Double-cover type automatic stirring cup

An automatic stirring, double-cover technology, applied in the direction of drinking utensils, etc., can solve the problems that the magnetic block is easy to be eaten by mistake, cannot control the start and stop of the stirring action, etc., so as to save stirring time and energy, simple structure and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

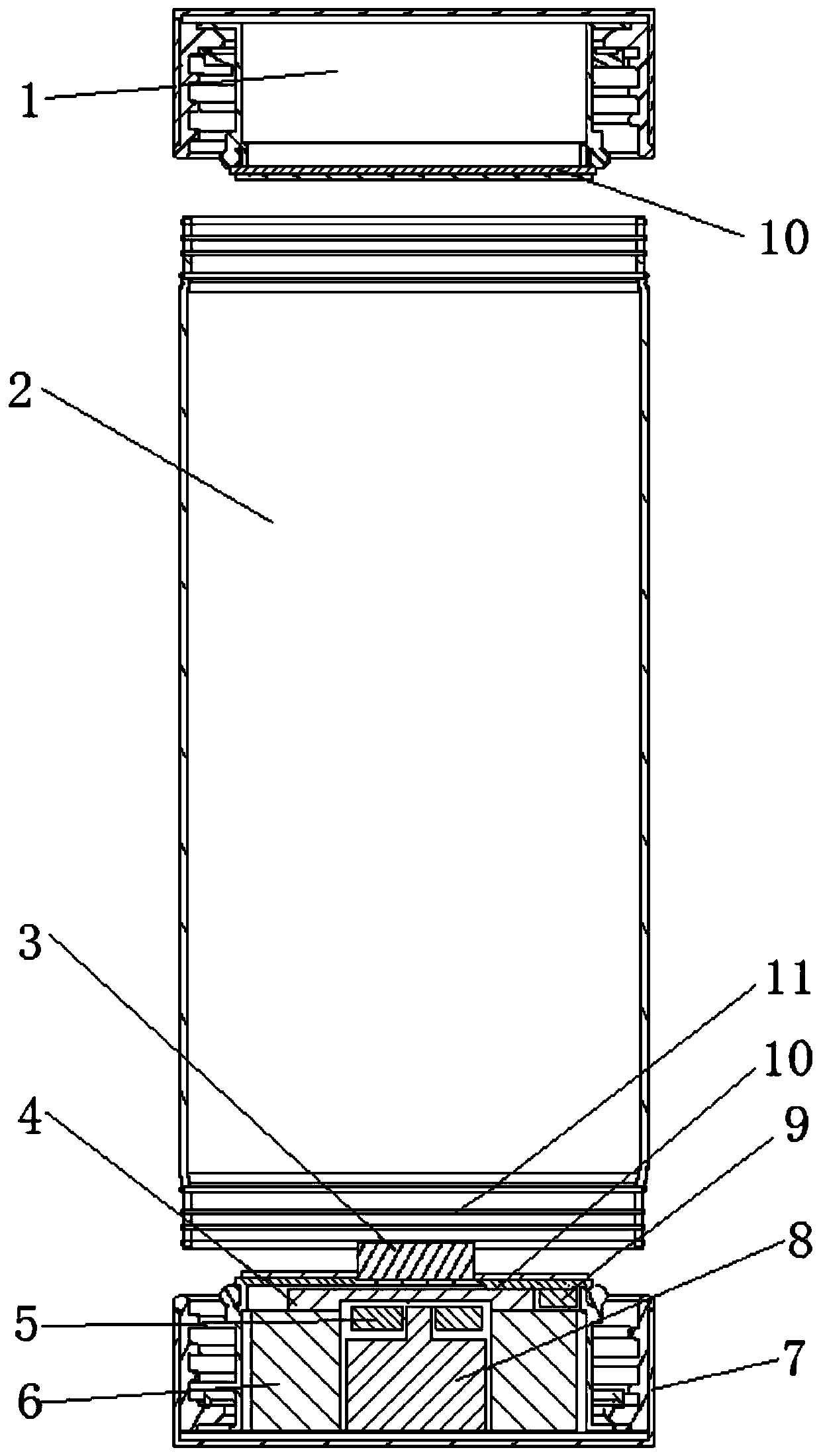

[0017] Embodiment 1: The present invention provides a double-cover type automatic stirring cup, its structure is as follows figure 1 As shown, at least an upper cup cover 1, a lower cup cover 7 and a cup body 2 are provided, and a motor 8, a magnet 5, a thermoelectric sheet 4, a heat-absorbing component 6 and a PCB board 9 are arranged in the lower cup cover, and the described motor Located in the center of the inner bottom surface of the lower cup cover, a pair of magnets 5 are installed on the motor shaft; heat-absorbing components 6 are arranged around the motor, and the thermoelectric sheet 4 is installed above the magnet 5, and the thermal surface of the thermoelectric sheet is attached In the shell on the upper surface of the lower cup cover, the cold surface of the thermoelectric generator is connected to the heat-absorbing component; the PCB board 9 is installed on one side of the thermoelectric generator, and the PCB is electrically connected with the thermoelectric ge...

Embodiment 2

[0023] Embodiment 2: The present invention provides a double-covered automatic stirring cup, its structure and usage are basically the same as in Embodiment 1, the only difference is that the cup body 2 is made of glass, double-layer vacuum structure, and the cup body is bulging Up and down through the structure, the material of the upper cup cover and the lower cup cover is ABS / PMMA alloy material, and the heat absorbing part 6 is a radiator made of aluminum. The stirring cup of this embodiment can observe the stirring situation at any time, and can start or stop the stirring action at any time.

Embodiment 3

[0024] Embodiment 3: The present invention provides a double-covered automatic stirring cup. Its structure is basically the same as that of Embodiment 1. The difference is that a handle is provided on the cup body 2. The cup body is made of single-layer transparent engineering plastics. , The material of the lower cup cover is PC plastic. The heat absorbing part 6 is a radiator made of copper. The magnetic stirring bar is installed on the outer surface of the lower cup lid, the stirring process can be observed at any time during the stirring process, and the stirring action can be started or stopped at any time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com