Straightness evaluation method in any direction based on digitized gauge

A technology of arbitrary direction and straightness, applied in measuring devices, complex mathematical operations, instruments, etc., can solve problems such as low calculation efficiency, randomness, and inability to meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

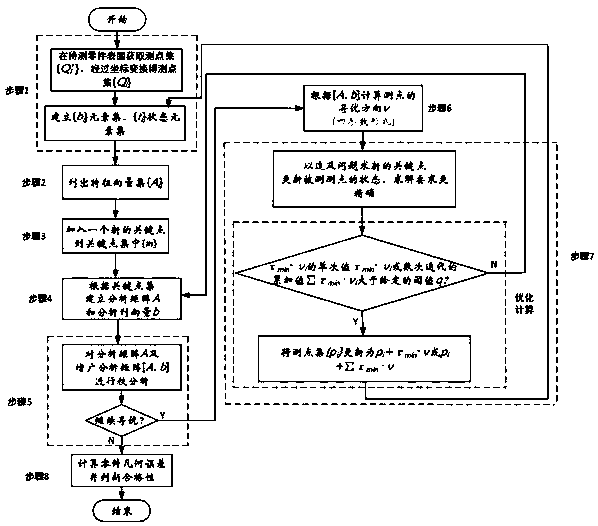

Method used

Image

Examples

Embodiment Construction

[0040] Below are specific embodiments of the present invention, and the scheme of the present invention is further described with reference to the accompanying drawings, but the present invention is not limited to these embodiments;

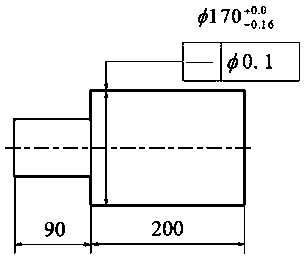

[0041] assessment_point_set { Q i} straightness error in any direction.

[0042] Step 1: Calculate and obtain the measuring point set { Q i}as follows:

[0043]

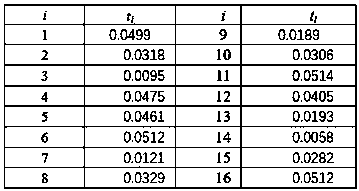

[0044] build state element set { t i}as follows:

[0045]

[0046] build-boundary-element-set { b i}as follows:

[0047] { b i}=[1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1] T .

[0048] After step 1, proceed to step 2.

[0049] Step 2: Build feature row vector set { Ai}as follows:

[0050]

[0051] After step 2, proceed to step 3.

[0052] Step 3: Take t 16 =0.0531 maximum value t max Corresponding measuring point Q 16 as the key point, and its measurement point number 16 is added to the key point set{ m}, such that { m}={16}.

[0053] After step 3, go to step 4.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com