Automatic packaging line for children's tableware

A technology for automatic packaging and tableware, applied in the directions of packaging, transportation and packaging, stacking of objects, etc., can solve the problems of misplacement between plates and plates, poor placement effect, complex structure of children's plate packaging lines, etc. The effect of high efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

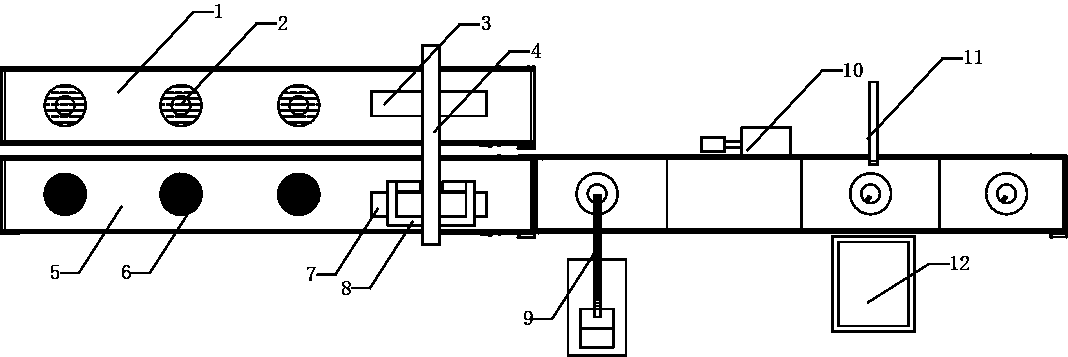

[0022] Embodiment: During use, the width of the first open strip-shaped groove 3 is smaller than the width of the first turned-over dinner plate 2, and similarly, the width of the second opened strip-shaped groove 7 is smaller than the width of the second turned-over dinner plate 6 .

