Exhaust gas recirculation with reduced condensate formation

A technology of exhaust gas recirculation and air supply, applied in exhaust gas recirculation, electrical control, charging system, etc., which can solve problems such as compressor blade damage, compressor damage, and complete compressor failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

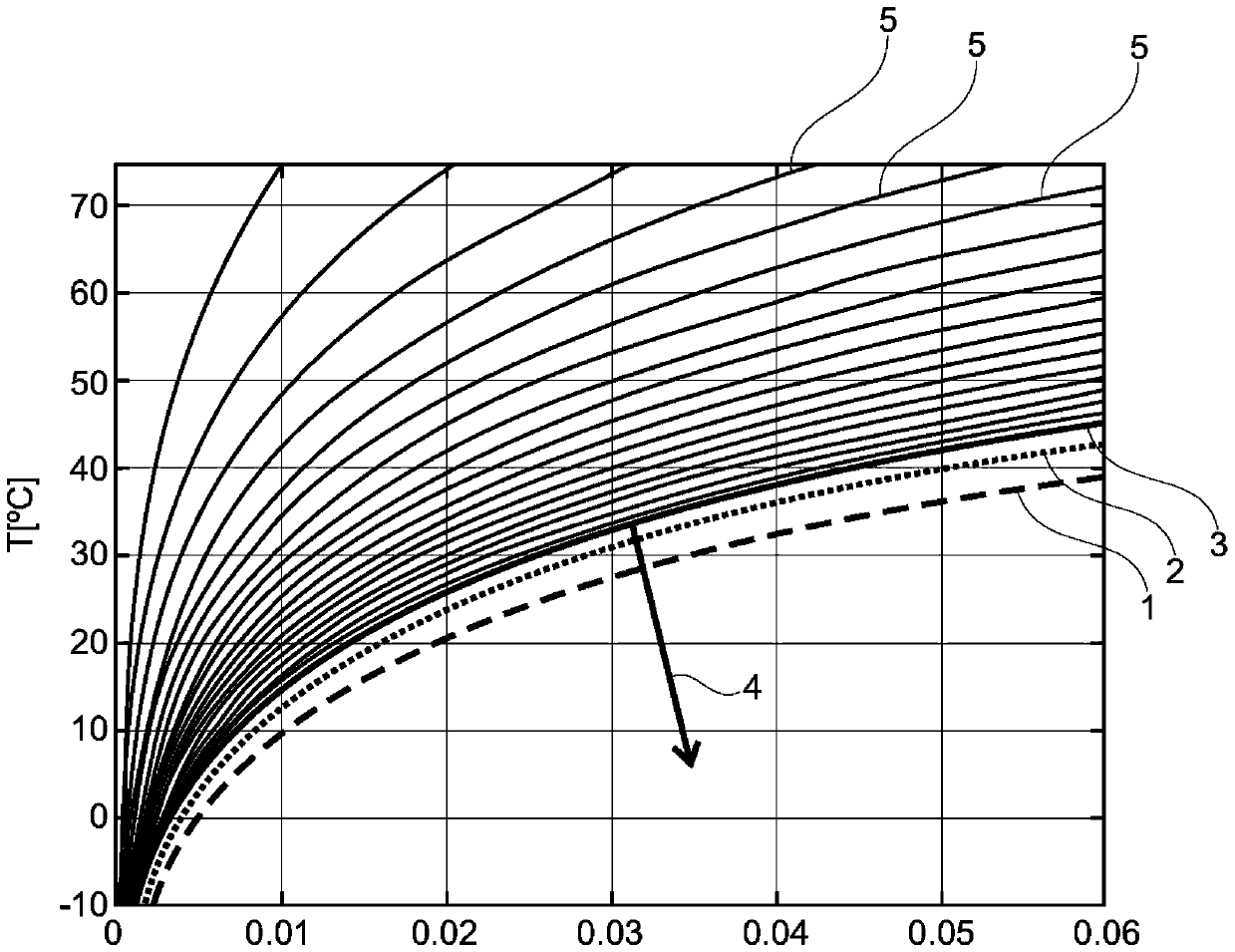

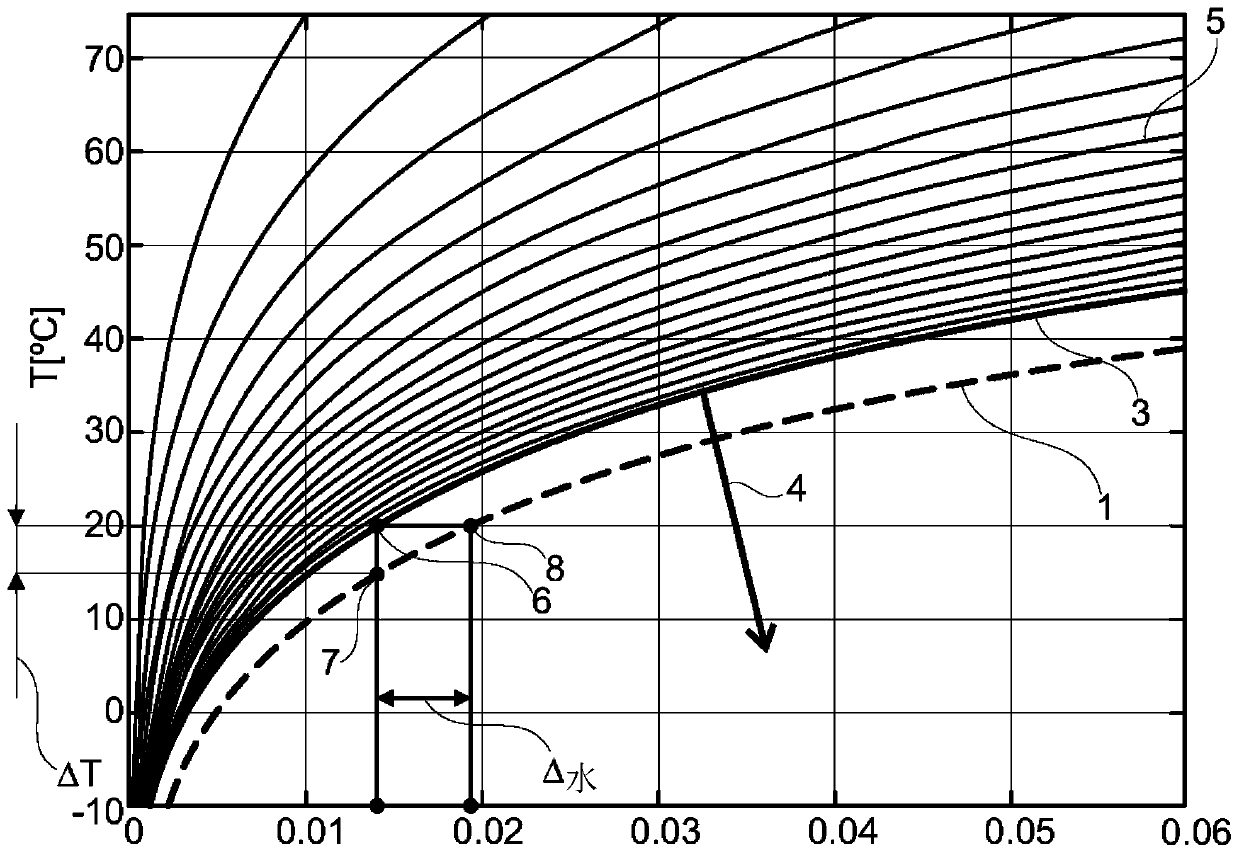

[0027] figure 1 It is schematically shown that the humidity saturation curve is represented as a graph as a function of temperature for various pressures. Humidity is plotted on the x-axis in units of kg water / kg dry exhaust-air mixture. The temperature T is plotted on the y-axis in degrees Celsius (°C). Curve 1 represents the saturation curve for an exhaust-air mixture at a pressure of 0.75 bar. In other words, it is characterized at 0.75 bar The relative humidity of the exhaust-air mixture. Curve 2 characterizes the saturation curve for the exhaust-air mixture at a pressure of 0.9 bar. Curve 3 characterizes the saturation curve of the exhaust-air mixture at a pressure of 1.0 bar. A further saturation curve is indicated illustratively with reference number 5 . Arrow 4 indicates the region of saturation curve 3 where condensation occurs. Thus, condensation occurs if the temperature decreases in the direction of arrow 4 or if the humidity increases in the direction of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com