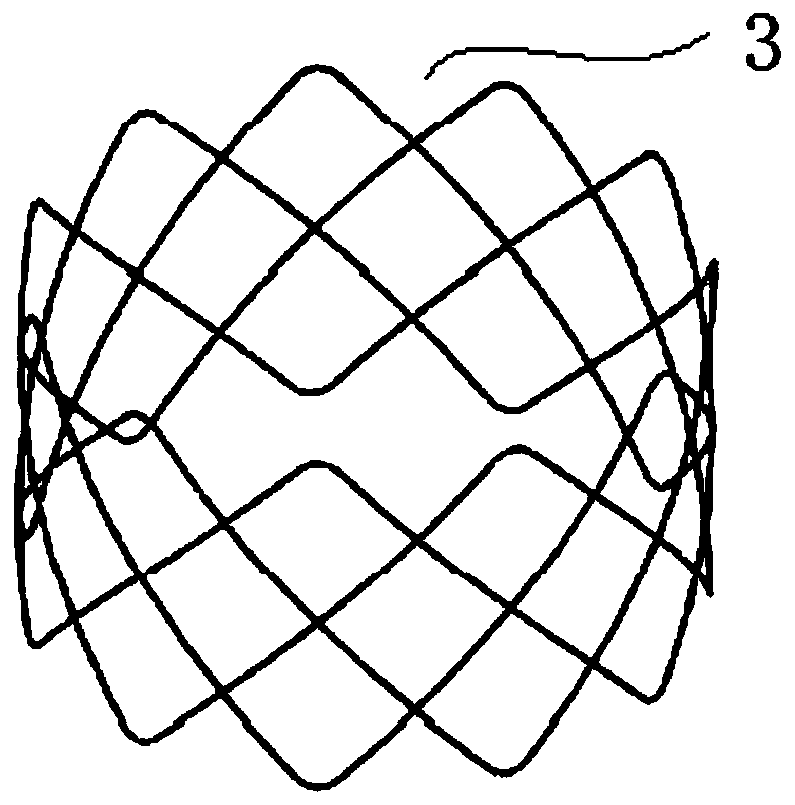

Nasal sinus stent

A technology of sinus and mesh stent, which is applied in the field of sinus stent and its forming application, which can solve the problems of improved nasal endoscopic surgery, poor compression effect, and nasal adhesion, and achieve good shape, practicability, and good stretching and compressibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The main raw materials involved in the sinus stent of the present invention are biodegradable polymer materials, which include polylactic acid PLA, L-PLA, polyglycolic acid / polylactic acid copolymer PGLA, polycaprolactone PCL, Polyhydroxypentylbutyrate PHBV, polyacetylglutamate PAGA, polyorthoester POE, polyethylene oxide / polybutylene copolymer PEO / PBTP, polylactide-cocaprolactone copolymer PLC or polycyclohexanone PDO.

[0033] The molding and using method of sinus stent of the present invention comprises the following steps:

[0034] Step S1, selecting a biodegradable polymer material with a viscosity of 0.5-5.0dl / L and a molecular weight of 50,000-1,000,000, and then using an organic solvent to dissolve the biodegradable polymer material to form a mixture;

