Non-crack type water breakthrough oil well repeated transformation method

A technology for repeated reconstruction and oil wells, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc. It can solve problems such as difficulty in guaranteeing effect and validity period, complicated construction procedures, and high construction risks, and achieves low construction risks and improved fractures. The degree of complexity and the effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

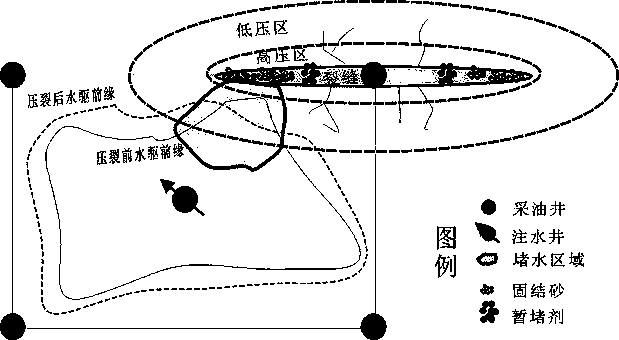

Image

Examples

Embodiment 1

[0032] In order to solve the problems that the effect and validity period of the existing water control technical measures are difficult to guarantee, the construction process of the "multi-slug gel + consolidation type plugging agent" water plugging and fracturing technology is complicated, the construction risk is high, and the operation period is long. This embodiment provides a non-fractured water breakthrough oil well repeated reconstruction method, including the following steps:

[0033] Step 1) inject temporary plugging agent;

[0034] Step 2) Inject guar gum base solution;

[0035] Step 3) Stop the pump and release the spray;

[0036] Step 4) Inject the cross-linked gel water blocking agent;

[0037] Step 5) Carry 40-70 mesh and 70-100 mesh consolidation sand into the cracks successively with guar gum cross-linking fluid;

[0038] Step 6) closing the well and waiting for solidification;

[0039] Step 7) Carry out temporary plugging and diversion to fracturing const...

Embodiment 2

[0042] This embodiment provides a non-fractured water breakthrough oil well repeated reconstruction method, including the following steps:

[0043] Step 1) Use the guar gum base fluid to carry the temporary plugging agent into the primary fracture, and form a bridge plug in the fracture, restricting the subsequent injection of liquid into the high-permeability section;

[0044] The role of the temporary plugging agent realizes flow restriction and prevents fluid loss in the effluent high-permeability channel before the cross-linked gel water blocking agent.

[0045] Step 2) Inject guar gum base liquid, and quickly form a filter cake on the wall of the crack in the front section of the bridge plug to ensure that the later cross-linked gel water blocking agent will not enter the low-pressure reservoir around the crack, so that it can directly enter the high-permeability of the effluent layers;

[0046] Step 3) Stop the pump, use the tubing to spray, use the reverse force of the...

Embodiment 3

[0057] This embodiment provides a non-fractured water breakthrough oil well repeated reconstruction method, including the following steps:

[0058] Step 1) inject temporary plugging agent;

[0059] Step 2) Inject guar gum base solution;

[0060] Step 3) Stop the pump and release the spray;

[0061] Step 4) Inject the cross-linked gel water blocking agent;

[0062] Step 5) Carry 40-70 mesh and 70-100 mesh consolidation sand into the cracks successively with guar gum cross-linking fluid;

[0063] Step 6) closing the well and waiting for solidification;

[0064] Step 7) Carry out temporary plugging and diversion to fracturing construction.

[0065] Step 1) The injected temporary plugging agent is a solid temporary plugging agent, and its dosage is 100-200kg.

[0066] Step 2) The injection volume of guar base liquid is 10-20 m 3 , construction displacement is 1.0-2.0m 3 / min.

[0067] Step 3) The discharge volume is 3-5 m 3 .

[0068] Step 4) The cross-linked gel water b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com