A quick release fixture for assembly line processing

An assembly line and fixture technology, applied in the field of manufacturing, can solve the problems of complex locking methods, low work efficiency, unstable locking, etc., to ensure the probability of finished products, improve efficiency, and not easy to fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

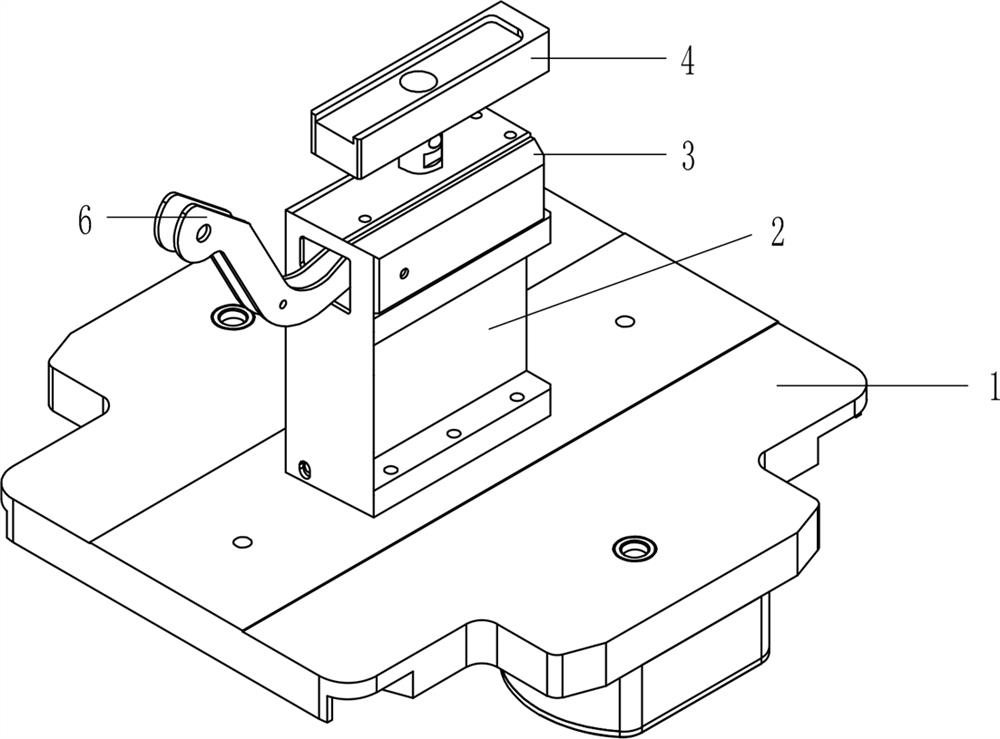

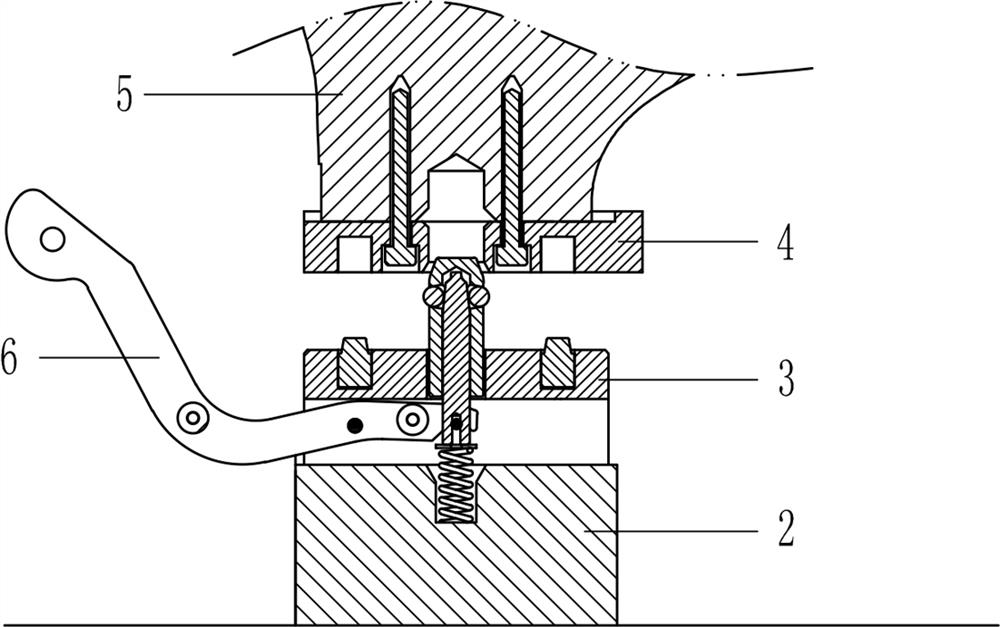

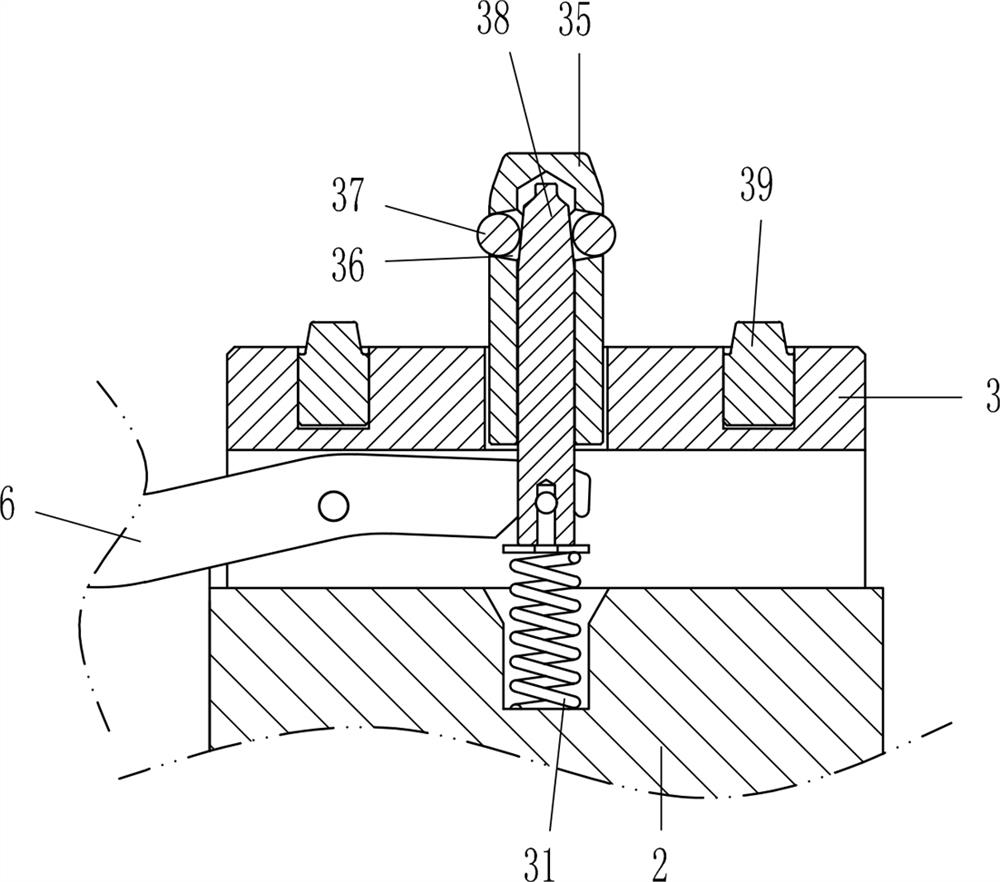

[0027] A quick release fixture for assembly line processing, characterized in that it includes a mounting base 2, a fixture fixing seat 3, a positioning block 4, a first swing lever 6, a first elastic member 31, a locking pin 35, a circular fixing Part 37 and taper pin 38; the fixture holder 3 is hollow and arranged on the top of the installation base 2, the inside of the locking pin 35 forms a hollow cavity and is detachably arranged on the top of the fixture holder 3, the taper The pin 38 is movably engaged with the hollow cavity of the locking pin 35; one end of the first elastic member 31 is connected to the mounting base 3, and the other end is connected to the taper pin 38; the first swing rod 6 is hinged to the fixture for fixing In the hollow of the seat 3, one end of the first swing rod 6 located in the hollow of the clamp fixing seat 3 is connected with the taper pin 38, the upper part of the locking pin 38 is provided with a tapered groove 36 with a narrow outside an...

Embodiment 2

[0035] A quick release fixture for assembly line processing, characterized in that it includes a mounting base 2, a fixture fixing seat 3, a positioning block 4, a first swing lever 6, a first elastic member 31, a locking pin 35, a circular fixing Part 37 and taper pin 38; the fixture holder 3 is hollow and arranged on the top of the installation base 2, the inside of the locking pin 35 forms a hollow cavity and is detachably arranged on the top of the fixture holder 3, the taper The pin 38 is movably engaged with the hollow cavity of the locking pin 35; one end of the first elastic member 31 is connected to the mounting base 3, and the other end is connected to the taper pin 38; the first swing rod 6 is hinged to the fixture for fixing In the hollow of the seat 3, one end of the first swing rod 6 located in the hollow of the clamp fixing seat 3 is connected with the taper pin 38, the upper part of the locking pin 38 is provided with a tapered groove 36 with a narrow outside an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com