A small diameter, long size non-equal thickness and thin rectangular pipe fittings forming tooling and method

A forming method and long-dimension technology, applied in the field of forming tooling for thick and thin rectangular pipe fittings, can solve problems such as insufficient pressure sensitivity at corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

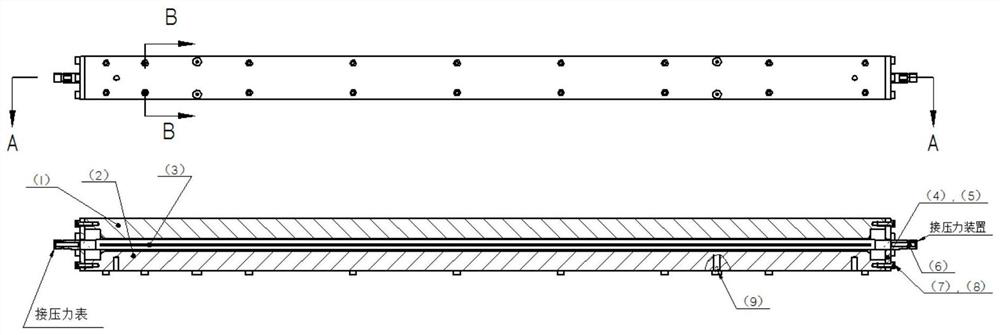

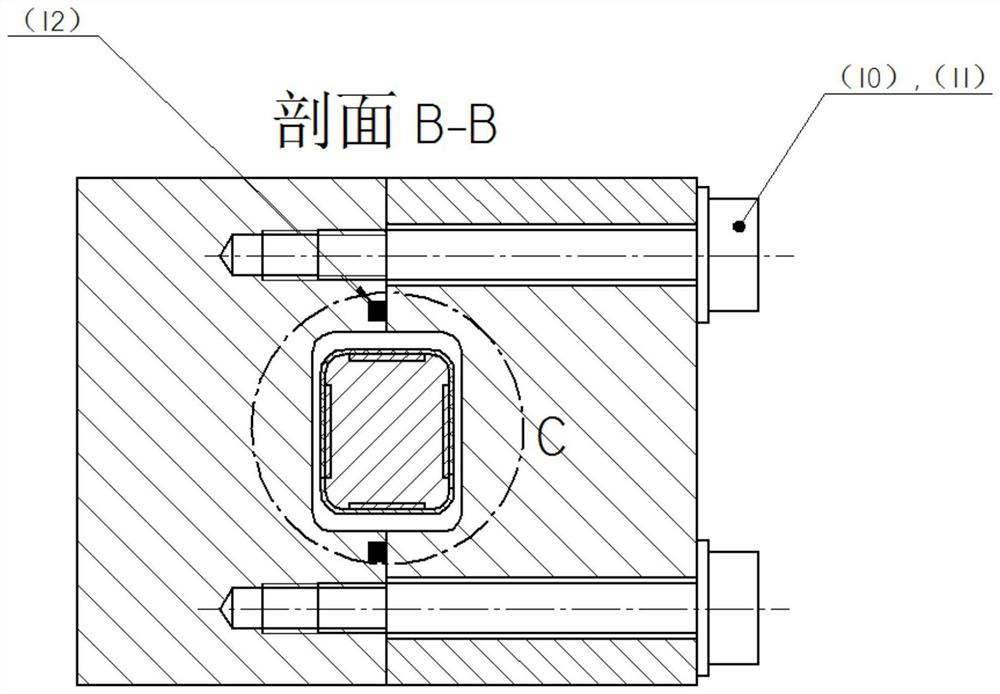

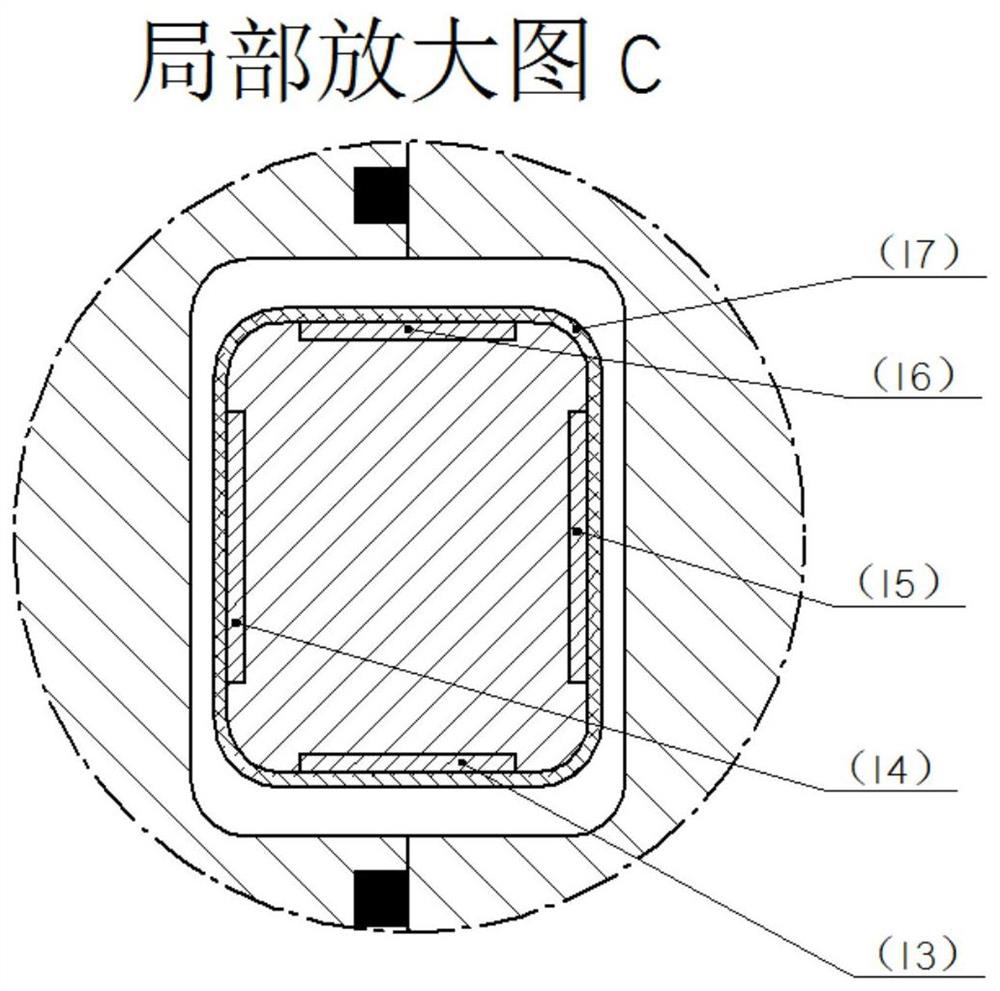

[0048] The present invention will be further explained and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0049] A small-caliber, long-dimension non-equal thickness and thin rectangular pipe fitting forming tooling. The mandrel can be disassembled step by step in the three directions of length and cross-section. The order of the corners "disassembles" the mandrel and comes out from the inside of the pipe fitting, solving the problem of difficult demoulding of long-sized, small-diameter thin-shaped pipe fittings. This operation is simple and convenient, and there is no damage to the pipe fittings during the demoulding process. And the disassembled tooling can be quickly assembled and reused.

[0050] In addition, the two ports of the mold are designed universally, and the key functions of the sealing mechanism, pressure charging interface and demoulding of the pipe fittings are all designed at the two ends. For the molding of pipe f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com