Efficient tower-type flocculation one-stop water purifying equipment

A kind of water purification equipment and flocculation technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of failing to meet purification standards, high turbidity of raw water, and high cost of use. Achieve the effect of improving energy saving effect and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

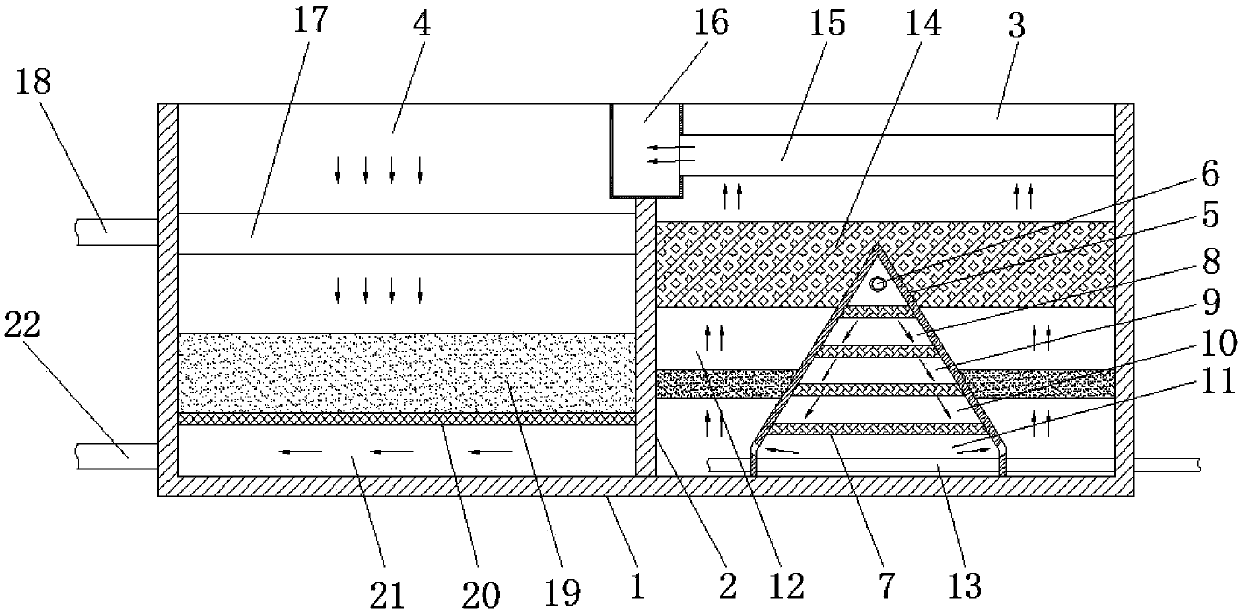

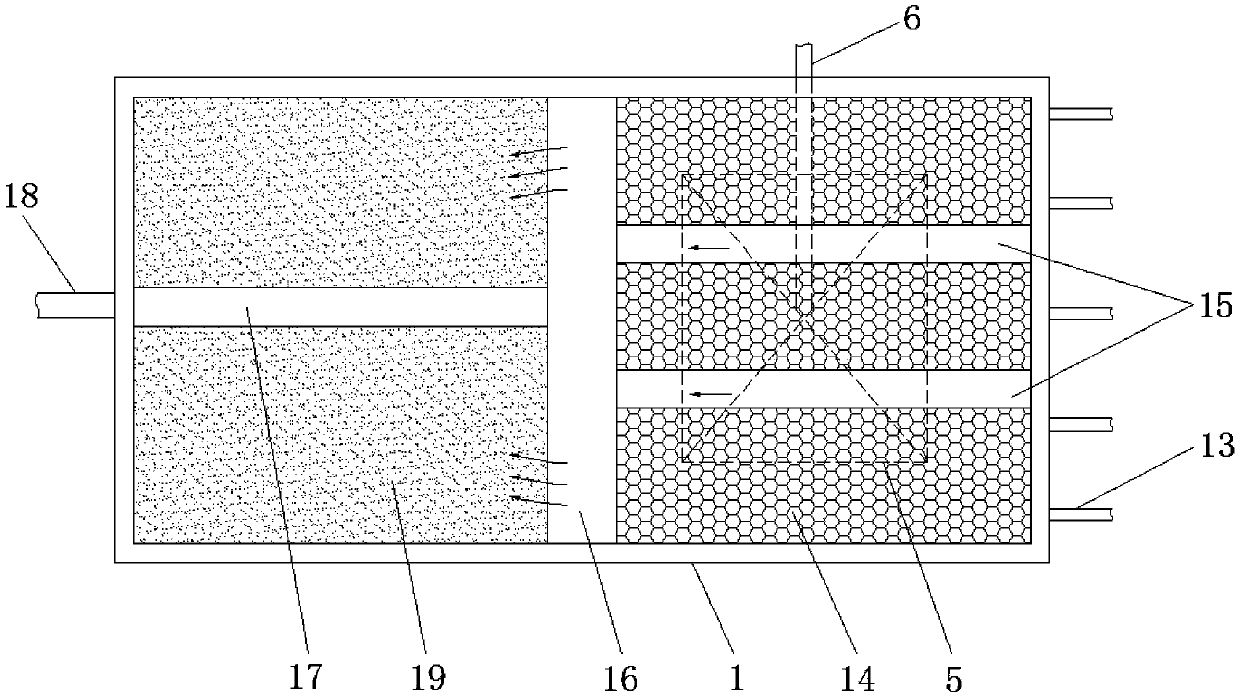

[0028] Such as Figures 1 to 3 As shown, this embodiment provides a high-efficiency tower-type flocculation one-stop water purification equipment, including a box body 1, a partition 2 is arranged in the box body 1, and the partition board 2 divides the interior of the box body 1 into a purification area 3 and a filtration area. Area 4, purification area 3 is provided with a pyramid-shaped isolation cover 5, the top of the isolation cover 5 is connected with a water inlet pipe 6, and the inside of the isolation cover 5 is provided with four flocculation plates 7 below the water inlet pipe 6. The flocculation plates 7 are used for Turning the water flow, four flocculation plates 7 divide the interior of the isolation cover 5 into the first flocculation zone 8, the second flocculation zone 9, the third flocculation zone 10 and the fourth flocculation zone 11 arranged in sequence from top to bottom, and the outer wall of the isolation cover 5 and the box body 1. The inner wall en...

Embodiment 2

