Nondestructive testing method and device for steel wire rope

A non-destructive testing and steel wire rope technology, applied in the field of steel wire rope testing, can solve the problems of low detection accuracy, inability to quantitatively detect cross-sectional loss, complex calculations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

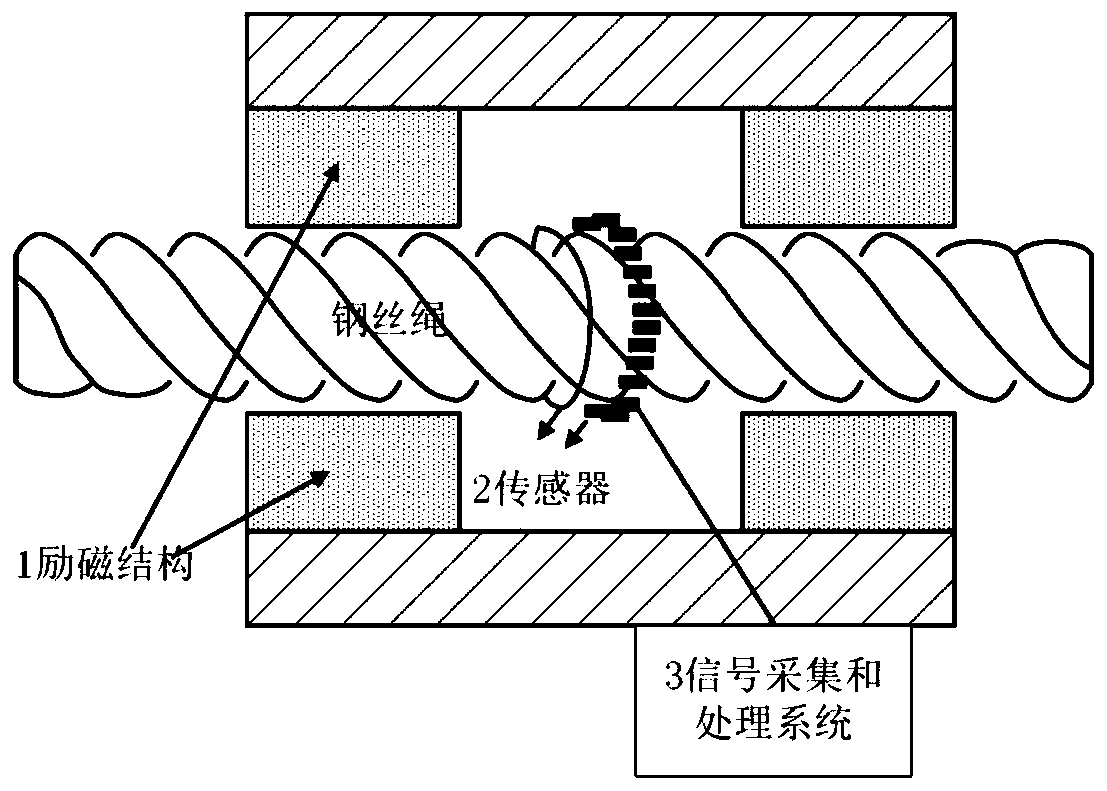

[0077] Considering that the current electromagnetic detection method cannot quantitatively detect the cross-sectional loss of all defects of the steel wire rope, and the detection accuracy is very low, and the calculation is complicated. Therefore, the present invention proposes a method and device for non-destructive detection of steel wire ropes by detecting magnetic flux and magnetic field leakage. , the present invention can not only identify all defect types including internal defects of the tested steel wire rope by detecting the magnetic flux and leakage field, but also has the advantages of high quantitative accuracy of section loss and simple calculation.

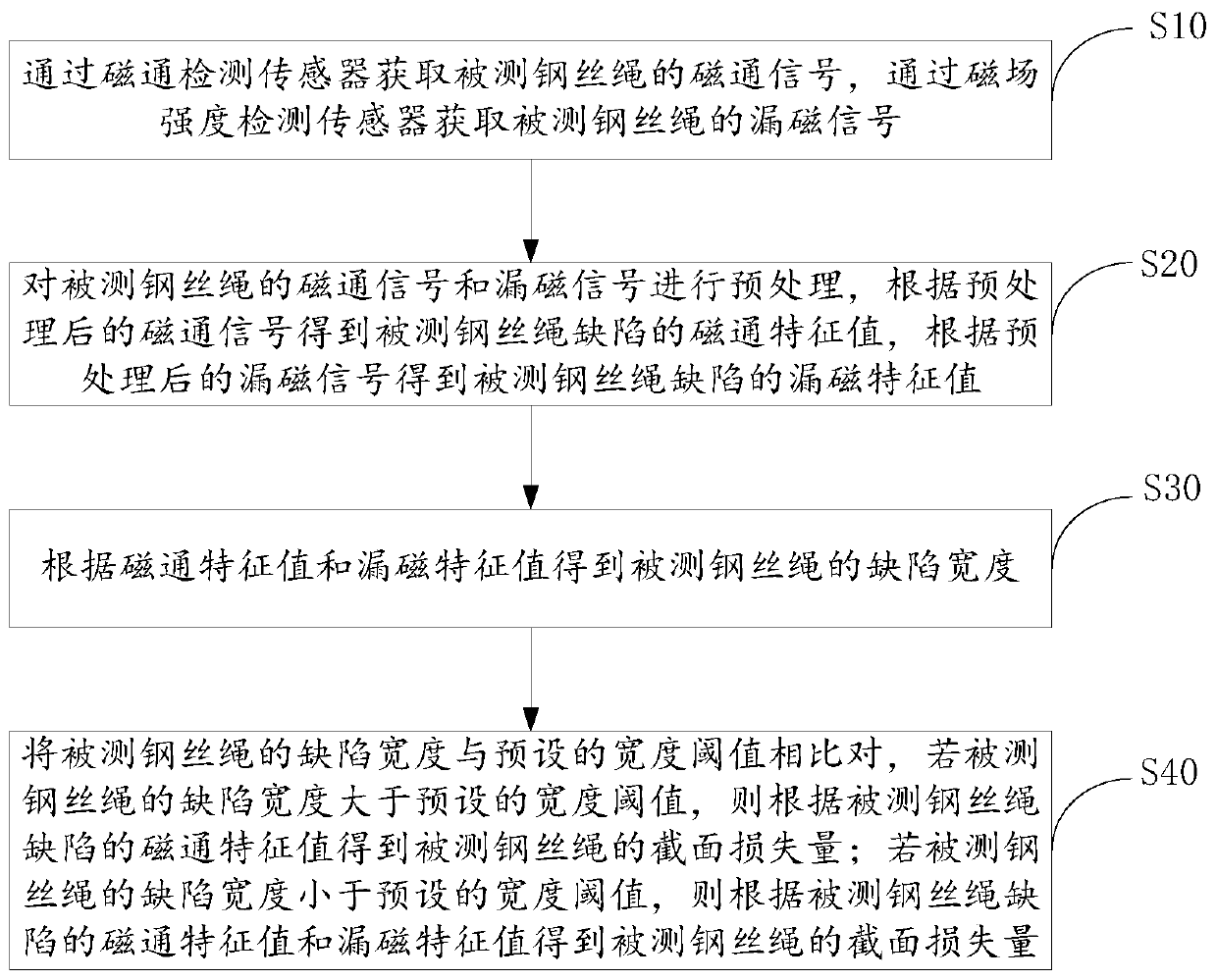

[0078] Specifically, please refer to figure 1 , figure 1 It is a schematic flow chart of a preferred embodiment of the non-destructive testing method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com