Manufacturing technology for natural zigzag simulated concrete expansion joint and ground structure comprising same

A technology of making craft and concrete, which is applied in the direction of floors, building structures, buildings, etc. It can solve the problems of not being able to realize natural cracks and destroying the decoration effect of theme park theme landscapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to fully illustrate the characteristics of the present invention and the mode of carrying out the present invention, examples are given below. Unless otherwise specified, the raw materials involved in the following examples can all be commercially available existing materials.

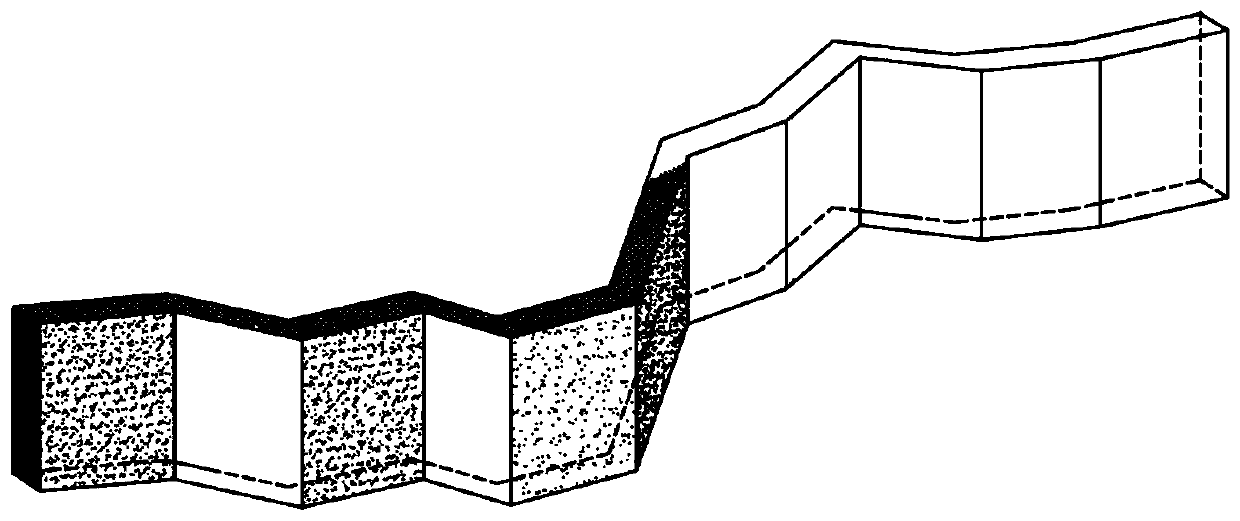

[0022] A manufacturing process for natural tortuous simulated concrete expansion joints, comprising the following steps:

[0023] (1) Support the A formwork in the concrete area, and install the curved formwork at the position where natural tortuous simulation cracks need to be made;

[0024] (2) pouring area A concrete;

[0025] (3) After the initial setting of the concrete in area A, remove the curved mold;

[0026] (4) Install a flexible expansion joint plate at the position of the original curve mold;

[0027] (5) Support concrete area B formwork, area B is adjacent to area A;

[0028] (6) pouring area B concrete;

[0029] (7) Trim the top of the expansion joint plate to keep i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com