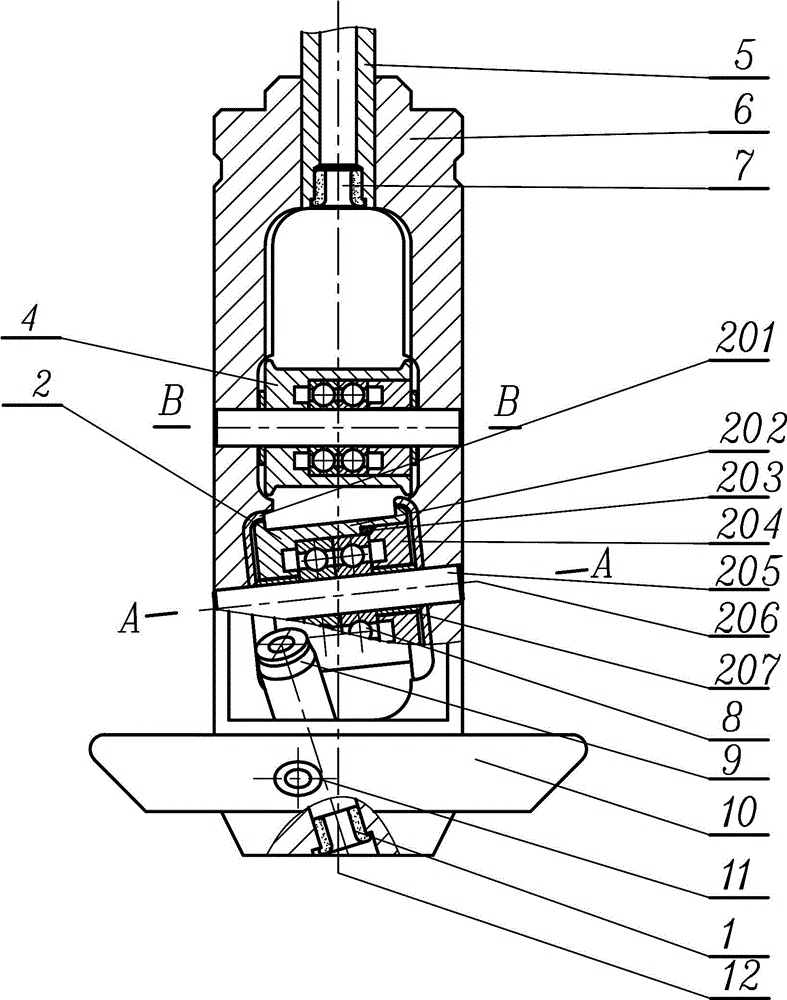

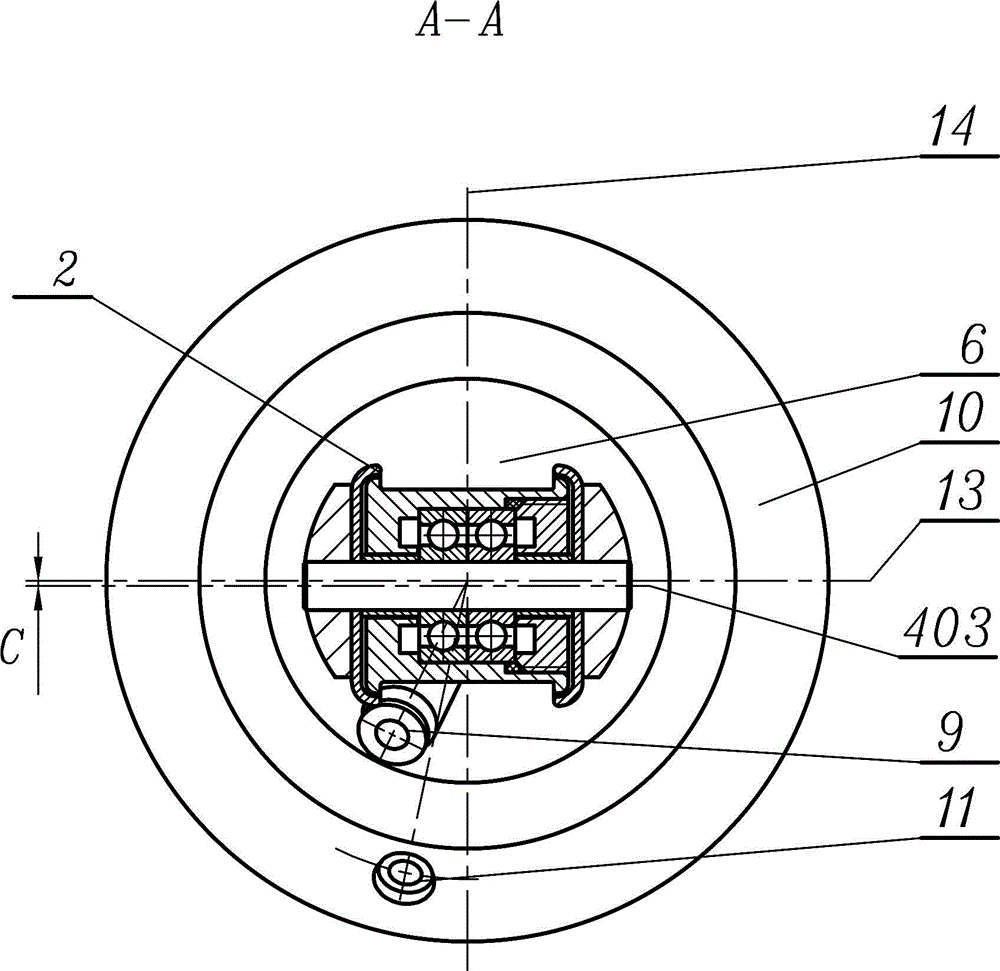

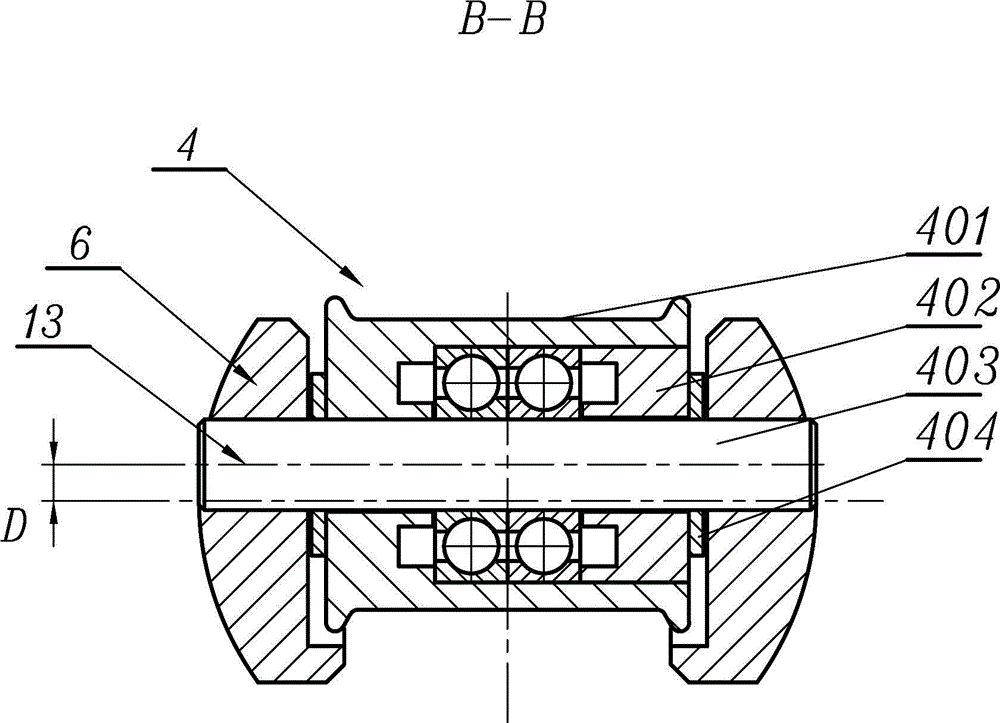

[0025] Such as Figure 1~4 Among them, a twister rotor mechanism, the upper part of the rotor frame 6 is fixedly connected with the yarn guide tube 5, the lower part of the rotor frame 6 is fixedly connected with the balance disc 10, the first ceramic ring 11 is arranged on the balance disc 10, and the rotor frame 6 is provided with a second ceramic ring 9 , the bottom end of the rotor frame 6 is provided with a third ceramic ring 1 , and a first roller 2 and a second roller 4 are provided near the lower part of the hollow part of the rotor frame 6 . With this structure, the unequal tension difference between the inner and outer yarns with fluctuating tension can be reduced and evened before the plying, so that the unequal length difference between the inner and outer yarns after plying can be reduced.

[0026] The preferred solution is as Figure 1~4 Among them, the first roller 2 is located below the second roller 4 , and the diameter of the first roller 2 is larger than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com