Foaming agent uncoupled explosive loading blasting method

A foaming agent and charging technology, applied in the field of rock blasting, can solve the problems of low construction efficiency and low positioning accuracy in holes, and achieve the effects of low cost, good on-site operability and high compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, but the embodiments of the present invention are not limited thereto.

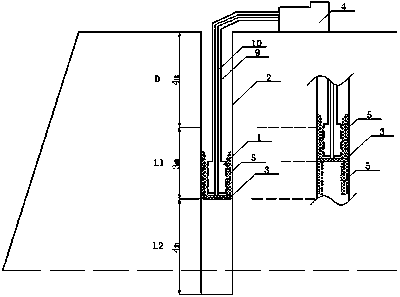

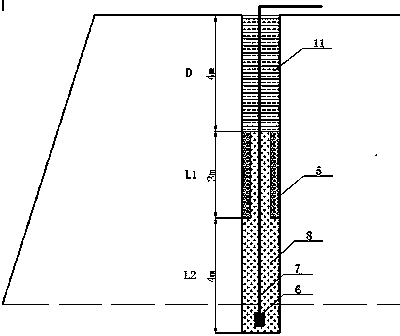

[0024] Optimum embodiment: the blasting method of the present invention is explained by taking a sectioned radial uncoupled blast hole in an open-pit mine as an example, which is specifically described below in conjunction with the accompanying drawings:

[0025] like figure 1 As shown, according to the actual formation conditions, the blast hole is designed as a segmented charge structure, the blast hole diameter is 138mm, the step height is 10m, the super depth is 1m, the filling section D=4m, the upper section is uncoupled charge length L1=3m, and the lower section is coupled The charge length is L2=4m.

[0026] (1) First, according to the uncoupling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com