Auxiliary machining device for robot hole-making end effector

A hole-making technology for end effectors and robots, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effects of wide application range, normal accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

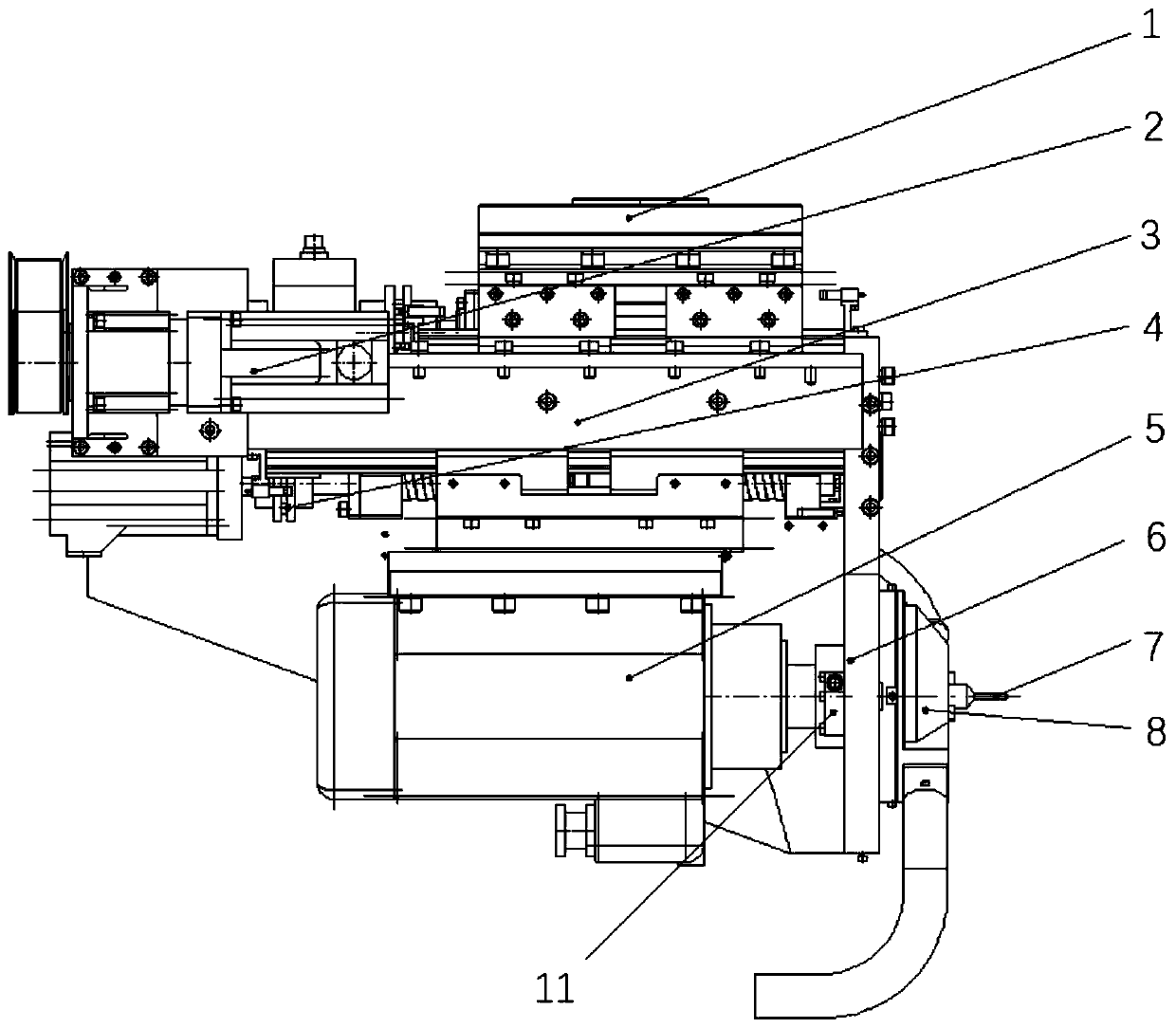

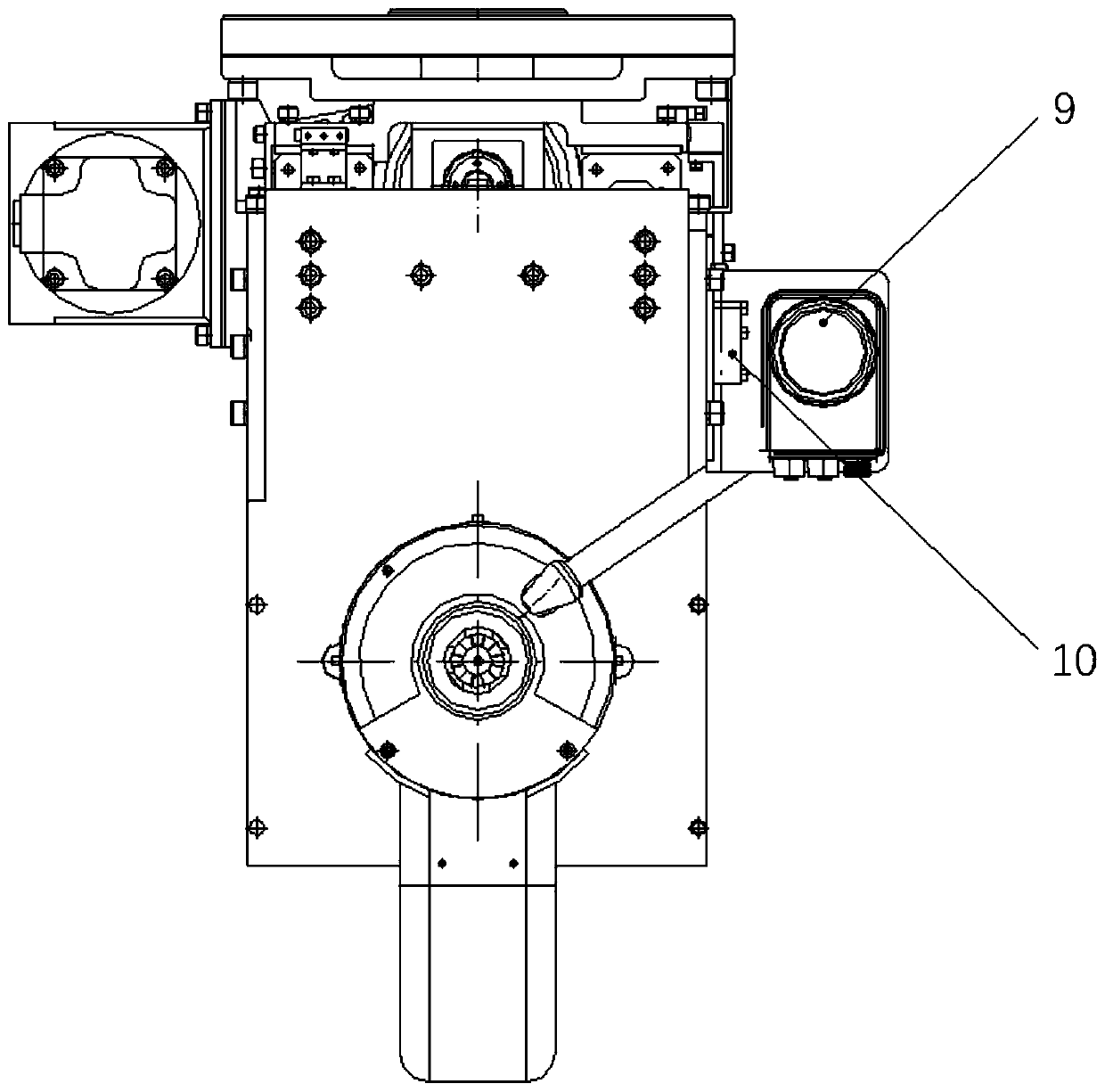

[0024] See attached Figure 1~4 As shown, the flange 1 is connected to the pressing mechanism 2, and the main connecting plate 3 connects the pressing mechanism 2 and the spindle feed mechanism 4 together. The tool 7 is installed on the electric spindle 5, the electric spindle 5 is installed on the spindle feed mechanism 4, the front plate 6 is connected to the main connecting plate 3 and is vertical, the multifunctional normal direction measurement module 8 is installed on the front plate 6, and is connected with the electric The main shaft 5 is coaxial with the tool 7, the visual camera 9 and the laser ranging sensor 10 are installed on the side of the main connecting plate 3, and the knife breaking detection sensor 11 is installed on the front plate 6 and distributed on both sides of the tool 7.

