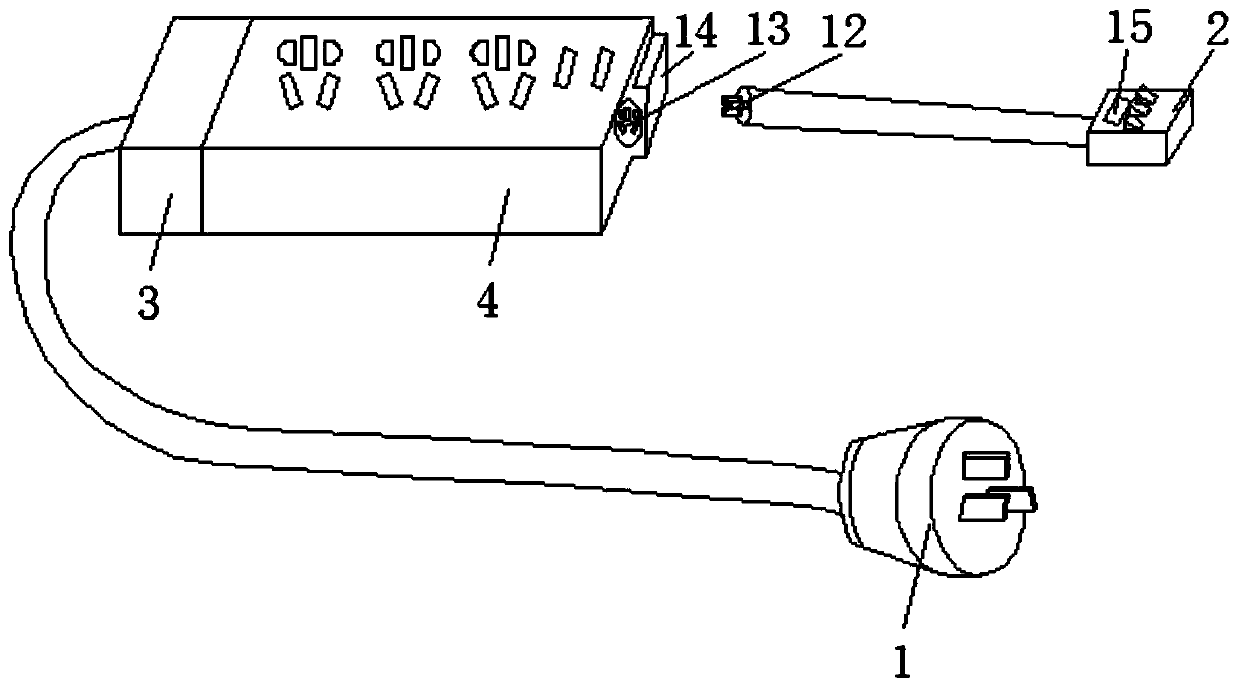

Split-type switch patch board

A plug-in, split-type technology, which is applied to devices with bendable leads, electrical components, bases/shells, etc., can solve problems such as poor applicability, inability to adjust the length of the power cord, and inconvenient opening and closing of the plug-in panel. To improve the applicability, the room is neat and beautiful, and the use is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

