Numerically controlled welding method with automatic compensation and filling of clearance

A technology of automatic compensation and welding method, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems affecting product quality and production efficiency, welding penetration or insufficient filling, sudden shutdown of equipment, etc., to avoid the risk of equipment shutdown , reduce welding defects, reduce the effect of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

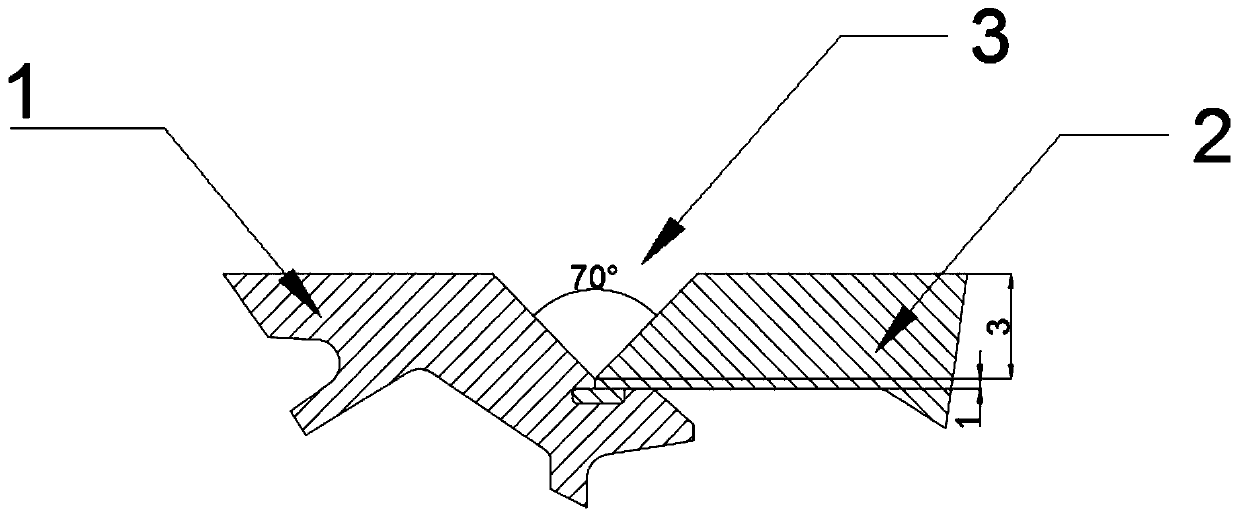

[0040] A numerical control welding method for automatic gap compensation and filling provided by a preferred embodiment of the present invention includes the following steps:

[0041] According to the groove form of the CNC welded parts, combined with the dimensional tolerance of the corresponding parts and the welding standard requirements, calculate the upper and lower extreme differences of the groove gap after assembly and obtain the fluctuation range ΔW of the groove gap value, so as to determine the upper part of the weld Spacing W, the formula for calculating the spacing W of the upper part of the weld is as follows:

[0042] W=W 1 +ΔW

[0043] Among them, W represents the distance between the upper part of the weld, and W 1 Indicates the plate thickness of the workpiece to be welded, ΔW indicates the fluctuation range of the groove gap value; W 1 It is a fixed plate thickness, a fixed value in the case of no gap. The distance W at the upper part of the weld used in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com