System of hot scarfing machine and for positioning head portion of slab and detecting whether steel slab gets stuck or not during scarfing

A flame cleaning and detection system technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as failure to meet high quality requirements, static slab, and burnt surface of slab cleaning, etc. Achieve the effect of novel concept, reduced cutting amount and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and example the present invention is further described

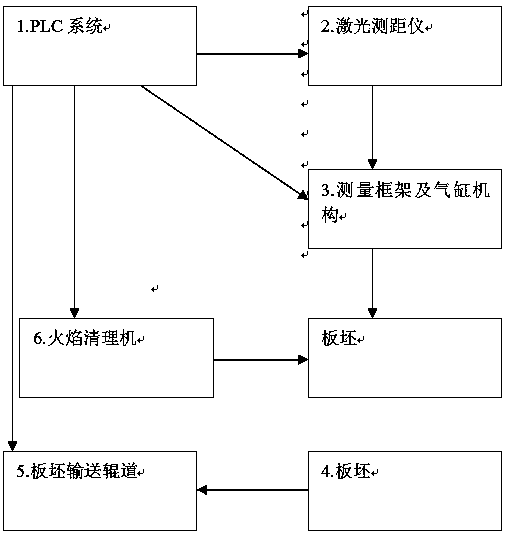

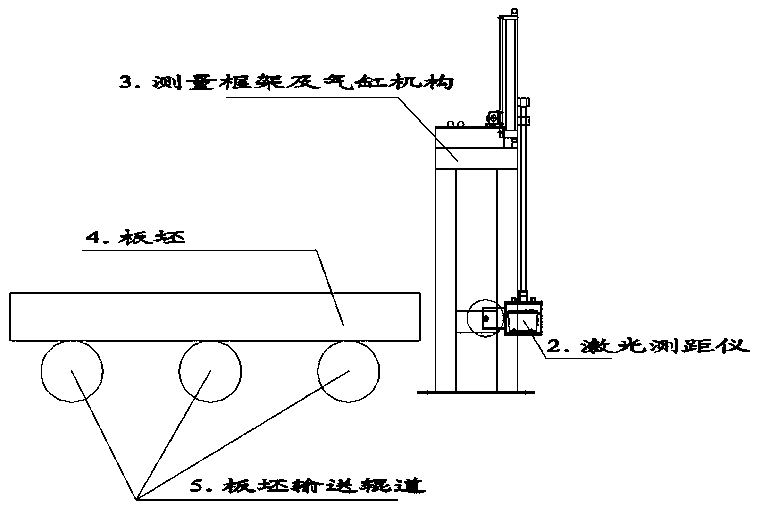

[0012] Real-time example 1: such as figure 1 As shown, it consists of PLC system 1, laser range finder 2, measuring frame and cylinder mechanism 3, slab 4, slab conveying roller table 5 and flame cleaning machine 6, wherein: laser range finder 2 is installed on the measuring frame and On the cylinder mechanism 3, the measuring frame and the cylinder mechanism 3 ride on the slab conveying roller table 5, and the laser range finder 2 directly measures the physical position of the slab 4, and sends it to the PLC system 1 in real time; the slab conveying roller table 5 Drive the slab forward or backward, see the specific schematic diagram figure 2 As shown, the flame cleaning machine 6 adopts a strong oxidation method to clean the surface defects of the moving slab 4, and the PLC system 1 receives the actual physical position of the slab 4 detected by the laser rangefin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com