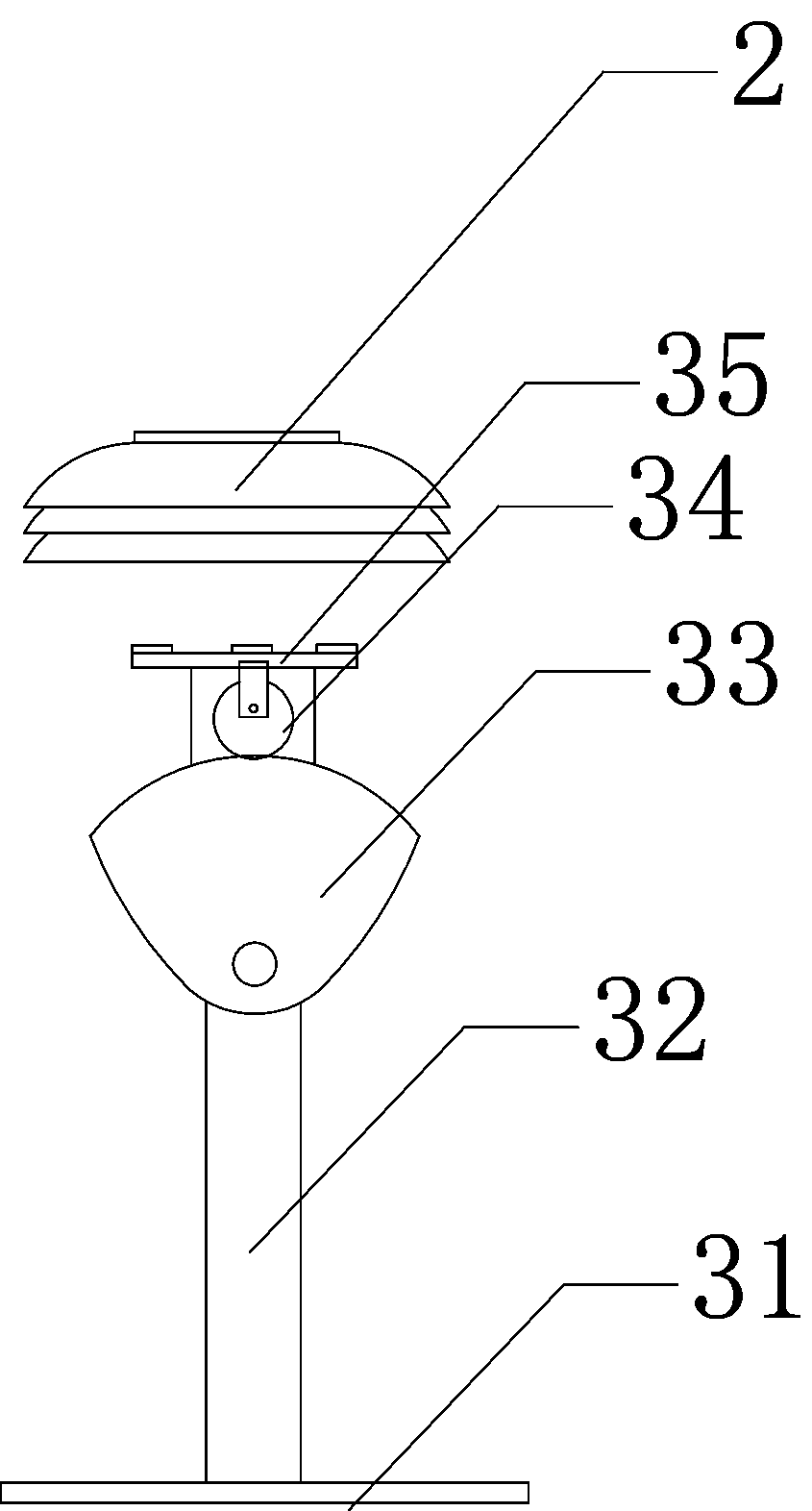

[0023] On the first conveyer belt 1, evenly transport the first turned-over dinner plate 2 to the top of the first open bar-shaped groove 3, and evenly transport the second turned-over dinner plate 6 to the top of the second open bar-shaped groove 7 on the second conveyor belt 5. Above, the first turned over dinner plate 2 is a superposition of three three-color dinner plates, and the second turned over dinner plate 6 is also a superposition of three three-color dinner plates.

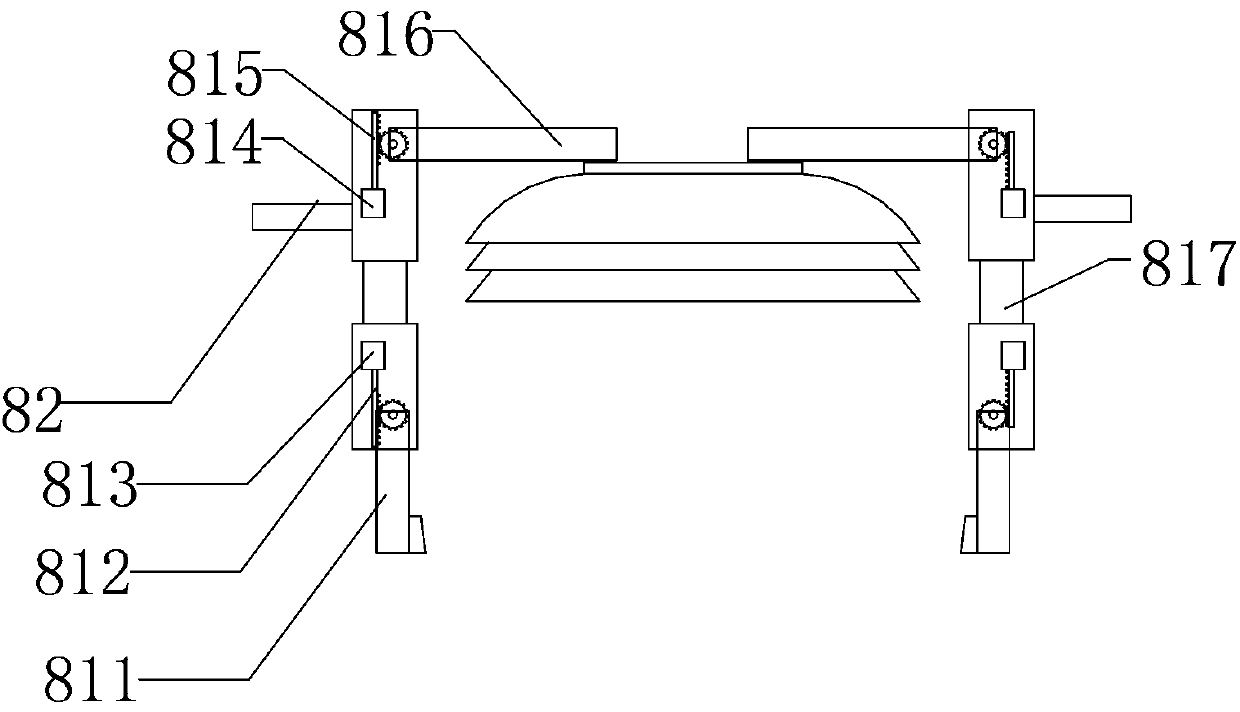

[0024] At this moment, the slidable dinner plate grasping mechanism 8 provided on the slideway 4 starts to move, and the dinner plate grasping mechanism 8 is provided with a slide block, and the slide block is clamped in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com