Novel self-balancing multi-stage energy-consuming anti-buckling support and manufacturing process

An anti-buckling bracing, self-balancing technology, applied in earthquake resistance, building types, protective buildings/shelters, etc., can solve problems such as out-of-plane instability, potential safety hazards, fatigue damage in the yield section, etc., and achieve good energy consumption. Effects of stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the drawings.

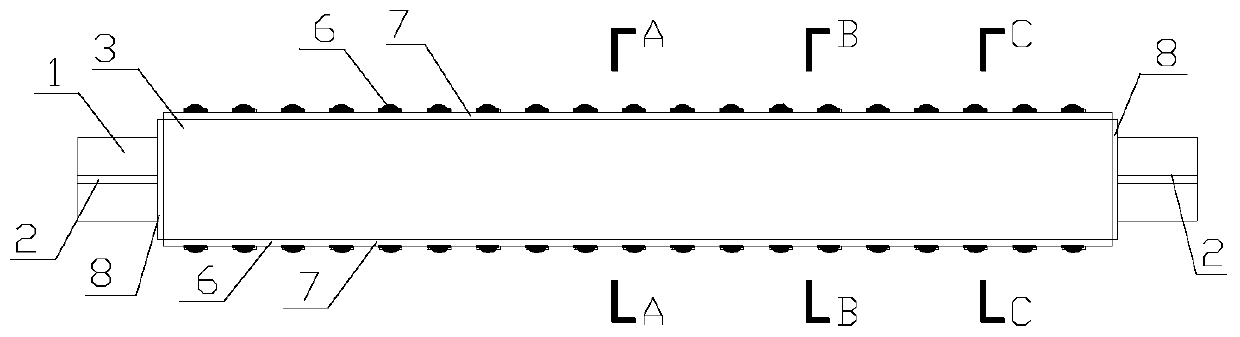

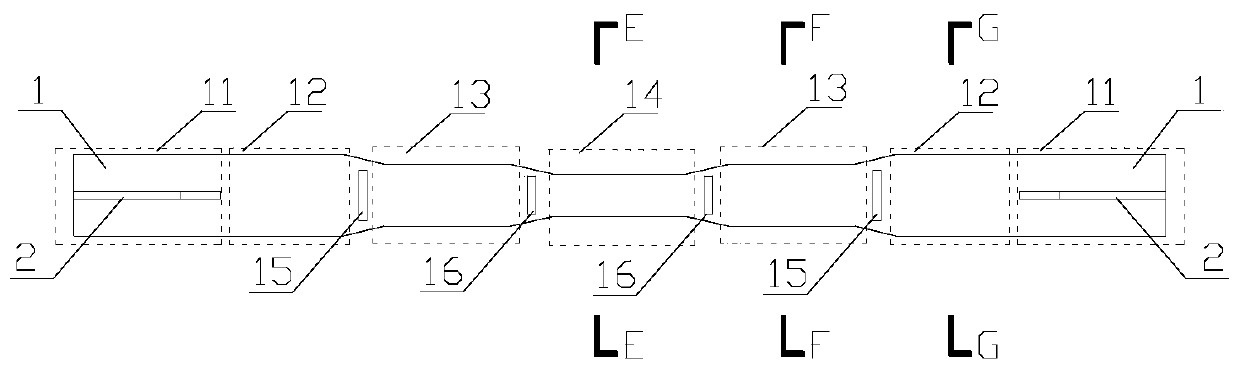

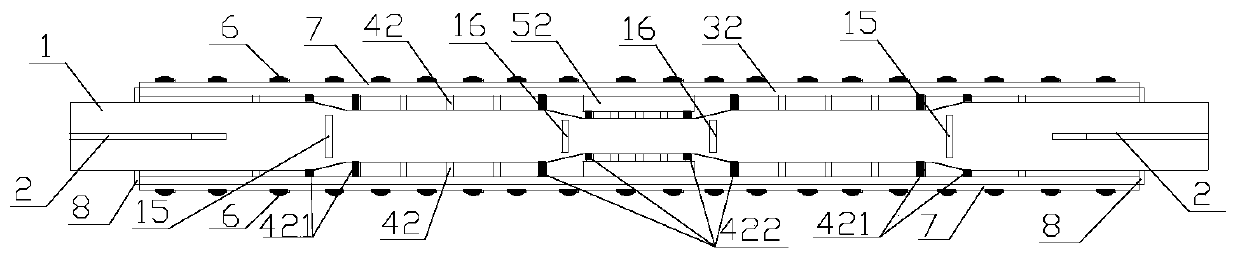

[0063] Reference Figure 1~Figure 10 , A new type of self-balancing multi-stage energy-consuming anti-buckling support, including core material 1, end stiffening plate 2, casing 3, half casing 1 31, half casing 2 32, connecting hole 33, first stiffening plate Component 41, second stiffening plate component 42, first side limiting device 411, first central limiting device 412, second side limiting device 421, second central limiting device 422, first anti-buckling plate 51. The second anti-buckling plate 52, the connecting piece 6, the connecting plate 7, the connecting plate hole 71, the cover plate 8 and the cover plate hole 81, the core material 1 includes a non-yielding section 11, a third yielding section 12, and a second The second yielding section 13, the first yielding section 14, the first yielding section 14 is located in the middle of the core material, and the second yield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com