Reagent for detecting content of polyethylene glycol in electroplating acidic copper solution and detection method

A polyethylene glycol and detection method technology, which is applied in color/spectral characteristic measurement, material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problem of difficult to meet the rapid regulation of components. Requirements, low precision and accuracy, poor operability, etc., to achieve the effect of low cost, high precision and accuracy, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A reagent for detecting the content of polyethylene glycol in an acid copper plating solution, the components of which include bismuth subcarbonate, an acidic agent and 0.1-1.0 mol / L potassium iodide, wherein the added amount of the bismuth subcarbonate is 0.1-2.0 g; the acidic agent is any one of glacial acetic acid, 5-20% hydrochloric acid, and 0.2-2mol / L nitric acid, and the addition amount of the acidic agent is 5-30mL; the addition amount of the potassium iodide is 2-30mL ;

[0040] The preparation method of the reagent of polyethylene glycol content in the above-mentioned detection electroplating acid copper solution is:

[0041] Weigh bismuth subcarbonate into a brown Erlenmeyer flask, add an acidic agent, and ultrasonically treat for 5-20 minutes to disperse the powder evenly, then slowly add potassium iodide while stirring, seal the bottle with a cork, and continue the ultrasonic treatment for 5-20 minutes in the dark. After 60 minutes, the detection reagent wa...

Embodiment 2

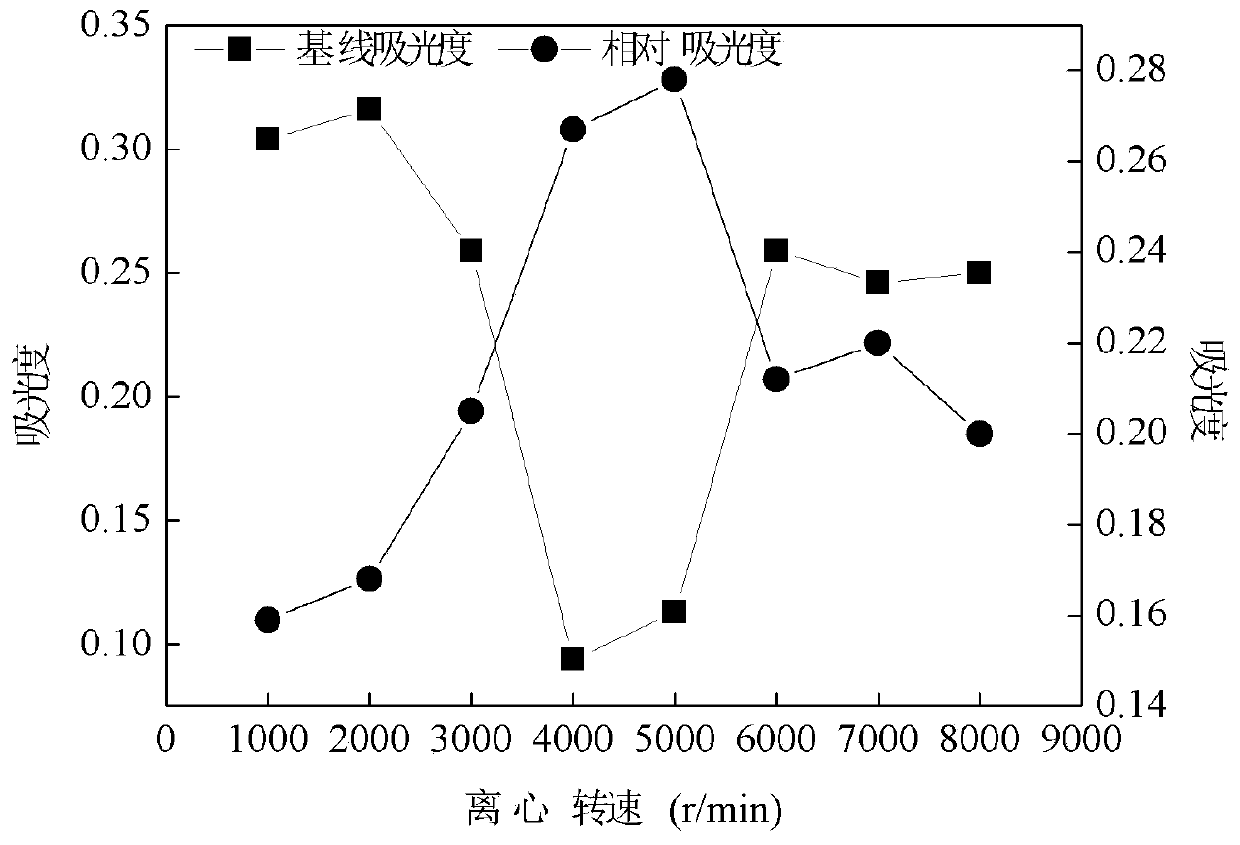

[0052] Taking 30mg / L polyethylene glycol (M=6000) as an example, explore the influence of centrifugation speed on absorbance during centrifugation during sample preparation:

[0053] Step 1. Configuration of standard electroplating solution

[0054] S1: Take polyethylene glycol with a molecular weight of M=6000 and put it in a vacuum drying oven, and dry it at 40°C for 4 hours to remove moisture; accurately weigh 1.0g of polyethylene glycol and dissolve it in a 1000mL volumetric flask, and use Dilute to the mark with deionized water, and make 1.0g / L polyethylene glycol stock solution;

[0055] S2: Measure 0-10mL of concentrated sulfuric acid in a 50mL beaker, add an appropriate amount of deionized water to dilute, then weigh 0-80g of copper sulfate pentahydrate into the aforementioned beaker, and heat it at 80°C to dissolve it. Then add 3.0 mL of the polyethylene glycol stock solution prepared in step S1 to the aforementioned beaker, and after the temperature drops to room te...

