Semi-automatic screw type steel pipe, flange and connecting plate grouping device

A semi-automatic, connecting plate technology, applied in the field of electric power towers, can solve problems such as unsatisfactory, high labor intensity of workers, and difficult adjustment of tooling size, and achieve the effect of solving the complex processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

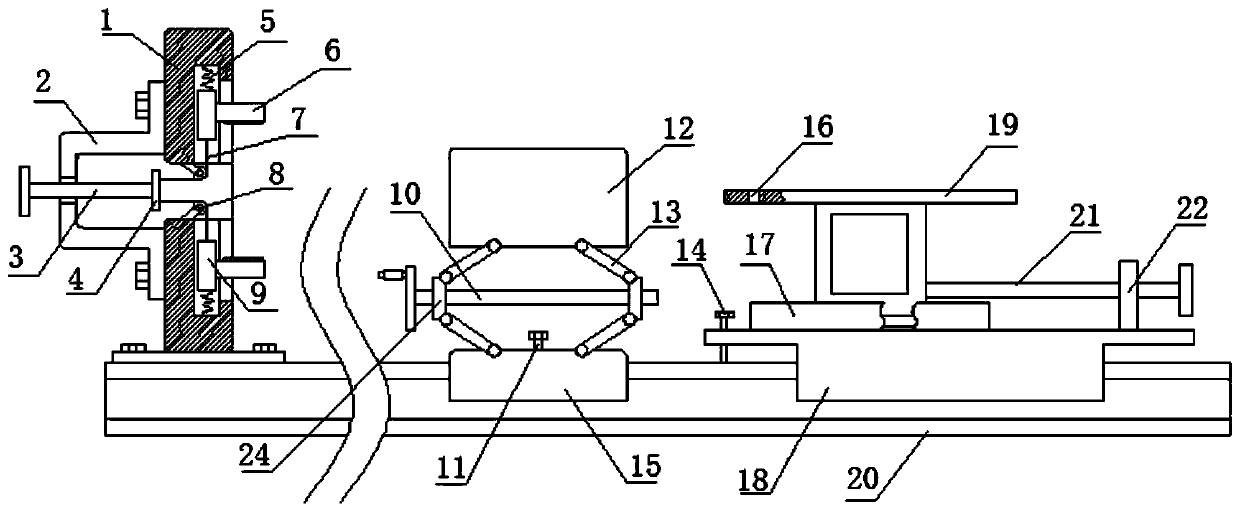

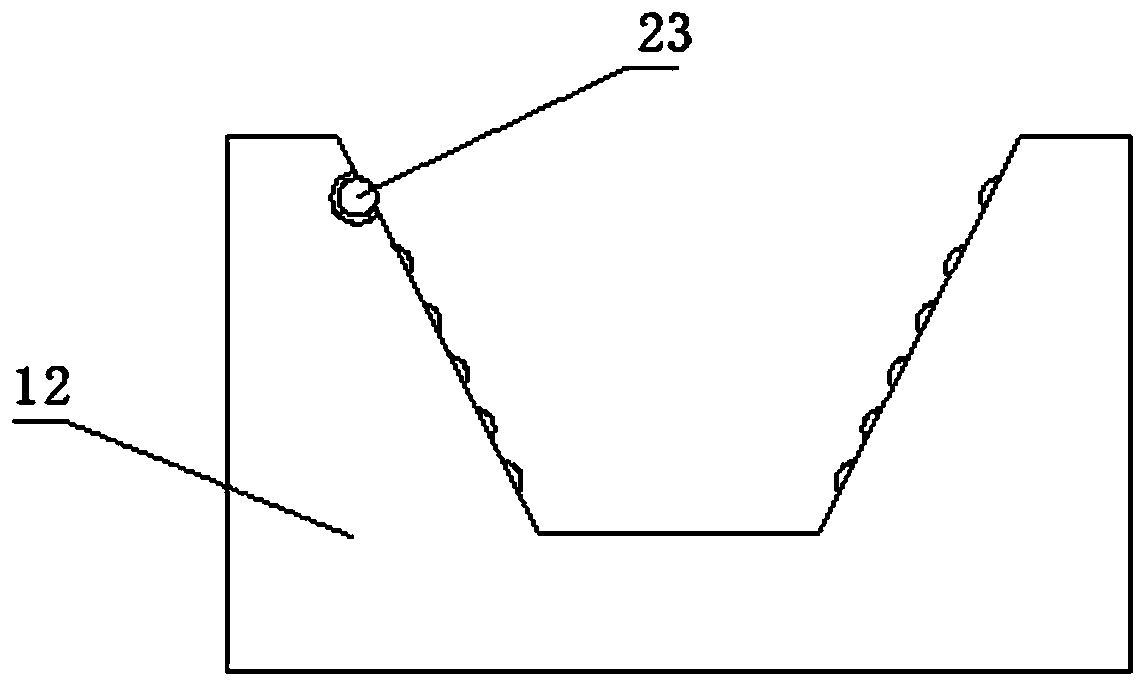

[0023] refer to Figure 1-2 , a semi-automatic screw-type steel pipe, flange, and connecting plate teaming device, including an I-shaped seat 20, and the top of the I-shaped seat 20 is respectively provided with an annular seat 1, a first sliding seat 15 and a second sliding seat 18, and the first sliding seat The seat 15 and the second slide seat 18 are all slidably connected with the I-shaped seat 20, the annular seat 1 is provided with an adjustable clamp, the top of the first slide seat 15 is provided with a V-shaped seat 12 that can be adjusted up and down, and the second slide seat 18 There is a top platform 19 that can be adjusted by horizontal sliding.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com