Normal Angle Measuring Unit

A technology of measuring unit and normal angle, applied in measuring/indicating equipment, metal processing mechanical parts, manipulators, etc., can solve the problems of poor quality consistency, quality defects of hole making, low efficiency, etc., to achieve simple implementation and fast transmission speed , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings.

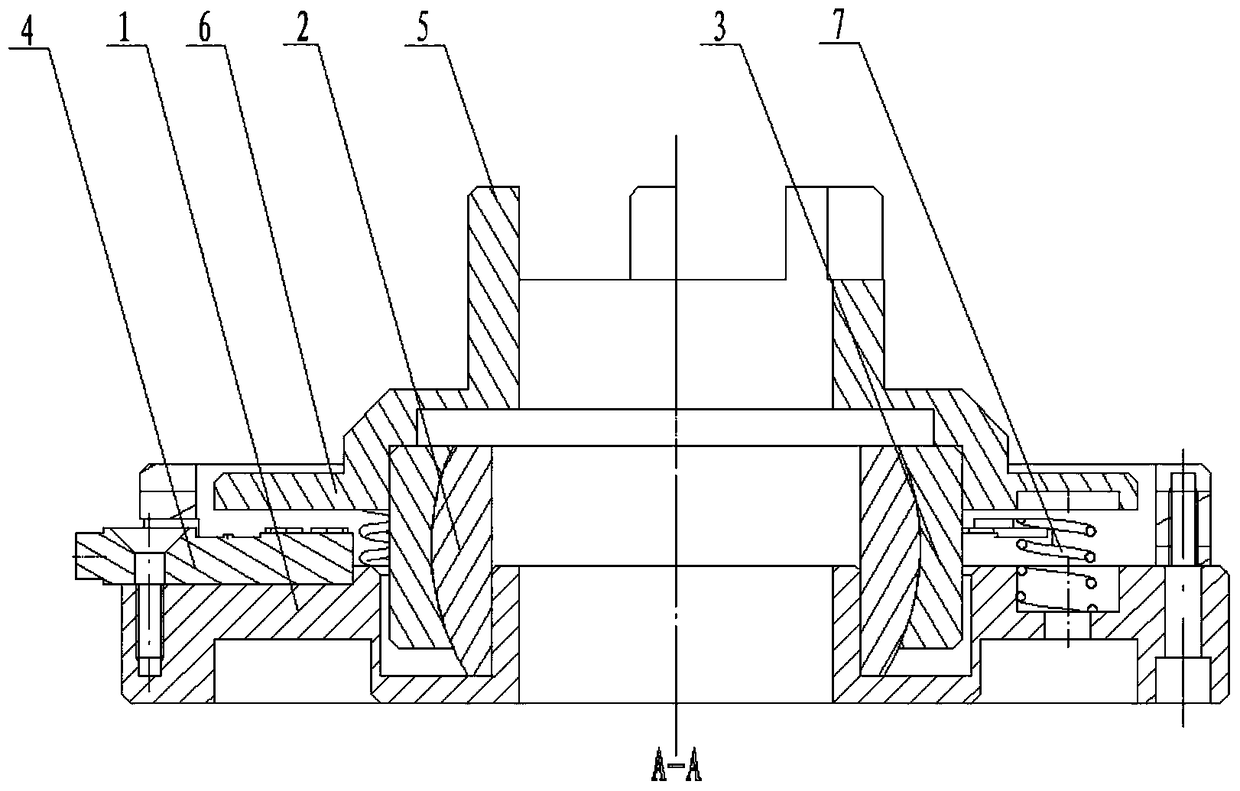

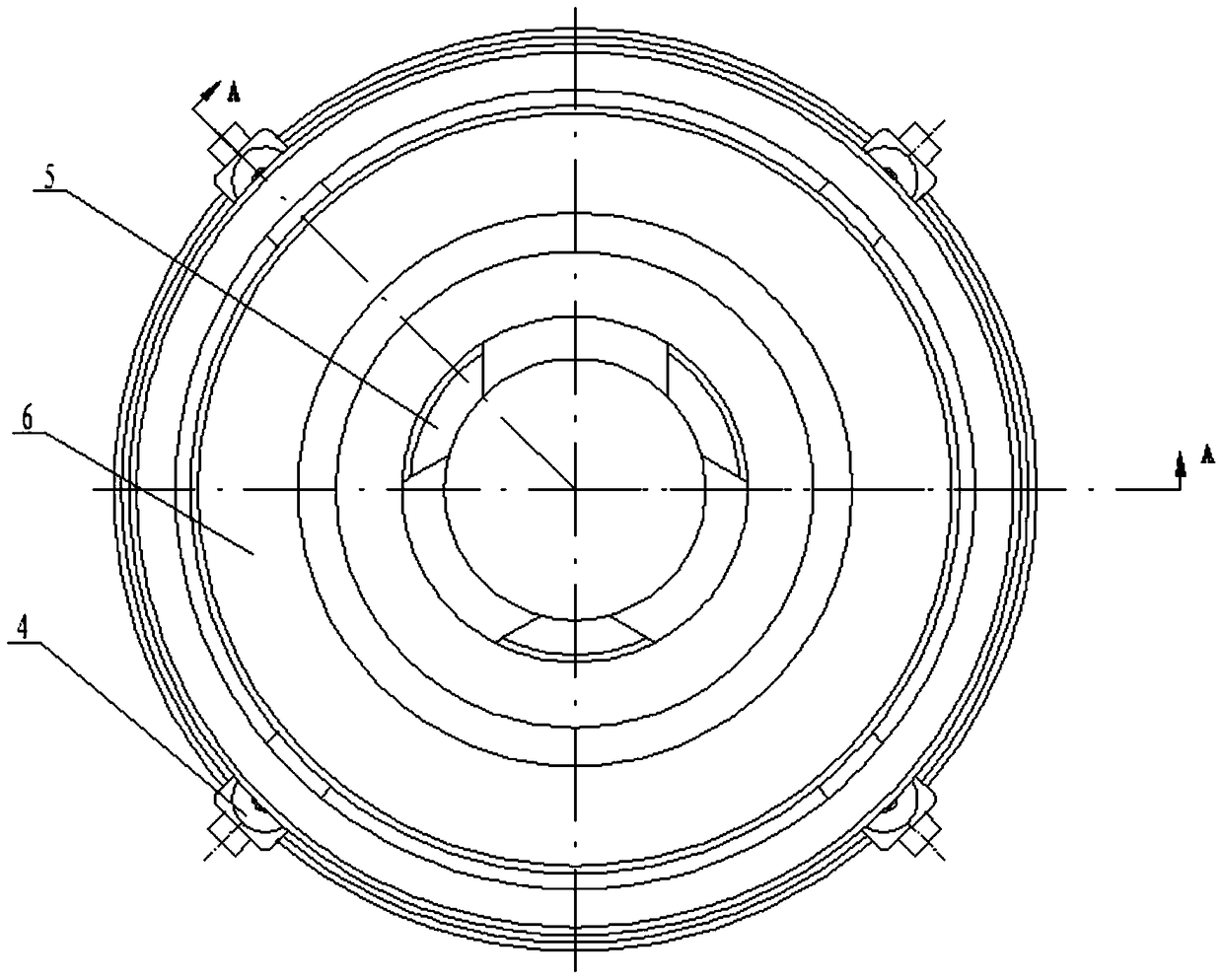

[0009] See figure 1 . The unit includes a supporting plate 1, a fixed ring of the universal mechanism 2, an outer ring of the universal mechanism 3, a displacement sensor 4, a measuring contact end 5, a measuring plate 6, and a return spring 7. The measuring contact end 5 and the measuring plate 6 are a whole, supporting There is a groove on the disk 1, the universal mechanism fixing ring 2 is installed in the groove of the supporting disk 1 and connected with the supporting disk 1, the universal mechanism outer ring 3 is connected with the universal mechanism fixing ring 2, and the outer ring of the universal mechanism The ring 3 rotates around the fixed ring 2 of the universal mechanism, the measuring disk 6 is clamped on the outer ring 3 of the universal mechanism, the top of the measuring contact end 5 is in contact with the measured piece, the support disk 1 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com