An adapter forming process

A molding process and adapter technology, applied in the field of launch systems, can solve problems such as low efficiency and complex process, and achieve the effects of high production efficiency, simple preparation process and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

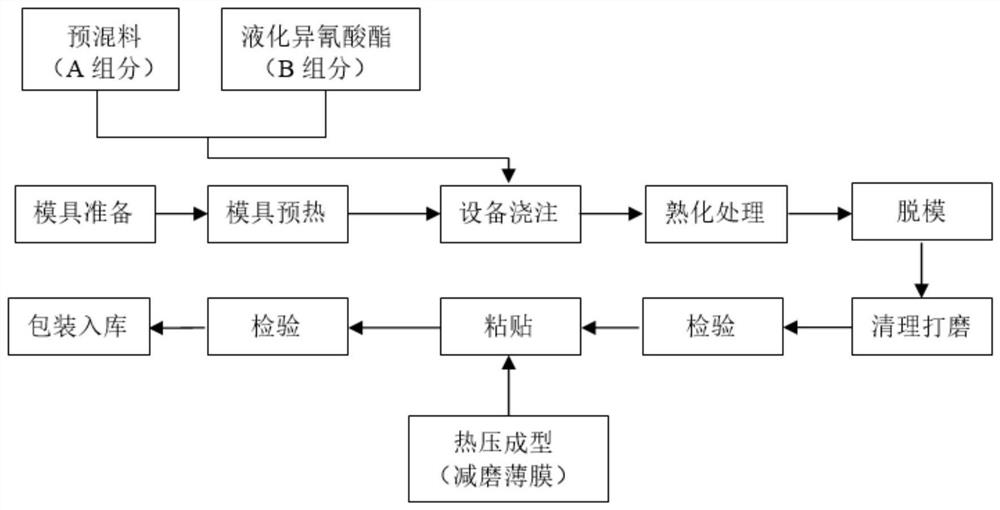

Method used

Image

Examples

Embodiment 1

[0057] S1: Prepare raw materials, weigh 100 parts of adipic acid-based polyester alcohol, weigh 3 parts of reinforcing material hollow glass microspheres, 4 parts of blowing agent dichlorofluoroethane, and 0.3 parts of catalyst triethylene diethylene glycol according to the ratio. Add amine and 2 parts of stabilizer simethicone to the adipic acid-based polyester alcohol to prepare a premix solution, place it for 72 hours, then stir it evenly with a high-speed mixer, add it to the high-pressure foaming machine tank, and stir for more than 40 minutes , to obtain component A;

[0058] Put solid diphenylmethane diisocyanate in an oven and heat to 60°C, heat and melt the solid isocyanate into a liquid state, weigh 100 parts of isocyanate and add it to the high-pressure foaming machine tank to obtain component B.

