Plastic folding bottom bag semi-automatic bottom sealing equipment

A semi-automatic, plastic technology, applied in bag making, paper/cardboard containers, packaging, etc., can solve the problems of increasing the production cost of plastic folding bottom bags, low efficiency of bottom sealing, and relying on manual operation, etc., to improve the efficiency of bottom sealing and adjust the operation The effect of convenience and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

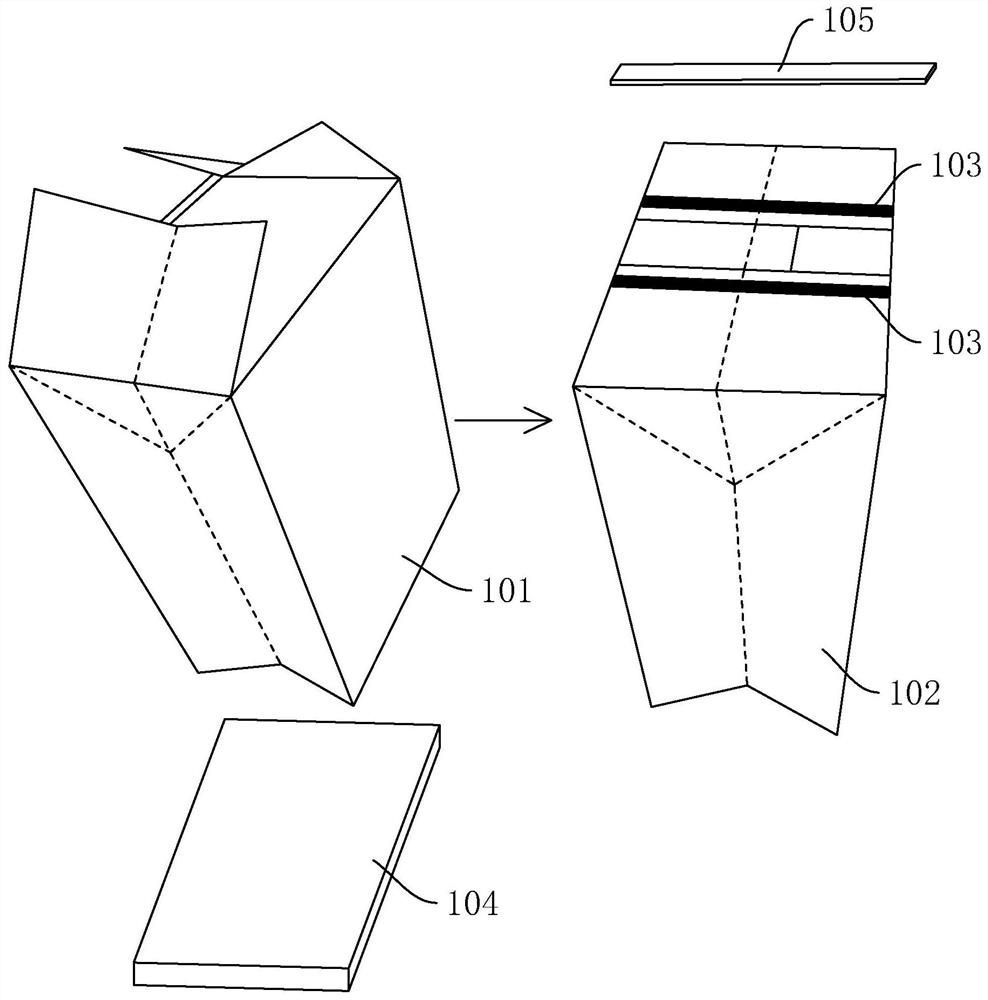

[0042] refer to figure 2 , is a semi-automatic bottom sealing device for plastic folding bottom bags disclosed in the present invention, comprising: a frame 1, a supporting mold 2, a hot pressing mold 3 and a driving mechanism 4.

[0043] There are two supporting molds 2 movable on the frame 1, and the driving mechanism 4 is also installed on the frame 1. The driving mechanism 4 drives the hot-pressing mold 3 to lift; The bag cover is placed on the support mold 2. When the support mold 2 moves to the hot pressing station, the bottom of the plastic folding bottom bag cover is just driven by the support mold 2 to directly below the hot pressing mold 3. When the hot pressing mold 3 falls to the lowest position, it passes Pressing and heating make the bottom of the plastic fold-bottom bag cover stick.

[0044] The supporting mold 2, the hot pressing mold 3, and the driving mechanism 4 are provided with 2 sets and are respectively arranged on different sides of the frame 1. In ot...

Embodiment 2

[0057] refer to Figure 5 and Image 6 , is a semi-automatic bottom sealing device for plastic folding bottom bags disclosed in the present invention. The difference from Embodiment 1 is that the inner side wall of the frame 1 is provided with a chute rail 14, and the bottom side of the support mold 2 is provided with a sliding rod 25. The end of the sliding rod 25 away from the supporting mold 2 is horizontally slidably assembled with the chute rail 14, and a pulley 26 is arranged between the end of the sliding rod 25 and the chute rail 14. to move horizontally.

[0058] The chute rail 14, the sliding rod 25 and the pulley 26 cooperate with each other, so that the support mold 2 can be horizontally slid and assembled on the frame 1. When the support mold 2 is covered with a plastic folding bottom bag, the support mold 2 should be slid to the outside of the frame 1 That’s it (at the set-up station), and then push the supporting mold 2 inside the frame 1 until the supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com