Combined structural anchor bolt

A structural and combined technology, applied in the direction of material gluing, connecting components, pins, etc., can solve the problems of not being able to strengthen the anchoring effect and organic combination, and achieve good anchoring effect, convenient packaging, and improved shear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

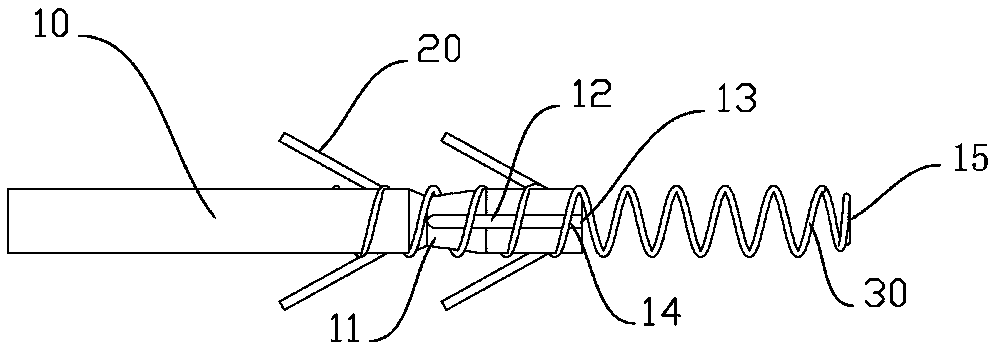

[0044] Such as figure 1 As shown, the combined structural anchor bolt of this embodiment includes an anchor rod 10, an expansion device 20 and a spring 30. The expansion device 20 is arranged at the front of the anchor rod 10, and There are transverse glue flow grooves 11, longitudinal communication grooves 12 and screw grooves 13. The end face of the front portion of the anchor rod 10 is provided with a glue inlet 14 communicated with the longitudinal glue flow groove 12; the adhesive enters the longitudinal glue flow groove 12 from the glue inlet 14 and is connected with the glue flow groove 12. The expansion device 20 is glued and connected; the front part of the anchor rod 10 is provided with a threaded groove 13 that matches the spiral of the spring 30 . The front end of the spring is provided with a spring ring 15 .

[0045] The transverse glue flow groove 11 and the vertical glue flow groove 12 intersect each other to form a cross glue flow groove, and the transverse ...

Embodiment 2

[0047] A method for using a combined structural anchor bolt, comprising the following steps:

[0048] (1) Pre-open corresponding matching anchor holes on the substrate;

[0049] (2) Screw the spring to the anchor rod to reach the specified position, or adjust the spring extension length according to the actual needs;

[0050] (3) Attach structural adhesive to the front end of the anchor rod and / or inject injection adhesive into the anchor hole;

[0051] (4) Push the combined structural anchor into the anchor hole, and then hammer the end of the structural anchor until the structural anchor reaches the preset position;

[0052] (5) Flatten or scrape off the glue overflowing from the anchor hole, and wait for the structural glue to solidify to form a structure of glue bars.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com