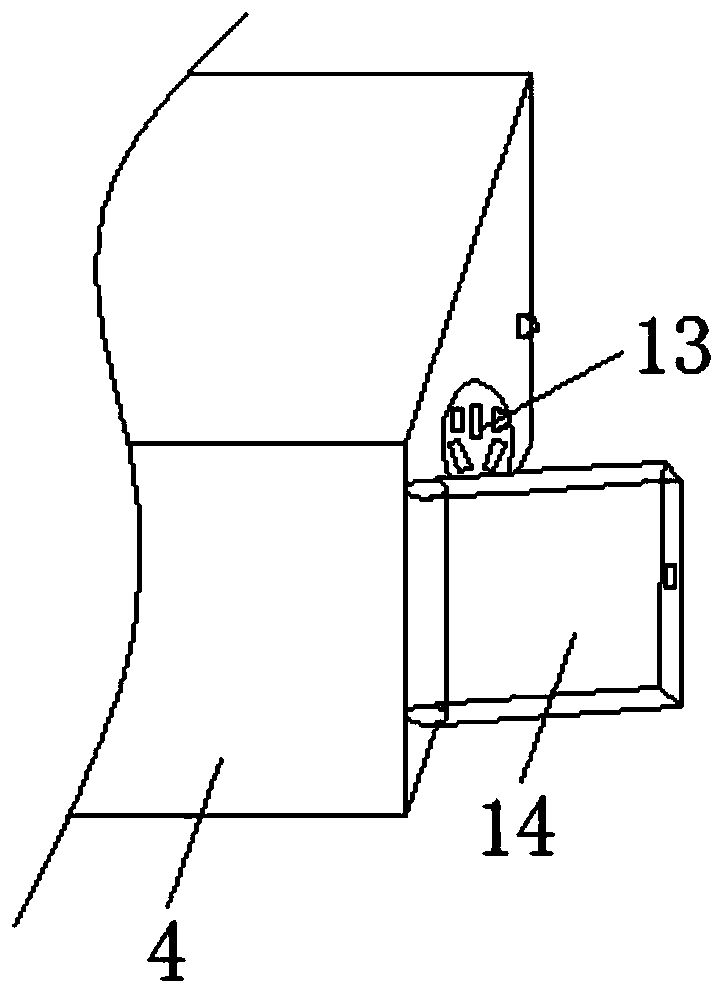

[0037] On the basis of the above structure, in this embodiment, the box body switch 2 is fixedly installed with an indicator light 15 showing its working status, which is convenient for people to know the usage status of the socket. In addition, a plurality of switch buttons are installed on the box body switch 2, and the plurality of switch buttons are respectively used to control different socket power sources.

Embodiment 2

[0039] On the basis of Embodiment 1, in this embodiment, the winding device includes a winding shaft 5, and the two ends of the winding shaft 5 are positioned to be rotatably connected to two opposite sides of the wire storage box 3, and on two opposite sides of the wire storage box 3 There are rotating holes matched with both ends of the winding shaft 5; the second power cord is wound on the winding shaft 5, and the winding shaft 5 is rotated to wind or release the second power cord to adjust the length of the second power cord. The structure is simple, and the length of the second power cord can be adjusted by means that those skilled in the art can think of, such as manually turning the bobbin 5 forward or reverse so that the second power cord is wound on the bobbin or released from the bobbin.

[0040] It should be noted that the bobbin 5 can be installed in the wire storage box 3 to rotate vertically, and can also be installed in the wire storage box 3 to rotate horizontal...

Embodiment 3

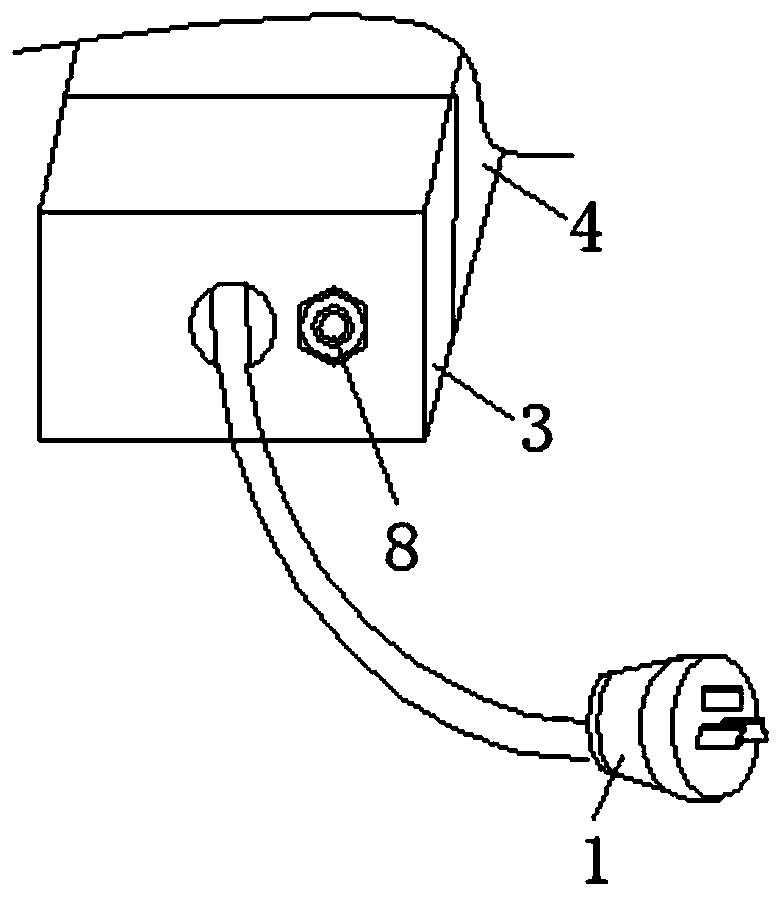

[0042] On the basis of Embodiment 2, in this embodiment, one end of the winding shaft 5 is coaxially fixed with a positioning disc 6, and the center of the positioning disc 6 is provided with a through hole for the winding shaft 5 to pass through, and the positioning disc 6 passes through this The way those skilled in the art can think of is fixed on the winding shaft 5, such as welding, which is convenient for disassembly and assembly. A plurality of positioning holes 7 are evenly spaced on the circumferential surface of the positioning plate 6; The hole internal thread is connected with set screw 8. In the process of adjusting the second power line, tighten or loosen the positioning screw 8 until one end of it is inserted into or withdrawn from one of the positioning holes 7 to fix or loosen the positioning plate 6. The structure is simple, the operation is simple, the positioning is convenient and quick, and the Save time and effort.

[0043] It should be noted that the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com