Flame-retardant and compression-resistant cable

A technology for cables and cable core wires, applied in the field of flame-retardant and compression-resistant cables, can solve the problems of low visibility, shear resistance, general compression resistance, core wire damage, etc., and achieve good heat dissipation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

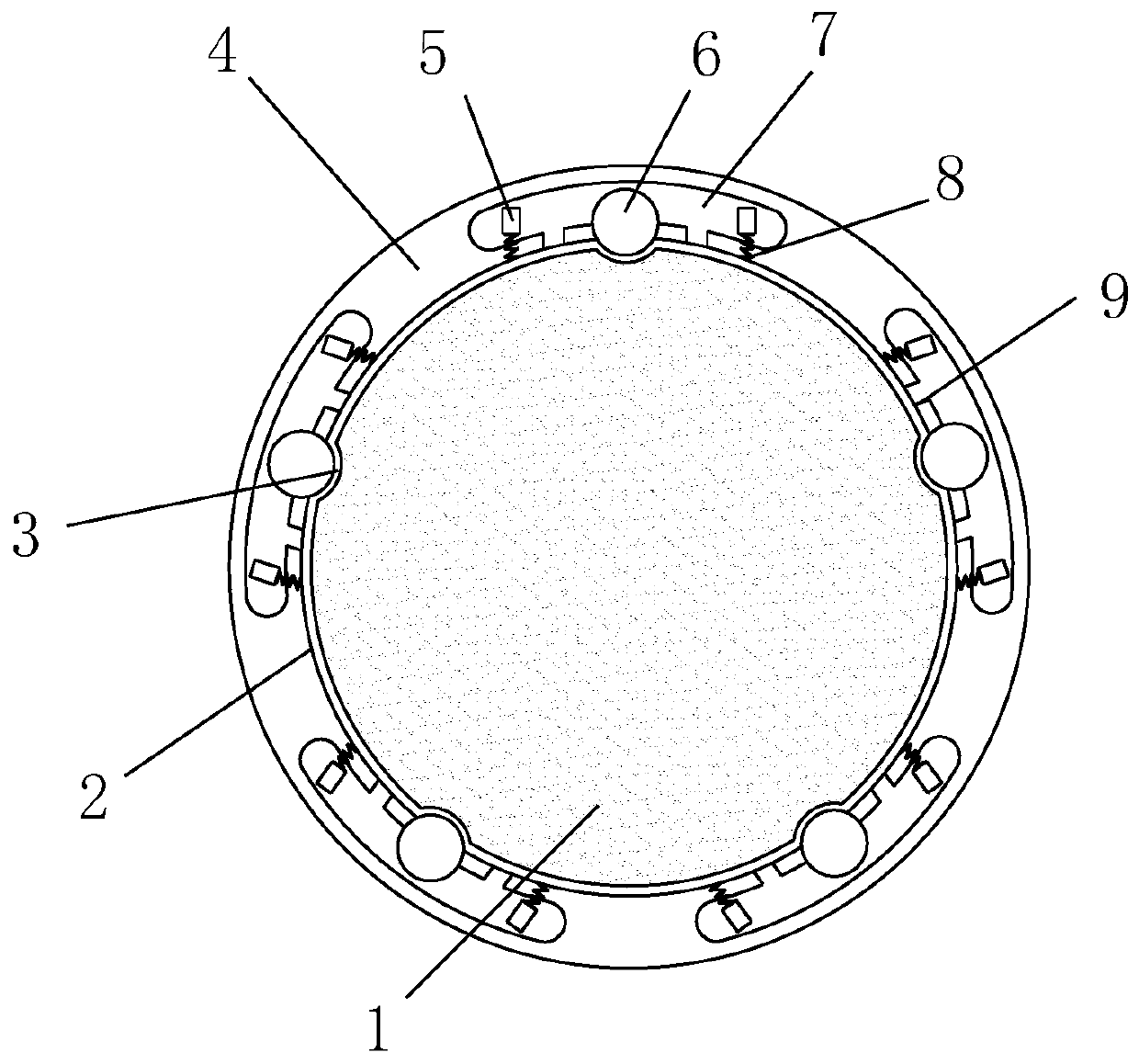

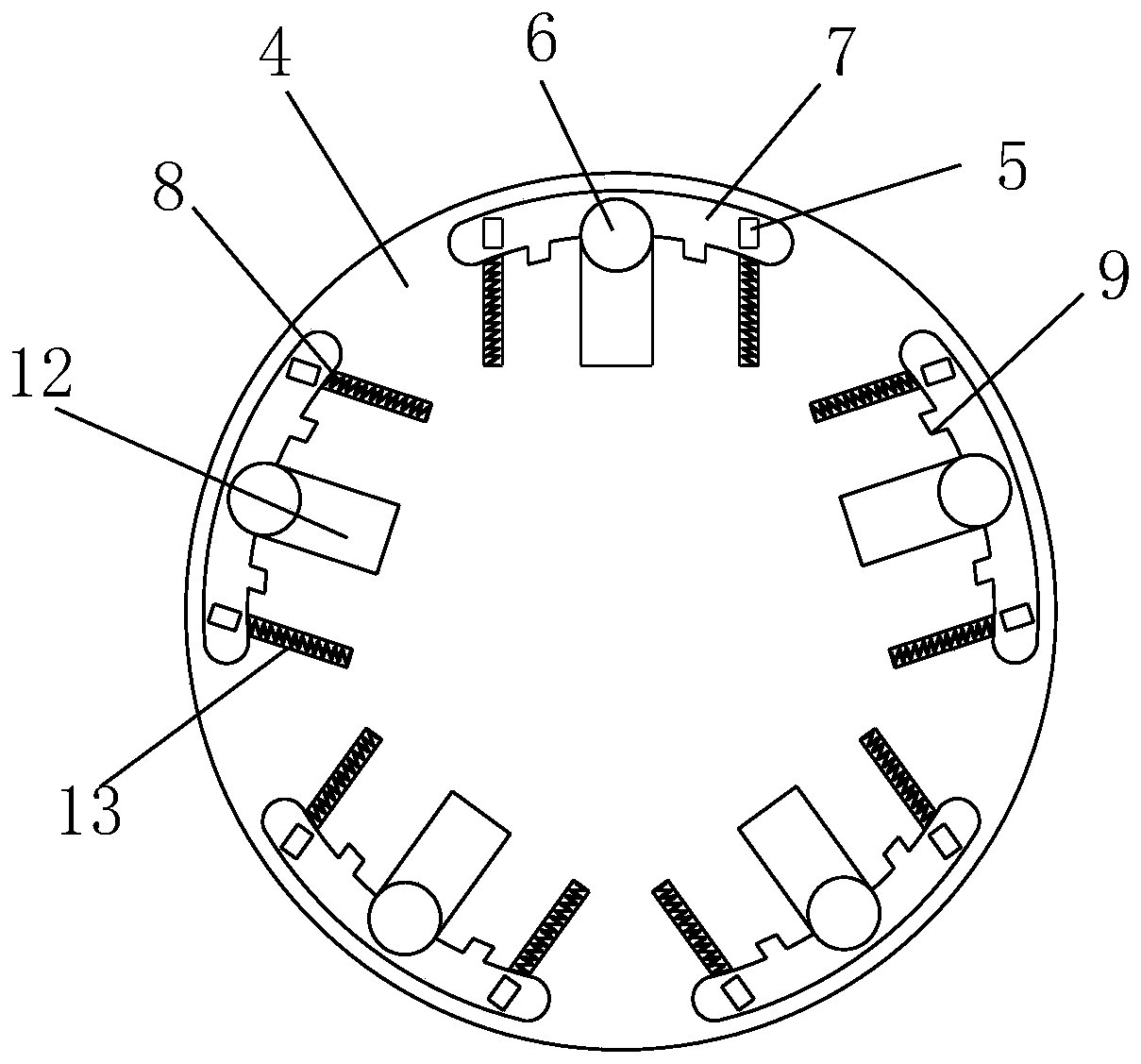

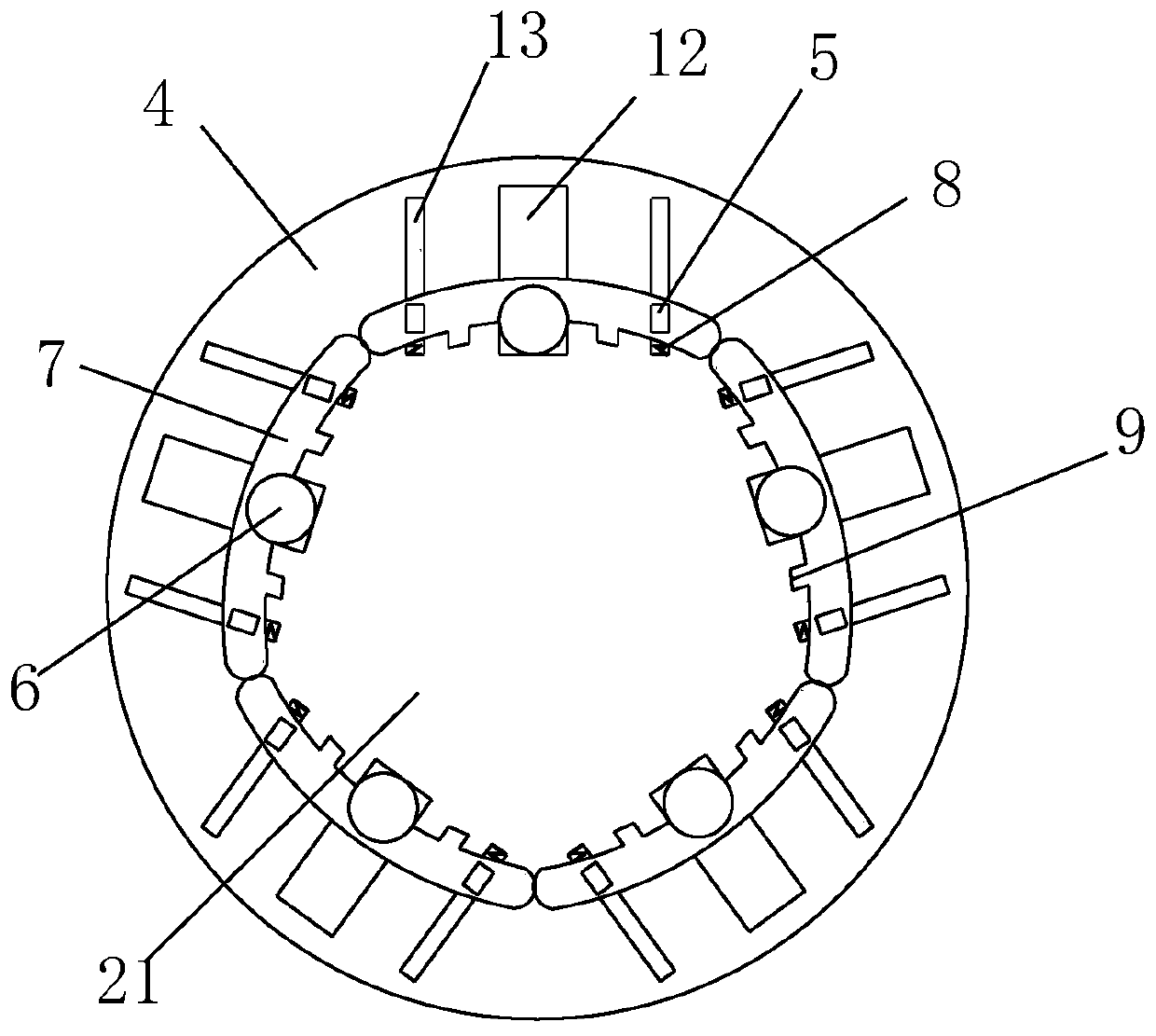

[0018] Such as figure 1 As shown, the flame-retardant and pressure-resistant cable includes more than one fixing part 4, and an elastic fire extinguishing assembly is fixedly arranged in the middle of adjacent fixing parts 4. The outside of the elastic fire extinguishing assembly is provided with more than one outer protection sheet 7, and more than one The outer protective sheet 7 is arranged equidistantly around the fixed part 4, and is spliced with each other to form a circular outer cover layer. Two slide grooves 13 are respectively arranged on the end faces of the fixed part 4, facing the outer protection of the slide grooves 13. A slider 5 is arranged on the end surface of the piece 7, and the outer protection piece 7 is respectively slid and buckled into the chute 13 through the sliders 5 on both sides, and a group of springs 8 are arranged in the chute 13, and are located between the two chute 13. A through groove 12 is provided on the fixed part between each piece o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com