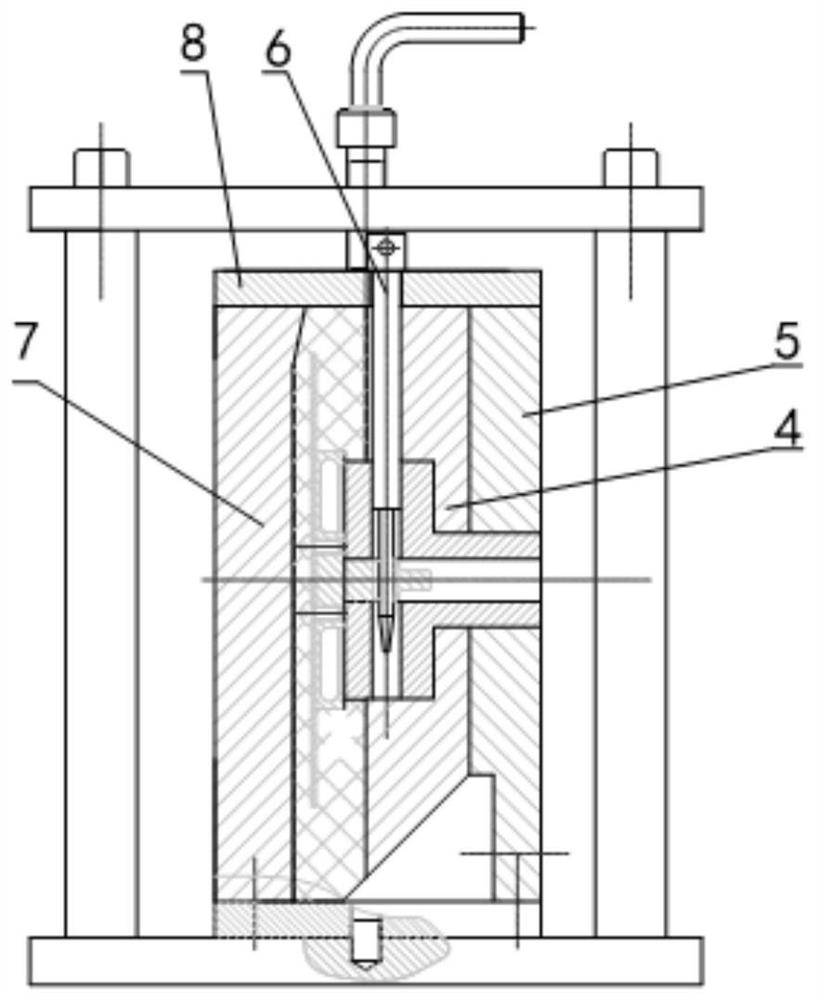

[0059] S2: mold assembly, including the following steps:

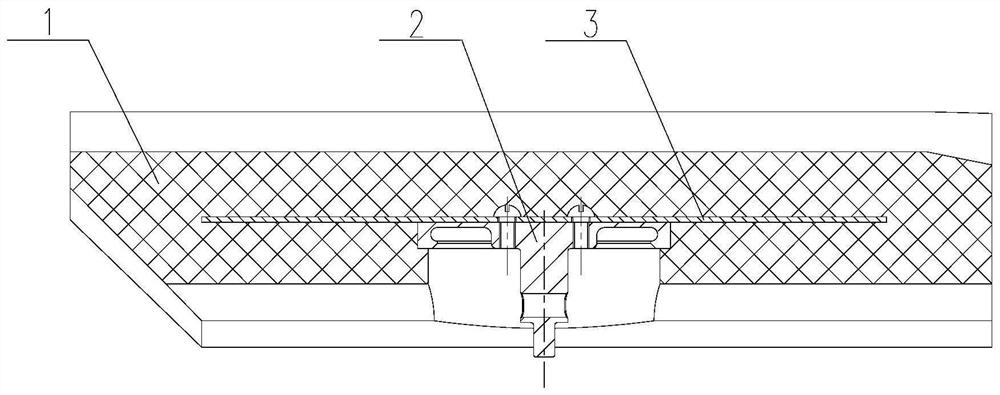

[0060] S21: install the rib plate 3 on the spring seat pin 2, and fasten it with standard parts screws to ensu...

Embodiment 2

[0070] S1: Prepare raw materials, weigh 100 parts of adipic acid-based polyester alcohol, weigh 2 parts of reinforcing material hollow glass microspheres, 5 parts of blowing agent dichlorofluoroethane, and 0.1 part of catalyst triethylene diethylene glycol according to the ratio. Add amine and 1 part of stabilizer simethicone to the adipic acid-based polyester alcohol to prepare a premix solution, place it for 72 hours, then stir it evenly with a high-speed mixer, add it to the high-pressure foaming machine tank, and stir for more than 40 minutes , to obtain component A;

[0071] Put the solid diphenylmethane diisocyanate in an oven and heat to 70°C, heat and melt the solid isocyanate into a liquid state, weigh 95 parts of the isocyanate and add it to the high-pressure foaming machine tank to obtain component B.

[0072] S2: mold assembly, including the following steps:

[0073] S21: install the rib plate 3 on the spring seat pin 2, and fasten it with standard parts screws to...

Embodiment 3

[0086] S1: Prepare raw materials, weigh 100 parts of adipic acid-based polyester alcohol, weigh 4 parts of reinforcing material hollow glass microspheres, 6 parts of blowing agent dichlorofluoroethane, and 0.2 parts of catalyst triethylene diethylene glycol according to the ratio. Add amine and 3 parts of stabilizer simethicone to the adipic acid-based polyester alcohol to prepare a premix solution, place it for 72 hours, then stir it evenly with a high-speed mixer, add it to the high-pressure foaming machine tank, and stir for more than 40 minutes , to obtain component A;

[0087] Put the solid diphenylmethane diisocyanate in an oven and heat to 70°C, heat and melt the solid isocyanate into a liquid state, weigh 98 parts of the isocyanate and add it to the high-pressure foaming machine tank to obtain component B.

[0088] S2: mold assembly, including the following steps:

[0089] S21: install the rib plate 3 on the spring seat pin 2, and fasten it with standard parts screws ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com