A kind of thermoplastic material surface treatment agent and preparation method thereof

A surface treatment agent, thermoplastic material technology, applied in the direction of coating, can solve the problems of slow curing, not suitable for modern industrial requirements of rapid assembly, unable to promote the curing of anaerobic adhesives, etc., to improve the bond strength, promote decomposition, The effect of increasing the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

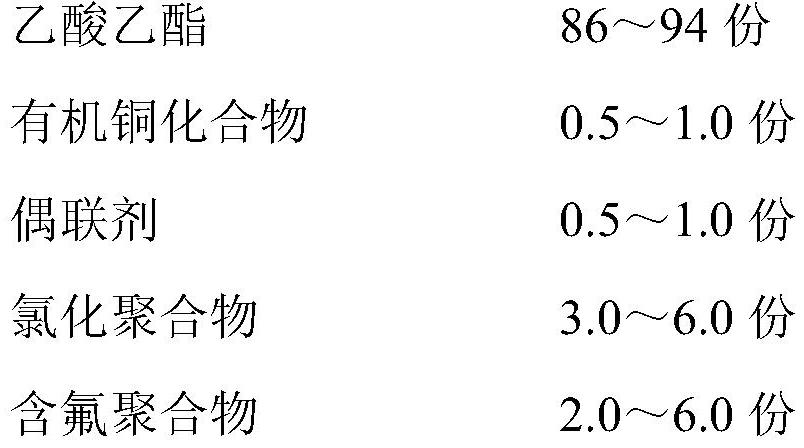

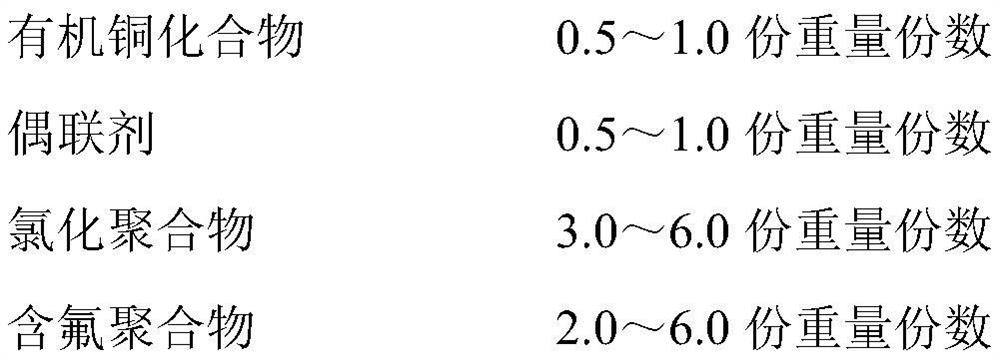

Method used

Image

Examples

Embodiment 1

[0019] 1) Synthesis of the fluoropolymer:

[0020] Add 100 grams of ethyl acetate in a four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, and a condenser, then slowly add 5 grams of trifluoroethyl methacrylate, 2 grams of 2-hydroxyethyl acrylate, 10 grams of butyl acrylate, 0.4 grams of azobisisobutyronitrile, and 0.5 grams of n-dodecanethiol are uniformly mixed. During the dropping process, the temperature was kept at 70° C., and after the dropping, the temperature was slowly raised to 95° C., and the reaction was continued for 4 hours to prepare a transparent fluoropolymer.

[0021] 2) At room temperature, add 1g of copper acetate and 3g of chlorinated polypropylene to 93g of ethyl acetate, the chlorine content is >45%, and after dissolving, add 1g of diisopropoxy diacetylacetonate titanate and 2g of the above-mentioned Fluoropolymer, stir evenly and filter to remove impurities to obtain polypropylene surface treatment agent.

Embodiment 2

[0023] 1) Synthesis of the fluoropolymer:

[0024] Add 100 grams of ethyl acetate to a four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, and a condenser tube, then slowly add 3 grams of hexafluorobutyl acrylate, 3 grams of 2-hydroxyethyl acrylate, and 12 grams of Butyl acrylate, 0.2 g of azobisisobutyronitrile, and 0.4 g of n-dodecanethiol are uniformly mixed. During the dropping process, the temperature was kept at 80° C., and after the dropping, the temperature was slowly raised to 90° C., and the reaction was continued for 5 hours to prepare a transparent fluoropolymer.

[0025] 2) At room temperature, add 0.8 g of acetylacetone ketone and 3 g of chlorinated polypropylene to 90.4 g of ethyl acetate, the chlorine content is >45%, and after dissolution, add 0.8 g of diisopropoxydiacetylacetonate titanate and 5 g of The fluorine-containing polymer obtained above is stirred evenly and then filtered to remove impurities to obtain a polypropylene surfa...

Embodiment 3

[0027] 1) Synthesis of the fluoropolymer:

[0028] Add 100 grams of ethyl acetate to a four-necked flask equipped with a stirrer, a thermometer, a dropping funnel, and a condenser, then slowly add 2 grams of trifluorooctyl acrylate, 1 gram of 2-hydroxyethyl acrylate, 8 gram of butyl acrylate, 0.2 gram of azobisisobutyronitrile, and 0.3 gram of n-dodecanethiol homogeneous mixed solution. During the dropping process, the temperature was kept at 80° C., and after the dropping, the temperature was slowly raised to 95° C., and the reaction was continued for 6 hours to prepare a transparent fluoropolymer.

[0029] 2) At room temperature, add 1g of copper tartrate and 6g of chlorinated polyethylene to 86g of ethyl acetate, the chlorine content is >65%, and after dissolution, add 1g of γ-methacryloxypropyl trimethoxysilane and 6g of the above to obtain The fluorine-containing polymer is stirred evenly and then filtered to remove impurities to obtain a polyethylene surface treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com