Sand flushing and plugging removal pipe string

A technology for plug removal and sand flushing, applied in drill pipe, casing, wellbore/well components, etc., can solve the problems of reducing pump efficiency, oil well production reduction, production stoppage, etc., and achieve the effect of reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

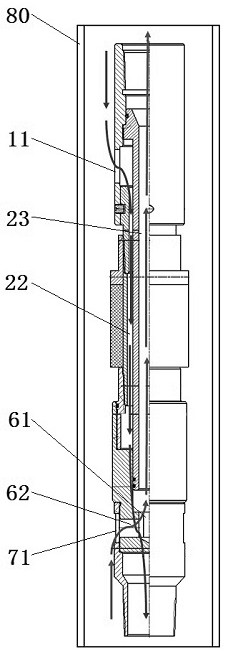

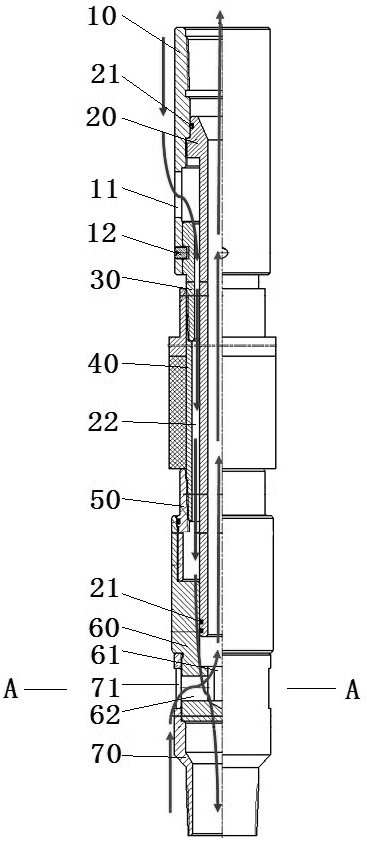

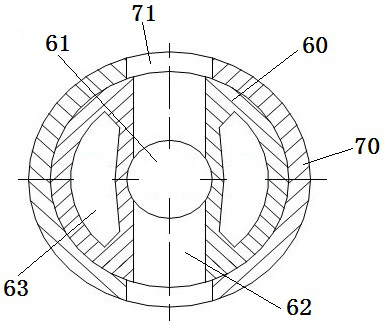

[0031] The specific implementation of the sand flushing and plugging removal pipe string in the present invention will now be described in conjunction with the accompanying drawings.

[0032] Such as figure 1 As shown, it is an embodiment of the present invention: the relative positional relationship of each structure is represented by the up, down, left, and right directions in the figure. The upper joint 10 , the packer 40 , the bridge joint 60 and the lower joint 70 used in conjunction with the base pipe 20 . The upper joint 10 is a sleeve structure with an inner cavity, and the upper joint 10 and the packer 40 are connected through a first variable joint 30. The outer peripheral surface of the first variable joint 30 is provided with external threads, and the packer 40 The ends of the upper joint 10 and the first variable joint 30 are respectively provided with internal threads, and the ends of the upper joint 10 and the packer 40 are all arranged on the first variable j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com