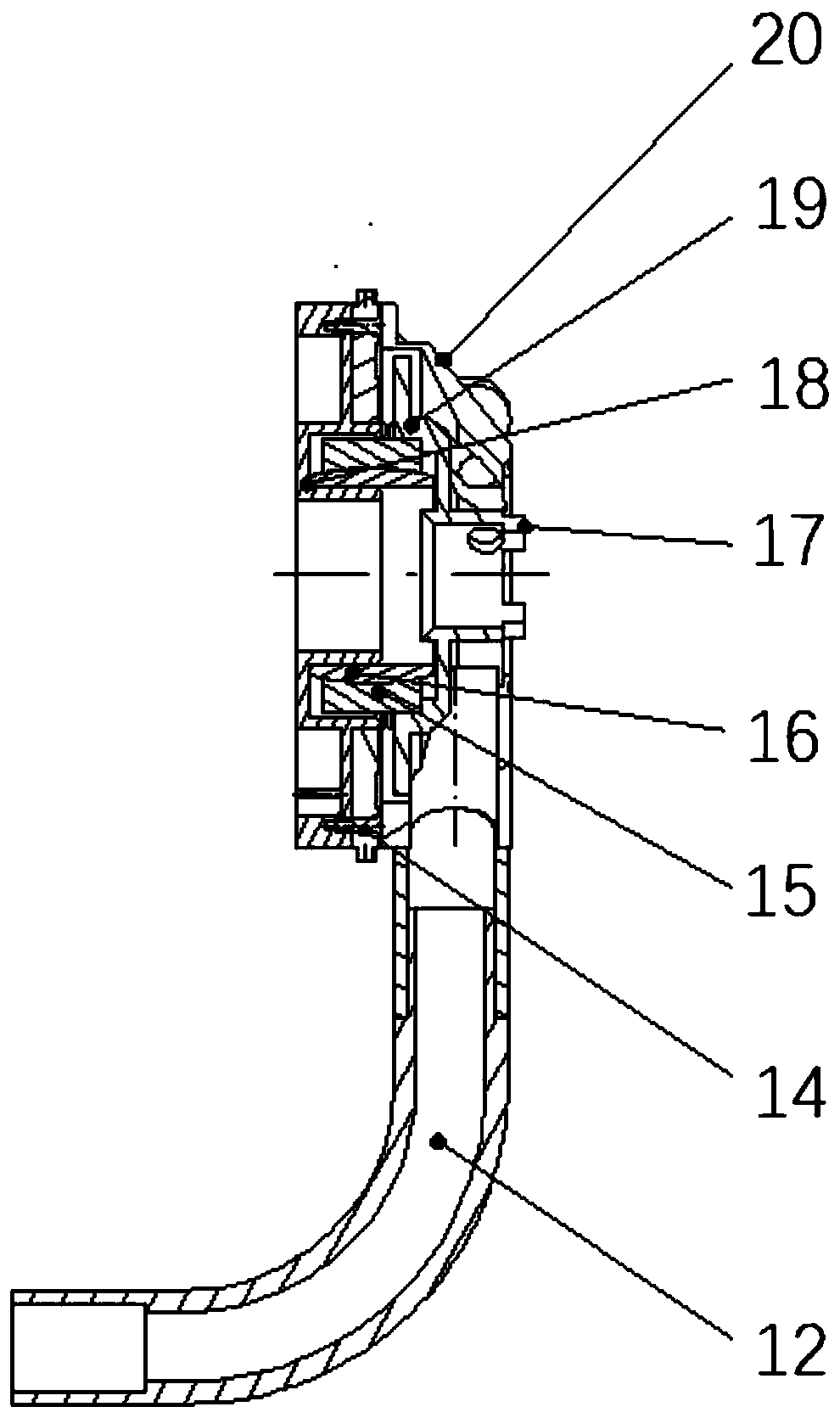

[0025] The multifunction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com