Low-water-mist flushing device

A technology of flushing water and water mist, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems of target observation obstruction, machine service life impact, and poor effect, etc., to solve the problem of water mist Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is a detailed description based on the embodiment shown in the drawings:

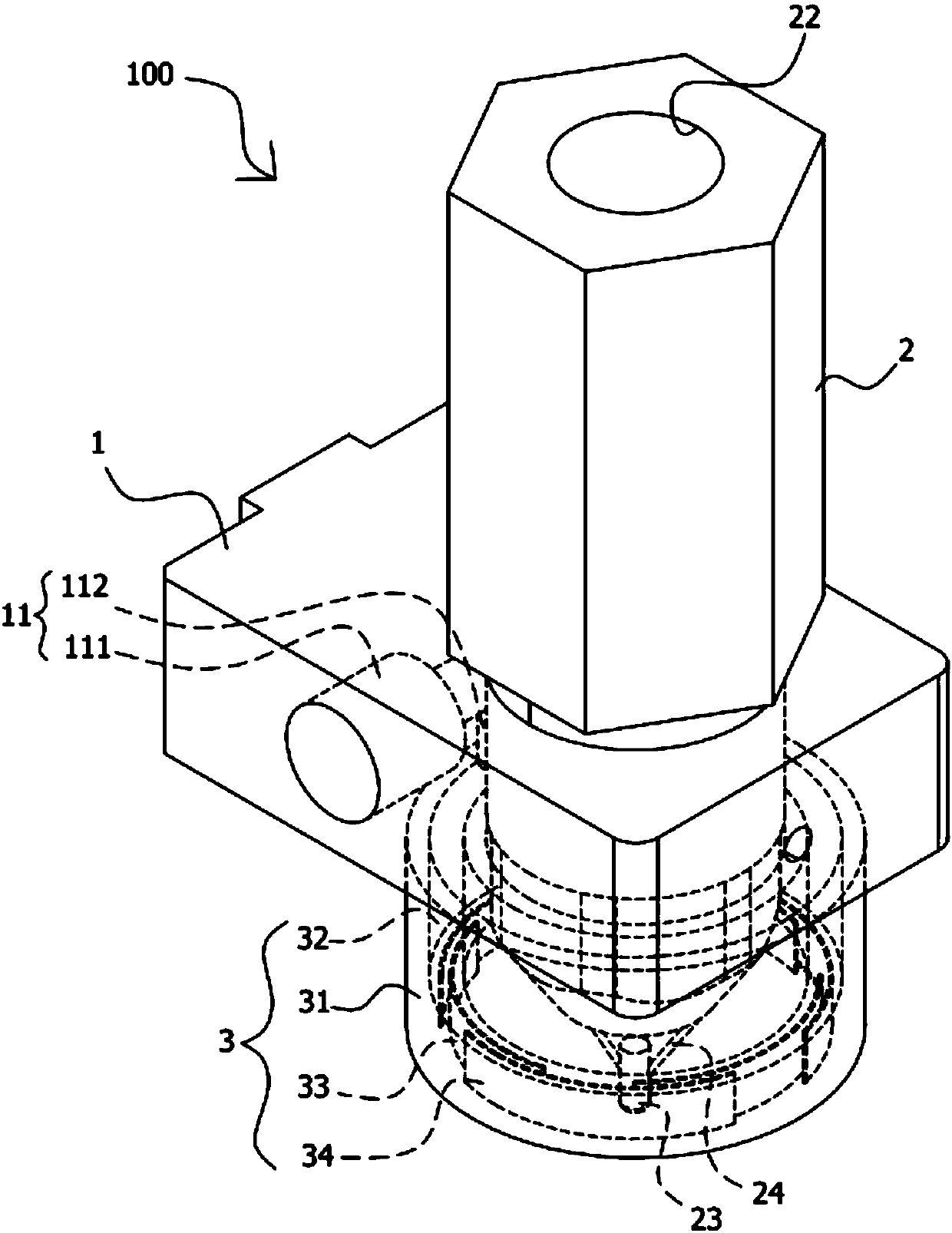

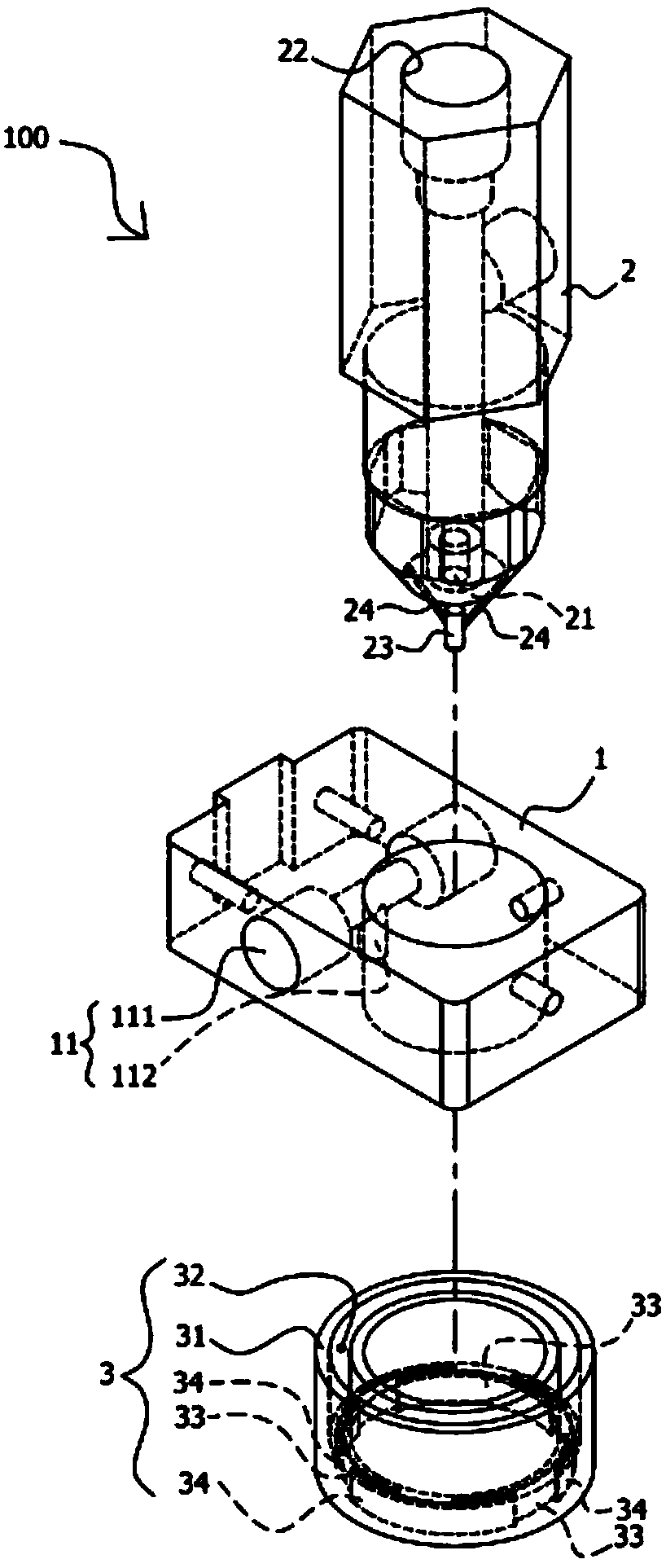

