Magazine type magneto

A magneto, magazine-type technology, applied in synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electric components, etc., can solve the problems of inconvenient disassembly and assembly, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

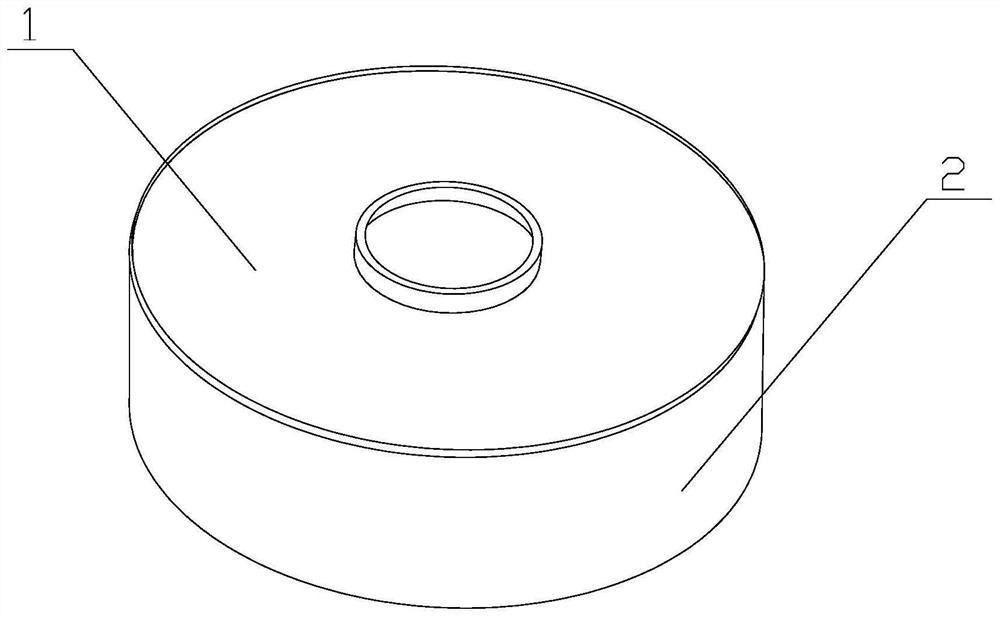

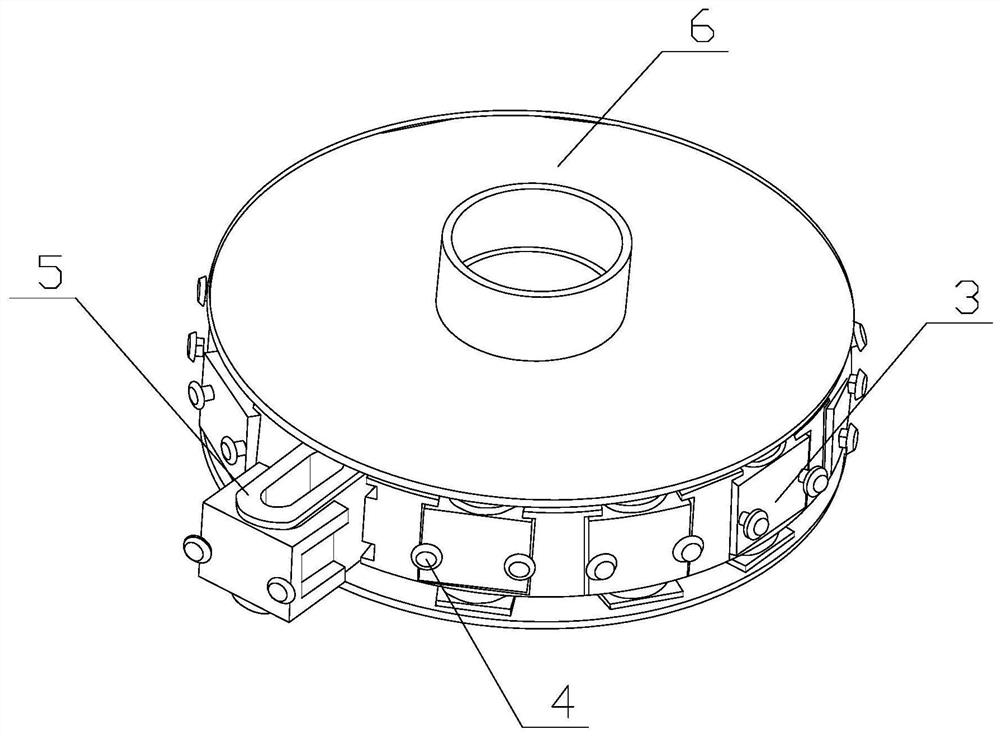

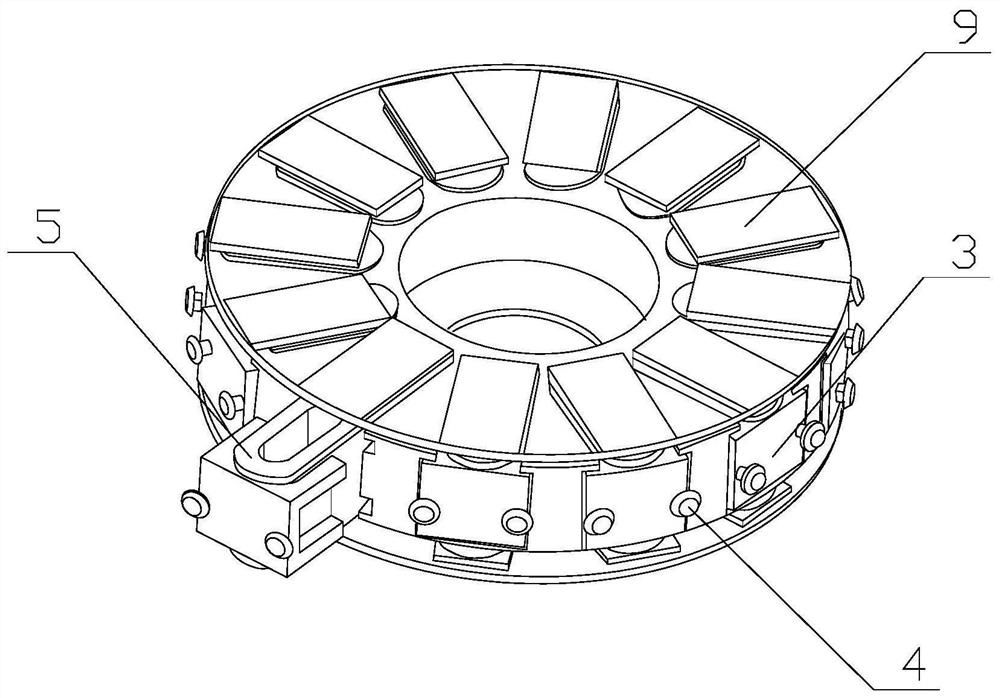

[0022] Example 1, such as Figure 1 to Figure 5 As shown, a magazine-type magneto includes an upper end cover 1, a main end cover 2, a stator frame 7 and a rotor cover 6, the upper end cover 1 and the main end cover 2 are connected, and two rotor cover 6 are placed at the main end In the cover 2, the stator frame 7 is fixedly placed in the main end cover 2. It is characterized in that the two rotor glands 6 are respectively rotatably arranged on both sides of the stator frame 7, and the two rotor glands 6 are Several rotor magnets 9 are arranged at equal angles on the opposite surface, a bushing is arranged at the center of the back of the rotor cover 6 , and several stator coils 5 are detachably arranged on the stator frame 7 .

[0023] Connect the rotating shaft so that the rotating shaft is connected to the sleeve. When used as a generator, connect the two ends of the rotating shaft to the wires, drive the rotor gland 6, so that the rotor magnet 9 and the stator coil 5 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com