Pre-coating solution for enhancing surface adhesion of transparent PI base material, and application method thereof

A technology of substrate surface and application method, applied in the direction of coating, etc., can solve the problems of decreased adhesion, decreased performance of hardened layer, difficult adhesion of hardened layer, etc., and achieve the effect of improving bonding force, increasing adhesion, and high transparency

Active Publication Date: 2019-12-20

新恒东薄膜材料(常州)有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the molecular chain of transparent polyimide film contains a relatively large proportion of fluorine elements, which makes the hardened film on the surface have poor adhesion to it. Improving its adhesion has become the focus of research on flexible and foldable screens.

[0003] In the existing transparent PI hardened film products, the transparency of the transparent PI substrate is generally improved by fluorine modification, and the f

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

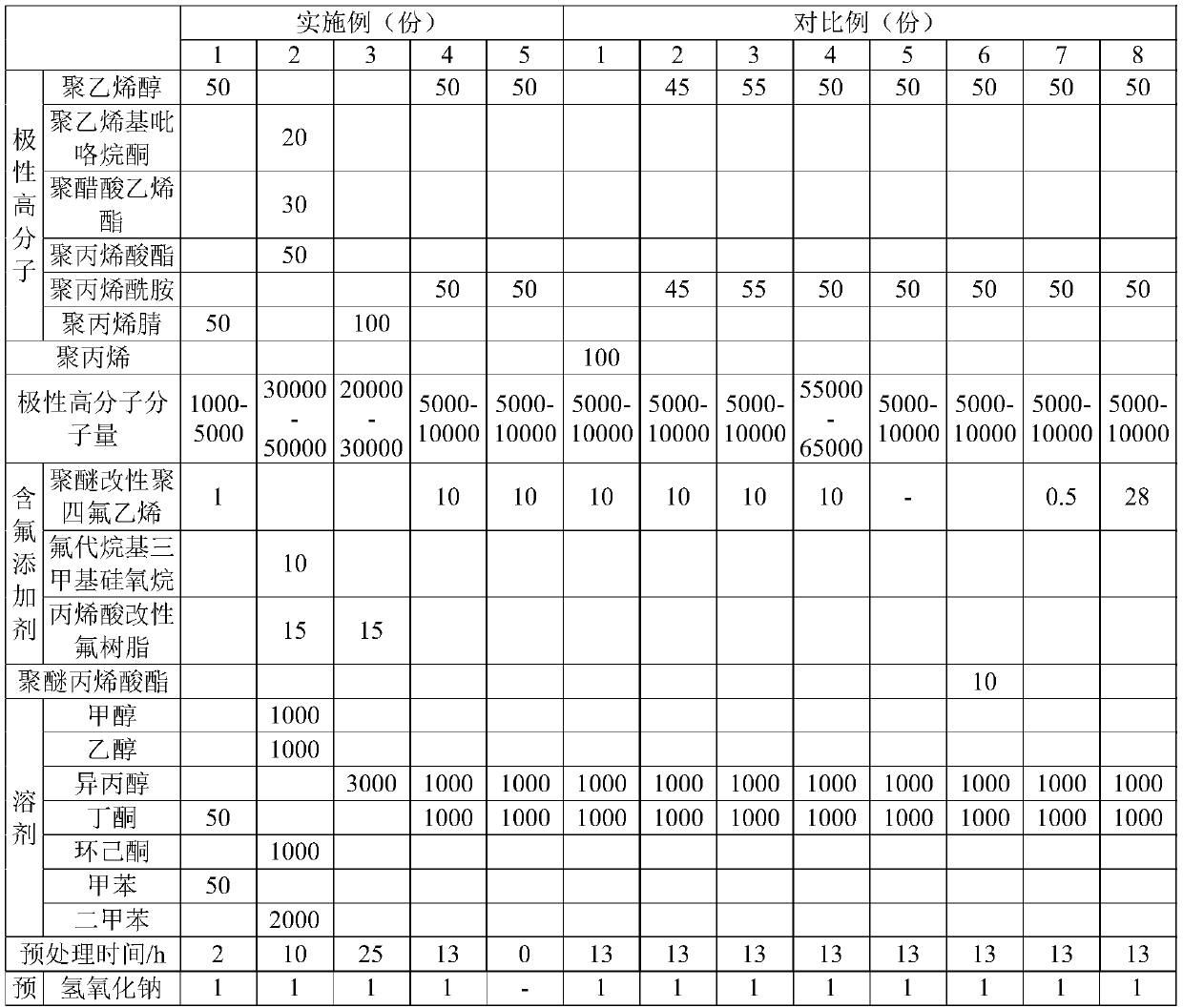

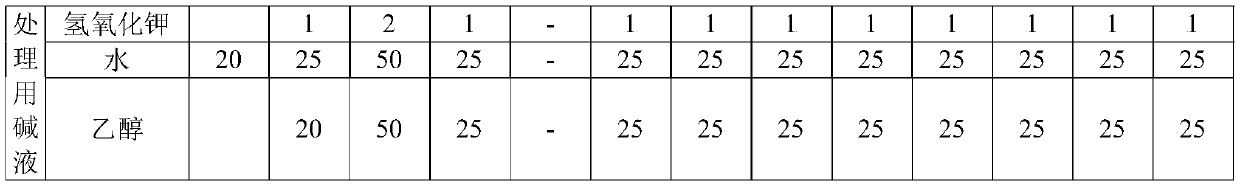

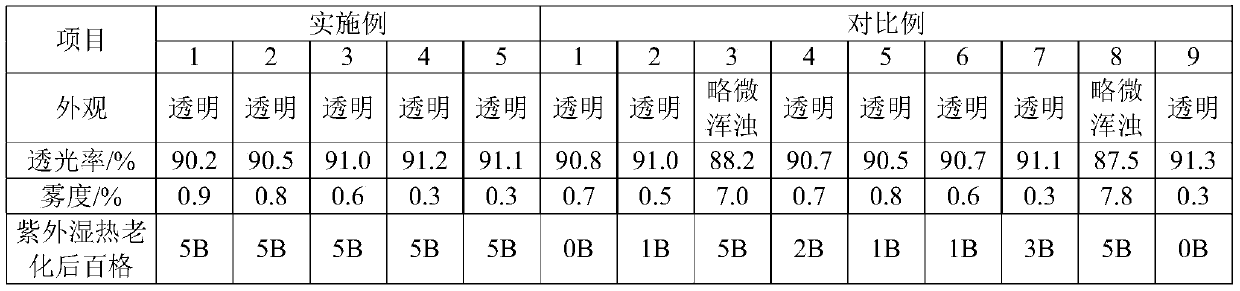

The invention belongs to the technical field of pre-coating solutions for transparent polyimide hardened films, and particularly relates to a pre-coating solution for enhancing the surface adhesion ofa transparent PI base material, and an application method thereof, wherein the pre-coating solution comprises, by weight, 100 parts of polar polymer, 1-25 parts of a fluorine-containing additive, and100-5000 parts of a solvent. According to the present invention, by adding the polar polymer and the fluorine-containing additive, based on the similar intermiscibility between the fluoride in the fluorine-containing additive and the fluorine-modified transparent PI base material and the strong polarity of polar polymer, the pre-coating solution can permeate into the transparent PI base materialand interpenetrate with the base material, and can be firmly attached to the surface