Test device for detecting bearing corrosion resistance

A test device and corrosion-resistant technology, which can be used in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., and can solve problems such as abnormal use, wear and damage of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

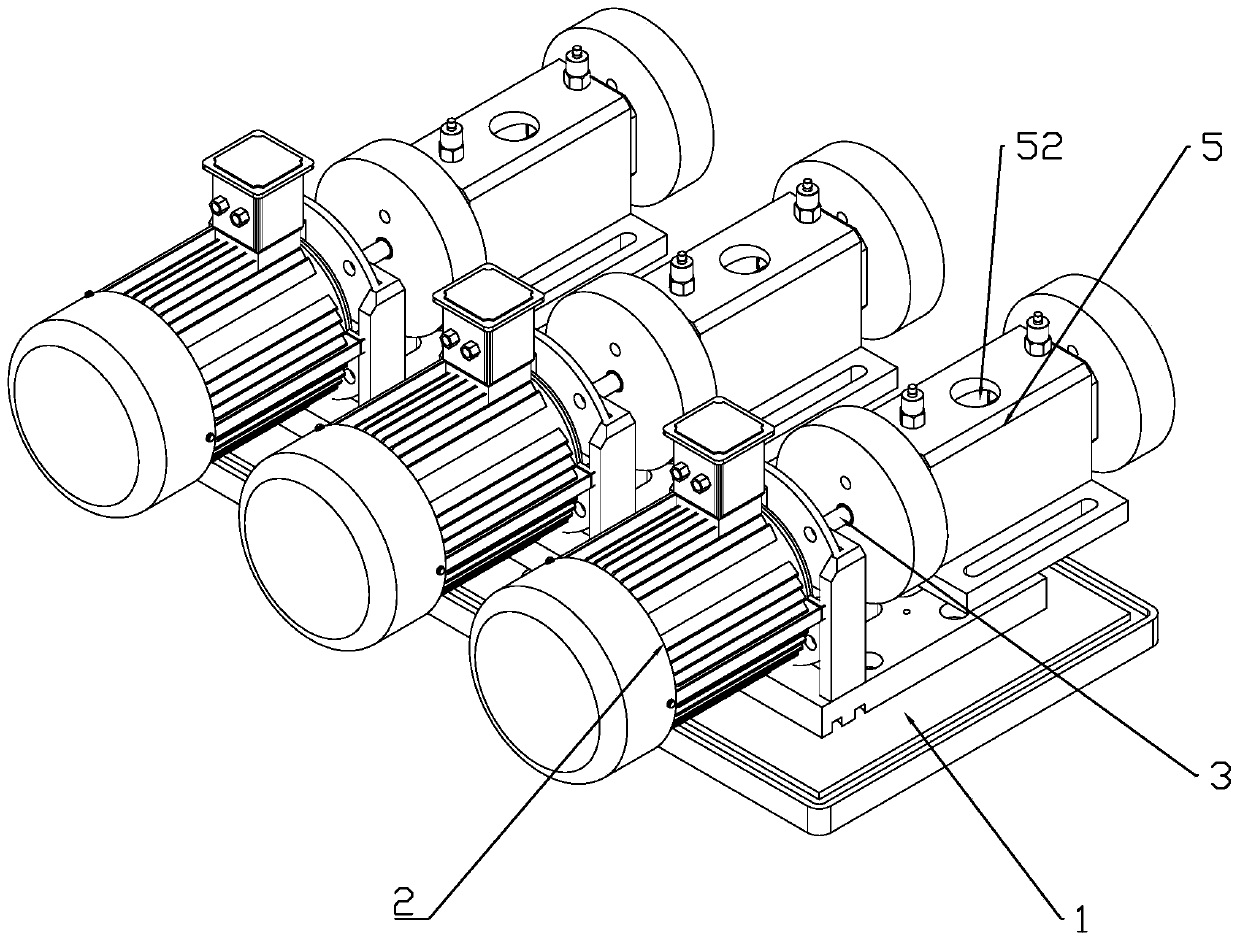

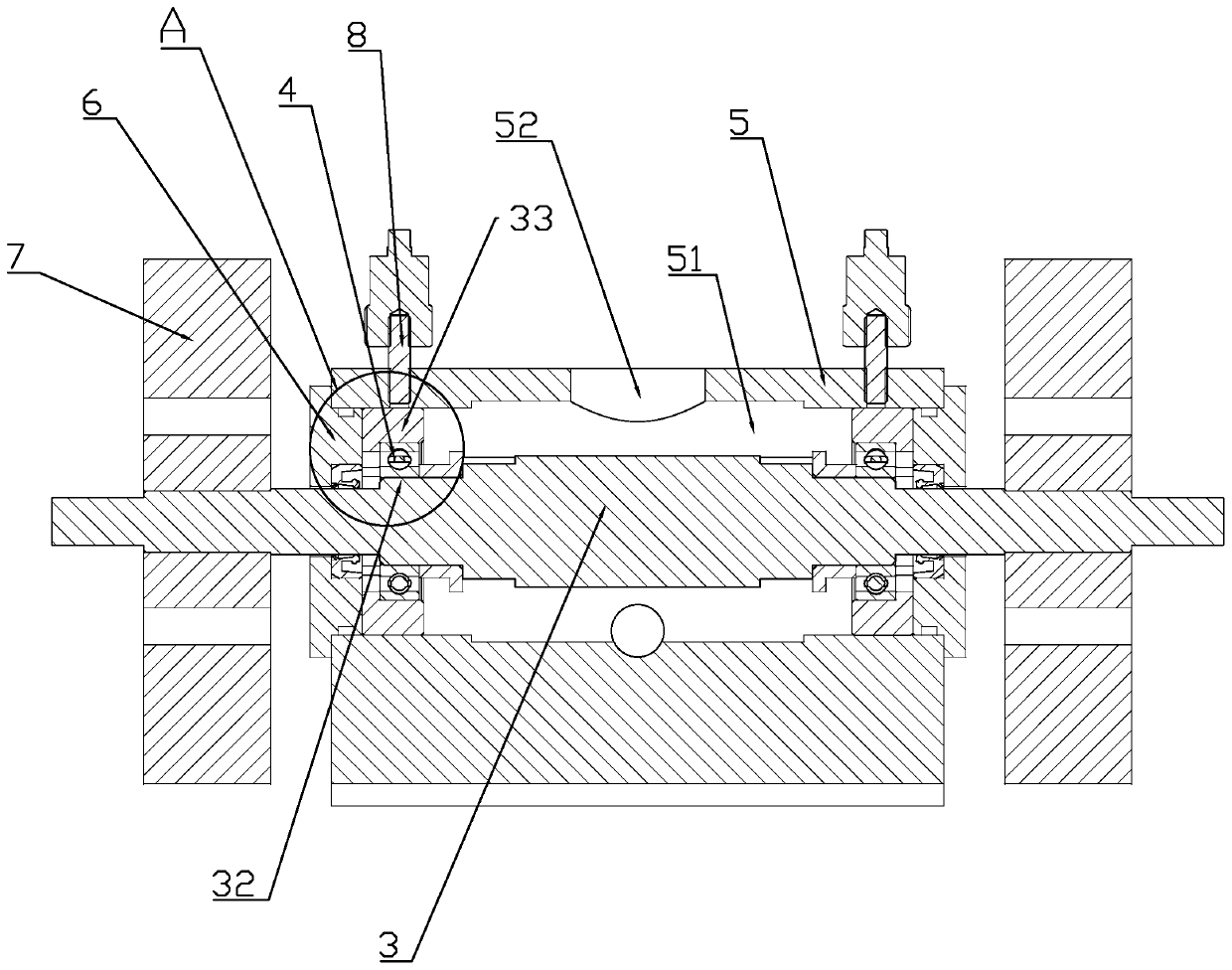

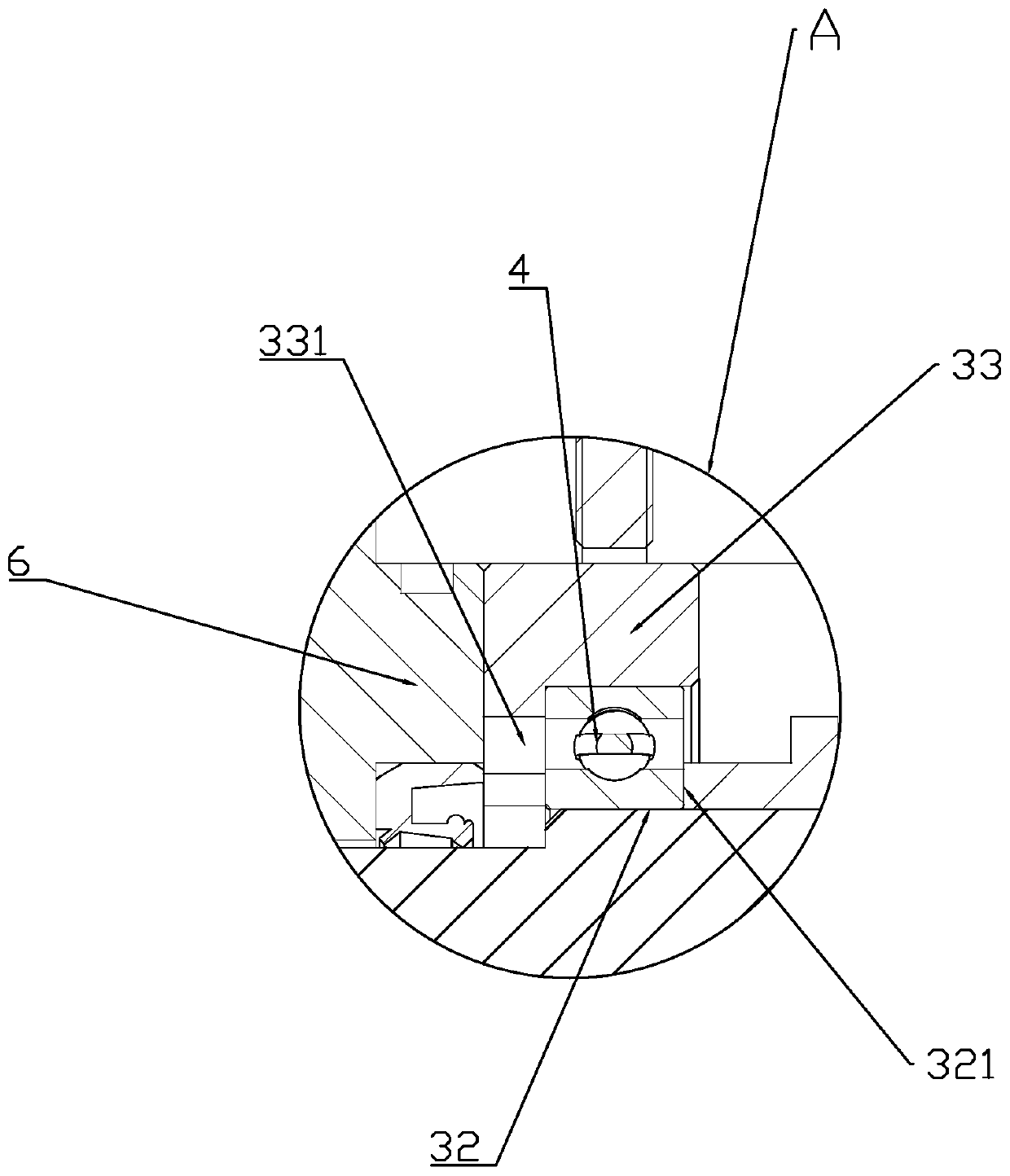

[0021] Depend on Figure 1 to Figure 5 It can be seen that the present invention discloses a test device for detecting the corrosion resistance of bearings, including a machine base 1 and a driving motor 2, on which a rotating main shaft 3 is rotated, and the rotating main shaft 3 and the driving motor 2 The output end transmission connection of the rotating shaft 3 is provided with a test station 31 for installing the bearing 4 to be tested. The test station 31 is covered with a test case 5, and the test case 5 is hollow formed for adding A test cavity 51 for the chemical test reagent, the test cavity 51 is connected to the test station 31 and arranged to realize the contact between the bearing 4 to be tested and the chemical test reagent. Before testing the corrosion resistance of the test bearing 4, the bearing 4 to be tested is first installed on the test station 31 of the rotating main shaft 3, and the inner ring of the bearing 4 to be tested is fixedly sleeved with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com