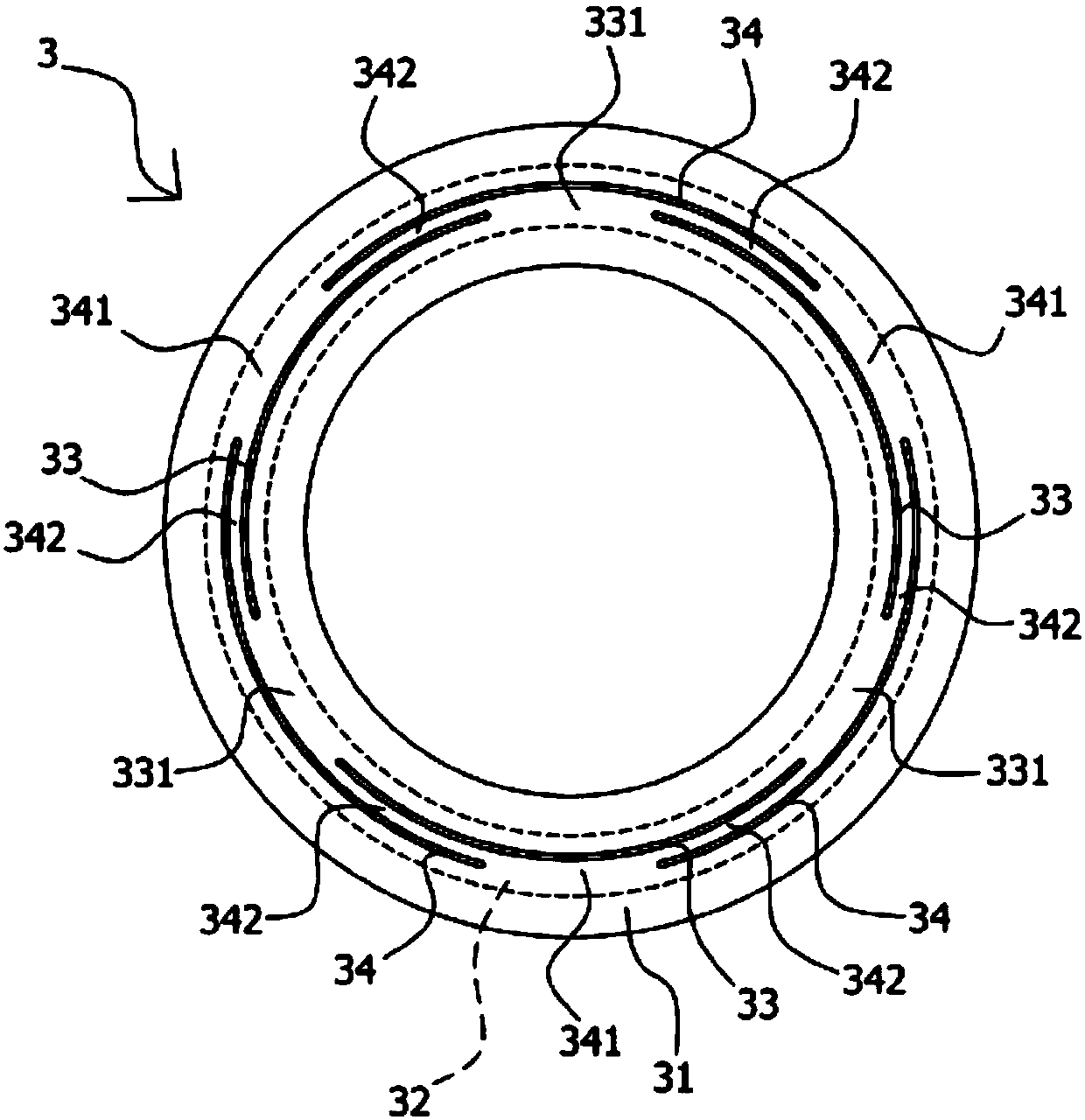

[0041] Such as Figure 1 to Figure 5 As shown in the figure, it is disclosed that a low water mist flushing device can be used in conjunction with wet process equipment, wherein the low water mist flushing device 100 includes a positioning unit 1, a flushing unit 2, and a The air knife cap 3; the positioning unit 1, one end of which can be connected to the corresponding side of the wet process equipment, and has an air guide channel 11 capable of outputting gas to the bottom side; the flushing unit 2, which is vertically arranged on the positioning At the free end of the unit 1, there is a water outlet 21 at the bottom and a water inlet 22 at the top; the air knife cap 3 includes an annular housing 31, a slot 32, at least two internal air outlets slit 33, and at least two air outlet slits 34; the annular shell 31, which is sleeved outside the water outlet 21; the slot 32, which is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap