Heating maintenance method for thin-walled concrete of steel-concrete composite bridge

A steel-concrete combined beam and concrete technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as the inability to use wraps for heat preservation and maintenance, and the inability to maintain the heat required for thin-walled concrete 3 winter maintenance, so as to speed up The effect of health preservation rate, construction period saving and construction quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

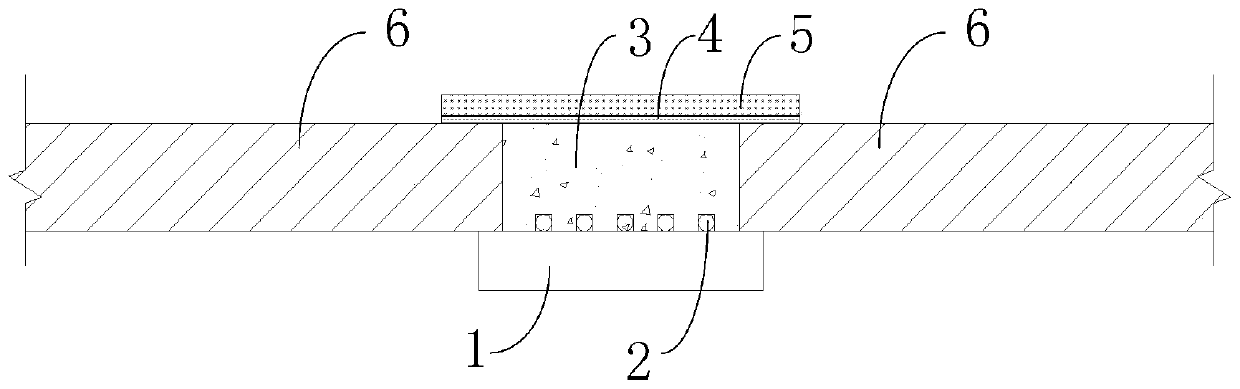

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

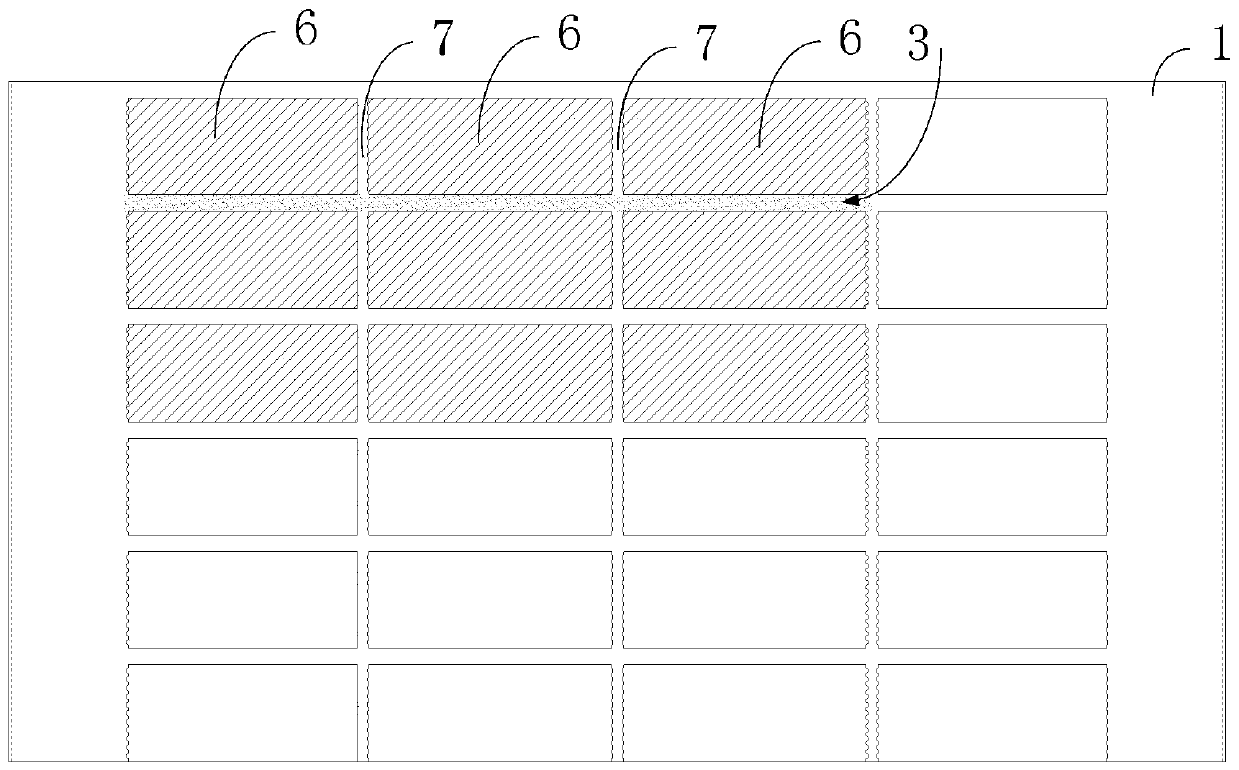

[0035] see figure 2 As shown, the embodiment of the present invention provides a method for heating and curing thin-walled concrete of steel-concrete composite beams, including the following steps:

[0036] S1: Provide a temperature control display and multiple temperature sensors, each temperature sensor is connected to the temperature control display; Lay and fix multiple carbon fiber heating wires 2 on the upper surface of the steel girder steel plate 1;

[0037] The carbon fiber heating wire 2 adopts the 12K specification, and its diameter is only 2.5 mm. The upper surface of the steel girder steel plate 1 is fully paved with a spacing of 8 to 10 cm. In this embodiment, the spacing can be set to 10 cm. The heating wire 2 is bonded and fixed to the steel girder and steel plate 1, and the fully plastic-wrapped plug of the carbon fiber heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com