Catalyst for preparing glycidyl tertiary carbonic acid ester and preparation method thereof

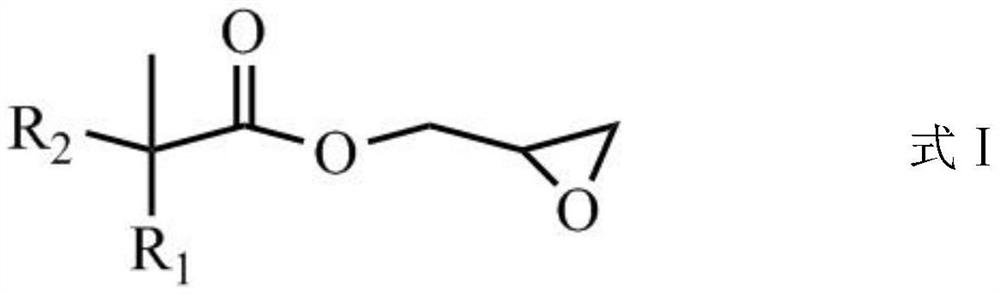

A technology of glycidyl ester and tertiary carbonic acid, which is applied in the field of new catalysts and its preparation, and can solve the problems of more dichloropropanol by-products and low selectivity of quaternary ammonium salt catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments will be described in detail below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereby.

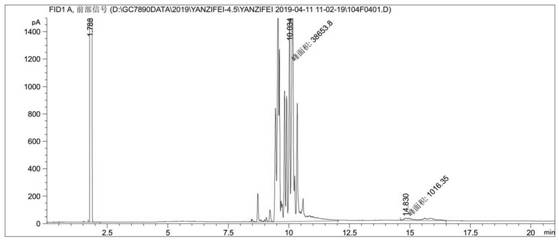

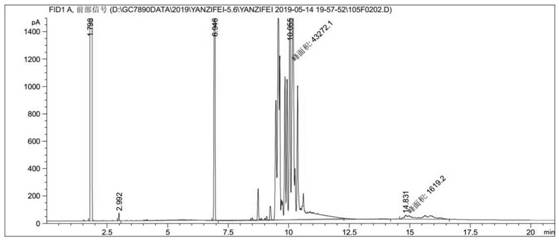

[0027] The implementation steps of the present invention are as follows: add a certain amount of catalyst and tertiary carbonic acid in a three-necked flask, control the temperature in an oil bath, stir magnetically, add epichlorohydrin at one time or dropwise to react, and continuously take samples to measure the acid value. When the acid value When it is lower than 3-1.5mg KOH / g, the first step reaction is completed. Since the present invention focuses on the reaction of the first step of tertiary carbonic acid and epichlorohydrin, the second step of saponification and the subsequent refining process are no longer discussed in depth. The specific reaction system is shown in Table 1, and the specific meanings represented by the abbreviations of each substance in Table 1 are as follows: tetramethylammonium ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com