[0031] like Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a backwash drainage tank 17 is provided in the filter area 4, and a backwash drainage tank 17 connected to the backwash drainage tank 17 is connected to the box body 1. The water outlet pipe 18 and the filter area 4 are provided with a sand filter layer 19 below the backwash drainage tank 17, and the bottom of the sand filter layer 19 is provided with a filter screen 20, and the filter screen 20 and the bottom of the filter area 4 form a clean water area 21, and the clean water The area 21 is communicated with a clean water outlet pipe 22 protruding from the box body 1 .

[0032] In this embodiment, after the clean water enters the filter area, it is backwashed under the action of the backwash drainage tank, and then passes through the sand filter layer and the filter screen in order to remove excess impurities, and finally forms a clean water area at the bott...

Embodiment 3

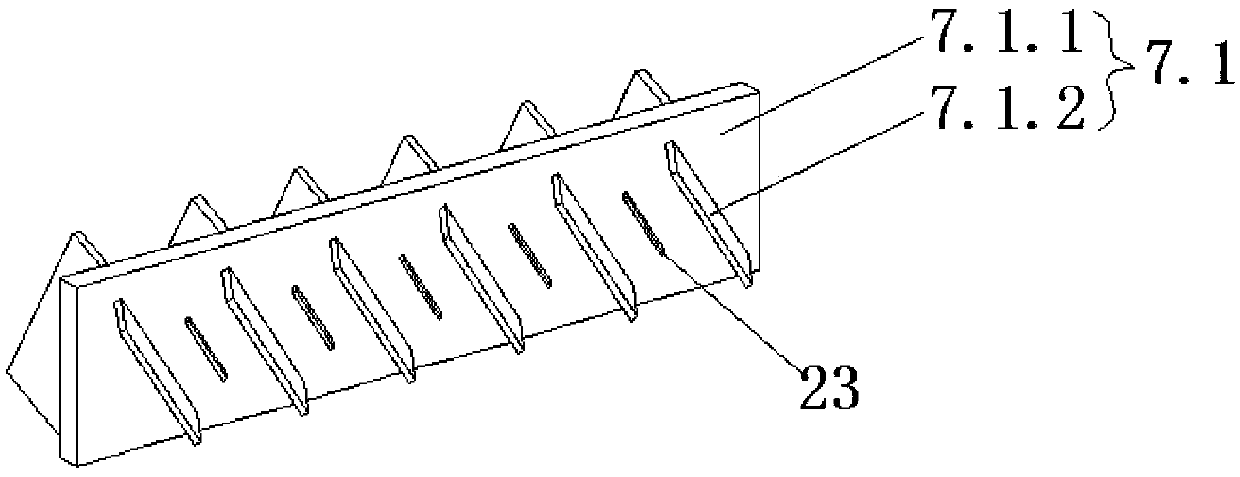

[0034] like Figures 1 to 3 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the flocculation plate 7 is composed of a number of special-shaped plates 7.1 surrounded by hexagonal honeycombs. The special-shaped plate 7.1 includes a base plate 7.1.1 and a base plate 7.1. 1 Both sides are provided with inclined corrugated boards 7.1.2, and the inclined direction of the inclined corrugated boards 7.1.2 on the same side of the base plate 7.1.1 is the same, and the inclined direction of the inclined corrugated plates 7.1.2 on both sides of the base board 7.1.1 On the contrary, the inclination angles of the inclined corrugated board 7.1.2 on both sides of the base plate 7.1.1 are 45° and 135° respectively, and a number of reinforcing ribs 23 are arranged on both sides of the base plate 7.1.1, and the reinforcing ribs 23 intersect with the inclined corrugated board 7.1.2 layout.

[0035] In this embodiment, when the water flow passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com