Self-propelled rice and wheat breeding harvester

A self-propelled harvester technology, which is applied to harvesters, harvesting platforms, agricultural machinery and implements, etc., can solve the problems of mixed seeds, long harvesting period of manual harvesting, and delayed farming time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

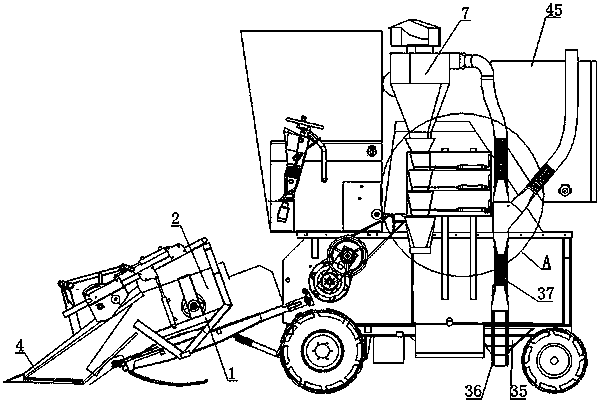

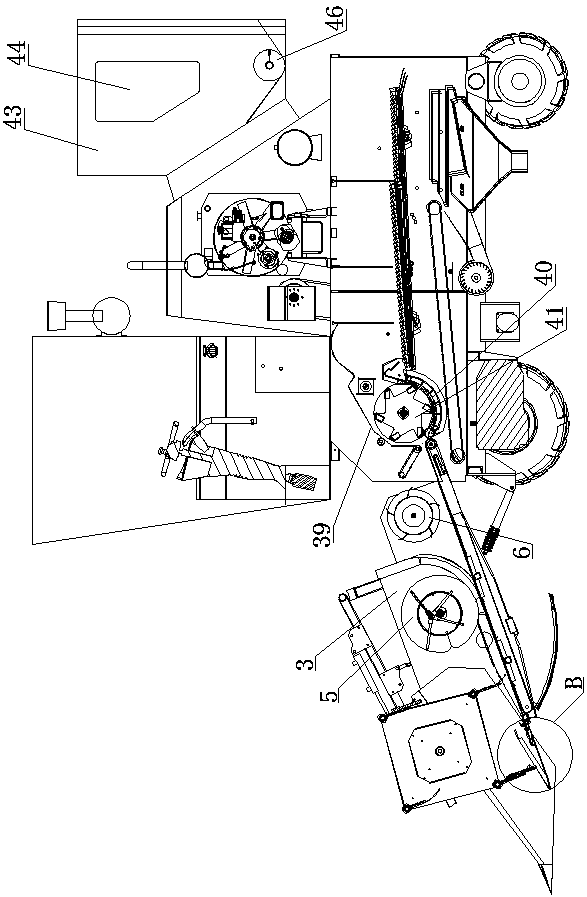

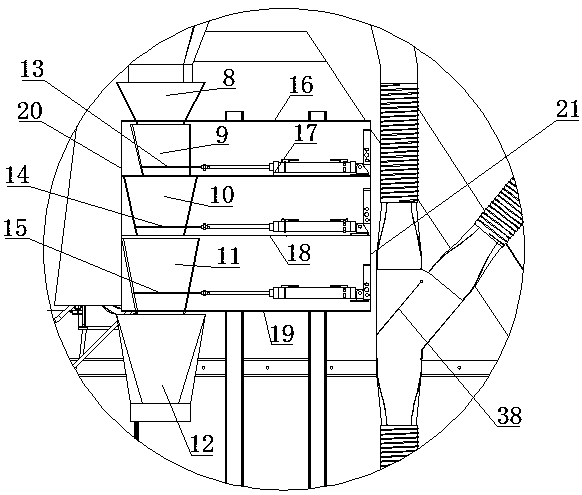

[0020] The front, back, left, and right described below are based on the walking direction of the harvester, such as Figure 1 to Figure 5 As shown, the self-propelled rice and wheat breeding harvester includes a frame, a walking device, a header device, a threshing device, a cleaning device, a pneumatic conveying device, a manipulation control device, and a driving device, wherein the walking gear, the cleaning device, the manipulation control The device and the driving device are prior art, and will not be repeated here.

[0021] Such as Figure 5 As shown, the header device includes a header frame 1, a left side plate 2, a right side plate 3, a crop divider 4, a reel, a cutting device, a first conveying device, a feeding auger 5, and a feeding roller 6 , Both sides of the header frame 1 are respectively provided with a left side plate 2 and a right side plate 3, and the reel is adjustablely installed on the header frame 1. In the present invention, the two ends of the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com