Cycle test device and cycle test method for durability of phase-change material

A cyclic test, phase change material technology, applied in measurement devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of high economic cost, influence of instrument service life, time-consuming and labor-intensive, etc. Heat transfer area, the effect of accelerating the rate of melting and solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

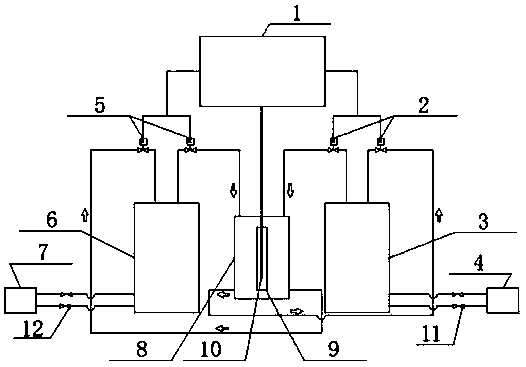

[0025] For better understanding and implementation, the present invention will be described in detail below in conjunction with the accompanying drawings.

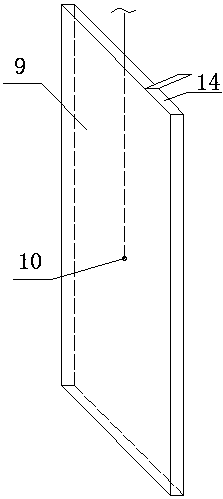

[0026]A durability cycle test device for phase change materials; including a control device 1, a cold water electric two-way valve 2, a cold water storage 3, a cold water generator 4, a cold water pump 11, a hot water electric two-way valve 5, and a hot water storage 6. Hot water generator 7, hot water pump 12, sample test box 8, sample storage box 9 and thermostat probe 10, the hot water generator 7 is connected to the hot water pump 12 through a pipeline, and the hot water pump 12 is connected to the hot water through a pipeline Reservoir 6, one side of hot water storage 6 is connected to hot water electric two-way valve 5 through pipeline, hot water electric two-way valve 5 is connected to sample test box 8 through pipeline; the other side of hot water storage 6 is connected to hot water electric two-way valve The throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com