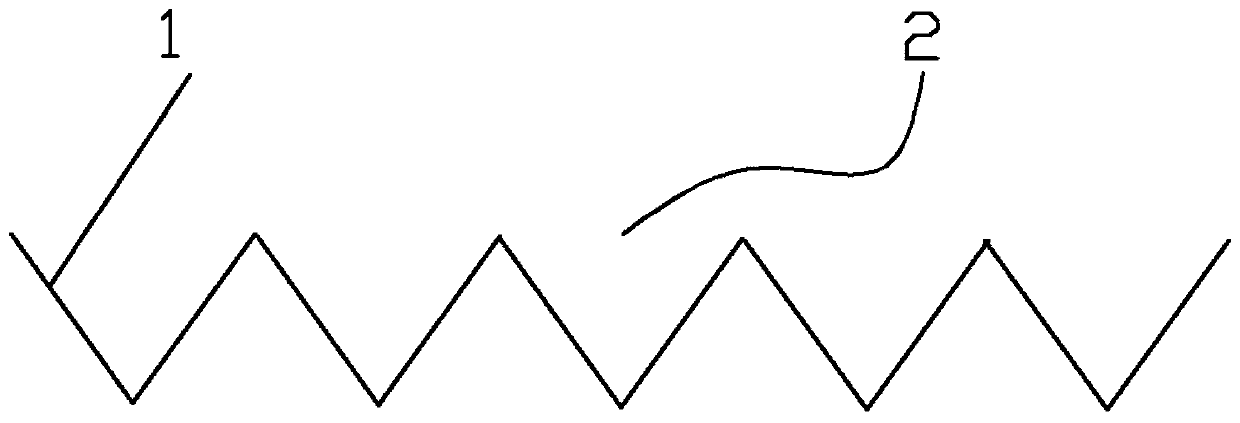

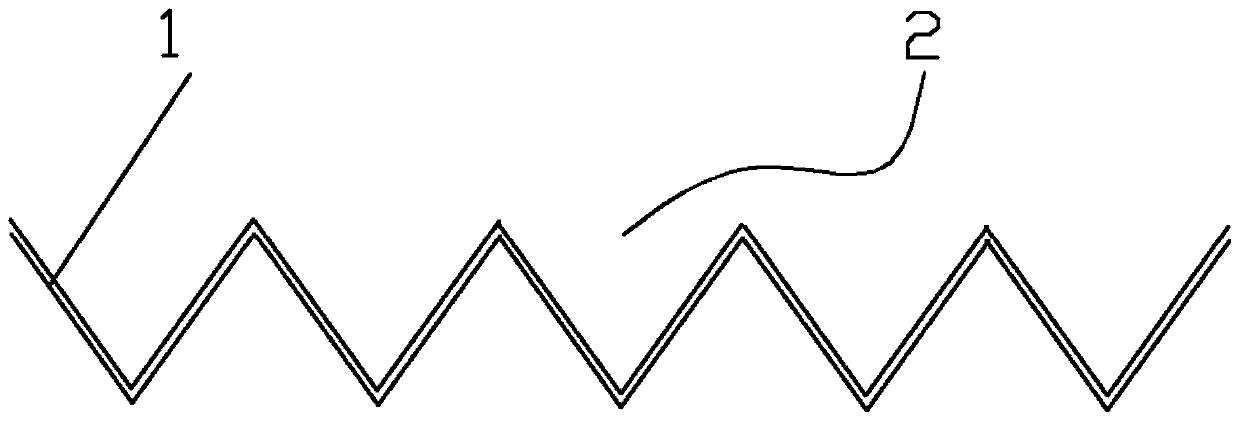

[0035] Step S2, extruding the mixture through an extruder, and then stretching to form a braided filament 1, the braided filament 1 is a polymer monofilament fiber carrying an active drug, and the monofilament fi...

Embodiment 2

[0042] The molding and using method of sinus stent of the present invention comprises the following steps:

[0043] Step S1, selecting a biodegradable polymer material with a viscosity of 0.5-5.0dl / L and a molecular weight of 50,000-1,000,000, and then using an organic solvent to dissolve the biodegradable polymer material to form a mixture;

[0044] Step S2, extruding the mixture through an extruder, and then stretching to form a braided filament 1, the braided filament 1 is a polymer monofilament fiber carrying an active drug, and the monofilament fiber has one or more biodegradable polymers composition;

[0045] Step S3, select a braiding machine with a longitudinal central axis, the braiding machine includes a plurality of first fixed points and a plurality of second fixed points arranged at intervals in the circumferential direction and in the axial direction, use the braided wire 1 to start weaving the initial configuration support, Form a V-shaped weaving path;

[0046]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com