A kind of leveling construction technology of wall base plate

A construction process and technology of base board, applied in covering/lining, construction, building maintenance, etc., can solve problems such as wall leveling, construction inconvenience, base board tilt, etc., to prevent dents and avoid being affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

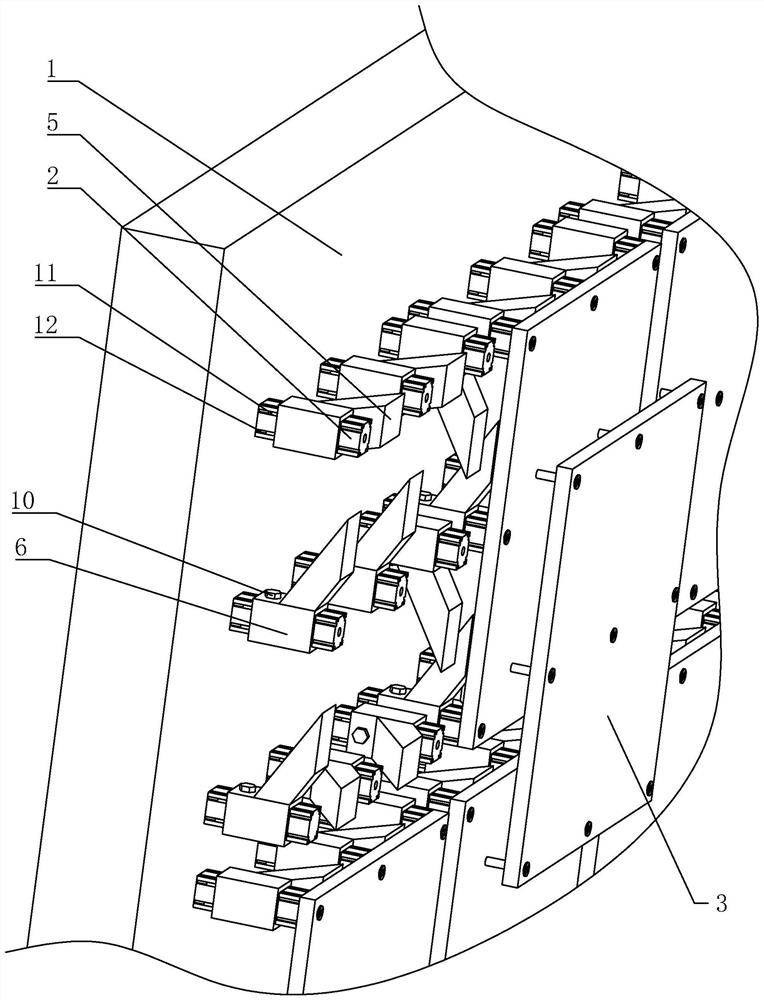

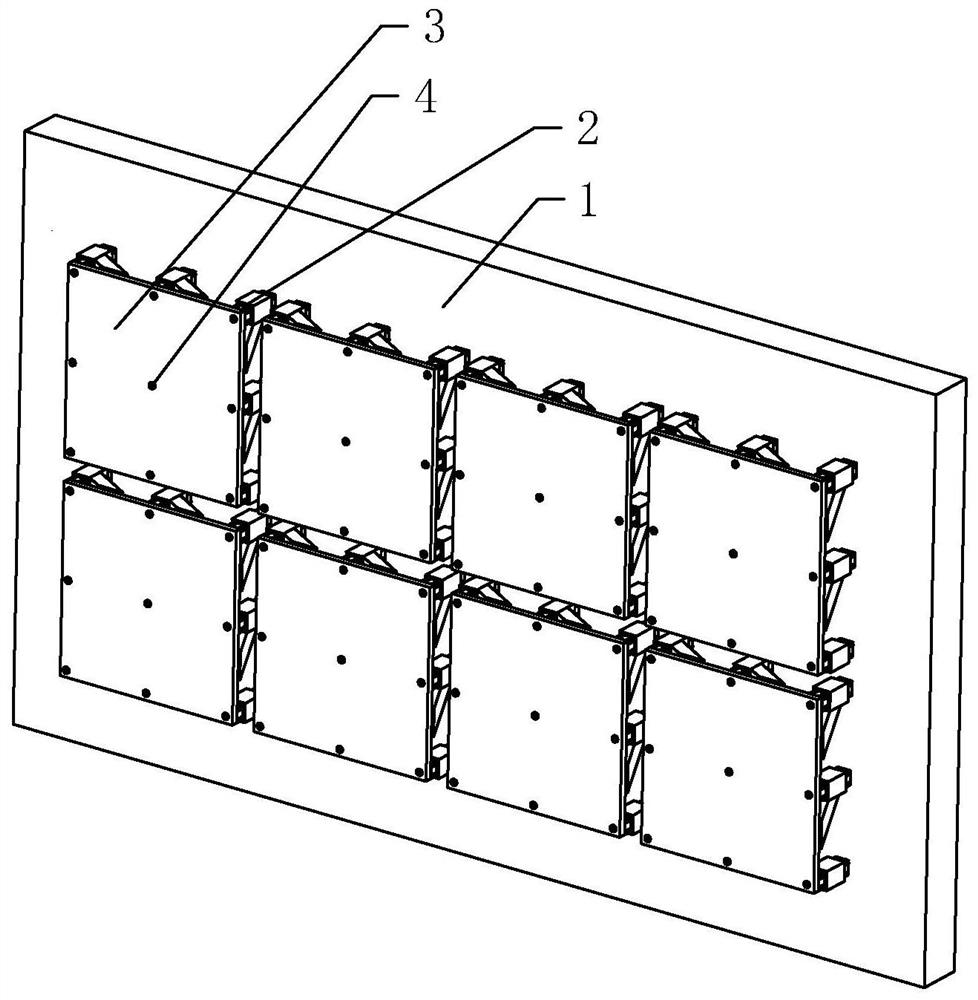

[0047] Embodiment: a kind of wall surface 1 base plate leveling construction technology, such as figure 1 and figure 2 shown, including the following steps:

[0048] S1, cleaning the wall surface 1;

[0049] S11. Preliminary cleaning of the wall surface 1 with a brush;