of the base material after being cross-linked and cured, such that the problem of poor adhesion caused by the fluorine modification of the base material can be effectively solved, and the hardened layer is firmly attached to the pre-coating layer so as to effectively improve the binding force between the hardenedlayer and the base material; and the adhesion is improved through the pre-coating layer between the base material and the hardened layer, such that the comprehensive performances such as optical transparency, hardness, abrasion resistance and the like of the hardened layer cannot be affected.

Description

technical field [0001] The invention belongs to the technical field of precoat liquid for transparent polyimide hardened film, and in particular relates to a precoat liquid for enhancing the surface adhesion of transparent PI substrates and an application method thereof. Background technique [0002] In recent years, with the vigorous development of the electronic information industry and its raw material industry, flexible and foldable mobile phones and other flexible electronic devices have become the focus of research and development in the industry. This requires the cover plate to be foldable. Because glass is difficult to achieve the bending effect, the industry explores the use of transparent plastic film instead of glass. Due to the high transparency and good weather resistance of transparent polyimide (PI) film, High hardness has become the preferred replacement for cover glass. However, the molecular chain of the transparent polyimide film contains a relatively la...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D129/04C09D133/20C09D139/06C09D131/04C09D133/08C09D133/26C09D7/65C09D7/63C08J7/04C08L79/08

CPCC08J7/042C08J2379/08C08J2429/04C08J2431/04C08J2433/08C08J2433/20C08J2433/26C08J2439/06C09D129/04C09D133/08C09D133/20C09D133/26C08L33/20C08L27/18C08L29/04C08L39/06C08L31/04C08L27/12C08K5/5419C08L33/26

Inventor 曾金栋

Owner 新恒东薄膜材料(常州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com