Extrusion section structure and process applied to inner shell and an outer shell of vending machine

A technology for vending machines and extruded profiles, which is applied in the direction of handling coins or valuable banknotes, instruments, etc. It can solve the problems of water mist on the surface of glass doors, affecting product sales, and difficult assembly, and achieves short mold opening cycle and assembly The effect of simplicity and low mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the present invention will be further described.

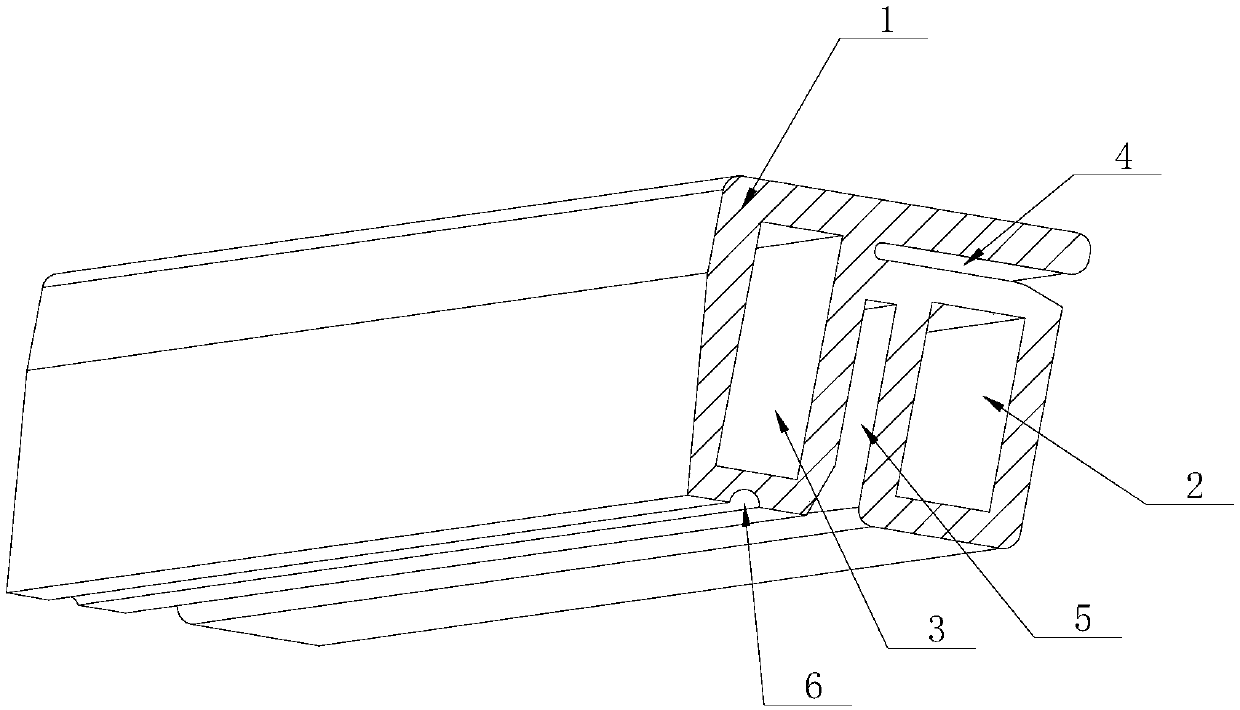

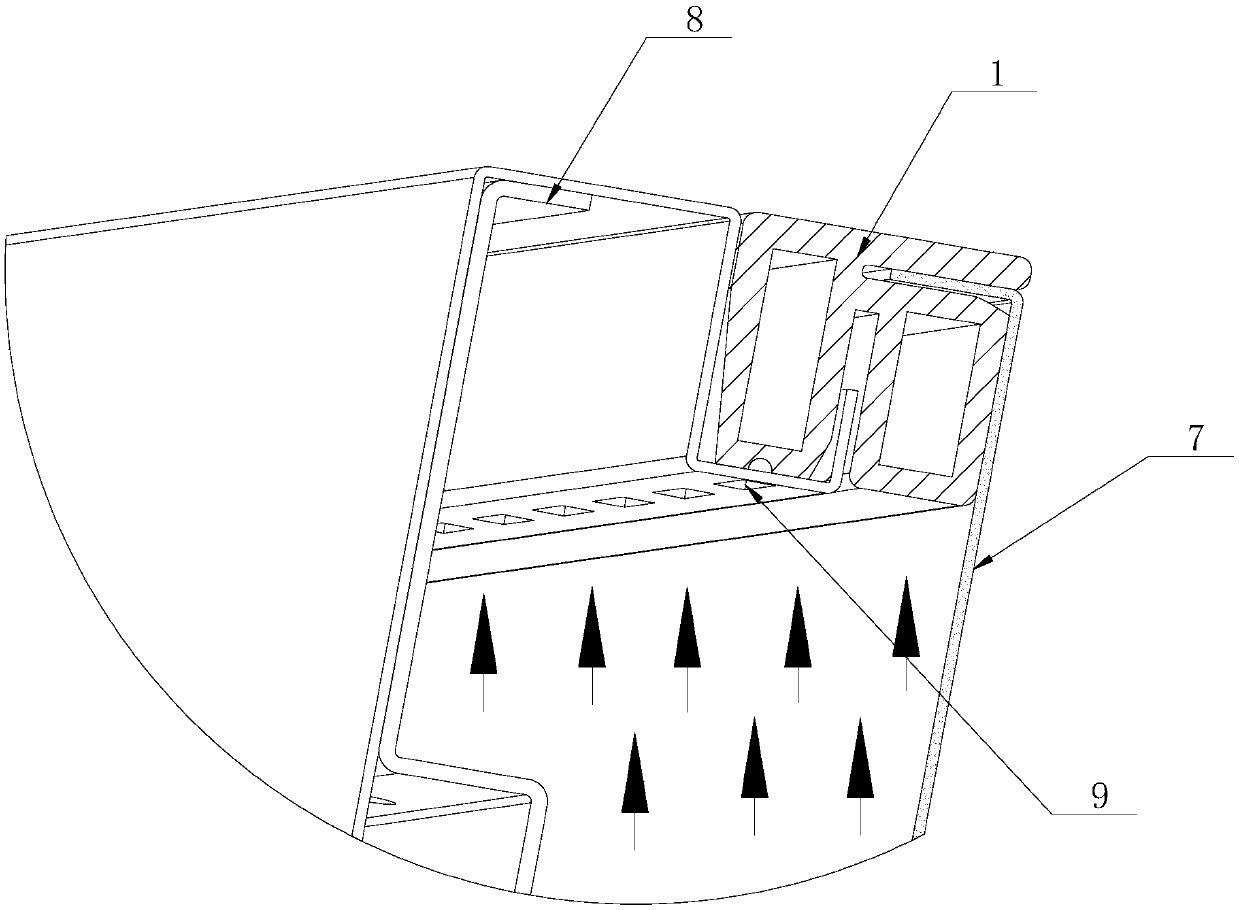

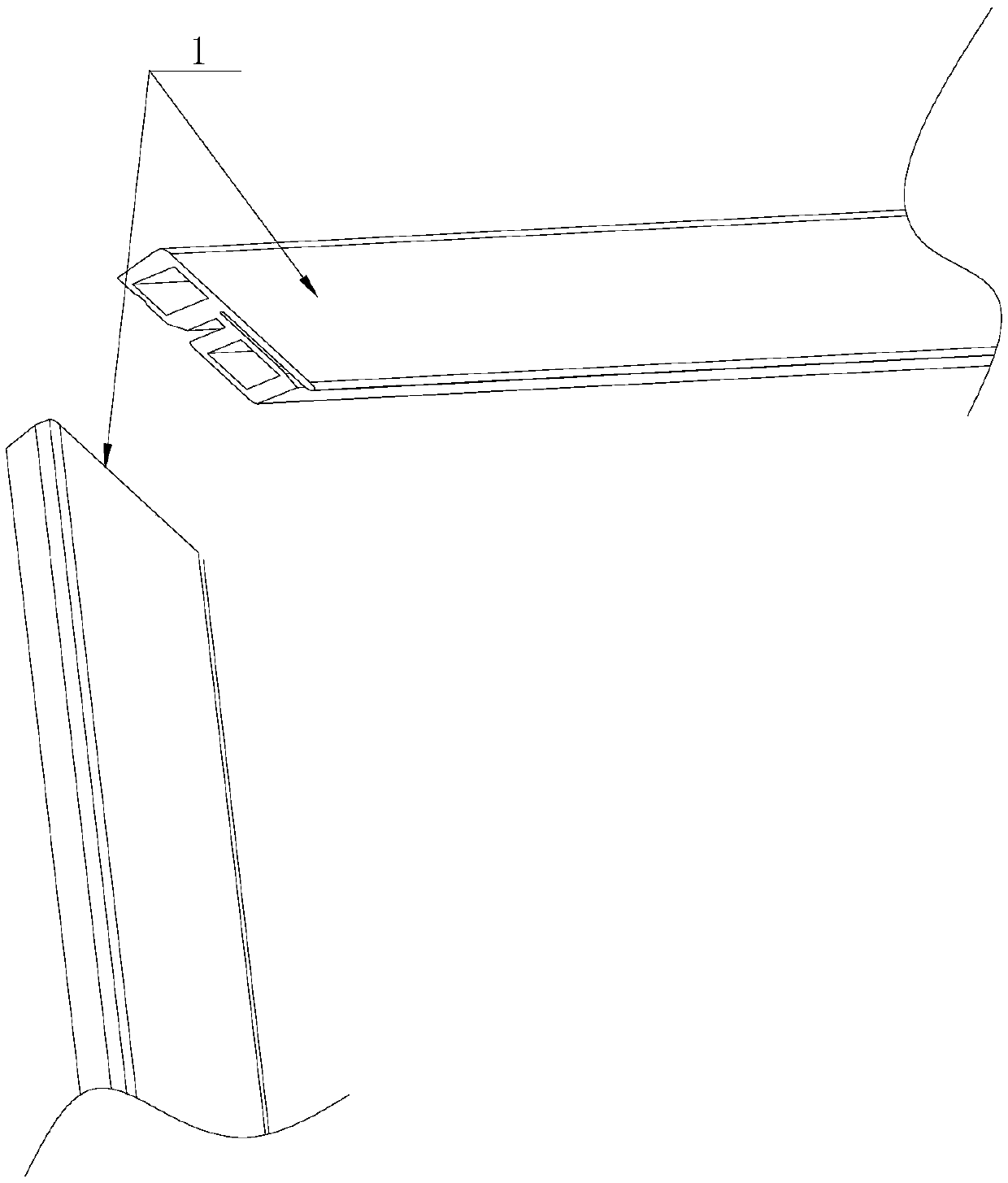

[0028] see as Figure 1-Figure 5 As shown, this specific embodiment adopts the following technical scheme: it includes extruded profile 1, buffer cavity 1 2, buffer cavity 2 3, inner shell slot 4, outer shell slot 5, ventilation groove 6, inside the vending machine Bladder shell 7, vending machine shell 8, air vent slot 9; inside the extruded profile 1 are provided with a pair of buffer cavity 1 2 and buffer cavity 2 3, the upper end of the buffer cavity 1 2 is horizontally An inner shell slot 4 is provided, and a shell slot 5 is longitudinally arranged in the middle of the first buffer cavity 2 and the second buffer cavity 3; a ventilating groove 6 is arranged outside the lower end of the second buffer cavity 3; The inside of the inner shell slot 4 is plugged with the right-angled side of the vending machine liner shell 7, and the outer shell slot 5 is plugged with the U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com