[0050] S12 , the wall 1 is cleaned again by the fan, and the fan cleans the floating ash remaining on the wall 1 .

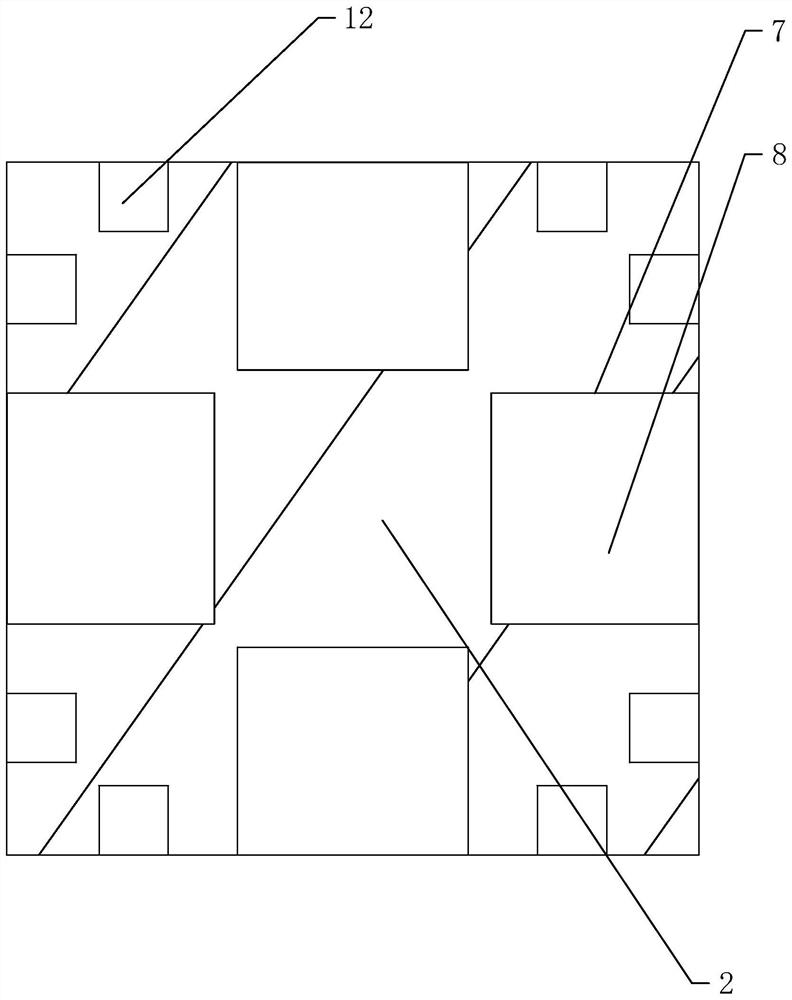

[0051] S2. According to the design drawings, the wall 1 is divided into lines and grids, leaving traces of lines and grids on the wall 1. In this implementation, the lines and grids are ejected through the ink fountain;

[0052] S3. Punch a hole at each intersection point of the line ejected from the ink fountain and insert the wooden wedge 2. In this implementation, punch the hole with an electric hammer;

[0053] S31. Install the brace plate 5 on the wooden wedge 2, and the end of the brace plate 5 away from the wooden wedge 2 is flush with the end of the wooden wedge 2 away from the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com