Embodiment 3

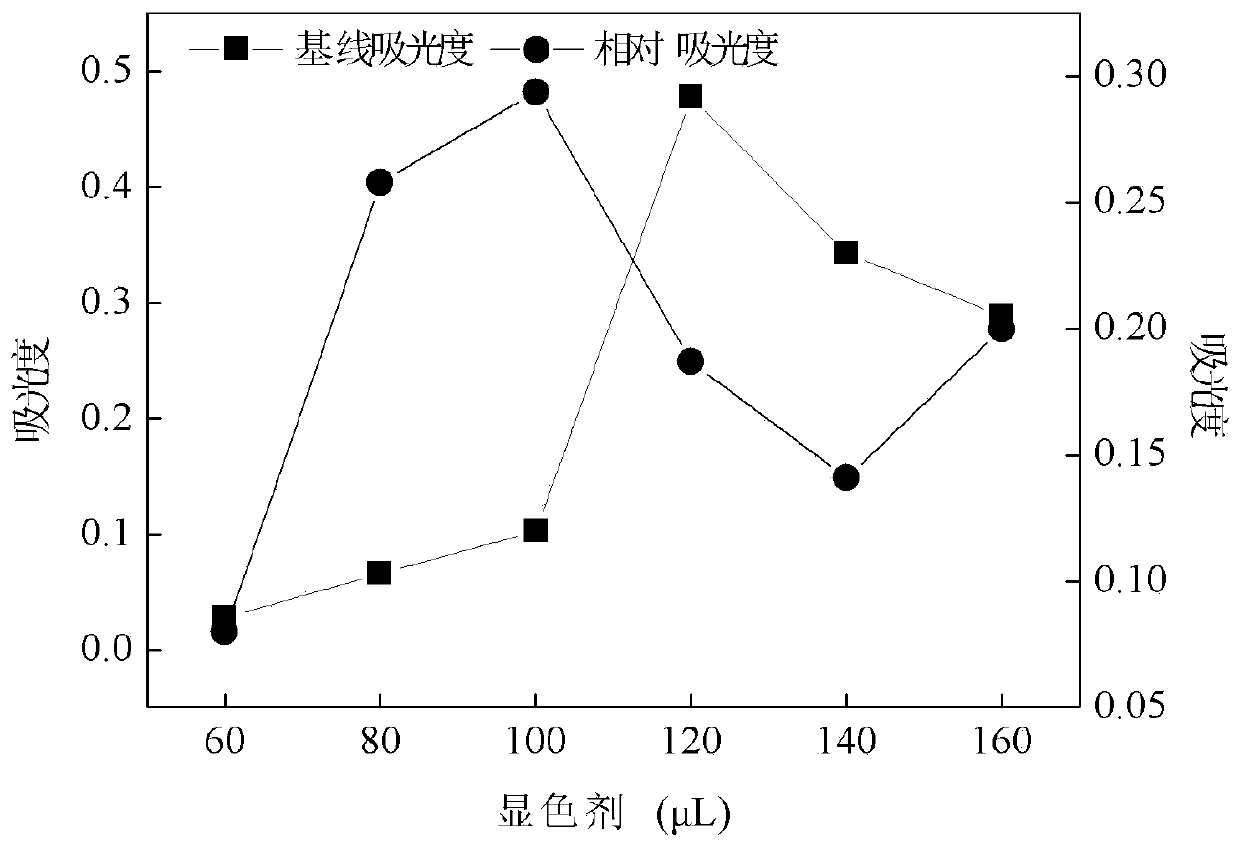

[0066] Taking 30mg / L polyethylene glycol (M=6000) as an example, explore the influence of the addition amount of the reagent used as the chromogen during the chromogenic operation on the absorbance:

[0067] Step 1. Configuration of standard electroplating solution

[0068] Its step is with embodiment 2.

[0069] Step 2. Sample configuration

[0070] S1: Use a pipette to pipette 15 mL of a prepared standard plating solution with a concentration of 30 mg / L into six 50 mL centrifuge tubes, and then adjust the pH value to 7 with sodium hydroxide solution to obtain 6 copies of the same pretreatment solution.

[0071] S2: Shake the pretreatment solution prepared in step S1, and then perform centrifugation at a speed of 5000 r / min for 8 minutes, and then take the supernatant to obtain 6 copies of the same solution to be tested.

[0072] Step 3, color development operation

[0073] Pipette 5mL of the solution to be tested prepared in step 2 into six 10mL stoppered test tubes, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap