A cold coke flash degassing treatment device and method

A treatment device and treatment method technology, applied in the field of delayed coking, can solve the problems of high frequency of tank cleaning, deformation of tank body, high operating cost, etc., and achieve the effect of reducing water consumption, reducing frequency of tank cleaning, and safe and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

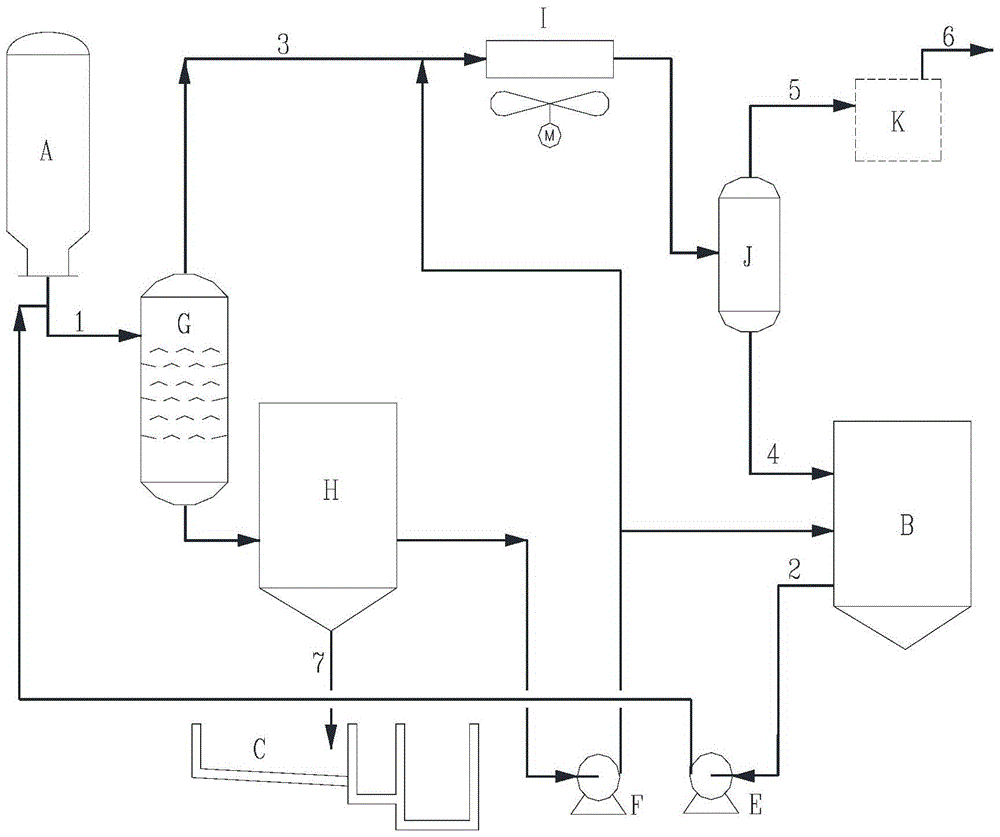

[0047] Such as image 3 Shown, a cold coke release water flash degassing treatment device.

[0048] Including: coke tower A, cold coke water release degassing tank G, cold coke water release tank H, cold coke water tank B, tail gas cooler I, tail gas water separation tank J and tail gas desulfurization facility K;

[0049] The bottom of the coke tower A is connected to the cold coke degassing tank G, the top of the cold coke degassing tank G is connected to the tail gas cooler I, the bottom of the cold coke degassing tank G is connected to the cold coke degassing tank H; the cold coke dewatering tank H is connected to the cold coke The pipeline behind the water delivery pump F is divided into two branches, one is connected to the inlet of the exhaust gas cooler I, and the other is connected to the cold coke water tank B; the outlet of the exhaust gas cooler I is connected to the exhaust gas water separation tank J, and the top of the exhaust gas water separation tank J is conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap